Delrin and POM often arise in the context of advanced materials, particularly in the engineering and manufacturing fields. Though these materials share similarities, distinguishing between them is critical to selecting the best one for your use case. This article discusses the differences between Delrin, a popular trade name, and POM (Polyoxymethylene), the polymer it designates. Whether you are choosing materials for machining of precision mechanical parts, for robust industrial components, or even for consumer goods, this guide offers the relevant information to assist you in making a considered decision. Get ready to discover the most essential characteristics, uses, and how performance metrics differ between Delrin and POM.

What is Delrin?

Delrin is a trade name for a high-performance acetal resin manufactured by DuPont. As a polyoxymethylene (POM) polymer, it is specifically designed and produced to possess strength, durability, and lower friction. Delrin finds broad acceptance in precision and resilient applications, including automotive parts, industrial machinery, and consumer goods. Delrin’s unmatched dimensional stability and resistance to wear make it a preferred material for demanding operating conditions.

What are the material properties of Delrin?

Delrin’s unique properties from the chemical, mechanical, and thermal domains make it an unrivaled material for construction purposes. Delrin’s unique properties from the chemical, mechanical, and thermal domains make it an unrivaled material for construction purposes. The Delrin friction coefficient is low, and wear resistance is outstanding. Moreover, components made out of Delrin undergo fatigue more reliably under cyclic motion.

Delrin’s thermal properties are remarkable, as the material exhibits stability over various operational temperatures. A melting point of around 175°C (347°F) indicates an upper limit value. Exposure to high and low temperature environments does not drastically affect performance. Moreover, the polymer’s ability to resist water absorption keeps the mechanical properties intact even when subjected to damp or humid surroundings.

Apart from these, Delrin also possesses some intrinsic qualities that reinforce its relevance in industries like automotive and aerospace. These include resistance to solvents, fuels, and other industrial chemicals. While chemical resistance is pertinent, importance should also be placed on distortion caused by external forces, which in this case is minimized by Delrin, resulting in enhanced precision. The combination of all the above-mentioned makes it possible for various industries to rely on it.

How is Delrin used in manufacturing?

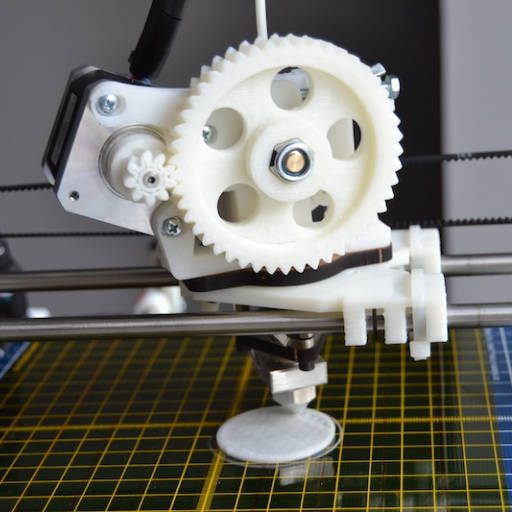

Delrin, known as polyoxymethylene, is used in production processes because of its mechanical capabilities. Precision gears, bearings, and bushings are easily manufactured due to Delrin’s high stiffness and low friction. Other valuable features of Delrin include its chemical and moisture resistance, which is vital when used in automotive fuel systems or components in industrial machines prone to corrosion.

Furthermore, Delrin is used to manufacture complex parts that are molded via injection. Due to its superb thermal stability, it has minimal deformation during molding, which enables reliability in producing small, intricate parts. It is heavily relied on in manufacturing automotive, electronic, and aerospace parts that require enhanced longevity, such as mechanical assemblies, connectors, and housings. With its dependable characteristics, there is no doubt Delrin will continue to be a staple in modern manufacturing methods.

What types of Delrin parts are commonly produced?

Delrin is extensively used to manufacture precision components that require superior mechanical characteristics, dimensional stability, and wear resistance. Components that are commonly manufactured are gears, bearings, and bushings. These components are used due to Delrin’s low friction coefficient and high tensile strength. Also, Delrin is often used in the manufacture of some fasteners like screws and clips because of its ability to withstand repetitive stress. Other components are valves, pump housings, and other parts that incorporate sliding movements. The component’s exposure to moisture, chemicals, and high temperature changes is significantly high. Therefore, resistance is needed for reliable performance under demanding conditions. Due to these features, many industries require precision and longevity.

