The design of products and their manufacturing have been made easier with the advent of thermoplastic materials since they are highly flexible, versatile, and durable. Two materials that can be highlighted from the collection are Thermoplastic Elastomers (TPE) and Thermoplastic Polyurethanes (TPU), each with its own independent uses and features. The characteristics of TPE and TPU often lead to discrepancies, making it difficult for someone to distinguish between the two, especially when trying to determine which material is best for a particular scenario. The purpose of this article is to highlight the differences between TPE and TPU in a simple manner, requiring no prior knowledge of the materials.

What are TPE and TPU?

Both TPE (Thermoplastic Elastomer) and TPU (Thermoplastic Polyurethane) are multifunctional polymer materials with a wide range of uses. TPE is an elastomer that can be easily combined with plastics, making it suitable for products like grips and seals. TPU, a subtype of TPE, is more resistant to abrasions, chemicals, and temperature extremes, making it ideal for use in industrial belts, cables, and other protective coatings. Both materials are helpful in many industries because they are easy to recycle and can be reused.

Definition of TPU

Thermoplastic polyurethane (TPU) is a type of thermoplastic elastomer with outstanding versatility due to its elasticity, durability, and resistance to wear. TPU is made of linear segmented block copolymers formed by hard and soft segments, which give it unique mechanical and physical properties. TPU is resistant to oil, grease, and many chemicals, which makes it a preferred material in demanding environments. Its high tensile strength and flexibility, even at low temperatures, make it widely used in the automobile, medical, and electronics industries. Furthermore, TPU can be easily processed through injection molding and extrusion, allowing the production of intricate and accurate parts applicable in many advanced technologies.

What is TPE?

TPE, short for Thermoplastic Elastomer, refers to a subclass of polymers that exhibit traits of rubber as well as thermoplastic materials. Thanks to the property mentioned below, TPE materials can be heated, remolded, and cooled repeatedly with only minor damage, making them easy to manufacture. To meet requirements that require flexibility, durability, and a soft-touch feel, TPE finds applications in automotive parts, seals, wire coatings, medical equipment, consumer products, and more. It usually has a mixture of hard thermoplastic and soft elastomeric segments, which provides TPE with good mechanical properties, such as fatigue strength and excellent resilience. Additionally, unlike other materials, TPE is appreciated for being easily reconstructed and for meeting the needs of different industrial regulatory policies.

Characteristics of thermoplastic elastomers

Thermoplastic elastomers have a unique characteristic of combining two or more features of different materials, which is a blend of thermoplastics and traditional elastomers. They do stand out from the other materials with one particular feature: being repeatedly heated and cooled without being damaged is a unique capability worth noting. For situations that require comfort and adaptability, such as in consumer and medical devices, these materials provide an excellent level of softness, flexibility, and elasticity, and are safe for use.

TPEs, from a mechanical perspective, withstand tension well, have low compression set resistance, and a remarkable resistance to abrasions, which makes them ideal for challenging environments. Another essential characteristic is the ability to perform in extremely low-temperature environments while still maintaining tensile properties and pliability. Furthermore, TPEs have remarkable resistance to destructive environments, including strong chemicals, oils, greases, and a variety of solvents.

Thermoplastic elastomers have an easily processable nature that is also strong. They can be used in standard thermoplastic processes such as injection molding, extrusion, and blow molding. This also allows for cost-effective measures without sacrificing precision and efficiency. This enables TPEs to increasingly replace traditional materials in industries due to their low weight and high precision.

What is the difference between TPE and TPU?

Although TPE (Thermoplastic elastomers) and TPU (Thermoplastic polyurethane) are both classified as thermoplastics, each serves a different purpose. TPE is a broad spectrum of materials that exhibits the elasticity of rubber while retaining the ease of processing like a plastic. Due to its softness, flexibility, and recyclability, it is used in many industries.

Specifically, TPEs with superior durability, higher hardness levels, and increased resistance to abrasion are called TPUs. Used for stronger protective shoe soles, casings, and even some industrial parts, these elastomers are considered the go-to for anything that requires enhanced mechanical strength.

