Despite outstanding differences, novices perceive plastic granules and pellets to differ. This blog aims to demystify the terms with a straightforward explanation to understand their distinguishing characteristics, applications, and value to other industries. Whether you want to expand your knowledge of the raw materials, enhance your sourcing options, or simply deepen your understanding of which fits your requirements best, this guide has your back to make informed choices.

Introduction to Plastic Granules and Pellets

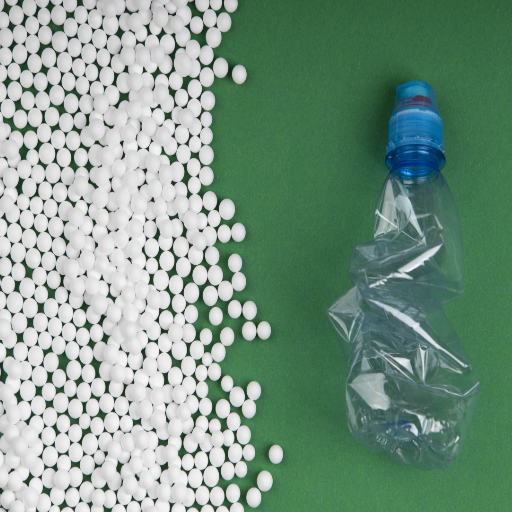

What are Plastic Granules?

Plastic granules are small bead-like materials used as raw materials in any plastic product manufacturing organization. Polymerization processes usually produce the granules from various polymers, including polyethylene, polypropylene, and polystyrene. Depending upon the polymer and its end use, plastic granules can vary in size, color, and texture, which helps accommodate industries such as packaging, automotive, construction, and consumer goods.

Since granules are consistent with one another and are easy to handle in industrial processes, they are melted and transformed into products of specific shapes, textures, or other specific uses during manufacturing. The demand for plastic granules is huge globally as they enable the industries to function on production lines due to their consistent quality and ease of handling. With the presence of recycled plastic granules, the spotlight is also on sustainable manufacturing to reduce the environmental impact while meeting the requirements of industries. The properties and types of granules should be well understood when selecting materials for production, performance, and testing requirements.

What are Plastic Pellets?

Plastic pellets, also known as resin pellets or polymer granules, denote small or sometimes rather minute, typically cylindrical or spherical plastic particles, which are raw material stocks with which one manufactures plastic. Two methods may be employed for manufacturing pellets: polymerization or crushing recycled plastics into uniform shapes and sizes. The industries wherein pelletized polymers find applications include packaging, automotive, construction, consumer goods, and many others, myriad by their versatile nature and easy handling.

Plastic pellets have a high demand worldwide mainly because, as feedstocks, they are found to be used in the extrusion process, injection molding, and blow molding. For instance, HDPE pellets may be molded into bottles and containers, whereas polypropylene pellets are used in automotive parts and textiles. The size of pellets allows uniformity in controlling the production so that the desired consistency, strength, and quality are embodied in the final product.

Sustainably sourced plastic pellets, including post-consumer recycled, are increasingly favored from an industrial perspective as producers and manufacturers want to use environmentally conscious production methods. By using recycled polymer materials, manufacturers reduce their environmental footprint and help advance the circular economy.

Importance of Knowing About Plastic Types

Understanding plastic types has become critical for industries and consumers alike, to the point that it is now affecting material choice, product design, and sustainability measures. Each plastic type, such as polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET), has its own set of properties, making it fit for specific applications. For example, PET, considered by some as the best available packaging, is mainly used for beverage bottles because of its lightness and durability. Polypropylene, on the other hand, is used widely in food containers because of its resistance to chemicals and ability to stay intact at high temperatures.

Acting through an analysis of the various characteristics offered by the diverse plastics, polymer technology allows manufacturers to make decisions. HDPE is a perfect packaging plastic because it is strong and recyclable. Nowadays, the trend suggests the choice of biodegradable and recyclable plastics, primarily because governments are regulating these materials, and conscious consumers are very much concerned about environmentally friendly products.

Therefore, it can also be used to reduce risks involved in regulatory processes, minimize production wastage, and contain costs. By choosing the right materials, companies can provide better-performing, longer-lasting products while helping with global waste reduction and environmental preservation efforts.