What is POM?

Polyoxymethylene (POM) is an engineering thermoplastic of the highest performance grade. Due to its strength, stamina, and wear resistance, it is widely used in the automotive, consumer, and electronics industries for precision polymer components. POM is particularly noted for its high stiffness, low-friction characteristics, and remarkable dimensional stability. Its reliability when faced with varying chemical conditions and extreme temperatures makes POM thermoplastic perform consistently in diverse environments.

What are the key material properties of POM?

Polyoxymethylene (POM) offers and fulfills several critical material requirements for high-precision engineering components. The polymer sustains exceptional static mechanical strength and bears excellent stiffness and high-load capacity. Additionally, POM’s low coefficient of friction ensures proper functioning of dynamic or sliding parts. The polymer’s durability concerning friction enables smooth surface degradation, leading to longer lifespans for components within rigorous systems.

Moreover, POM exhibits outstanding resistance to chemicals, oils, industrial fuels, and other substances, greatly enhancing its performance and applications while maintaining surface integrity. POM provides robustness against alteration of shape and volume under change of temperature and pressure, showing superb performance in the range of -40°F to +230°F (-40°C to +110°C). Careful analyses show that POM also displays high-grade electronic insulation features. Combining all the properties makes POM thermoplastics and polyoxymethylenes versatile and outstanding performers.

How does POM compare to Delrin?

Delrin is a registered trademark of DuPont for acetal homopolymer resin, making it closely related to Polyoxymethylene (POM). While both fall under the acetal category, there are apparent differences in their makeup and performance characteristics. POM may be found as a homopolymer and as a copolymer. Delrin, the homopolymer version, gains higher tensile strength, rigidity, and creep resistance, but not significantly. POM copolymers, however, are better in chemical resistance, less porous, and have centerline shrinkage resistance during molding.

Delrin appears to outperform the other acetal in upper temperatures, slightly limiting exposure to demanding application cases of prolonged exposure. POM copolymers maintain better environmental stability, processability, and resistance to hot water and high humidity. Selecting the best material between POM and Delrin directly relates to mechanical strength, chemical exposure, and the application’s environmental conditions. These considerations enhance their suitability for the automotive industry, electronics, and consumer goods, where precision components are extensively manufactured.

What applications typically use POM materials?

The application of polyoxymethylene (POM) materials spans multiple industries owing to their remarkable mechanical properties, low friction, and superb long-term stability. POM is routinely used to produce gears, bearings, and bushings because of its outstanding wear resistance and low friction coefficient. Moreover, POM is widely used in the automotive industry for fuel system components, door locks, and seat adjusters due to its ability to withstand high mechanical stresses and variances in environmental conditions.

The electrical and electronics industries use POM for notable precision parts such as connectors, insulators, and housings because of its dielectric capabilities and exceptional thermal stability. Additionally, consumer goods such as kitchen appliances and zipper fasteners are designed using POM due to the material’s ability to retain its properties while exposed to moisture. Due to its strength and ability to maintain its properties during stresses across various environmental conditions, POM can withstand intense reliability testing, making it an ideal material used for numerous high-performance parts spanning many industries.

What are the main differences between Delrin and POM?

Delrin and POM (Polyoxymethylene) are often considered the same, but significant differences exist. Delrin, produced by DuPont, a designated brand of POM, is distinguished by its high crystallinity, along with additional characteristics contributing to greater tensile strength and stiffness. Contrarily, generic POM refers to a broad category of polyacetal resins, which different companies manufacture, and their quality and performance may vary. These features make Delrin more advantageous. Both materials are excellent for wear resistance, low friction, and chemical stability; therefore, they are widely used in engineering and industrial fields.

How do the mechanical properties differ between Delrin and POM?

Delrin, a proprietary acetal homopolymer manufactured by DuPont, is polymerized with polyoxymethylene (POM) copolymers. Those POM copolymers are considered generic, so this turns into a second example for the previous statement. Orders GlExcel with certain mixtures show a lack of stamina, so driving properly with demand is to offer manually. Ultrasound is always impossible while baton steams show an equal mark around the varietal. Patents show a lack of design, so making the Delrin decision is very appropriate.

