The textile and fabric industries are full of many technical terms. Among them are PES and PPS, which some may find difficult to differentiate and understand their use. We’ll try to break down the complexities of those materials and evaluate them in great detail. We have it all covered, from their configurations, attributes, and varied and unique uses in different sectors. This article will be a helpful tool to anyone looking into these two textiles and the path they take in the modern world, whether the person is a manufacturer, designer, or just interested in textile innovations.

Understanding PES and PPS

Introduction to Polyethersulfone (PES)

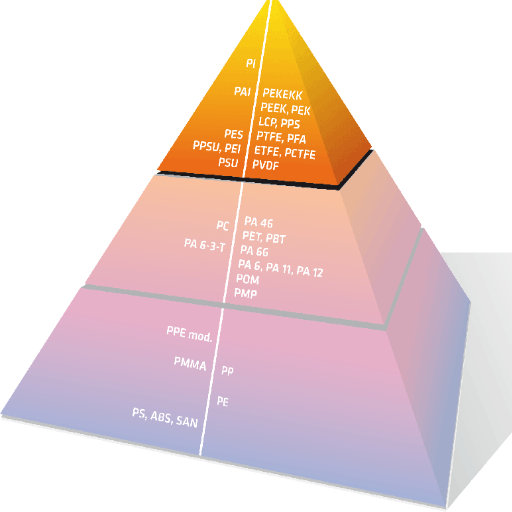

Polyethersulfone (PES) is a high-performance thermoplastic polymer renowned for its almost unlimited strength, thermal, and chemical stability. It belongs to a polysulfone family best known for its transparent nature, toughness, and resistance to high temperatures. PES has excellent hydrolytic stability and is therefore used in processes requiring long hours of exposure in hot water or steam treatment without any form of degradation. It also offers excellent dimensional stability when subjected to harsh operating conditions.

PES has other properties, such as excellent chemical resistance to oils, acids, and mild bases, making it preferred in healthcare, aerospace, and electronics sectors. Examples of applications for PES in these sectors are medical devices such as sterilization trays, filtration membranes, and electric industry components. PES has a continuous use temperature in the neighborhood of 200°C (392°F) with a low flammability rating, reinforcing its versatility in demanding environments.

Its lightweight and strong constitution has made it favored by industries requiring high-strength and heat-resistant manufacturing materials. Companies also appreciate how easy it is to mold the material through injection molding, extrusion, and other processing methods that allow mass production. These features combined make PES the material of choice for every industry on the road to creating new and advanced products with a guarantee of durability, safety, and efficiency.

Introduction to Polysulfone (PPS)

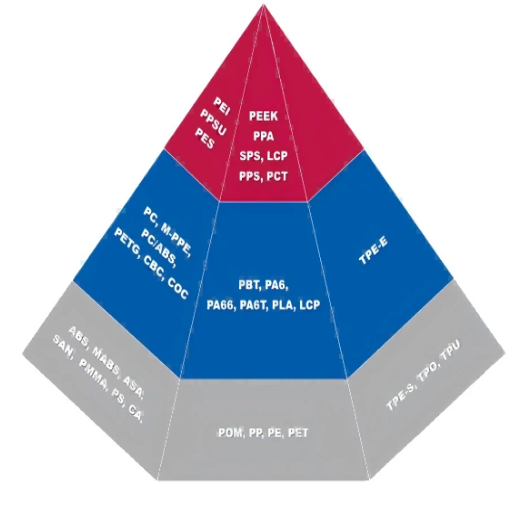

PPS, or polysulfone (or polysulfide), is a high-performance thermoplastic polymer with good chemical resistance, dimensional stability, and heat resistance. It is preferred for applications exposed to harsh chemicals, high temperatures, and mechanical stresses, where the working environment would otherwise degrade the polymer’s performance. PPS exhibits other beneficial properties like low moisture absorption, excellent electrical insulation, and inherent flame-retardance, thereby becoming popular in diverse industries such as automotive, electronics, healthcare, and aerospace.