Key differences between TPE vs TPU

While differentiating between TPE and TPU, these were the two points that stood out the most. TPE is more widely applicable due to its flexibility, lightweight nature, and ease of processing. In contrast, TPU, a subtype of TPE, offers enhanced mechanical strength, superior abrasion resistance, and higher hardness, making it better suited for industrial components and protective equipment. As a summary, if greater durability is required, TPU is the better option. However, TPE will consistently outperform in matters where comfort and flexibility are necessary.

Hardness and elasticity of TPU and TPE

Regarding the comparison of hardness and elasticity between TPU and TPE, I noticed that TPU has higher hardness and tends to resist deformation under pressure more than TPE. This makes TPU ideal for use in situations where structural integrity or durability is required. TPE, on the other hand, is more flexible and easier to bend, making it perfect for softer, pliable applications. Finally, the decision revolves around whether rigidity or flexibility should take priority for the intended purpose.

Abrasion and chemical resistance comparison

We can see that TPU is more abrasion-resistant than TPE in terms of repetitive wear and friction. The dense molecular structure of TPU allows for enhanced endurance, which is helpful in industries that require materials to withstand prolonged mechanical stress, such as in footwear soles and conveyor belts. On the other hand, TPE has moderate abrasion resistance but is more susceptible to wear due to continuous friction, making it less suitable for high-stress applications.

In terms of chemical resistance, TPU outperforms TPE in resisting oil, grease, and industrial chemicals. The mechanical strength and integrity of TPU remain intact in harsh environments compared to TPE, which tends to degrade or swell over time when exposed to such substances. In cases where exposure to chemicals is frequent or unavoidable, TPU is much superior to TPE.

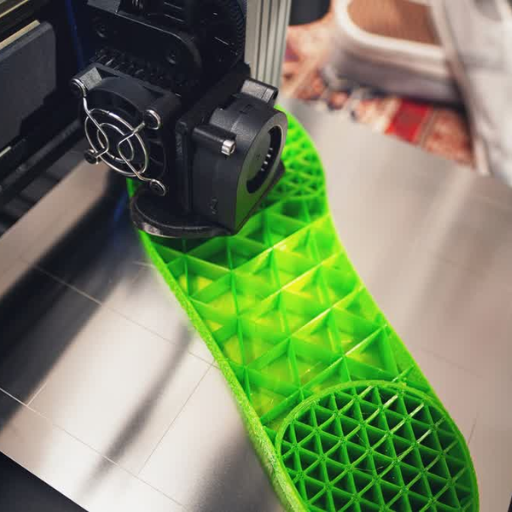

How are TPU and TPE used in 3D printing?

In 3D printing, TPU and TPE filaments are popularly used because of their flexibility, resistance to impact, and durability. For stronger and more elastic materials that resist abrasion, such as phone cases, industrial seals, and footwear parts, TPU is the preferred option. For grips and handles, which are simpler applications that require softer and more flexible materials, TPE works well. These two materials offer a range of flexibility and complex 3D design, while also making them versatile during manufacturing.

3D printing materials: TPU filament vs TPE filament

Each of TPE (Thermoplastic Elastomer) and TPU (Thermoplastic Polyurethane) filaments has distinct competitive advantages that are useful in different 3D printing applications. Regarding shore hardness, TPU tends to have a higher shore hardness than TPE, ranging from 80A to 98A, making it more rigid and durable. TPU’s longevity and durability, with its oil, grease, and abrasion-resistant properties, make it a popular choice for functional parts such as gaskets, automotive parts, and strong protective cases.

Flexible and Soft Thermoplastics both boast wide resistance to chemicals. The materials can be printed with any direct drive extruders, but TPE may be prone to more filament jams or malfunctioning due to its soft and flexible structure. On the contrary, TPU is known for its elasticity, which makes cooling settings a bit tricky, where fine-tuning can lead to better results. Overall, these factors can affect the results of 3D printing, along with meeting the user’s project requirement of burst supports.

Applications of TPU in 3D printing

TPU (Thermoplastic Polyurethane) is popular in 3D printing due to its good blend of flexibility, durability, and chemical resistance. One of its primary uses is in the making of custom gaskets and seals, as its elasticity and toughness ensure a proper fit in even the most intricate geometries. Wearable devices like straps, bands, and insoles are best made from TPU due to their comfort and resistance to repeated stress. Moreover, its abrasion resistance makes it ideal for prototyping industrial machine components that are subjected to friction or impact. Easier post-processing and dyeing make the material more useful for consumer goods by creating designs that are easy to strengthen, which is needed in modern projects that demand flexibility.

