Small and versatile plastic material in pellet form serves as a foundational element for virtually any plastic product. Plastic pellets have gradually attained paramount importance in a world where industries and governments aim to forge a more sustainable environment and adopt circular economy models. These tiny yet powerful materials carry the potential for innovated recycling techniques, resource efficiency, and waste minimization, therefore garnering a spotlight in the movement to close the loop of plastic production. This article delves into the lake of plastic pellets in terms of mitigating environmental damage, furthering the road to advanced techniques in recycling, and systemic changes towards sustainability, thereby stressing their critical role in putting circular economy concepts into action. Having understood plastic pellets’ lifecycle potential, industries then stand to commercialize scalable solutions to a paramount environmental challenge facing the world today.

Understanding Plastic Pellets

Definition and Types of Plastic Pellets

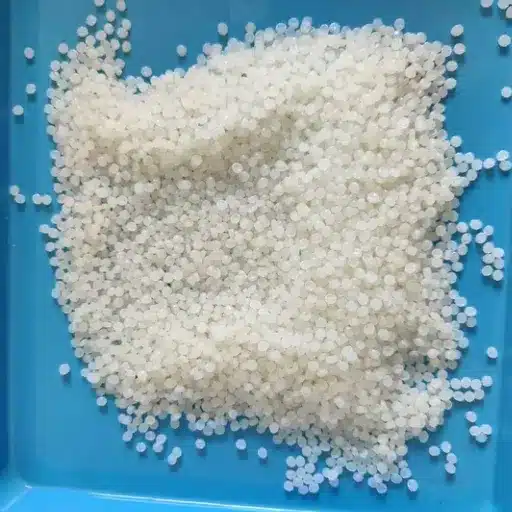

Plastic pellets are small granules that act as raw plastic material. These pellets are then used as basic building blocks for making various plastic products. Created genuinely through polymerization processes, the pellets have to be subsequently melted down and converted into specific forms throughout plastic manufacturing.

Generally, plastics pellets can be classified as thermoplastics and thermosetting plastics. Thermoplastic pellets, including polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC), are highly versatile since they can be repeatedly reheated and reshaped. This is advantageous when applications call for recycling and adaptability. Contrastingly, thermosetting plastic pellets, such as epoxy resins and phenolic resins, once set, are rendered infusible and insoluble, thus providing better durability and heat resistance at the expense of being difficult to recycle.

Material science advances have increased the scope from the list of specialty plastic pellets, including biodegradable and compostable options manufactured from polylactic acid (PLA) or polyhydroxyalkanoates (PHA). These state-of-the-art pellets are provided to sustainability goals by decreasing the dependency on conventional fossil-based plastics. Recycled plastic pellets are, however, also becoming popular, the thought being that industries integrate the principles of a circular economy in their production cycles from now.

The Role of Polyethylene and Polypropylene

Being versatile, durable, and economic, renowned in the family of thermoplastic polymers, polyethylene (PE) and polypropylene (PP) are extensively used. Polyethylene is known for its high impact resistance and chemical inertness, which finds widespread usage in packaging, construction materials, and consumer goods. Low-density polyethylene (LDPE) and high-density polyethylene (HDPE) distinguish the molecular structure of polyethylene for applications varying from plastic bags and piping to rugged containers.

Likewise, polypropylene is good at putting up with heat-melting-point type setting, resistance to fatigue, and low weight. It is used majorly in automobile making, in medical equipment, and in textiles. Advances in polymer science have made it possible for us to enhance recyclability and even develop copolymers, combining the properties of PE and PP for application in particular environments where optimum performance is needed.

Both of the polymers have found their way into industrial applications in order to reduce initial material costs and increase the efficiency of the production process. Yet their sustainable production and disposal remain within the sphere of their research. Innovations in mechanical recycling and chemical recycling techniques are being explored toward this. On the other hand, the shift to a more sustainable and circular plastics economy is being foster.

Comparison between Moldable Plastic Pellets and Beads

In the production of domestics, plastic pellets and beads are very similar to each other in the basic composition and applications, but both present somewhat differing variations towards respective industrial adaptations. Plastic pellets are generally of larger dimensions, cylindrical or oval in shape, optimized for processes like injection molding and extrusion. The pellets ensure wonderful flowability due to their consistent sizes and shapes, which is of great value for large-scale production. On the other hand, the plastic beads are smaller and quite spherical, which would make them well-suited for applications whereby fine uniformity and controlled melting and molding are required, such as rotational molding and 3D printing.