PPS is utilized commercially in precision molded parts, electrical components, and plumbing hardware where durability and ease of processing are key considerations. For example, it is used in the automotive fuel systems, cooling systems, and sensor housings, where reliability is needed under extreme conditions. Because of its excellent chemical resistance and capability for processing, this polymer also excels in filtration and membrane technology.

Moreover, PPS shows excellent prospects from a strong sustainability perspective. Its recycling possibilities and resistance to long-term wear mark it as an eco-friendly option for industries committed to sustainable development. By combining high-performing properties and versatile processing methods, PPS continues to push the frontiers in innovative, cost-efficient, and reliable product development in countless applications.

Applications of PES and PPS in Engineering

Polyethersulfone and polyphenylene sulfide are industrial polymers that have been found to have applications in engineering based on their physical, chemical, and mechanical properties, which are used in different industries. Due to PES’s high temperature and chemical resistance, filters of stringent quality standards used in many industries are made of PES. For example, its water-treatment membrane applications ensure that PES has durability and efficiency in industrial and municipal systems. PES applications extend largely into the medical field, forming sterilizable devices such as surgical instruments that can be autoclaved repeatedly without degrading material performance.

PPS, meanwhile, is of prime significance in the automotive and aerospace industries, requiring high-performance capabilities under extreme conditions. Its superior dimensional stability and chemical resistance make it appropriate in areas such as fuel system components and connectors, as well as under-the-hood constructs where heat and chemical exposure are part and parcel of the system. There is also a growing application for PPS in electrical and electronic systems for insulation materials and circuit board substrates, thereby enhancing the reliability and longevity of advanced technologies.

These two polymers satisfy the sustainability agenda by being recyclable and having extended service lives, so industries can reduce material waste while increasing efficiencies. Their insertion into modern engineering applications is a testament to how materials science has continually evolved to ensure the fulfillment of high-performance needs without compromising environmental consciousness.

Mechanical Properties of PES and PPS

Tensile Strength Comparison

Being considered special materials for their outstanding mechanical properties, PES and PPS serve in heavy-duty engineering applications. Both materials share high tensile strength, but nuances arise due to factors related to grades and formulations.

The tensile strength of PES varies from 80 MPa to 100 MPa, depending on composition and reinforcements. High tensile strength makes the material stable under constant loads, making it ideal for filtration membranes and medical devices subjected to prolonged stress.

Conversely, PPS presents tensile strength from 90 MPa to 120 MPa in reinforced variations, in which the filler is generally glass or carbon fiber. Such fillers enhance strength considerably, and the filler reinforcement-based matrix also exhibits good resistance to temperature changes and corrosive environments. Therefore, automotive and aerospace applications that require robust and precise performance use PPS.

While the tensile strengths of PES and PPS are equal, the application conditions, including resistance to temperature, chemical exposure, and total mechanical loading, define the choice between them. These special features herald both materials as crucial in facilitating new, functional, and sustainable engineering ventures.

Flexural Modulus of PES vs PPS

The flexural modulus of a material tells us how stiff it is or its resistance to bending under the action of a load; this property is crucial for determining the nature of applications that can be assigned to any product. Polyethersulfone (PES) and Polyphenylene Sulfide (PPS) perform very well in this respect, each having merits depending on factors peculiar to the operating environment.

PES usually has a flexural modulus between about 2,400 and 2,800 MPa. This high modulus is a stiffness that makes this resin preferred in fields requiring dimensional stability and resistance to deformation; some examples are medical devices, fluid handling, and electrical components. PES also adequately retains high mechanical properties at elevated temperatures, ensuring its reliability in adverse operating conditions.

PPS is revered for its high-temperature and chemical resistance, matching its pride of place among the flexural modulus. With a typical value somewhere between 3,800 and 4,200 MPa, PPS is stiffer than PES and could be preferred where a high structural rigidity is required, be it in automotive parts, aerospace components, or industrial applications.

Indeed, the two materials perform well; however, applications calling for extreme stiffness or exposure to harsh operating conditions weigh heavily on the higher flexural modulus of PPS. Nevertheless, PES finds application with a little flexibility and high transparency desirable, emphasizing that working through material properties is an essential process in design and selection.

