Acrylic is considered one of the most versatile and widely used materials in the industrial sector, whether in fine arts and design or architecture and large-scale manufacturing. Acrylic has become an important design element in numerous creative and functional applications due to its durability, versatility, and value. The article aims to vividly describe the multifaceted character of acrylic, its unique properties, the science behind its formation, and how it enables innovations in various fields. Suppose you are an artist seeking the best medium, a designer looking for flexible materials, or anyone interested in discovering what makes the world’s most common plastics so versatile. In that case, this guide will walk you through how this material has impacted the arts and industries. Embark on an excursion to explore the limitless possibilities of this extraordinary material.

Understanding Acrylic and Its Meaning

Definition of Acrylic

This term acrylic is applied to the class of synthetic polymers derived from acrylic acid and related compounds. Acrylic, perhaps more than any other polymer, symbolizes versatility in manufacturing and the creative arts. Chemically, an acrylic polymer is primarily polymethyl methacrylate (PMMA), a thermoplastic that exhibits excellent optical clarity and high impact resistance. Acrylic materials possess qualities such as lightness and durability, enabling them to be widely utilized in signage, paints, adhesives, and protective barriers. Especially, acrylic glass, also known as plexiglass, can withstand impacts 17 times better than ordinary glass and is significantly lighter and shatter-resistant. High-performance acrylics, produced through advancements in technology, exhibit excellent thermal and UV resistance, thereby expanding their range of applications to areas such as aerospace, automotive, and medical devices.

History of Acrylic Development

The creation of acrylic materials began in the early 20th century, marking a significant milestone in polymer chemistry. In 1928, the first acrylic glass, polymethyl methacrylate PMMA, was synthesized by German chemists Wilhelm Rudolph and Walter Bauer. Its commercialization then followed in 1933 under the trade name “Plexiglas” by the German company Röhm and Haas. This breakthrough material quickly gained popularity due to its transparency, strength, and versatility.

During World War II, acrylic plastics were first used on a large scale in areas where optical clarity and shatter resistance were required, such as aircraft canopies, submarine periscopes, and gun turrets. After World War II, the material gained vast civilian applications due to its ease of manufacture through molding, extrusion, and casting methods.

The physical properties of acrylics have improved with consideration of the polymerization process over the decades. These include thermal resistance and optical precision. In the 1970s, UV stabilizers were developed for other applications as well, allowing acrylics to maintain their clarity and prevent yellowing when exposed to long-term outdoor conditions, thereby significantly enhancing the utility of acrylic. More recently, innovations in copolymerization and composites have made it possible to create high-performance acrylic variants capable of meeting the demanding requirements of industries such as healthcare, where materials must be biocompatible and sterilizable.

Modern acrylic materials serve as a primary example illustrating how the early discoveries of polymers evolved into essential materials for various industries. Continuous improvements to their manufacturing processes keep these acrylic materials relatively cost-efficient, durable, and adaptable to new technological and design challenges.

Acrylic vs. Other Polymers

Acrylic polymers possess unique features that distinguish them from commonly used polymers, such as polycarbonate (PC), polyethylene (PE), and polyvinyl chloride (PVC). One key feature that acrylics possess is maximum optical clarity, with excellent light transmission of up to 92%, making them a superior option to many other choices in circumstances where transparency is required, such as in lenses, displays, and windows. They also share contrasting properties with polycarbonates, which include being fairly impact-resistant but yellowing as a result of ultraviolet light. In contrast, acrylics have superior weatherability and UV resistance, allowing them to last longer when used in exterior applications.

Acrylic is typically considered to have a higher tensile strength, as well as a broader range of working temperature conditions, than polyethylene, making it a suitable option in environments that require structural integrity at high temperatures. PE is appreciated for being flexible and inexpensive, yet it is less rigid and does not afford the same aesthetic possibilities as acrylic. Likewise, although PVC is considered the most adaptable form of plastic due to its flame-retardant properties, it emits harmful chemicals during production and use. In contrast, acrylic is deemed more environmentally friendly due to its non-toxic nature.

However, the machinability of acrylic, combined with its compatibility with various fabrication techniques such as laser cutting, injection molding, and thermoforming, enhances its adaptability across different industries. The characteristics, therefore, make the material very versatile, combining strength, durability, and aesthetic appeal that other polymers often cannot rival. Its prominence in applications, ranging from medical devices to architectural design, must demonstrate its continuous existence and superiority when it truly matters.