Raw Materials in Plastic Production

Types of Plastic Raw Materials

Plastic raw materials are usually divided into two major categories: natural polymers and synthetic polymers, which also have different properties and applications. Some familiar examples in the first group are rubber and cellulose, which are derived from plants and other natural resources. Depending on their type, they are usually used for applications in the textile industry and packaging, considering their biodegradable nature.

Meanwhile, synthetics are made through chemistry and exist as three products: thermoplastics, thermosetting plastics, and elastomers. Thermoplastics, such as PE, PP, and PS, are some of the most used classes of polymers because of their recyclability and versatility. Thermoplastics become molten on heating and then harden by cooling, thus proving great choices for industries such as automotive, construction, and consumer goods. On the other hand, thermosetting polymers exhibit a complicated setting character once heated and formed. Therefore, these were used in electronics and aerospace applications based on their resistance to heat and mechanical stress. Elastomers are popular for applications exposed to extreme conditions, employing elasticity and durability, such as in medical equipment, sealants, and adhesives.

An influx of data highlights the conversion towards biodegradable and bio-based polymers due to their eco-friendly nature and increasingly stringent regulations. For instance, Bio-PE and PLA capture packaging markets as sustainable alternatives to traditional plastics. The reports also emphasize that demand for recycled materials such as rPET continues to grow, with regulatory incentives materializing for manufacturers to pursue circular production strategies.

A clear understanding of the types of plastic raw materials and their applications allows industries to innovate in meeting performance and environmental needs. This classification also equips producers to make a more strategic choice of their material, hence ensuring cost-effectiveness, regulatory compliance, and product excellence.

Role of Additives in Plastic Granules

Additives are instrumental in improving the properties and performance of plastic granules so that they can meet the requirements for various industrial applications and environmental criteria. The additives are incorporated in the production process to change the properties of the granules, like toughening, softening, heat resistance, color vibrancy, etc. For example, antioxidants and UV stabilizers are key additives that prevent polymer degradation from environmental exposure. At the same time, plasticizers provide flexibility to ordinarily rigid plastics and, therefore, find applications in various industries.

Flame retardants may be added to plastics requiring flame retardancy for safety considerations in construction and electronics, and fillers and reinforcements enhance mechanical strength and reduce production costs. Antimicrobial additives are an increasing trend and help inhibit microbial growth, thus offering better hygiene. Generating interest is studying greener additive technologies, such as bio-based or non-toxic variants, mulling over functionality, and conservation.

These ensure that plastic granules are designed to meet technical specifications and follow current sustainability and efficiency trends to gain a market-competitive advantage.

Processing Raw Materials into Granules and Pellets

Conversion from raw materials into granules and pellets is a multi-step system that enhances the versatility of materials while maintaining consistency in quality parameters and performance. Typically, one begins by selecting raw materials such as polymers, additives, or recycled materials meant to be sorted and cleaned to remove impurities. Such materials are melted or softened to a certain viscosity level in the extruder so that they can be optimally mixed with any additives that may be required, such as colorants, stabilizers, or plasticizers.

Extrusion presents the most significant step, ensuring uniformity in mixing and homogenization. While the material exits the extruder, it is cooled and solidified using water baths or air-cooling systems into cylindrical strands. These strands are then sent into pelletizers that cut them precisely into granules or pellets of uniform size and dimension.

Presently, it is possible to control temperature, pressure, and feed rates during the process with high accuracy, thus reducing waste, lowering energy consumption, maintaining consistent output quality, and fulfilling stringent industrial standards. For instance, fully automated systems supported by sensor technology and real-time analytics enable continuous monitoring and adjustment of performance, thereby driving efficiency and enhancing quality control.

Granules and pellets created using these methods are then commercially utilized in several industries, including automotive, packaging, and construction. Standardized sizing facilitates handling, transportation, and manufacturing processes of injection molding and extrusion. This method of processing raw materials into granules and pellets is more efficient and represents the industry’s commitment to quality, innovation, and sustainability.

Properties of Plastic Granules and Pellets

Physical Properties of Plastic Granules

Plastic granules possess many physical properties that make them flexible and suitable for various uses. Often, these granules are of uniform size and shape to ensure continuity of material flow during processing. The density of plastic granules depends on the polymer; predominantly, it ranges between 0.9 g/cm³ for polypropylene and 1.4 g/cm³ for polyvinyl chloride (PVC). These differences in densities can be utilized for industries that require lightweight or heavy-duty materials.