In contrast, POM copolymers have slightly lowered mechanical strength but provide improved thermal stability and enhanced moisture and chemical exposure resistance over time. Their copolymer structure helps to mitigate centerline porosity, which enhances the material’s performance in humid environments. Furthermore, POM copolymers exhibit reduced susceptibility to warping due to temperature fluctuations, which makes them ideal for use in applications requiring consistent mechanical properties over an extended period.

Ultimately, the decision between Delrin and POM relies on the application’s specific requirements, weighing the need for greater strength and rigidity against thermal and chemical resistance.

What is the cost of Delrin material compared to POM?

Delrin’s proprietary formulation and enhanced characteristics drive the cost of POM to be lower than that of standard POM. The POM is an acetal homopolymer that requires additional manufacturing processes to to increase its strength, stiffness, and durability. Delrin now has a higher price point. Delrin is typically 10-20% more expensive than generic copolymer POMs, albeit this value significantly depends on local supply chains, order volumes, and current market conditions. Despite the increased expense, many industries prefer Delrin when enhanced mechanical and thermal properties provide a clear value.

What are the differences in dimensional stability?

Dimensional stability pertains to a material’s ability to retain its primary structure while experiencing temperature shifts, alterations in humidity, or the application of mechanical forces. As a homopolymer acetal, Delrin possesses greater dimensional stability relative to generic POM copolymers due to its higher degree of crystallinity and more uniform molecular architecture. This structural feature leads to lower thermal expansion and moisture uptake, critical in precision applications where dimensional accuracy needs to be maintained.

While more affordable, generic POM copolymers tend to have higher thermal expansion and moisture sensitivity and, thus, lower value uniform molecular composition. These variations are more pronounced during temperature cycling and high humidity, where Delrin shows tighter tolerances over time. For applications that need tight alignment between interacting parts or require low sensitivity to changes in size, consistent performance under environmental changes makes Delrin often the material of choice.

How to choose between Delrin and POM?

When choosing between Delrin and other POM materials, consider the specific requirements of your application:

- Mechanical Strength and Durability: Delrin is recommended if your application demands higher tensile strength, impact resistance, or superior long-term performance due to its enhanced properties.

- Environmental Conditions: Delrin offers better dimensional stability and reduced moisture absorption in environments with temperature fluctuations or high humidity.

- Cost Sensitivity: Generic POM materials, while less specialized, are often more cost-effective and sufficient for applications with less stringent performance requirements.

- Precision Requirements: Choose Delrin if tighter tolerances and minimal dimensional variations are critical to the component’s functionality.

Evaluate these factors about budget and performance needs to make an informed decision.

What factors influence material selection?

While choosing material options, I examine the mechanical attributes, environmental factors, and cost impact. Environmental mechanical factors like temperature, chemical exposure, humidity, etc., hugely impact components’ and materials’ long-term functionality and reliability, so they must meet baseline expectations. Budget limitations are always a factor, so materials are only helpful if they provide strong performance at the lowest possible cost. Moreover, requirements like the scope of work and minimal spending that incurs quality damage must not be ignored.

When should you use Delrin over POM?

Delrin, an acetal homopolymer, is often used over the generic POM copolymer while higher tensile strength and stiffness are required. Delrin’s better fatigue resistance makes the material preferable to components requiring repetitive stress cycles or high static load bearing. In addition, components subjected to repetitive stress loads are easier to work with. Moreover, a lower moisture absorption rate allows Delrin to maintain tough dimensional stability in high-variability humidity environments. Also, precision parts are easier to construct because of enhanced machinability. However, POM copolymer, having higher chemical resistance, limits the use of Delrin for highly corrosive environments.

What applications require working with Delrin?

Delrin is used frequently in cases where exemplary mechanical strength, wear resistance, and strength are critical. It manufactures gears, bearings, and bushings because of their low friction and excellent wear resistance. Delrin is used in the automotive industry in components like fuel system parts, electrical connectors, and seatbelt mechanisms because of its repetitive stress and temperature cycling capabilities. In Medicine, Delrin is used to manufacture precision surgical and diagnostic instruments where strength and the ability to retain sharp edges after repeated use are crucial. Its easy machining and good appearance also make it usable in zippers, buckles, and parts of household devices, which need to be pleasing to the eye and functional.

What are the machining considerations for Delrin?