Types of Acrylic and Their Properties

Types of Acrylic Plastic

Cast Acrylic

Cast acrylic is produced by pouring liquid acrylic into molds and curing it under closely controlled conditions. Due to its outstanding ability to resist scratches and its sturdily built nature, which provides the best optical properties, it is used where precise detail is required, such as in scientific instruments, aquariums, and signage. Cast acrylic generally has better thickness consistency and mechanical properties than extruded acrylic, but its price is higher.

Extruded Acrylic

Manufactured through a continuous process where sheets are created when acrylic is pushed through rollers, extruded acrylic is a process that lends cost efficiency to the product and also places less internal stress on the material. However, on the downside, it is less rigid and more susceptible to scratching compared to cast acrylic. Extruded acrylic is suitable for applications where cost is a critical factor, such as lightweight display cases, shelving, and decorative panels.

Impact-Modified Acrylic

Acrylic by itself is somewhat brittle in nature, so having objects bend and break is naturally much more common. Impact-modified acrylic, therefore, contains additives designed to improve its resistance to the cracking and shattering of the object. This variant is well-suited for applications that require a more robust material, such as protective barriers, automotive parts, and safety glazing.

UV-Filtering Acrylic

UV-filtering acrylic blocks the sun’s harmful ultraviolet rays using sophisticated technology while retaining maximum optical clarity. An acrylic of this sort is typically used in museum exhibitions, photography framing, and other areas where it is essential to protect the underlying material from UV deterioration or color fading.

Heat-Resistant Acrylic

Heat-resistant acrylic can withstand high temperatures without losing its shape or physical properties. These are often used for lamps, industrial machines that require high-temperature tolerance, and some architectural applications.

Depending on their attributes and properties, every type of acrylic represents specific performance requirements, demonstrating the material’s versatility in fulfilling various industrial and commercial needs.

Significant Properties of Acrylics

Optical Clarity

Acrylics have an exceptional light transmission rate, transmitting up to 92% of light compared to plain glass. Optical lenses, display cases, and windows require this kind of transparency and non-yellowing property from the material.

High-Impact Resistance

Compared to glass, this acrylic yields higher impact resistance, being at least 10 times stronger. Therefore, applications requiring properties such as protective barriers and automotive parts ensure much greater durability and safety.

Light Structure

Acrylic weighs half that of glass, making it nearly twice as light. Popular in industries where significant weight reduction cannot be sacrificed for strength and performance, these include aviation and construction.

Ultraviolet and Weather Resistance

Acrylic has good resistance to the ultraviolet rays and weathering effects and hence it maintains its integrity and appearance even after a considerable period of exposure to the outdoor environment. Therefore, it proves very useful for signage, covers for outdoor luminaries, and skylights.

Chemical Resistance

Standard acrylics are resistant to a variety of chemicals, including dilute acids, alkalis, and cleaning agents. This property makes it suitable for use in laboratories and industrial applications against heavy wear.

Thermal Stability

Advanced acrylic materials, such as heat-resistant grades, retain their structural properties and transparency at elevated temperatures, making them suitable for high-end applications, including lighting and industrial machinery.

Ease of Fabrication

Acrylics offer a high degree of versatility, making them easily adaptable to machining, thermoforming, bonding, and other processes. This ease facilitates the fabrication of complex shapes and designs, reducing production time and cost across various manufacturing processes.

By instilling these properties, acrylic materials thus continue to hold enough importance to be applied in modern-day engineering and design, theoretically forming a sustainable and versatile choice for many industrial, architectural, and commercial applications.

Comparison with Other Plastics

| Property | Acrylic | Polycarbonate | Polyethylene | Polystyrene |

|---|---|---|---|---|

| Light Transmission | Up to 92% | 88-90% | Lower | Lower |

| UV Resistance | Excellent | Yellows over time | Degrades | Degrades |

| Impact Resistance | Good | Excellent | Moderate | Poor |

| Scratch Resistance | Excellent | Moderate | Poor | Poor |

| Cost | Moderate | Higher | Lower | Lower |

Acrylic shows some drawbacks when comparing the properties of acrylic to those of other commonly used plastics such as polycarbonate (PC), polyethylene (PE), and polystyrene (PS). One of the chief advantages would be optical clarity. Light transmission through acrylic measures approximately 92%, which is indeed better than that of polycarbonate, whose transmission rate averages between 88% and 90%. It finds application wherever higher transparency is warranted, such as glazing, display cases, and optical equipment.