Benefits of 3D printing with TPU

TPU stocks are readily available, and the Convenience of use, when combined with 3D printing, makes TPU and other polyurethanes widely adopted in various industries. With the numerous pre- and post-processing conveniences it offers, in contrast to its high strength, broad adaptability, and easy form, strength, and structure tailoring, TPU presents a wide range of temperature blends that can help enhance gaskets, seals, and even wearables.

In addition, TPU has outstanding resistance to wear, tear, and abrasion, which guarantees the durability of functional components even in extreme operating environments. Its resistance to chemical attack by oils, greases, and some solvents widens its use in industrial settings where violent materials are present. TPU also retains its properties over a broad range of temperatures, which is helpful for products that experience high thermal cycling.

Absorption of impact energy is another vital feature of the material that makes it worthwhile for producing soft parts, such as shock-absorbing and protective equipment. Moreover, TPU’s relationship with 3D printing processes, such as fused deposition modeling (FDM) and selective laser sintering (SLS), broadens its use across different industries. Its post-processing ease and the ability to create intricate designs make it an essential material for manufacturers looking for flexible and efficient designs tailored to specific needs.

What are the applications of TPU and TPE?

Both thermoplastic polyurethane (TPU) and thermoplastic elastomers (TPE) are commonly used in various industries due to their unique characteristics. The heat and impact resistance of TPU make it widely used in the footwear industry, sports equipment, and cable jacketing, as well as in automotive components like seals and gaskets. On the other hand, TPE is often used in manufacturing medical devices, toys, household goods, and consumer electronics due to its balance of elasticity and strength. The flexibility and adaptability of these materials are exceptional, yielding high-performance results.

Typical uses of TPU material

TPU stands for thermoplastic urethane, and it is one of the most versatile materials due to its elastomeric properties, which span across different sectors. The combination of elasticity, transparency, abrasion resistance, and resistance to oil and grease makes it strong in high-demand environments. Assertively, TPU is one of the most widely used products for protective films, particularly for electronic screens, guard films, and automotive paint, due to its durable and reliable nature.

Moreover, in the footwear sector, TPU (Thermoplastic Polyurethane) is widely used in outsoles and midsoles due to its lightweight and durable nature, which enhances comfort and performance. Its flexibility and toughness are equally crucial in industrial uses like pneumatic tubing, conveyor belts, and drive belts. The material is also widely used in 3D printing because it strikes the right balance between strength and flexibility, allowing for the construction of complex and durable prototypes.

Industries utilizing TPE material

Thermoplastic elastomers (TPEs) are used across numerous markets for their unparalleled elasticity, durability, and ease of manufacturing. The automotive industry, for example, uses TPE for seals, gaskets, airbag covers, and interior trims due to their mechanical, weather, and wear resistance. Just as advantageous are TPEs’ biocompatibility for the medical industry, where they are used for syringe plungers, catheters, and other wearable medical devices. TPEs are also crucial in packaging, as they are used in flexible closures and seals that help preserve product integrity.

Because of the cushioned feel and non-slip properties of TPEs, the consumer goods industry has had no problem utilizing them in the manufacturing of ergonomic grips, footwear parts, and other household items. The construction sector also capitalizes on TPEs for window seals and roofing membranes due to their weatherproofing capabilities. Because TPEs resist UV radiation and environmental wear, these materials are essential to modern product design and construction.

Comparison of applications in automotive and medical devices

The automotive and medical device industries are just two of the many sectors where thermoplastic elastomers (TPEs) are used as plastic materials. The unique mechanical and chemical characteristics of TPEs help to tackle specific issues within distinct sectors.

TPEs are widely used in the automotive industry due to their softening point, resistance to cracking under high or low temperatures, flexibility, and resistance to wear. They play a vital role in the formation and construction of air ducts, cable looms, and interior trim parts, serving as a glue that holds everything together. Additionally, TPEs have improved the seals and gaskets used in vehicles due to their durability when exposed to force and environmental damage. This provides further vehicle weight reduction—an essential element in fuel efficiency.

