Polyetherimide is a polymer that is widely acclaimed for having high-performance properties. It has revolutionized industries ranging from aerospace to medical technology. It may be said that PEI has a set of characteristics unequaled by conventional plastics: exceptional thermal stability, mechanical strength, and resistance to harsh chemical environments. This blog post delves into PEI plastic’s crucial properties, versatile usages, and numerous benefits, explaining why this material has become so popular for cutting-edge design and manufacturing solutions. Engineers considering advanced materials for their work or simply interested in the science behind high-performance plastics are the primary audience for this guide, which contains everything about Polyetherimide and its versatility. Keep reading to find out how PEI is carving a way into the future of innovation.

What is PEI Plastic?

Origins and Development of Polyetherimide

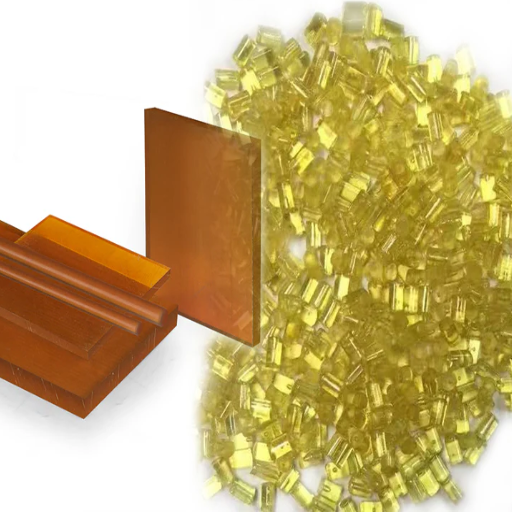

Polyetherimide (PEI) was initially developed in the early 1980s by General Electric (GE). Designed as a high-performance thermoplastic, it was created to satisfy materials’ needs for extreme conditions. The invention was revolutionary in polymer chemistry as it combined the strength and thermal stability of engineering plastics with the lightweight and versatile properties. PEI consists of repeating aromatic imide and ether units in its molecular structure, which impart excellent mechanical strength, resistance to heat, and extraordinary chemical stability.

The need to develop PEI arose from the need for new materials in the aerospace, automotive, and electronics industries. It can withstand a temperature of 356°F (180°C) while staying rigid and durable, allowing it to be used in demanding environments. Besides that, PEI brought about better processability- it can be molded or extruded easily so that manufacturers can form complex parts with fine precision. Over the following decades, advances in materials have considered improving PEI formulations for better impact resistance, UV stability, and flame retardancy; these formulations continue to serve as a foundation for their wide applications in advanced technology sectors.

Comparison with Other Engineering Thermoplastics

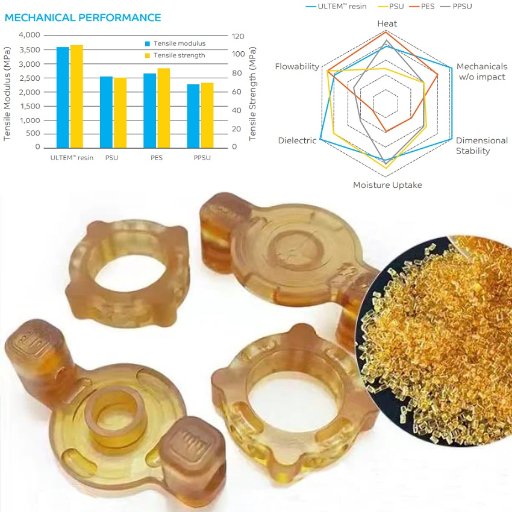

With its rare class of material combinations, Polyetherimide (PEI) stands out in the field of engineering thermoplastics. It features thermal burst stability, mechanical strength, and flame retardancy by nature. It is an affordable alternative for high-temperature applications, away from the extreme chemical resistance and mechanical toughness provided by polyetheretherketone (PEEK).

PEI resists heat better and maintains dimensional stability better than polycarbonate (PC), and thus, Embodying PEI might be apt for any thermal or mechanically demanding environment. However, PC is more accepted for applications where impact resistance and optical clarity are considered, including automotive glazing and electronics enclosures.