Regarding durability, polycarbonate is highly regarded as more impact-resistant than acrylic, while also being scratch-resistant, which enhances its aesthetic appeal for applications in weathering conditions. Besides, it is more resistant to UV degradation than polyethylene and polystyrene, all of which lose color and disintegrate when subjected to prolonged sunlight exposure.

From a chemical standpoint, acrylic offers higher resistance to a wider range of acids and bases compared to polystyrene, making it more suitable for chemical processing and industrial applications. Nevertheless, one must keep in mind that its use may be restricted when impact strength is required because acrylic has less impact strength than polycarbonate.

The considerations for processing also greatly favor acrylic. It can undergo thermoforming into intricate shapes with little concern for structural integrity, whereas other plastics, such as polyethylene, may require either more careful processing or additives to accomplish similar feats. Lightweight and recyclable, acrylic is thus a green material in designs that consider ecology.

Depending on cost factors, acrylic is always the middle choice in the market. It is less expensive than polycarbonate and more expensive than polystyrene. However, for large-scale jobs where cost is a factor, it becomes cost-effective. The decision on materials is dependent on the particular application, where clarity, durability, chemical resistance, and price efficiency are considered.

Common Applications of Acrylic Across Industries

Use of Acrylic in Art and Design

The other parts of the world embrace acrylic for its extreme versatility and aesthetics. From studios sculpting objects in intricate patterns, to artisans forming frames and display cases, the spatial clarity provided is prized, laden with opportunities to be bent, molded, and generally manipulated for intricate designs. Artists create paintings or art objects from acrylic sheets and paints that glow forever, as they resist UV and retain their color in fading. Laser cutting and CNC machining development empower highly evolved customization and minutest precision in acrylic artwork. Designers often utilize acrylic for furniture, lighting designs, or decorative art installations, taking advantage of the material’s lightweight yet sturdy properties. The possibilities for creating artworks are limitless as acrylic can be dyed, textured, or patterned, propelling innovative and utilitarian arts around diverse industries.

Acrylic in Architecture and Construction

Given the need of acrylics for qualities such as durability, adjustability, and optical clarity, acrylics are now considered vital in modern construction and modern architecture. Instead of glass, its used in situations where there is the need for basaltic resistance and lightness. With good refinement, acrylic panels are used in applications such as skylights, windows, and facades, with weather resistance and slight loading effects compared to typical glass.

Innovations in acrylic technology made it a better and more preferred choice for both interior and exterior architectural elements. Recent developments have enabled the production of UV-resistant acrylic sheets that will not yellow or degrade over time, ensuring long-term aesthetic and functional performance. Moreover, acrylic can be thermoformed into complex shapes, giving architects greater ways to realize curved and unconventional designs that were not formally possible with conventional materials.

The best use of acrylic is in making protective barriers, signage, and even noise-reducing panels in urban areas, considering its ability to resist extreme temperatures and chemical attacks. Therefore, recyclable and light, this improves sustainability by reducing transportation emissions and keeping the material in a cycle of reuse. So it has rightfully earned its status as an architectural medium on which new and sustainable ideas are being built.

Medical and Laboratory Uses of Acrylic

Acrylic is a popular choice of plastic in medical and scientific settings due to its strength, clarity, and properties. One of its applications involves manufacturing medical devices and equipment, such as incubators, IV components, and dental prostheses, which must be biocompatible and non-toxic. Lab equipment made of acrylic includes safety shields, transparent enclosures, and specialized storage units, all of which employ this material since it is highly impact-resistant and able to withstand sterilization at high temperatures without degradation. It also offers optical clarity, which allows precision work and analysis to be performed without impediment. Recent improvements in acrylic polymer chemistry have enhanced aerospace-grade UV durability and generally increased resistance to chemical interactions, making it a preferred choice where both operational reliability and cleanliness are mandatory requirements. The materials and properties of acrylic strongly demonstrate its role as a vital medium for promoting medical and scientific advancements.