Melt flow index (MFI) is another critical consideration parameter—it measures how easily melted plastic can flow. Granules with a high MFI are more suited to injection molding using lower temperatures for accurate shaping. In contrast, granules with a low MFI are suited for extrusion processes requiring high mechanical strength. Thermal stability remains very important because most plastic granules are designed to withstand processing temperatures ranging from about 200 to 300°C without any decomposition, depending on the polymer involved.

Moisture content is also checked in granules, as too much moisture can cause rough manufacturing defects, such as bubbles or voids. Sophisticated drying systems throughout production ensure the moisture content remains under 0.02%, well within acceptable standards. These carefully designed physical properties of plastic granules highlight their indispensable nature in meeting the standards of the final products for numerous industries.

Chemical Properties of Plastic Pellets

Complex molecular chains predominantly made up of polymers represent plastic pellets from a chemical standpoint. Thus, polymers chiefly influence the chemical behavior of an application and, consequently, its performance. Resistance to chemicals is one of the most prominent features that allow the pellets to remain stable under the attack of acids, alkalis, and other harsh chemicals. For example, PE resists most solvents, while PC stands up well against UV and weathering in specific applications.

The other most crucial characteristic is thermal stability. In its making, an individual batch of pellets will be designed for specific temperature ranges beyond which it will not retain its stability but will start to degrade thermally. For example, PP pellets can withstand temperatures in the region of about 130°C, which is crucial since polypropylene application requires heat resistance. Furthermore, flame-retardant additives may be added for safety in critical applications such as electronics or construction.

Another factor affecting the performance of the pellets in the final product is molecular weight distribution, which affects the flow properties during processing. The higher molecular weight polymers enhance strength and impact resistance, while the lower ones enhance ease of molding and casting. Various additives, such as stabilizers, plasticizers, and fillers, can additionally modify the chemical nature of the plastic pellets for performance in specialized industry applications.

Advanced analytic methods, such as spectroscopic, chromatographic, and thermal analysis, are employed for chemical compositional analyses of the plastic pellets to ensure they meet industry standards. The analyses help ensure that no harmful substances, such as bisphenol A (BPA) or heavy metals, are present in concentrations that would render the material unsafe for its intended application, such as food packaging or medical devices.

Comparative Analysis of Properties

When comparing plastic pellets to other popular materials, these factors are becoming essential: durability, flexibility, thermal stability, and environmental impact. Plastic pellets boast supreme versatility because their properties, like hardness and elasticity, can be adjusted and customized according to the required application. Plastics may generally perform better as thermal insulators than metal and glass for specific applications, thus making them a choice worthy of consideration for temperature-sensitive products.

Plastic pellets are valued at a somewhat lower cost. Their manufacturing processes offer a higher degree of scalability and efficiencies, ultimately lowering the cost of manufacture in comparison with ceramics and composites. Besides, improvements in polymer science now allow plastic pellets to compete in mechanical strength with conventional materials such as wood or aluminum in various structural uses.

Sustainability is another big term. In recent times, as the use of biodegradable and recycled plastic pellets has increased, sustainability concerns have been addressed. This technology reduces waste and energy use during production, making it a plausible alternative for companies promoting environmentally friendly working conditions.

With this analysis in full, plastic pellets still lead due to their extreme versatility, use, and potential as an eco-friendly approach across industries.

Difference Between Granules and Pellets

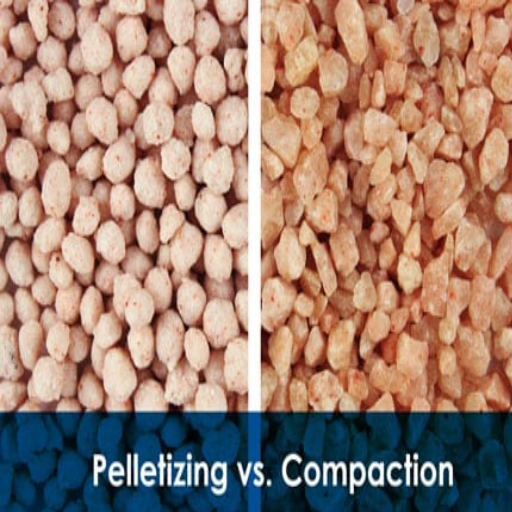

Key Differences in Manufacturing

The manufacturing processes for plastic granules and pellets differ primarily in production methods and applications. Granules are typically obtained through fairly simple grinding or crushing processes: the bigger pieces of plastic materials are broken down into the smaller pieces of irregular shapes. It is a relatively cheap method widely used in recycling or blending raw materials. In contrast, pellets result from extrusion; molten plastic is forced through a die and cut into cylindrical shapes of uniform size. These regular dimensions ensure consistent melt behavior of the pellets at the downstream stages of injection molding or extrusion.