Additionally, factors such as melting point, chemical resistance, and material distribution may influence the choice between pellets and beads. Pellets usually have higher bulk density and hence are easier to transport and store in large quantities, whereas beads have higher surface area-interactions which may be important in certain chemical or coating reactions. Thus, moldable-grade plastics in both formats play a pivotal role in the design of lightweight yet sturdy and cost-effective products in various industries, including automotive, construction, and consumer goods. However, with global efforts to enhance the sustainability of materials, such as advances in biodegradable options and upcycling methods, the industrial relevance is also changing accordingly.

The Circular Economy and Plastic

Contribution of Plastic Pellets to Sustainability

Plastic pellets help in the realization of sustainability through elegant material design and production optimization. The small, uniform pellets are the basic raw material for plastic products, and control is exerted on production processes so as to reduce the wastes that arise during molding or extrusion. Plastic pellets, by implementing effective use of resources, lead manufacturers to save on energy and waste of materials.

More recent methods in the integration of recycled plastic into pellet production thus augment the sustainability mix of these materials. Recycled pellets produced from post-consumer or post-industrial plastic are increasingly employed to reduce the demand for virgin polymer resins. This ensures minimized environmental impact upon manufacturing and fits the circular economy idea wherein already existing plastic waste is re-used. Other industry innovations are even looking into bio-based plastic pellets, which would, during production, probably result in less greenhouse gas emissions and in better biodegradability, thus helping fit long-term environmental goals.

In developing these far-sighted applications using plastic pellets, industries present more sustainable pathways for production while addressing an adversarial challenge of environmental impact. It is indeed clear that these developments place these pellets as near the center of any current movement that envisions a more resource-conscious future in the field of plastics.

Instances of Reusable and Meltable Polymorph Pellets

Polycaprolactone (PCL): A thermoplastic polyester of low melting point with its usual applications in prototyping and sculpting. The PCL pellets melt down and become moldable at a mere 140°F (60°C), meaning that they can be used multiple times for reshaping without ever losing product integrity. It is capable of giving end-user applications in medical-grade implants, biodegradable engineering, and educational tools owing to its durability and ecologically sound properties.

Polymorph Thermoplastic Pellets: These are pellets that are designed to soften in hot water (approx. 150°F or 65°C) and can be molded easily by hand or through conventional manufacturing methods. They are highly durable and find multiple uses in fields ranging from DIY projects to orthotics to repair applications. Their nontoxic nature and versatility make them ideal options for consumer as well as industrial ends.

Polyvinyl Alcohol (PVA) Pellets: PVA, being a water-soluble polymer, has been considered for biodegradability and offers functional versatility. Meltable at certain temperatures, the pellets find wide application in 3D printing for support materials, packaging materials, and medical applications. The environmentally safe manner in which PVA degrades adds to its appeal in sustainable manufacturing systems.

PLA-Based Biodegradable Pellets: Polylactic Acid (PLA) is a plant-based polymer that melts, reuses, and composts under industrial conditions eventually. PLA pellets, creating an interlude between functionality and sustainability, find use in a myriad of temporary fixtures, prototypes, and disposable items. Their eco-friendly appeal and renewable status have made them worthy of the production journey of any conscientious manufacturer.

As an example, these cases demonstrate the functionality of reusable and meltable polymorph pellets across industries, which speaks of their versatility, sustainability, and growing importance in advancing material innovation.

Applications of Plastic Pellets

Molding Techniques Using Plastic Pellets

The molding of plastic pellets encompasses various techniques and must be tailored to satisfy a particular specification of an industrial or creative nature. Injection molding is a spending of fame to this method wherein the pellets are heated until molten and then injected into pre-designated molds at very high pressure. This method, because of its ability to reproduce detailed and consistent components on an industrial scale, has become highly favored in industries such as automotive, consumer goods, and electronics casings.

The other process that ranks very high in the precedence list is compression molding. In this technique, pellets are placed inside a mold cavity; then the pellets are compressed and heated to form the desired shape. This process, basically for strong, hard finishes, finds application in aerospace and construction.