Cleaning and Maintenance of Acrylic Products

Best Practice for Cleaning Acrylic

Cleaning acrylic effectively to maintain its integrity requires the use of non-abrasive methods and materials to prevent surface damage. Start by using a soft, lint-free microfiber cloth or a damp cellulose sponge, moistened with water, to gently brush away dust and debris. For everyday washing, use a mild detergent, without ammonia, diluted in lukewarm water. For general-purpose applications, avoid using solvent chemicals such as acetone, alcohol-based cleaners, or cleaning materials containing ammonia. These materials can degrade surface treatments, cause clouding, or micro-cracks.

For managing stubborn stains or marks, one should opt for acrylic-safe cleaning agents, which are explicitly labeled for use on acrylic products. Always patch test in an inconspicuous area before applying it broadly. Rinse off with lukewarm water to remove any remaining chemical residue, as leftover chemicals can degrade the material. Dry with a soft cloth in circular motions to prevent streaks.

Other measures worth taking to achieve ultimate levels of maintenance may include using an acrylic polishing compound recommended for scratch removal and following the manufacturer’s instructions. Regularly checking and following proper cleaning procedures would substantially add years of usability to acrylic products, preserving their clarity and integrity over time.

Tips on Preserving the Clarity of Acrylic

- Avoid Abrasive Materials:

Always use a non-abrasive microfiber cloth when cleaning the acrylic surface. Abrasive pads or brushes can cause micro-scratches that eventually diminish the clarity of an acrylic surface.

- Choose the Right Cleaning Solutions:

Use the cleaning solutions specifically designed for acrylic-based products. Mild soap and water dilution, or commercial acrylic cleaners, are options to consider. Avoid products containing ammonia, as it can cause clouding or crazing, resulting in loss of transparency and decreased structural strength.

- Protect from UV Exposure:

Discoloration and loss of clarity in acrylic items can be avoided by applying UV protective coatings or keeping these items out of direct sunlight.

- Handle with Care:

Acrylic is prone to cracking due to excessive force or impact. Handle acrylic surfaces carefully and avoid dropping heavy objects on them, as this can cause stress fractures that reduce durability.

- Regular Polish for Lasting Clarity:

Occasionally, polishing the acrylic with a proper acrylic polish helps retain its shine and transparency. This also helps reduce light scuffs or surface imperfections.

Hence, by following thorough maintenance procedures, the perfect optical clarity of acrylic materials can be maintained in good condition, allowing their visual quality and functionality to remain constant over long periods.

Common Mistakes While Cleaning Acrylic

- Using Abrasive Cleaners or Scouring Pads:

Abrasive substances like scouring pads or harsh chemical cleaners tend to cause scratching of the acrylic surface. Such scratches affect the optical clarity of the material and increase its susceptibility to more damage over time. Always use soft cloths or sponges with mild and non-abrasive cleaning solutions.

- Applying Solvents and Harsh Chemicals:

Solvents such as acetone, ammonia-based cleaners, and alcohols can react chemically with acrylics to discolor, warp, or crack them. Always ensure that they are certified safe for use with acrylics to prevent chemical damage.

- Excessive Cleaning Pressure:

Applying too much pressure while wiping may create micro-scratches or stress marks on the acrylic and damage. To protect the surface, clean gently with the least amount of pressure, taking care not to stress any part of the material.

- Not Rinsing Well:

If the cleaning solution remains on the acrylic surface, it may stain or, over time, cause clouding. Always wash the surface with clear, lukewarm water after cleaning and dry it with a soft, lint-free cloth to prevent streaks.

- Exposure to High Temperatures During Maintenance:

While cleaning, do not expose acrylic surfaces to typical hot water or heated tools, as high temperatures could compromise structural integrity. Water at room temperature or just barely lukewarm temperature can help maintain acrylic durability.

By avoiding such common pitfalls, acrylic surfaces will retain their clarity and functionality, thereby significantly extending the period over which they remain usable and attractive.