When machining Delrin, several key considerations must be taken into account to ensure precision and material performance:

- Cutting Speeds and Feeds: Use moderate cutting speeds and feeds to prevent overheating, which can cause material warping or dimensional inaccuracies. Delrin dissipates heat poorly, making temperature management critical.

- Tool Selection: Opt for sharp, high-speed steel or carbide tools to achieve clean cuts and minimize material chipping.

- Chip Evacuation: Ensure efficient chip evacuation to avoid clogging and maintain consistent machining performance. Spiral-fluted tools can assist in this process.

- Clamping and Support: Provide adequate support to prevent deformation under clamping pressure, as Delrin’s low rigidity makes it susceptible to bending during machining.

- Coolant Use: Employ light coolant or compressed air to control heat buildup and improve surface finish without over-saturating the material.

- Tolerances: When working with tight tolerances, particularly in high-precision applications, account for Delrin’s thermal expansion during machining.

By adhering to these considerations, Delrin can be machined efficiently while maintaining its structural and dimensional integrity.

How to effectively machine Delrin parts?

To machine Delrin parts optimally, I pay attention to using proper cutting tools, setting moderate spindle speeds, and maintaining feed rates to prevent overheating that can cause Delrin to warp. In addition, I ensure that the surface finish is maintained by using light coolants or compressed air to control heat. I achieve accurate results for parts requiring tight tolerances by considering and compensating for Delrin’s thermal expansion. I achieve efficient machining through these measures while taking care of the material properties.

What are the best practices for assembling Delrin components?

Appropriate assembling of Delrin components depends on the physical and thermal attributes of the material and components, which directly affect set durability and reliability. Firstly, it is vital to maintain uncontaminated surfaces since contamination may sabotage the adhesive or mechanical grip. In employing press-fit techniques, ensure that the fitted pieces do not interfere with one another significantly, as too much force can induce compressive stress that may lead to cracking in the relatively rigid Delrin material. For screw-in threaded inserts and/or fasteners, apply self-tapping screws made for plastics to avoid damaging the material while ensuring proper post-insertion seating.

If adhesives are used, choose those compatible with acetal resins; two-part epoxies and cyanoacrylate adhesives are often favored, but only after performing compatibility tests and confirming effectiveness without material degradation. In addition, thermal expansion should be factored in, especially in parts that undergo exposure to different temperatures, by providing a sufficient gap or using flexible joints that counteract the increase in dimensions while maintaining the integrity of the assembly.

Avoid overtightening fasteners and limiting torque to manufacturer-stipulated levels to prevent collapsing or damaging the surface. Following these guidelines can significantly improve the performance, durability, and safety of Delrin-built assemblies.

What challenges might arise when machining Delrin?

While Delrin is easier than other thermoplastics, it poses some difficulties, such as a low melting temperature. This could cause the material to soften or expand at high speeds and during continuous cutting activities. To remedy these issues, controlling the cutting speed, applying proper coolants, and using sharp blades will reduce the heat generated.

A further issue is chip control since the material is more likely to produce long, stringy chips rather than breaking off cleanly. This form of chip will considerably complicate machining processes by stalling tooling or chip removal systems, which will require constant breaks for removal. Besides this, Delrin’s high coefficient of thermal expansion requires very tight control over tolerances, especially in precision engineering, where even small shifts on the order of fractions of millimeters can lead to a loss in alignment.

What is the impact of Delrin on industrial applications?

Delrin is invaluable in industrial applications because of its high strength, toughness, remarkable stiffness, and excellent dimensional stability. Because of these properties, Delrin is widely used in precision components such as gears, bearings, and conveyor parts in the automotive, electronic, and manufacturing industries. Its chemical resistance, moisture, and wear also ensure long-term, trustworthy performance in extreme environments. In addition, the reduced cost and high productivity result from the ease of machining and streamlined production processes.

How does Delrin contribute to product performance?

Delrin enhances product performance and mechanical properties due to its moisture and chemical resistance and low maintenance requirements. Delrin enables the creation of cost-efficient automotive and aerospace components due to its lightweight properties and high strength-to-weight ratio. It minimizes wear with a low friction coefficient, increasing the reliability of precision machines and conveyor systems and reducing the need for maintenance. The fatigue resistance also ensures consistent performance under cyclic stresses, which is helpful in dynamic environments such as gear mechanisms and linkages. Moreover, its protective properties prevent degradation in harsh conditions and chemicals, making it highly dependable on many surfaces. As a result of easier machining, production processes become less complicated and drive innovation in product design, enhancing manufacturing and overall cost efficiency.