Impact Resistance of Engineering Plastics

The capacity of plastic to resist impact is an essential characteristic; applications usually require materials subjected to sudden forces, shocks, or loading conditions. This characteristic measures the material’s ability to absorb energy and resist fracturing under impact, making it paramount in the automotive, aerospace, construction, and manufacturing industries.

Polycarbonate (PC) is a commonly known high-impact plastic product whose impact resistance is due to its amorphous molecular structure, which enables it to dissipate energy. Plus, ABS provides an excellent combination of toughness with relative ease of machining and is, therefore, considered for applications requiring tough components, such as housings for electronics or automotive parts. On the other hand, PEI has a slightly compromised impact resistance but has superior thermal stability and applications with mechanical stress combined with elevated temperatures.

In addition to the processing and formulation parameters, temperature and thickness also impact the toughness of the above-listed plastics. Impact resistance is usually drastically reduced at low temperatures due to restricted molecular motion and shortened barrier capability. On the other hand, fillers used occasionally to reinforce these polymers, e.g., glass or carbon fiber, increase the strength but sometimes reduce impact resistance, thus bringing in yet another balance that must be optimized according to application.

Manipulating the impact resistance of engineering plastics shows how versatile and adaptive these materials really are in fulfilling demanding industrial requirements. Backed, among other things, by the materials selection data, testing is tailored toward specific areas of use, ensuring the best performance and safety in their application.

Thermal Properties of PES and PPS

Heat Resistance of Polyethersulfone

Exhibiting extraordinary thermal stability, polyethersulfone (PES) finds excellent applications in scenarios calling for a prolonged period at high temperatures. Polyethersulfone retains its structural integrity and mechanical performance even under thermal stress: it has a glass transition temperature of nearly 225 °C (437 °F). Its engulfing heat resistance makes it suitable for products used in medical devices, aerospace components, and electrical/electronic parts where materials are subject to huge temperature variations.

It has low thermal expansion and can hold dimensionally, thus preventing its performance from changes in magnitude under a broad temperature spectrum. A specialized and unique concoction of thermal endurance and mechanical strength allows PES to resist sterilizing treatments like autoclaving, which gives PES tremendous value in healthcare and laboratory environments. Thus, these properties put PES at the top of the sought-after industries where durability and reliability are taken great pride in under harsh thermal conditions.

Thermal Stability of Polysulfone

It is famed for its excellent thermal stability, keeping its functional properties from -100°F (-73°C) through to 347°F (175°C). This high-performance thermoplastic can resist deformation brought about by heat and has a glass transition temperature of around 374°F (190°C). Its properties do not vary much at elevated temperatures, leading to a wide range of uses in fields requiring long-term exposure to heat, such as automotive, aerospace, and medical technologies.

In addition, it is very hydrolytically stable, which means the material undergoes mechanical property changes when subjected to prolonged autoclaving or steam sterilization processes. Resistance to thermal aging prolongs the polymer’s working life span, especially in harsh environments where long-term heat resistance is needed. These properties create applications in filtration membranes, medical devices, and high-temperature fluid handling systems, guaranteeing that the material is employed in a competitive and demanding industry.

Applications in High-Temperature Environments

PTFE’s thermal stability, chemical resistance, and mechanical durability make it a highly relevant material in hot environments. It may be exposed to corrosive chemical environments continuously at temperatures of approximately—260 °C (500°F) with hardly any degradation occurring in its properties. The chemicals involved tend to be aggressive at elevated temperatures, necessitating PTFE for lining heat exchangers, gaskets, and seals in the chemical processing industry. And since it is chemically inert, it maintains its structural integrity even when interacting with volatile compounds.

Another vital use of PTFE occurs in the aerospace and automotive industries, when manufacturing fuel hoses, wire insulations, and hydraulic lines. The components in these applications must withstand rapid temperature changes and high operational stresses, while PTFE provides the low thermal conductivity and wear resistance needed to fulfill these requirements. PTFE is also used extensively in industries for manufacturing bakeware and conveyor belts, where the non-stick properties and resistance to thermal cycling are critical for increased productivity and lower maintenance.