This made pellet manufacture ideal for automation, thus achieving efficient production with minimal material wastage. Granules offer flexibility but may lack the uniformity required for precision processes, making them competitive wherever cost is decisive or operational requirements are not that stringent. Another feature of newer manufacturing technology now allows the making of pellets from bioplastic and recycled materials, catering to the increased demand for sustainable industrial practices. Understanding these factors is essential for deciding on the proper plastic material form to be injected in processes that maximize production efficiency and product quality while still adhering to environmental attentiveness.

Applications of Granules vs. Pellets

Given their distinct qualities, granules and pellets serve several different purposes in industrial and manufacturing procedures. Granules, being relatively minor and irregularly shaped, are best suited for more precise applications such as injection molding, which requires consistent flowability and controlled dosing. They are also used extensively in the pharmaceutical and agricultural sectors, depending on the formulation, chemical nature, and ease of blending.

Pellets, on the other hand, are widely applied in processes requiring uniformity and efficient bulk handling. Their cylindrical shape and correct sizing suit them for extrusion work, especially in making films, pipes, and profiles. Due to their compact shape, pellets also generate less dust, thus enhancing safety in the workplace and guarding against material loss during large-scale manufacturing activities.

Recent material and production technological developments have enhanced the versatility of either granules or pellets. As such, granules and pellets are more often used for processing bioplastics and recycled polymers, in line with the growing concern for sustainability. The application of these materials has improved production efficiency and environmental impact, making them meet worldwide sustainability targets. The choice between granules and pellets lies in considering production needs, costs, and environmental concerns to guarantee the best performance in particular industrial environments.

Cost Implications of Using Granules and Pellets

The costs of granules versus pellets vary depending on production scale, material variation, and preferred end-use. Granules supermarket production and processing are relatively cheap due to more straightforward and minimal processing methods, but this is an economical consideration for bulk producers. Pellets have a somewhat refined and highly technical process, which justifies the higher cost.

But it’s not about the initial price- the action efficiency sets much on the scale. Being uniform, pellets improve feeding with less downtime and hence more precision in automated systems, whose efficiency and reduced wastage gains can more than compensate for the initial investment. Granules, whilst cheaper, may need continuous system calibrations or cause more wastage, hampering long-term efficiency costs.

The worldwide movement toward green practices has also been impacting cost considerations. Recycled granules and pellets, for example, undergo cost iterations, giving industries an edge regarding green credentials. Recycling-based materials cut raw material costs and, in turn, reward companies for meeting regulatory requirements and marketing the companies higher on the brand equity scale. Hence, a comprehensive cost-benefit analysis of one’s production dictates and sustainability aspirations must be undertaken before making a granular versus pellet selection.

Storage and Handling of Plastic Granules and Pellets

Best Practices for Storing Granules

In considering all the different facets of storage, I have found that possession of an adequate environment and following appropriate standards is the key for plastic granules. The first thought I entertain before storing anything is ensuring that it is clean, dry, and free of contaminants. From my experience, moisture is one big enemy of plastic granules that can affect material quality and cause impediments later during processing. Hence, I prefer to store my granules either in a sealed container or in moisture-proof bags, and I ensure that the packaging is continuously inspected and replaced when found damaged. Temperature control comes second, with sudden ups and downs; it would be the death of granules. So, I would always go for storage places that neither get hot nor cold.

Another method that I apply is keeping the granules systematically stored. This means the containers are labeled either with granule material type, batch number, or date of receipt to prevent any mix-up and smooth inventory control operations. Through my experience, using a first-in, first-out (FIFO) inventory application has proved helpful as it ensures that those granules received earlier are used first, thereby reducing the chances of degradation with time. Also, I provide that all materials are stored off the ground on pallets or proper shelving to avoid spills, infestations, or moisture.

Of course, safety while handling granules is another matter. Proper training and the use of safety measures, such as PPE, reduce the risk to the lowest possible. By aggregating these best practices, I maintain the quality of plastic granules as best as possible and present them optimally for production purposes.