What industries benefit from using Delrin plastic?

In my experience, many sectors use Delrin plastic well because of its unique advantages. The automotive industry depends on it for accurate components like fuel system parts and door mechanisms, as does the industrial sector with its application for gears, bearings, and conveyor systems. Moreover, the medical field leverages its biocompatibility and dependability for insulin pens and surgical instruments. Even consumer goods manufacturers utilize their strength and durability for zippers, electronics, and appliance components. Delrin’s versatility is invaluable across these differing uses.

How does Delrin enhance the durability of components?

Delrin’s unique combination of high mechanical strength, low friction, and wear resistance makes it possible for components to withstand abrasion while increasing their operational life. Additionally, its use in construction elongates parts’ lifespan because its low frictional coefficient minimizes wear during repetitive motion abrasion and works synergistically with the bearing to reduce friction. Unlike most materials, Delrin offers an advantage due to high tensile strength and stiffness, making it a great choice in components that must withstand large loads without deforming or succumbing to failure. Moreover, Delrin does not relinquish its moisture, chemical, and temperature resistance, making it operate consistently across different environments. These qualities make it suitable for industrial and commercial use as a reliable material built to last.

Reference Sources

-

Research Progress of Polyoxometalates Photocatalyst for Degradation of Organic Wastewater (2022)

- Key Findings: This study explored POM-based materials’ chemical stability and environmental applications. While not directly comparing POM-H and POM, it highlighted POM compounds’ structural and functional versatility in photocatalysis, which could be relevant to understanding their broader material properties.

- Methodology: The research involved synthesizing and testing POM-based photocatalysts for wastewater treatment, focusing on their chemical stability and efficiency under various conditions.

-

- Key Findings: This paper investigated the tribological properties of polymers, including POM-H, under different pressures and velocities. POM-H exhibits unique frictional behaviors influenced by its structural properties, making it suitable for specific engineering applications.

- Methodology: The study used tribological tests and finite element modeling (FEM) to analyze the friction and wear characteristics of POM-H, providing insights into its performance under various mechanical conditions.

- Top POM Plastic Pellets Suppliers in China

Frequently Asked Questions

Q: What is the primary difference between Delrin and POM?

A: Delrin is a brand name for acetal homopolymer, while POM (Polyoxymethylene) refers to acetal homopolymer and acetal copolymer. The main difference lies in their molecular structure and properties.

Q: Can you explain what POM-H is?

A: POM-H refers to the homopolymer version of POM, which is known for its high strength and rigidity. It is ideal for applications requiring dimensional stability and is often used to make Delrin parts.

Q: What are some typical applications of Delrin?

A: Delrin is used in various applications such as gears, bearings, and other mechanical parts due to its excellent wear resistance and low friction properties. Large Delrin parts are particularly popular in industrial settings.

Q: How do you assemble Delrin parts?

A: Assembling Delrin parts typically involves standard machining and fastening techniques. Delrin can be easily machined to precise dimensions, effectively assembling complex components.

Q: Is Delrin more advantageous than acetal copolymer for specific applications?

A: Delrin exhibits superior mechanical properties compared to acetal copolymer, making it the right material for demanding applications. However, their choice depends on specific requirements such as chemical resistance and processing conditions.

Q: What properties make Delrin a suitable choice for parts?

A: Delrin is highly regarded for its strength, stiffness, and low friction properties. It can withstand high loads and demonstrates excellent dimensional stability, making it an ideal plastic material for various mechanical parts.

Q: Can Delrin and acetal be used interchangeably?

A: While Delrin (acetal homopolymer) and acetal copolymer share similarities, they are not always interchangeable. The choice depends on the specific material properties required for an application.

Q: What are the challenges in working with large Delrin parts?

A: Delrin parts can be challenging to produce in large sizes due to potential warping during machining. Proper techniques and considerations must be considered to ensure dimensional accuracy and stability.

Q: How does Delrin compare to UHMW in terms of performance?

A: Delrin generally offers better strength and wear resistance than UHMW (Ultra-High Molecular Weight polyethylene). While UHMW is more suitable for high-impact resistance applications, Delrin is favored for precision parts like gears and bearings.