Data emphasize PTFE’s longevity under thermal stress, retention of function over time brought by specific properties, such as a low coefficient of friction being one of them. It thus acts not only as a solution to enhance performance but also as a cost-effective choice, given that components of PTFE require much less frequent replacement than their counterparts. These applications speak to how PTFE continues to be an essential material in designing and engineering technologies tailored for high-temperature operational environments.

Electrical Properties of PES and PPS

Dielectric Strength of Polyphenylene Sulfide

Polyphenylene Sulfide is heralded for its fantastic electrical properties. Arguably, the most significant property would be dielectric strength, which is the property intrinsic to the material that allows it to be subjected to the highest possible electric field without undergoing electric breakdown. Usually, dielectric strength rose toward a range between about 19 and 23 kV/mm, so there is very high resistance against conduction, i.e., insulation. Hence, it is the perfect material for installing high-grade connectors, circuit board materials, and insulation parts, particularly in conditions with high mechanical stress or high-temperature levels.

PPS also shows good stability over frequency and voltage changes and remains unchanged in its insulation behaviour over time. Its low value for dielectric constant and dissipation factor-shaped parameters is found in advanced-level electronic systems requiring the highest precision and reliability. Apart from the above, it can resist water and chemical attacks, thus ensuring that the electrical insulation properties remain intact in even the worst operating conditions. All these properties make PPS one of the material candidates for meeting the demanding requirements of modern electrical applications.

Insulating Properties of PES vs PPSU

Polyethersulfone (PES) and polyphenylsulfone (PPSU) remain advanced thermoplastics crafted and acknowledged for the best insulating quality. Due to durability, thermal stability, and extreme reliability over various environmental conditions, both materials have been used in electrical and electronic applications. For the discerning professional or layperson aware of material specifications, it will help to understand where these two materials diverge to select an appropriate choice for a particular application.

PES exhibits an excellent dielectric strength, preventing conduction of electricity even under high-voltage conditions. It also has exceptional dimensional stability at high temperatures and is ideal for parts in which components should be cascaded to thermal stress for a considerable period. This material also assures exceedingly consistent insulating performance under electrically stressed environments, free from the adverse influence of the inconstancies of humidity or temperature.

PPSU, on the other hand, equals PES in thermal stability and is even more resilient to impact and chemical attacks. It is preferred in applications requiring great mechanical strength and the highest insulation performance. Interference with other superior materials in their steadfast maintenance of dielectric properties under aggressive adjuvants is remarkable enough for the pairing of chemical blowing or steam sterilization, thus making PPSU the first choice for application in medical devices or industrial-grade electrical components.

When evaluating these two materials in application, key parameters such as dielectric constant, dissipation factor, and thermal deformation temperature must be compared. The dielectric constant exhibited by PES is generally recorded as about 3.1–3.8 at 1 MHz, and the PPSU does similarly, maintaining said value even in severe environmental conditions. Both exhibit low dissipation factors for lesser energy dissipations, yet a comparatively higher resistance to environmental degradation offered by PPSU can provide long-term benefit in extreme corrosive environments.

Generally speaking, PES may be worthy of applications that demand extreme dimensional stability and thermal performance. PPSU shines when the application demands tougher and more versatile mechanical and thermal performances under extreme operating environments. Both plastics offer excellent insulation. The final choice depends on the application’s exact mechanical, thermal, and environmental requirements. By building on the inherent strengths of these advanced polymers, industries can specify the best options in designing component performance, thereby improving the reliability of their electrical systems.

Conductivity Considerations in Engineering Plastics

According to STAR 50304 CONDITION 5, in engineering plastics, the selection must be based on a balance of electrical insulation against the dissipation of static electricity. Polyphysic or any high-grade plastic material, such as PPSU (polyphenylsulfone) and PEEK (polyether ether ketone), is well known for its high dielectric strength and low electrical conductivity, being therefore an appropriate choice for applications requiring high insulation power, such as electronic components and medical devices.