On the other hand, in the medical industry, TPEs are crucial in maintaining patient safety and the efficacy of medical devices. They are highly utilized in the construction of syringe plunger devices, catheter tubes, and medical-grade seals. Their biocompatibility, cleansing efficiency, and stringent regulatory compliance make them invaluable in the medical field. Additionally, TPEs aid in meticulous molding of complex designs for medical devices, which helps improve patient care and the reliability of the devices.

How to choose the right material between TPU and TPE?

When choosing between TPU (Thermoplastic Polyurethane) and TPE (Thermoplastic Elastomer), consider the application requirements:

- Mechanical Performance: TPU offers superior abrasion resistance, tensile strength, and elasticity, making it ideal for applications requiring high durability and flexibility. TPE is softer and better suited for applications prioritizing comfort and less demanding mechanical properties.

- Environmental Resistance: TPU resists oils, chemicals, and extreme temperatures more effectively, while TPE is preferred for applications that do not face harsh environmental exposure.

- Application Context: For automotive, footwear, and industrial uses, TPU is often the better option due to its strength. Conversely, TPE is commonly used in consumer products, such as grips or medical devices, where comfort and compliance are crucial.

- Cost and Processing: TPE is generally easier and more cost-effective to process, making it a practical choice for high-volume applications that do not require stringent performance demands.

Evaluate your application’s specific needs in terms of performance, environment, and budget to make the most suitable choice.

Factors to consider for material selection

When selecting materials for any application, it is essential to consider several critical factors to ensure optimal performance and cost efficiency. These considerations include:

- Mechanical Properties: Assess the material’s tensile strength, elasticity, impact resistance, and durability. These properties determine how well the material can withstand operational stresses and environmental conditions.

- Thermal Stability: Evaluate the material’s thermal conductivity, maximum operating temperature, and resistance to thermal degradation. This is especially important for applications exposed to high temperatures or temperature fluctuations.

- Chemical Resistance: Consider the material’s compatibility with chemicals, solvents, or other potentially corrosive substances it may come into contact with. Materials with poor chemical resistance may deteriorate quickly under certain conditions.

- Environmental Impact: Investigate the material’s biodegradability, recyclability, and ecological footprint. Sustainable materials not only align with regulatory requirements but also support long-term environmental preservation.

- Ease of Processing: Examine how easily the material can be molded, welded, or manipulated during production. Materials requiring intricate processing steps or specific conditions may increase manufacturing complexity and cost.

- Cost Efficiency: Balance the material’s upfront cost with its lifespan and performance. While some materials might have a higher initial cost, their durability and performance could lead to long-term savings.

- Regulatory Compliance: Ensure that the material adheres to industry-specific certifications and standards, such as FDA approvals for medical devices or UL ratings for electrical components.

By systematically analyzing these factors, industries can make well-informed decisions that align with their functional requirements, financial constraints, and sustainability goals.

When to use TPU vs TPE

Choosing between TPU (Thermoplastic Polyurethane) and TPE (Thermoplastic Elastomer) boils down to the exact requirements of the application. TPU is my choice for high durability, abrasion resistance, and impressive load-bearing capabilities, such as in industrial or automotive settings. I opt for TPE, however, when softness, flexibility, and easy processing matter more, especially in consumer or medical devices. Because of the mechanical, chemical, and thermal properties that need to be satisfied for the end use, these materials become straightforward to work with.

Alternatives to tpe and tpu

When looking to replace TPE (Thermoplastic Elastomers) and TPU (Thermoplastic Polyurethane), many other materials can be equally or more effective based on the specific application needs. Silicone rubber, for instance, works amazingly well for applications that require high flexibility and thermal stability along with superb sealing properties in medical or food-grade environments. EPDM (Ethylene Propylene Diene Monomer) rubber is much more resistant to UV rays and ozone, making it popular for use in automotive and outdoor applications.

Yet another acute example is flexible and rigid PVC plastics, as they can help achieve the required flexibility and strength without increasing costs in construction and packaging. For seals, gaskets, and components in fuel systems, thermoset elastomers like Nitrile or Viton are superb due to their durability and resistance to chemicals. The selection of these alternative materials is based on their mechanical, chemical, and thermal properties, as well as compliance with legal operational requirements.