Innovative Techniques: Laser Cutting Acrylic

Introduction to Laser Cutting Acrylic

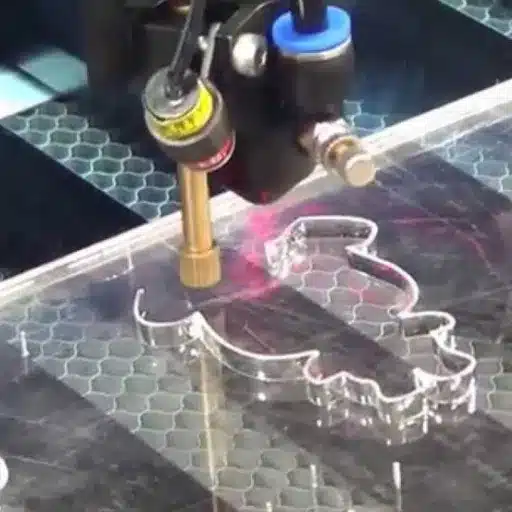

Laser cutting acrylic offers an exceptionally precise, efficient, and highly versatile method for crafting or manufacturing. The procedure involves cutting and engraving acrylic sheets under intense focus provided by a laser beam. The CO2 laser is the most common type of laser used in such processes for non-metallic materials, producing clean edges and finishing intricate designs without requiring further polishing. The technology also enables high-grade control, allowing for the placement of complex, high-quality components in signage, decorative applications, and industrial parts.

From my perspective, it is essential to emphasize that laser cutting is a significantly more effective way to optimize productivity, as it reduces waste and production times in stark contrast to other traditional power tools, such as saws or routers. For instance, the laser beam vaporizes the material rather than physically pushing it away upon hitting, thereby reducing contamination and assuring a smooth finish on the surface. Furthermore, adjustments can be made for the beam intensity and cutting speed to accommodate additional customization, depending on the acrylic thickness and type, whether cast or extruded. Setting adjustments are also very critical, depending on the type of acrylic, because if set wrongly, not only will it not cut cleanly, but the acrylic could also be charred or overheated.

Understanding the safety and maintenance aspects of laser cutting equipment is also essential. Proper ventilation systems are necessary to manage fumes generated during the cutting process, as acrylic releases vapors that could pose health risks if not adequately extracted. The laser optics, coolers, and other parts must be regularly maintained to ensure optimal performance and prolong the equipment’s life. Laser cutting acrylic, put simply, is a state-of-the-art process that combines speed, precision, and versatility —the three key attributes sought by any business or art studio.

Advantages of Laser Cutting on Acrylic Works

High Precision & Accuracy

Based on my experience, I consider one primary advantage of laser cutting for acrylic works to be the high accuracy it offers. Laser technology cuts with incredible accuracy, to the extent that the tolerance can be within fractions of a millimeter. This precision eliminates the need for tedious post-processing, with edges polished directly from the laser. Furthermore, extremely detailed patterns can be designed, ranging from sharp corners to intricate designs, making it particularly useful for more complex works such as architectural models, signage, and decorations.

Efficiency & Scalability

Another advantage I’ve learned is its efficiency. The laser cutters work quickly, and a fast speed means fast production without compromising quality. This is especially important when conducting mass work or when an identical design needs to be recreated multiple times. It is worth noting that laser cutting is also more flexible, allowing a prototype to be created and then mass-produced using a single process. This scalability is theoretically impossible with manual methods. The laser cutter stands out as an invaluable tool because it handles varying material thicknesses with unwavering precision and consistency across both manufacturing and creative industries.

Cost-Effective & Environmentally Conscious

I appreciate this technology because it reduces material wastage. A laser’s cutting width is so thin that more of the acrylic sheet is utilized while waste is minimized, thereby cutting material costs. Cost efficiency achievement is considered to be environmental-conscious by many, even if indirectly, by using maximum resources. Hence, with precision, speed, and cost-effectiveness, laser cutting provides a solid foundation for working with acrylic in any commercial or creative capacity.

Some Laser-Cut Acrylic Creations

Designing in laser-cut acrylic is a vast, open field with immense possibilities, all functional or decorative. One of the frequent uses I have seen is in custom signage. Laser-cut acrylic offers utmost precision and intricacy for lettering, logos, or design elements that can be internally lit using LED lights, thereby serving well for gallery outlets, exhibitions, or simply decorating the home. The approach ensures a crisp and sharp finish with high clarity, which is of utmost importance in branding and displays.