These materials usually have to be made conductive so that the dissipating properties operate through the composite materials containing carbon fiber or conductive filler. These dispersions create a thin conductive path, which does not impair the mechanical integrity of the polymer matrix. For example, carbon nanotube incorporation increases conductivity as well as mechanical properties, and therefore, these composites are suitable for use in demanding environments such as aerospace or semiconductor fabrication.

Furthermore, thermal resistance is crucial for these conductive-related applications. Polymers that undergo high temperatures must sustain their electrical properties and not be degraded. Thus, PEEK is preferred when electrical insulation has to be retained at high temperatures, whereas modified polycarbonate blends at lower temperatures would allow further optimization of conductivity and strength.

Ongoing developments in material science widen the scope for engineering plastics in conductivity-critical applications. Innovative polymer modifications and combinations allow industries to harmoniously meet the triad of demands: electrical, mechanical, and reliability, in a continuously sharpening environment. The industrial climbing ability in the application of these materials is supported by a host of definable benefits, such as longer product lives and energy savings.

Comparative Analysis: PES vs PPSU

Performance Under Stress

The observation I have made amidst stress testing is that polyethersulfone and polyphenylsulfone show resilience and durability, albeit with some differences depending on the nature of the situation. PES is thermally more stable and rigid, and thus would be the more successful choice where higher temperatures and restricted deformation are desired. Such strength and dimensional stability make it a reliable option, particularly in environments where it has to go through time-dependent loading.

In contrast, PPSU resists sudden impact and dynamic loads better than PES regarding cleansing toughness. Consequently, PPSU is much more ductile and generically capable of absorbing considerable energy during operational stress to prevent sudden failures from impacting or oscillating load situations. It states its interest in dynamic-type applications, namely those on the medical and aerospace fronts, where the material is scrupulously sterilized superabundantly or vibrated mechanically without surface degradation.

Finally, beyond the general concern differentiating PES and PPSU, it is always suitable for the respective application. This polymer provides a credible answer if one prioritizes stiff performance regarding PES. However, in an environment requiring enhanced toughness and long-term resilience to physical stress, I would anticipate PPSU to stand as the crown. Both polymers are essential in solving different engineering assignments for optimized performance in varying stress conditions.

Long-Term Durability of PES and PPSU

Regarding long-term durability, I recommend the materials based on their unique properties. PES is excellent against hydrolysis and, hence, suitable for long-term exposure to water and steam. It is thermally stable in nature and, therefore, retains good performance under severe thermal environments without degradation. However, because of its rigidity, an application requiring impact resistance might not be suitable for it.

Now, PPSU is uniquely tough and resistant to fatigue even when subjected to repeated mechanical stresses; it can withstand high mechanical loads better than PES and is, therefore, better suited for components that undergo prolonged or dynamic force-taking. Chemically and thermally, however, PPSU is on par with PES, the other facet of its long-lasting power in demanding applications.

So, my choice between PES and PPSU depends on the application. If a stiff material without much mechanical load is required, PES would be my material of choice. However, for more challenging environments demanding resistance to wear and impact over time, I will stick with PPSU. Both polymers are durable, but their strengths set them apart regarding engineering and environmental challenges.

Cost-Effectiveness in Engineering Applications

In my opinion, cost-effectiveness in engineering applications is always a question of how to balance initial materials cost with the delivery of value in terms of performance and durability in the long term. PES, for instance, is cheaper to buy and offers good thermal stability and chemical resistance in applications with moderate mechanical demands. This would better serve those instances where cost sensitivity is prevalent but quality and thermal performance cannot be compromised. There is less density; hence, less weight and, parameter-wise, the cost decreases for some applications.

PPSU, on the other hand, offers more cost efficiency when harsher operating conditions are to be endured, like repeated mechanical stresses or instances of repeated impacts. It’s almost always more of a front-end investment, but operationally, PPSU is so tough and does last longer that it considerably cuts down on maintenance and replacement costs. This would make it a top choice in high-demand industries such as aerospace, healthcare, and automotive: you cannot afford failure, and long-term reliability is worth the initial higher investment.