Storage Solutions for Plastic Pellets

When I think of storing plastic pellets, I imagine a clean environment: Dry, sweet-scented, and perfectly temperature-controlled. Moreover, using airtight containers or sealed bags protects the pellets from dust, dirt, and moisture, which can compromise the quality. These are placed in cabinets or storage areas with access restricted to prevent contamination and disorganization. Each container is labeled plainly so anyone can find and trace materials. Needless to say, this helps me troubleshoot and gets rid of downtime.

Shelving or pallets should be on hand or installed to protect from water damage or pest exposure. An organized storage system protects the integrity of the pellet while providing safety by alleviating clutter and providing ease of access. Periodically, I inspect the storage atmosphere and containers to confirm that all conditions are still optimum and adjust if necessary. This enables me to efficiently handle my plastic pellets inventory and maintain quality fairly well.

Safety Considerations in Storage

Regarding safety considerations in storage, my first concern is ensuring security and the absence of hazards to the materials and the surrounding environment. The entire area has to be well organized so that no accident occurs due to a misplaced item or improper container stacking. Another essential safety aspect includes labeling and segregating materials to avoid cross-contamination or mix-up, especially when dealing with various plastic pellets. Moreover, I inspect the racks and shelves regularly to ensure no structural failure will arise, which could consequently lead to injuries.

Temperature control is always an essential factor of attention because extremes of heat or cold may damage the quality of pellets and pose unsafe conditions for human beings. I never keep containers close to heat sources or under direct sunlight; instead, I prefer to use temperature monitors to keep a check on the storage conditions. One of the other critical factors is ventilation, which should ensure that no fumes or dust accumulate, thus posing respiratory hazards. Proper hull flow makes it safer and healthier for me and anyone who may go to the storage.

Lastly, I try to stay in line with the safety regulations and protocols of the industry to avoid any existing ones that could become emergencies, like fire and spills. Fire extinguishers, spill kits, and emergency exits are always within easy reach, and emergency measures are reviewed regularly to keep everyone on their toes. The works of organization, environment control, and safety regulations enable me to run my storage systems with complete efficiency and utmost conscientiousness of safety.

Reference Sources

- The Difference Between Plastic Pellets and Granules – KB Delta

- Plastic Raw Materials: The Different Types of Plastic Granules – Vismec

- Major Difference Between Granules and Pellets – ZanPVC

- Recycled Plastic Granules – Capeco Recycling

- What Are Plastic Pellets Used For? – Aceretech

- Top PC Plastic Pellets Suppliers in China

Frequently Asked Questions (FAQs)

Q1: What are plastic granules and pellets?

Plastic granules and pellets are the basic raw materials for plastic manufacturing. Granules are small, irregular-shaped bits of plastic, usually created by shredding and grinding larger plastic materials. Pellets are coalesced by extrusion, so they have nice diameters and lengths that give them consistent quality for injection.

Q2: How are they made?

Generally, plastic granules are generated by mechanically grinding or shredding technologies from post-industrial or post-consumer plastic waste. Pellets are formed by melting and extruding plastic, which is then cut into cylindrical shapes of even size. The pelletization assures uniformity; pellets serve as material for precision molding or manufacture.

Q3: What are the main areas of application?

Granules are more commonly used in the recycling industry or for common plastic manufacturing purposes. Some procedures are applied for uniformity. Pellets are better used for injection molding, plastic extrusion, and 3D printing applications. Their uniform size and low variability ensure the production of high-quality plastic products with precision and consistency.

Q4: Which is better for manufacturing?

Choosing depends on the application. Pellets are usually preferred when an automated manufacturing process must be precise for automotive or medical-grade plastics. Granules are more appropriate in less demanding applications or recycling processes as raw materials. Considerations like cost, manufacturing requirements, and specification of end-use products will influence the choice.

Q5: Are there environmental considerations?

Both plastic granules and pellets can be derived from recycled plastics, making them a point of consideration within a sustainable production cycle. Since pellets are used in the industry where strict quality control is applied, this limits the use of recycled materials. Granules, the less processed product, provide a larger room for incorporating recycled content, conjunctively working towards the goals of a circular economy. Both materials should be handled properly to safeguard against environmental pollution like microplastic spillage during transportation or manufacturing.

Q6: What advances in technology exist in granule and pellet technology?

Recent innovations refer to bioplastic granules and pellets made from renewable resources and intended to be biodegradable. Moreover, the advancement of extrusion has rendered it more efficient and better at maintaining the quality of pelletized plastic. These developments intend to satisfy the calls for eco-materials and superior manufacturing choices.