Hand-crafting and vacuum forming are more experimental and open-ended solutions in prototyping or small-scale production. Hand-crafting is very specific by heating the pellets in hot water and shaping them by hand, while under vacuum heating, the pellets are made into thin sheets, which can then be stretched over molds for packaging purposes or some lightweight designs.

Whatever processes are chosen, the manner that plastic pellets undergo depends on the temperature of the material; melting, setting, cooling, and hardening processes are involved. Thus any precision-consuming process that cannot tolerate variance would rather use plastic pellets in production.

A Trend Analysis for Weighted-Beads Stuffed Animals

In stuffed toys, weighted beads have really become popular-and that is a trend right now in both the toy and wellness markets. These weighted beads are often created with materials like polypropylene or glass and are installed within these items for some sensory benefits. By weighing down plush toys, manufacturers make the toys a little calming and therapeutic for people who need help fighting anxiety, concentrating, or even going through the sensory process.

Weighted plush toys are in higher demand among multiple age categories, as highlighted by market research. Parents seek weighted stuffed animals for their children, as they may promote relaxation and sleep. On the other hand, weighted plush toys remain a sometimes discreet alternative to weighted blankets for office or travel use. This trend has also affected industry productions, resulting in greater development of light yet durable bead materials that preserve comfort and durability. In a way, this shift in consumer trends makes weighted beads a vital component of modern-day plush toy productions, as consumers wholly favor multi-purpose and emotionally supportive products.

Plastic Pellets in Rock Tumbling Media

These pellets fulfill yet one other function of tumbling media: serve as a cushion to protect stones from chipping and breakage during tumbling. These pellets are used during both polishing and smoothing stages to provide for uniform abrasion, which helps guarantee quality finishing. Very light and durable, plastic tumbling pellets are highly reusable and serve to fill voids between media and stones in the tumbling barrel to create a good mix to maximize tumbling performance. They also work with abrasives and polishing compounds under neutral buoyancy to assist in their even distribution through the barrel and polishing compounds for even results, making them an indispensable ingredient for every hobbyist and professional lapidary striving for precision in their tumbling jobs.

Environmental Impact and Safety

Assessment of Environmental Footprint of Plastic Use

The environmental footprint of plastic use, having a substantial influence on the ecosystem and society, becomes one of the major topics of study. An emission source for the greenhouse gases due to its petrochemical origin, plastic is also a pollutant in the environment because of its resistance to degradation. Studies reveal that almost 400 million metric tons of plastics are being produced every year, a majority of which end up in landfills or into marine environments. Once plastics enter the natural environment, they are gradually disintegrated into microplastics, which create hazards to aquatic organisms and may also infiltrate the human food chain.

While recycling programs and biodegradable plastics could provide potential mitigating factors, their effectiveness is limited by inadequate infrastructure and cost constraints. For example, the global recycling rates for plastic materials fall below 10%, implying inefficiency issues pertaining to waste management systems currently. Additionally, bioplastics, which seem like a great solution, require the use of agricultural resources that come with competing issues concerning food securities and land use. Against all these, an array of strategies appears necessary to address the environmental impacts; these include innovations in material science coupled with enhanced regulatory frameworks and emphasis on practices that reduce plastic consumption.

Safety Guidelines for Plastic Pellets

The safe handling and use of plastic pellets operate under strict guidelines that ensure the safety of human life and that of the environment. Persons working should use adequate personal protective equipment, which includes chemical-resistant gloves, safety goggles, and respiratory protection protection when exposed to harmful amounts of dust and fumes. Sometimes, good ventilation is the best way to ensure that any emission or particulate formation is eliminated or dispersed to below harmful levels into the atmosphere.

Spill prevention measures must be made in full force to help reduce contamination. The facility should contain the transfer operation on the basis of closed-loop processes and enforce immediate pellet spill response procedures, to reduce the chances of pellets entering aquatic systems. Another measure is storing plastic pellets inside sealed containers in designated areas to minimize leakage and ensure compliance with regulatory requirements.

Employees must undergo training and keep themselves updated in pellet handling, storage, and transportation. Staff must be familiar with the Material Safety Data Sheet (MSDS) specific to the pellets being used, and they must be aware of potential hazards such as flammability and chemical reactivity. Following these safety practices will protect employees while also supporting sustainable practices in industry, which are important from the environmental perspective.