On the same train of fire retardancy, PEI stands tall compared to nylon (PA), which usually requires processing with additives to meet fire requirements. While nylon affords greater wear resistance and flexibility, PEI presents better strength and thermal stability for precision parts in aerospace or medical applications. Such distinctions enable PEI to be an enabling material for sectors that demand a balance of performance, safety, and durability in consonance with cost-effectiveness.

Understanding the Trade Name Ultem

The trade name Ultem is for polyetherimide (PEI) – a high-performance thermoplastic polymer by SABIC. Because of its high strength-to-weight ratio, Ultem is a thermoplastic with top-grade mechanical properties even at elevated temperatures. It is used in highly demanding applications in several industries, such as aerospace, automotive, and healthcare. Natural flame-retardant properties with low smoke emissions further create an appeal for applications demanding safety.

Ultem possesses chemical resistance and resistance to hydrolytic degradation to maintain structural integrity in harsh environments or humid conditions. It finds applications in parts that require electrical insulation and mechanical strength, such as connectors, medical devices, and aircraft interior components. In some grades, its transparency allows Ultem to be used for optical and lighting applications. In contrast, fiber-filled grades with glass or carbon fiber provide additional reinforcement for applications demanding high strength.

One factor favoring Ultem is its processability. It can be molded, extruded, or machined to suit manufacturing requirements. It also complies with regulatory standards, such as FDA, UL, and others, ensuring critical application suitability, from food processing to electronic components. In addition to performance, this adaptability and reliability make Ultem an essential material for several industries.

Key Material Properties of PEI Plastic

High Temperature and Thermal Properties

One of PEI’s outstanding applications in the plastic realm is its fabulous high-temperature performance. The glass transition temperature of around 217 °C (422°F) and continuous use of about 170 °C (338°F) give PEI an excellent reputation as a product in places where it’s always expected to be under thermal exposure. These features enable PEI to retain enough strength and mechanical characteristics in thermal stresses, sometimes more than other engineering-grade plastics.

Due to its thermal stability, deformation or failure is unlikely even if PEI is subjected to harsh conditions, ranging from automotive engine parts to sterilizable medical devices. It also has a low thermal expansion coefficient, meaning it can maintain its dimensions if subjected to temperature changes, an essential quality in precision parts. This blend of thermal resistance and stability makes PEI an ideal choice in top-performance applications where nothing short of absolute dependability is expected.

Mechanical Strength and Tensile Strength

Polyetherimide (PEI) is regarded for its superior mechanical properties and tensile strengths, and is thus used in very demanding environments. With tensile strengths well above 100 MPa, PEI shoulders the stresses of any everyday use while retaining its structural properties. It is, therefore, suitable for any mechanical strain applications like aerospace fasteners, gears, and parts of heavy industrial machinery.

In addition, its relatively high modulus of elasticity, mostly about 3,000-3,800 MPa, allows it to remain stiff or rigid when deforming forces oppose it. Its mechanical applications are supplemented with good abrasion and wear resistance properties that, in turn, extend the life of parts subjected to friction or conditions of high stresses. PEI’s apparent toughness and impact resistance allow it to be used in applications that demand excellent performance across varying environmental stresses. These attributes create a solid reputation for PEI as a versatile and reliable solution in advanced engineering applications.

Importance of Dimensional Stability

Dimensional stability is a vital property of engineering materials in applications demanding stringent tolerances, guaranteeing consistent performance under varying conditions. This refers to the aptitude of a material to keep its configuration and dimensions under the influence of environmental factors, such as heat, humidity, and mechanical forces. In industries like aerospace, automotive, and electronics, where exact specifications are of utmost importance, even the slightest alterations in dimensions can hamper functionality, safety, and reliability.

PEI is an excellent, dimensionally stable polymer with a coefficient of thermal expansion that is low enough and capable of resisting environmental factors. This ensures that pieces remain accurate and reliable under severe temperature variations or prolonged use. In the electronics sector, PEI exhibits consistent performance on thermal cycling and does not allow the product to warp or deform over time, thereby assuring greater service life for circuit boards or housings. This characteristic also allows for the stable assembly of multi-material systems, reducing the risk of issues related to stresses causing distortion, misalignments, etc. These characteristics make PEI a key technology in precision applications.