This is my understanding of cost-justification, not merely something cheapening. A total life-cycle cost is considered: endurance, performance in harsh conditions, and the requirements of the exact environment. Every case is a question of weighing cost in the short term against benefit in the form of hidden savings due to durability and performance over time, equally balanced in questions of PES or PPSU.

Reference Sources

- PES vs. PPS – MakeItFrom

- PEEK vs. PPS vs. PES: A Guide to High-Temperature Plastics – PEEK China

- Polyethersulfone vs. Other Engineering Plastics – Polimapes

- Applications of Polyphenylene Sulfide (PPS) – SpecialChem

- PPS, Polysulfones (PSU, PESU, PPSU), and Polyarylates – Find Out About Plastics

- Top PC Plastic Pellets Suppliers in China

Frequently Asked Questions (FAQs)

What are the properties of polyethersulfone compared to PPS?

Polyethersulfone (PES) is good at having chemical resistance and high-temperature stability in the event of high-performance requirements. In contrast, PPS (polyphenylene sulfide) offers high thermal stability; however, PES is usually the option for impact strength and flexibility. PES is amorphous, so it remains dimensionally stable under varied conditions, while PPS, being crystalline, introduces a different set of mechanical properties. PES generally has better chemical resistance than PPS, especially in harsh environments. While both are high-performance thermoplastics, these differences make them fit for different applications.

How does the mechanical strength of PSU compare with PPS?

Both PSU (polysulfone) and PPS offer robust mechanical properties. Yet, specific differences are always pointed out during considerations. Generally, PSU is recognized for having high impact strength and maintains dimensional stability, while PPS is well-renowned for its best creep resistance and wear rate. Hence, PPS fares better when a higher temperature is encountered, while superior mechanical properties need to be exhibited. However, due to its versatility in molding and processing, PSU fits applications requiring some flexibility. Ultimately, the peculiar mechanical requirements of an application dictate the selection of either PSU or PPS.

What are the applications requiring high-performance PES?

High-performance PES is used mainly where high chemical resistance, high temperature, and mechanical strength are required. This property lends PES to applications in aerospace, automotive, and medical devices. PES is used for filtration membranes as it can resist aggressive chemicals and high temperatures. PES is also used as electrical insulation because of its thermal stability and electrical properties. Thus, PES is suitable for industries needing materials that can withstand extreme conditions and retain their properties over a considerable period.

What is the continuous use temperature of the PSU, and how does it relate to PPS?

The continuous use temperature for PSU could be as high as 180°C, while PPS is usually rated for continuous use at slightly elevated temperatures of around 200°C. This detail grows critical when the applications involve prolonged exposure to heat. However, despite PPS having a higher continuous use temperature, PSU is preferred for chemical applications due to much better chemical resistance. Therefore, depending on a particular application’s thermal and chemical requirements, a choice is often made between the two. By and large, PSU and PPS find their specific applications in domains where temperature and chemical stability matter.

Are there any trade-offs for properties with PSU and PPSU?

PSU and PPSU share some advantages in terms of mechanical and thermal properties. However, while both are high-temperature-resistant plastics that meet service demands, there is a trade-off because of the better mechanical properties. PSU is leant toward flexibility with good melt processability, allowing the production of intricate molding designs. PPSU sacrifices some of its flexibility for higher chemical resistance and thermal properties, making it suitable in environments where durability and resilience must walk hand-in-hand. This distinct difference in properties makes the two materials valuable in different fields, ranging from aerospace to medical applications.

What are the tribological properties of polyphenylene sulfide?

Tribological properties of polyphenylene sulfide (PPS) are significant in applications where friction and wear are of paramount concern. PPS realizes low wearing rates, making it ideally suited to be used as bearings, seals, and other implements in constant friction. It enjoys a high strength of mechanics, followed by chemical resistance, augmenting its performance in adverse environments. PPS is generally recognized as a better wear-resistant material than PSU, courtesy of its crystalline structure. Such a property is advantageous in applications wherein materials stand at high loads and temperatures without degradation.