Protecting Fragile Items with Tumbling Media Plastic Filler

Tumbling media plastic filler contributes to the safekeeping of delicate articles during finishing procedures. This engineered filler material provides a buffering layer to prevent abrasion, chipping, or physical damage to thin components. It is typically composed of high-density polymeric material, hence making it lightweight yet durable to withstand prolonged use under industrial conditions.

In vibratory tumbling machines, plastic fillers keep the contact distribution uniform while dissipating mechanical stresses. Thus, they remove a direct impact to polish the surface under desired parameters without destroying the integrity of sensitive specimens. Recently, more-complex filler geometries and surface treatment coatings, which allow further adaptations with respect to material compatibility and application may be conversed about.

High levels of performance are demanded of plastic fillers nowadays by industries like aerospace, electronics, and precision manufacturing. They protect surfaces against incidental damage and maintain operational continuity. From the choice of tumbling media plastic filler for the specific project, the criteria include hardness, density, and reusable lifespan; the rest falls upon the pan. Protective features adopted in the manufacturing process increase reliability in their products while positively enhancing operating efficiency.

Future Trends in Plastic Pellets

Innovations in Reusable Moldable Plastics

The recent developments in reusable moldable plastics have shown tremendous potential for industry applications and to sustainability end. I believe one groundbreaking innovation consists in new polymer blends able to preserve their structural integrity upon multiple molding cycles. These materials are designed to endure extreme temperatures and stresses so that manufacturers may reuse plastics without compromising the quality of their products. Certain additives and stabilizers contributed further in improving the properties of these plastics, making them less susceptible to degradation over time and adaptable to almost all production environments.

Bioplastics and closed-loop recycling systems also seem very promising. More and more companies concentrate on the development of moldable plastics from renewable sources such as plant-based polymers. These bioplastics provide an option to reduce the dependence on fossil fuels and most importantly ensure that these materials are biodegradable or recyclable at the end of their useful life. This is the principle of the circular economy, where used plastics can be broken down and reprocessed into new products, so essentially, no waste is produced. Additionally, machine learning techniques are being considered more and more for optimizing the molding process to further reduce material waste and sustain the life of the reusable plastics.

This type of technology has given rise to a new age of reusable plastics, promoting sustainability within the industrial domain. Through the utilization of recycle coatings, advanced stabilization technology, and environmentally friendly production methods, industries are being given the means to greatly reduce their ecological impact, while still being economical and durable. All these developments are pivotal changes toward greener and multifunctional plastic solutions, ensuring manufacturers and the planet win in the long run.

Market Forecast for Plastic Pellets in Various Industries

In my view, the plastic pellets market will witness steady growth across industries, depending on the increasing demand for lightweight, durable, and economical materials. It is anticipated that the automotive sector will continue to act as a major driving force towards the demand since manufacturers work more and more on weight reduction to promote higher fuel efficiency and lower carbon emissions. With the progress of engineered plastics, plastic pellets are being used for the manufacture of high-performance parts, such as interior trims, under-the-hood components, and electrical housings. Another thrust towards EVs is accelerating demand for plastics with properties of high thermal and electrical resistance.

Packaging industries are yet another major contributor in plastic pellet growth, especially with the expansion of e-commerce in the world today. Market trends now indicate a shift to recyclable and biodegradable plastic materials due to stringent environmental regulations and consumer preference for sustainability. This is fueling innovation in the production of bio-based polymers, providing an avenue for companies to meet packaging solutions on both functional specification and ecological considerations.

On the other hand, construction and infrastructure sectors are anticipated to increase the use of plastic pellets for applications such as piping, insulation, and flooring. These materials are considered and prized for cost, durability, and weather resistance in infrastructure projects, especially in places seething with development and urbanization. Hence, it is evident enough that the future of plastic pellets will hold faster developments working forth to support a green ambience and hence toward newer applications and increased market demand in various industries.

Challenges and Opportunities in the Plastic Industry

From my point of view, an industry within the plastic arena has been accepted to represent a kind of unfortunate mixture featuring a couple of grave problems set against some promising avenues and opportunities. On the challenge front, environmental concern rules the discourse, as gradually and increasingly, the near and far environment has been disclaiming the detrimental effects of plastic wastes. Non-biodegradable plastics keep choking oceans and landfills with growing rebuke against the single-use plastic ones. Governments, businesses, and consumers have started strengthening their regulations against plastic, through bans and incentives on alternative materials. Further, manufacturers have been discouraged in achieving cost efficiency because of the rising volatility in raw material prices and in the disruption of supply chains.