Good Electrical Properties and Chemical Resistance of PEI Plastic

Therefore, PEI plastics exhibit superior electrical properties and are chosen for use in environments demanding high-voltage insulation. With a dielectric constant ranging from 3.15 to 3.85 (typical at 1 MHz), it performs reliably for an electronic component, even under harsh conditions. A low dissipation factor ensures that losses are minimal in high-frequency applications. The flame resistance of PEI with a rating of UL94 V-0 further complements its use in electrical and electronic industries where there is a fire risk: critical systems require protection.

PEI is next in line for resistance as it maintains its chemical resistance, strength, and mechanical integrity in the presence of many chemicals. It shows resistance to most hydrocarbons, alcohols, and many acidic solutions, while simultaneously being able to withstand elevated temperature levels without degradation for prolonged periods. These properties of PEI make it ideally suited for application in an environment where toughness and uncompromising chemical resistance are required, like medical instruments, aerospace parts, and industrial machinery. PEI fits the bill of high-tech, performance-demanding applications due to its dual endorsement: electrical reliability and chemical robustness.

Applications of PEI Material

Use in the Aerospace Industry

Polyetherimide (PEI) is a choice material for the aerospace industry since it still needs to perform in extreme conditions while remaining lightweight and dependable. It has several features that make it desirable in aerospace applications: one of the greatest factors being its thermal stability, where it maintains strength at temperatures above 200°C. These qualities make PEI useful for engineering and manufacturing parts exposed to near-engine heat or atmospheric pressure at high altitudes. It additionally boasts low-flammability characteristics with minimal smoke emissions, making it a preferred material for interior structural panels, seat frames, and air ducts.

The strength-to-weight ratio of the material fulfills the need for a lightweight material that provides fuel efficiency and low emissions. It also sports superior chemical resistance, so it can take exposure to aviation fuels, hydraulic fluids, and cleaning fluids without losing its physical properties. From metal to surface treatment and layups and reinforcements to application in the cabin interior, PEI is celebrated for consistently meeting stringent specifications while contributing to greener and safer industry direction.

Applications in Automotive Manufacturing

Polyetherimide is another crucial component in the automotive sector, where the suite of properties of the material solves serious design problems. HisIdiedThermalandOhighMechanicalStrength could be used in high-temperature environments, like engine parts, under-hood applications, and electrical systems. And easy to keep it light-weight would feed into the industry’s aspirations to view fuel efficiency and lowered carbon emissions. The other few properties PEI offers are its flame retardancy and electrical insulation: flame-retardant properties are used in connectors and housings for electronic components in modern vehicles. The other property is chemical resistance, which gives high assurance of durability when exposed to automotive fluids such as oils, coolants, and other cleaning agents, all of which are good considerations in the high-demand IT living conditions. Another dimension to the increased adoption of electric vehicles is the increasing use of PEI toward battery components, which require high performance, and the secondary lightweight structural components that guarantee energy efficiency and safety of the next-gen vehicles.

Role in Plastic Machining and Plastic Parts Production

The unique properties make PEI ideal for plastic machining and high-performance plastic parts. The unparalleled thermal stability offers exact machining while maintaining very tight tolerances required by sophisticated industries such as aerospace, electronics, and healthcare. Especially when addressing intricate and dimensionally stable components and low thermal expansion rates, PEI ensures the reliability of parts under extreme temperature variation.

Its chemical resistance and electrical properties also increase the versatility for producing components that need insulation, connectors, and housings for a challenging atmosphere. Being flame-retardant on its own, PEI also conforms to the safety standards of most industries, making it a significant consideration wherever material safety is of top priority. These properties, in combination with its ability to sustain high-speed machining processes, have made PEI one of the pillars of modern manufacturing, catering to the ever-changing demands of advanced industries while paving the way for efficiency and performance innovations.