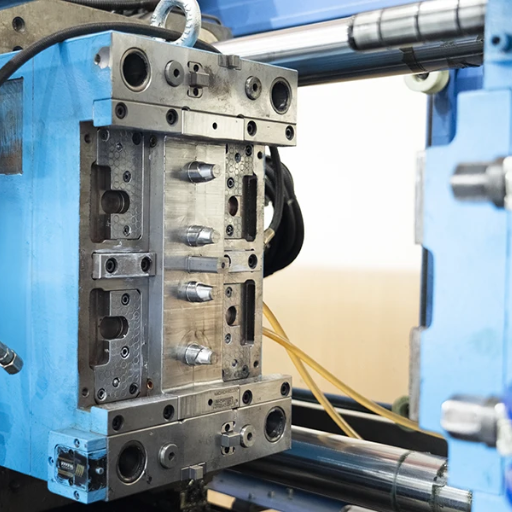

What is the process of injection molding with TPU and TPE?

The process of injection molding with TPU (thermoplastic polyurethane) and TPE (thermoplastic elastomers) involves several key steps to ensure precision and material integrity:

- Preparation of Material: TPU or TPE pellets are dried to remove any moisture, as excess moisture can affect material properties and part quality during the molding process.

- Melting and Injection: The dried pellets are fed into the injection molding machine, where they are heated and melted. The molten material is then injected into a pre-designed mold under high pressure.

- Cooling and Solidification: The material cools and solidifies within the mold, taking the shape of the mold cavity. This stage is critical for ensuring the dimensional accuracy of the final product.

- Ejection: Once cooled, the molded part is ejected from the mold using ejector pins or plates.

- Post-processing (if necessary): The part may undergo additional processes, such as trimming, inspection, or secondary finishing, based on application-specific requirements.

This process is widely used in industries such as automotive, consumer goods, and medical devices due to the versatility of TPU and TPE.

Understanding injection mold techniques

These methods refer to the combination of contemporary industrial procedures and more advanced techniques to increase accuracy and the effectiveness of injected materials. In modern industry, molding injection covers a lot of sophisticated processes. A good example is multi-shot molding, which allows the addition of various parts or colors to a single component, improving the strength and reliability of the finished product while reducing assembly time. Another instance is gas-assisted injection molding, where gas is used to pressurize the thick parts of a component, creating holes while lowering its weight and maintaining strength.

One particularly noteworthy development is the inclusion of conformal cooling channels, designed to maintain uniform cooling rates, minimize cycle times, and follow the shape of the mold cavity. This improves the cooling accuracy of the part and increases the likelihood of uniform cooling, resulting in fewer warps or stresses in the finished parts. No less important, the development of more advanced simulation software allows engineers to model flows, cooling, and defects, and make pre-production changes, thus optimizing design and minimizing material waste.

Advantages of using TPU in injection molding

Thermoplastic polyurethane (TPU) is distinguished by its unique versatility and performance in injection molding, making it one of the most widely used materials for injection molding across various industries. The ability to manufacture rigid and flexible parts is due to the excellent intrinsic elastomeric properties of TPU, high abrasion resistance, and superior tear strength. Because TPU withstands harsh environments and industrial chemicals, it is preferred in applications that require resistance to chemicals and oils. Also, TPU can vary in hardness from soft rubbers to rigid plastics, allowing for customized solutions to meet specific needs.

The flex in low temperatures keeps the material working, and its repeated bending adds to its overall lifetime. Moreover, TPU can easily bond with other materials, including metals and plastics, through overmolding, which expands the possibilities for multi-material designs. TPU, alongside TPU’s ability to support thin-walled structures, enhances lightweight product development, while recycling further promotes sustainable manufacturing. This makes TPU an eco-friendly material choice, especially with low-carbon-footprint injection molding technologies.

Challenges in molding TPE materials

Thermoplastic elastomers (TPEs) often become challenging to mold due to their specific characteristics and certain requirements during the molding process. Controlling the flow and filling the mold cavity is frequently a struggle, since TPEs have a broad range of compositional viscoelasticity. This requires tight control of thermal, mechanical, and pneumatic processing parameters, such as temperature, injection speed, and pressure, to prevent flaws like short shots or flow marks.