In contrast, environmental scrutiny, acting as an emerging force, is also providing opportunities for innovation and growth. Investments in bio-based and biodegradable plastics are gaining momentum not only to meet demand but also to match the performance of their traditional counterparts while reducing environmental impact. Scaling up the resolution for plastics waste with chemical recycling: by breaking plastics into monomers for reuse-the foundation for the circular plastic economy is created. Automotive, construction, and healthcare industries stand ready for high-performance lightweight plastics for fuel efficiency and sustainability targets.

Looking further ahead, adaptation shall be the key to thriving in this evolving landscape. Companies that put sustainable practices first, investing in new and emerging technologies, and working toward an environmental goal that is considered global, are probably going to stand to claim change as leaders in their field. In tackling these challenges and catching opportunities, the plastic industry has the potential to reinvent itself into an industry that is in tune with economic forces yet ecologically crucial.

Reference Sources

- Benefits of Using Recycled Plastic Pellets – Discusses how recycled plastic pellets contribute to reducing waste and supporting a circular economy.

- Unlocking the Power of Recycled Plastic Pellets – Explores the role of plastic pellets in advancing sustainable solutions and circular economy practices.

- Recycling Technologies by Plastics Europe – Highlights the importance of efficient recycling in transitioning to a circular economy.

Frequently Asked Questions (FAQs)

What are plastic pellets used in molding for?

Plastic pellets in injection molding are built into a range of plastic products. The pellets, mostly thermoplastics such as polyethylene and polypropylene, were heated until molten and then injected into molds. Any object might be made with plastic pellets, ranging from consumer goods to industrial components. The uniformity of the pellets in shape and size facilitates the uniform melting and distribution of the pellet throughout the molding process. Apart from that, using pre-production plastic pellets helps to improve the quality of the finished product.

What are the ways I can make crafts with plastic pellets?

Plastic pellets can be considered a lightweight modeling compound for do-it-yourself crafts. These are available in different types: moldable plastic thermoplastic beads are melted and molded into various designs. Hence, these are well suited for custom designs in cosplay or for craft work with different throws. Sometimes these plastic pellets are combined with other materials, such as eco-friendly fillers or polyfill pellets, to add weight to stuffed animals or blankets. Craft lovers register a vote for versatile and easy-to-use materials in their creative projects.

Are options available for plastic pellets that are more environmentally friendly?

The available eco-friendly plastic pellets generally work toward the reduction of plastic pollution. These biodegradable/recyclable pellets can be used in a sustainable way in crafting or industrial applications. Some brands may even insist on pellet manufacturing that makes nontoxic plastic pellets in the USA, thus foreseeing the safety as well as being environmentally responsible. Consumers choosing such plastics will add toward offsetting their carbon footprints even while they reap the benefits from using plastic products.

What kind of plastic pellets are available for use in rock tumbling?

Plastic pellets, also called rock tumbling media, are used for rock tumbling. These pellets are supposed to cushion and protect delicate stones during polishing in a tumbler. The plastic fillers act as padding so that there is little to no risk of damage during tumbling. Options like 5 lbs plastic pellets rock tumbling and lbs plastic pellets rock tumbling are readily available to cater to different tumbling needs. Cementing the choice of tumbling media will see to it that the process of polishing rocks will go smoothly and efficiently.

Should I put plastic pellets in my weighted blanket?

Certainly! Poly pellets weighted stuffing beads are among stuffing materials for weighted blankets. They are safe to use and of non-toxic nature. These pellets could be washed in a machine, thereby allowing weighted comforter providers to produce a smooth and safe-weighted blanket. The pellets are meant to weigh down the blanket for sensory purpose, while giving it flexibility. The weighted blanket could weigh anywhere times one with ten pound plural pellets of polyfill for even weight distribution to ensure efficiency in providing calm and relaxation.

How should I pick the plastic pellets for my project?

The choice of plastic pellets relies upon the given application and its properties. For injection molding, resin pellets compatible with your molding machine should be considered. If considering crafts, moldable plastic beads or thermoplastic that is easily shaped are excellent choices. Poly pellets for weighted stuffing beads would be good for anything needing weight, such as stuffed animals or blankets. Always check the specifications and warnings for the pellets to know they are intended to be used for your project.