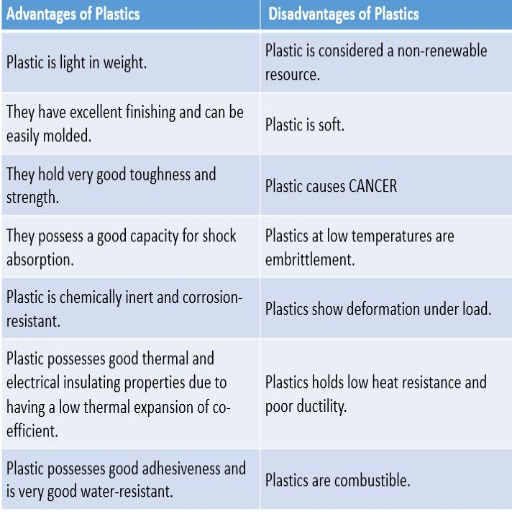

Advantages and Limitations of PEI

Benefits of Low Smoke and Flame Resistance

Polyetherimide (PEI) has become famous for its almost perfect smoke and flame resistance; hence, it is indispensable in applications where safety and regulatory compliance are paramount. PEI’s most significant advantage is its tremendous reduction in smoke density during combustion. Low smoke density leads to visibility enhancement in case of any fire, minimizes the inhalation of toxic fumes all significant in enclosed spaces like aircraft, trains, or even submarines. PEI also stands the test of fire safety codes such as UL94 V-0, which ensures that the material ignites only within seconds or a smaller duration while acting as a barrier to flame spread.

In the second place, the flame retardance of PEI is also very significant in high-profile industries like aerospace, automotive, and electronics. For example, in aerospace, the low smoke toxicity of materials is paramount to passenger safety during an emergency. In these situations, PEI has remained the front-runner for all interior components, striking an impeccable balance between lightweight and safety standards. In the electronics industry, other flame retardant materials, such as PEI, protect sensitive circuits and components during surges or power faults, thereby lessening the possibility of massive failures.

Yet another reason PEI deserves such exalted status is its ability to maintain its structural integrity when subjected to extremely high temperatures. With its low smoke production, resistance to flame, and hard characteristics, PEI is perceived as a leading brand in the industry for the safety and reliability of high-end systems. All these benefits account for regulatory compliance, besides giving assurance in a domain where human lives and multimillion-dollar investments are at stake.

Challenges: Prone to Stress Cracking and Chlorinated Solvents

Though PEI (polyetherimide) offers several benefits, it also presents some challenges that should be considered to achieve the best performance in any application. One of the significant issues is its proneness to stress cracking due to environmental factors. Stress cracking happens when PEI parts are under mechanical stress in the presence of aggressive chemicals or environmental conditions, and this behaviour breaks down the structural integrity of the product over time. The susceptibility mandates utmost care during design, especially in reducing the residual internal stresses developed in manufacturing and preventing the overcharging of PEI parts during operation, from overloading. For industries concerned with precision and durability, the threat of stress cracking is very real because even the most minor cracks can now lead to failures of something critical.

Another drawback of PEI is its inferior resistance to chlorinated solvents. Such solvents attack the polymer matrix, swelling, softening, or disintegrating it during prolonged exposure. These limitations reject the acceptance of PEI in an environmental setup in which chlorinated chemicals are abundantly present, especially in the aerospace and chemical process industries. Engineers generally resort to various protective coatings, blending options, or alternative cleaning agents to circumvent this weakness and protect the polymer’s functionality and lifecycle. During the initial product design, careful consideration is given to ensuring that PEI matches applications suitable for its resistance capabilities.

We need a blend of innovation, engineering, and ruthless testing to confront these challenges. With better chemical resistance through additives and improved processing, PEI’s performance in various fields is ever-expanding, balancing safety and durability. Despite its drawbacks, understanding and working around these limitations make PEI a good choice for complicated, high-performance applications.

Considerations for Cost-Effective Production Process

Cost-effective PEI manufacturing demands a balanced approach that optimizes resource use without sacrificing quality. Raw material procurement is an important aspect. Supplies from reliable sources at competitive prices bring tremendous opportunities for cost-cutting. From a production point of view, the enhancements should encompass advances in automation for superior process control, waste reduction, and labor cost savings.