Creating acrylic jewelry or accessories may represent another interesting application. Laser-cutting technology can achieve intricate and delicate patterns that cannot be produced using conventional methodologies. Designers thus have the opportunity to work with a wide range of colors, finishes, and thicknesses to craft earrings, necklaces, and unique designs for bracelets. Acrylic is a very versatile material that lends itself easily to creative possibilities, which is further enhanced by laser cutting.

In prototype making and model making, acrylic is also an essential material. These two forms—interactive scale models, product prototyping, and artistic sculpture—require the high precision provided by laser cutters to translate demanding designs. By layering or combining with other materials, it is possible to create very dynamic and three-dimensional designs that are faithful to the original. This kind of flexibility and atomic-grade control would set the spirit of ingenuity working in any industry, anywhere, from engineering to the arts. In fact, laser-cutting technology presents a true crossroads between creativity, function, and technology.

Reference Sources

Curbell Plastics – Acrylic Material Properties: Provides an overview of acrylic’s properties, strength, and optical clarity.

Bee Plastic – Acrylic in Action: Discusses how acrylic is used in modern architecture and other industries.

Acrylics by Design – The Versatility of Acrylic: Explores common uses of acrylic in technology, design, and manufacturing.

Alands Plastic – Common Uses of Acrylic Sheets: Highlights applications in advertising, retail displays, and interior design.

Architecture Lab – Acrylic in Building and Design: Focuses on the role of acrylic in architecture, interior design, and as a substitute for glass.

Frequently Asked Questions (FAQs)

What Is Acrylic and Its Uses?

Acrylic is the common name used for polymethyl methacrylate (PMMA), a transparent plastic that is relatively more durable. This synthetic resin has a wide range of applications, including signage, display work, and possibly the automotive field. Many people, and a significant number of them, use acrylic for arts and crafts because it is very versatile. It cuts easily, shapes adeptly, and bonds well with many adhesives, allowing for ease of manipulation by both artisans and manufacturers. Additionally, acrylics are typically available in several grades, which can alter their properties or suitability for specific uses.

What Are the Properties of Acrylic?

Some of the characteristics of acrylic consist of transparency, light weight, and impact resistance. Acrylic has glass-like clarity; hence it can be considered an alternative to glass for many projects. Weathering properties of acrylic ensure that it does not become yellow or brittle over time. Additionally, acrylic is a non-toxic substance that finds applications in various areas, including the production of toys for children. It bonds well with adhesives and solvents, factors that further add to its applications in various manufacturing processes.

How to Clean Acrylic?

The key to cleaning acrylic is to not allow scratching of the surface during cleaning. Use a soft microfiber cloth with a mild soap solution to clean. Never use cleaners containing ammonia or abrasive materials, such as steel wool or cleaners for window glass, as they can damage clear plastic. Stubborn stains may require a cleaning agent designed expressly for acrylic surfaces. Regular care retains the acrylic’s clarity and presents it as a pleasing sight to view.

What Is the Difference Between Cast Acrylic and Extruded Acrylic?

The two materials differ primarily in their manufacturing processes. Cast acrylic is produced by pouring liquid resin into molds; hence it is thicker and often clearer. On the other hand, extruded acrylic is formed by forcing the acrylic into a die, which achieves a uniform thickness but often lacks clarity. Both types of acrylic have distinct properties and use; for instance, cast acrylic is used for objects requiring high optical quality, whereas extruded acrylic is used mainly for sheets and general applications.

Can Acrylic Be Used in Laser-Cutting?

Yes, laser cutting acrylic is an excellent choice, as it produces a clean edge while engraving intricate designs. Laser cutting offers precise results with acrylics and can shape detailed forms that cutting with conventional mechanical means may struggle to achieve. The type of acrylic chosen is significant because cast and extruded materials might respond differently to laser cutting. Also, an adequate ventilation system and safety precautions must be observed to prevent inhalation of any hazardous fumes.

What Is the Meaning of Acrylic?

The interpretation of acrylic relates directly to its composition and properties as a synthetic polymer derived from acrylic acid or a methacrylate. Being a type of plastic, it is considered highly desirable due to its clarity, usefulness, and strength. The term acryl refers to numerous materials made with this polymer; for example, artists use acrylic paints for their allure of color and quick drying. Understanding what acrylic means is essential for comprehending the numerous applications it has in various industries.