Shrinkage and warpage are usually among the problems that arise when molding TPEs. These materials, compared to other thermoplastics, have higher shrinkage rates, which are detrimental to the dimensional accuracy of the end products. These problems could be reduced by designing the molds with proper tolerances and using more advanced simulation tools.

Moreover, high shear, heating, and dampness may result in severe degradation of TPEs during processing. Proper handling of the material, such as precise drying and maintaining the melt temperature, is key to preserving the inherent performance characteristics of the material. Also, the use of overmolding or multi-material molding is challenging due to the interfacial binding surfaces, which require intense surface treatment, as bonds form between different materials.

Finally, there are logistical and technical challenges with recycling and reusing TPE for production. With the addition of recycled TPE, they may have reduced mechanical strength, which requires adjusting the product’s processing to ensure quality. It is optimal to have an aggressive strategy for selecting materials, optimizing processes, and designing molds due to the characteristics of TPE formulations.

Reference Sources

-

Thermoplastic Elastomers: Emerging Trends and Applications in Rubber Manufacturing

- Key Findings: This study highlights the differences between TPE and TPU in terms of their applications and properties. TPU is noted for its superior abrasion resistance and durability, making it ideal for automotive and industrial applications, while TPE offers greater flexibility and processability, making it suitable for consumer goods and medical devices.

- Methodology: A comprehensive review of literature and industry reports was conducted to evaluate the properties, applications, and advancements of TPEs and TPUs.

-

- Key Findings: This study focuses on TPU’s thermal conductivity enhancement through hybrid fillers, showcasing its adaptability for thermal management in electronics. It contrasts TPU’s thermal properties with other materials, emphasizing its unique ability to form 3D thermal networks.

- Methodology: Experimental analysis was conducted using hybrid fillers in TPU to evaluate thermal conductivity and mechanical properties, with a focus on large-scale manufacturing applications.

-

Rapid-Manufacturing-Process for Elastomeric Components

- Key Findings: This paper discusses the use of TPU and other thermoplastic elastomers in rapid manufacturing processes, such as Selective Laser Sintering (SLS). It highlights TPU’s suitability for complex geometries and its mechanical robustness compared to other thermoplastic elastomers (TPEs).

- Methodology: The study examines the mechanical properties and manufacturing processes of TPU and TPE components, with a focus on their performance in rapid prototyping and industrial applications.

- Top TPE Plastic Pellets Suppliers in China

Frequently Asked Questions

Q: What is the main difference between TPE and TPU?

A: The main difference lies in their properties; TPE stands for thermoplastic elastomer, which combines rubber and plastic properties, while TPU, or thermoplastic polyurethane, is a type of TPE that offers enhanced abrasion resistance and flexibility.

Q: What are the applications of TPE?

A: The applications of TPE include products like seals, gaskets, medical devices, and consumer goods due to its thermoplastic and elastomeric properties.

Q: Can you explain the comparison to TPU?

A: Compared to TPU, TPE is generally less expensive and has different mechanical properties, making it suitable for various applications where flexibility and softness are preferred.

Q: What types of TPE are available?

A: There are several types of TPE, including styrenic block copolymers, thermoplastic polyurethanes, and thermoplastic polyolefins, each with unique characteristics and applications.

Q: Is TPU a type of TPE?

A: Yes, TPU is a type of thermoplastic elastomer known for its durability and resistance to abrasion, making it ideal for applications where toughness is crucial.

Q: What are the advantages of using TPU over TPE?

A: TPU offers superior abrasion resistance, flexibility, and temperature resistance compared to TPE, making it a preferred choice for demanding applications such as automotive and industrial uses.

Q: Are TPE and TPU materials safe for use in consumer products?

A: Yes, TPE is non-toxic, and many TPU compounds are also safe for use in consumer products, particularly in medical and food applications.

Q: How do TPE and TPU perform in 3D printing?

A: Both TPE and TPU can be used as materials for 3D printing, with specific formulations designed for optimal performance, offering flexibility and durability in printed objects.

Q: What is a derivative of TPE?

A: A derivative of TPE could refer to specific formulations or blends that enhance certain properties, such as improved chemical resistance or enhanced mechanical strength for specialized applications.

Q: What should I consider when choosing between TPE and TPU?

A: When choosing between TPE or TPU, consider factors such as cost, required flexibility, abrasion resistance, and the specific environmental conditions the material will be exposed to in its application.