The production of PEI is energy-intensive. Therefore, energy consumption becomes one of the significant factors in operational costs. Energy-efficient process equipment and systems, such as heat thermodynamic recovery, are recommended to maintain operational costs optimally. Instead of traditional batch production methods, production capacity can be scaled according to actual demand so that no materials or resources are wasted. Moreover, regular maintenance is crucial to avoiding equipment failures that can easily steal months from production schedules.

PEI waste materials can be recycled and profitably reprocessed, reducing the purchase of virgin raw materials. These measures, combined with good quality control and continuous process improvement, should go a long way toward achieving a compromise between efficient costing and providing high-performance PEI products.

Choosing the Right PEI Grade and Reinforcement

Factors Influencing the Selection of PEI Resin

When selecting the right PEI resin, some factors are prioritized to ensure the material conforms to the specific needs of an application. First, I evaluate mechanical properties such as tensile strength, stiffness, and impact resistance. If the material will be subjected to some degree of tensile stress in its application, choosing a PEI grade that meets those requirements would be necessary. I could go for a glass or carbon fiber-reinforced grade if strength and rigidity are required.

Then comes the thermal performance. Being a high heat-resistant polymer, one must still weigh the thermal stability needed for its application. Whether it is an aerospace component that holds up under extreme temperatures or an industrial part working under continuous heat, I ensure the resin has the required heat deflection temperature and long-term thermal endurance to be reliable.

Chemical resistance is also something I regard. If the environment contains harsh chemicals, keeps solvents, or requires frequent cleaning cycles, I pick a resin that has been guaranteed against attack under those conditions. Another consideration is regulatory and compliance standards, which can be FDA or UL certification, depending on the industry that the application is in. Once these are addressed, the choice balances performance, cost, and durability.

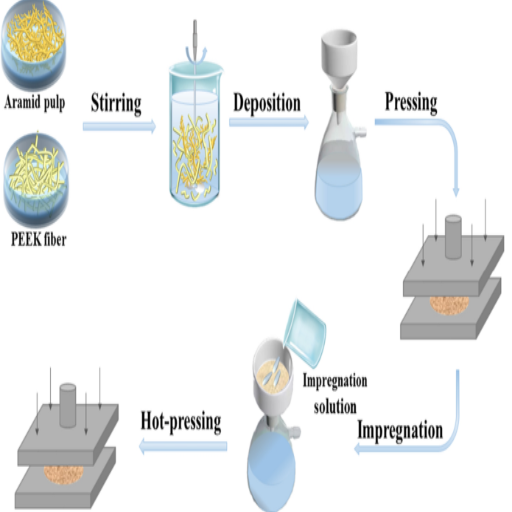

Understanding the Role of Glass Fiber and Amorphous Polymer

Glass fiber has been excellent for improving the mechanical properties of a polymer. When incorporated into a polymer matrix, it enhances strength, stiffness, and dimensional stability, thereby making it suitable for demanding applications. I commonly use glass fiber reinforcement when the application requires that the material withstand high loads, resist deformation, and bear the test of time without losing structural integrity. The selection of type and amount of glass fibers must be made with great care, depending upon specific mechanical requirements, since too much reinforcement can adversely affect its processability and sometimes also increase material costs. Glass fiber also offers better thermal resistance, which becomes a necessary criterion for applications involving exposure to high temperatures.

Amorphous polymers, however, have their benefits, helping them strike the right balance with glass fibers for impact-resistant applications, or in cases where optical clarity and easy processing are desired. They do not melt at one particular temperature and thus technically have an extensive processing range, which makes them great for parts with complicated geometry or fine details. I consider amorphous polymers when transparency and looks matter, they make for consumer products, or when it’s all about dimensional precision. They also would fare well with chemical resistance and are less likely to warp, letting them perform reliably in different conditions.

By understanding how glass fibers complement amorphous polymers, I can best work materials into a mold for a given application’s demands. If high mechanical strength or exceptional formability and clarity are required, all materials are sorted accordingly for an optimal formula to further depressivization.

Optimizing Strength and Rigidity through Reinforcement

To gain an optimization of strength and stiffness through reinforcement, I have an ideal combination of two factors: material properties and structural design. From the standpoint of increasing the base materials’ tensile strength, stiffness, and durability, adding two reinforcing agents, namely glass fibers and carbon fibers, will prove most effective. These agents disperse mechanical stresses, which means the end material resists deformation to a great extent when subjected to loads or impact. Selection of this reinforcement is governed by application requirements, i.e., balancing weight/strength or resistance to environmental aggressors like heat and moisture.

The matrix material is the binding agent for the reinforcements. Thermoplastics, thermosets, or amorphous polymers are chosen based on their compatibility with the reinforcement and their properties, such as elasticity, chemical resistance, or easy processing. The combined action of reinforcement and matrix produces a material of optimum mechanical performance while allowing it to fulfill its function satisfactorily.

A combination of reinforcement type, concentration, and orientation is considered and tailored by me for specific applications to achieve optimum rigidity and strength eventually. From lightweight parts for aerospace to large and heavy parts for industrial machinery, this meticulous procedure guarantees the performance and durability required from the material in cost-effective or practical terms when applying.

Reference Sources

- Polyetherimide – Wikipedia: A comprehensive overview of PEI, including its properties and uses.

- PEI Plastic – TECAPEI by Ensinger: Detailed information on PEI material, its mechanical strength, and applications.

- Polyetherimide – An Overview on ScienceDirect: Insights into PEI’s engineering properties and industrial applications.

- Polyetherimide (PEI): How to Select the Right Grade?A guide to PEI’s key features, like high-temperature resistance and mechanical strength.

- Polyetherimide (PEI) by Drake Plastics: Focused on PEI’s applications in electrical and industrial components.

- Top PEI Plastic Pellets Suppliers in China

Frequently Asked Questions (FAQs)

Q: What is PEI plastic?

A: PEI plastic, in trade terms Ultem®, is a true high-performance engineering plastic renowned for its mechanical capabilities, mainly high strength and impact resistance. It is an amorphous thermoplastic, giving rise to a peculiar relationship between tensile strength and temperature.

Q: What are the key features of PEI plastic?

A: The key features of PEI are high strength, excellent impact resistance, and inherent flame-retardant properties. It also possesses resistance to high temperatures and processability. PEI plastics resist stress cracking by chlorinated solvents.

Q: What is the difference between PEI and PEEK?

A: PEI is an amorphous thermoplastic possessing good mechanical properties, while PEEK is a semi-crystalline thermoplastic noted for superior chemical resistance and high-temperature performance. Both are materials for demanding applications; the choice depends on application requirements.

Q: Where is PEI plastic commonly used?

A: Common applications in the medical field are electrical connectors, medical devices, and machined plastics. It is also used in plastic sheet production and other components requiring high strength and temperature resistance in the aerospace and automotive industries.

Q: Why do engineers prefer Ultem® plastics?

A: Ultem® plastics are preferred due to their high tensile strength, impact resistance, and ability to withstand high temperatures. These excellent mechanical properties and dimensional stability make it ideal for applications that require precision and durability.

Q: Can PEI plastic be used for high-temperature applications?

A: Yes, PEI plastic maintains its properties when exposed to high temperatures to be used for high-temperature applications, provided that high temperature is the only service condition that the polymer must endure. PEI can sustain prolonged exposure to high temperatures without any appreciable loss in its properties.

Q: What significance does the Ultem trademark name have in PEI plastic?

A: The Ultem trademark name was derived from introducing a new class of specialty plastic materials known as polyetherimides. Simply put, it is a designation for a high-performance PEI polymer known for excellent mechanical and thermal properties.

Q: Is PEI plastic resistant to chemicals?

A: PEI plastics are generally considered to have good chemical resistance but are attacked by some solvents. For example, 1,1,2-trichloroethane will dissolve polyetherimide; hence, care should be exercised in any environment with such chemicals.

Q: What advantages does PEI plastic have over medicine?

A: In medical applications, PEI plastic’s advantages include sterilization capability, strength, and resistance to repeated autoclaving. It is also stable and biocompatible, making it suitable for medical devices and components.