Get in touch with us

Leave a message

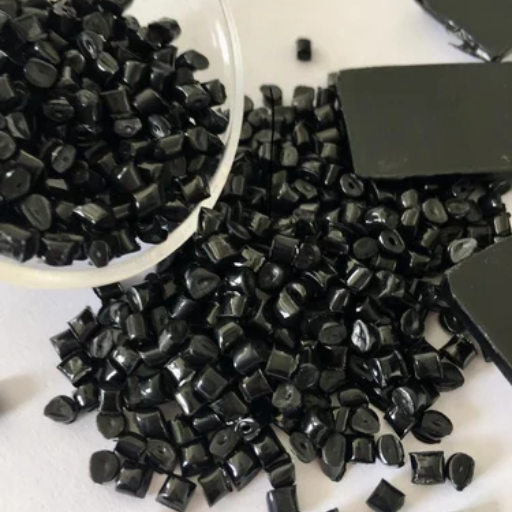

Our business specializes in custom engineered and premium grade PA66 pellets (nylon 66) plastic because of its high impact, heat resistance, and durability. Sprayed, automotive, industrial and other parts per PA66 offered ss. We also help optimize proceses for innovation with out of the box solutions to design efficiently meeting quality standards.

PA66 (nylon 66) resin delivers exceptional versatility and strength, revolutionizing applications across diverse industries. With outstanding durability, heat resistance, and reliability, it ensures top performance in challenging environments, empowering your business with innovation and efficiency.

PA66 pellets provide superior mechanical strength, ensuring long-lasting performance in high-stress applications.

These pellets withstand elevated temperatures, making them ideal for demanding industrial and automotive uses.

PA66 offers remarkable durability against abrasion, extending the lifespan of manufactured components.

Easy to mold and process, PA66 pellets support a wide range of manufacturing techniques for diverse applications.

| Property | Value | Advantage |

|---|---|---|

| Tensile Strength | 60-85 MPa | High durability for load-bearing parts |

| Impact Resistance | 50-100 J/m (Izod) | Reliable toughness for mechanical stress |

| Heat Deflection Temp | 180-240°C | Maintains stability in high-heat settings |

| Service Temperature | -30°C to 150°C | Performs consistently in varied conditions |

| Density | 1.13-1.15 g/cm³ | Lightweight yet strong for diverse uses |

| Moisture Absorption | 1.5-2.5% (24h) | Requires drying for optimal processing |

PA66 (nylon 66) resin provides exceptional strength and versatility, transforming applications across various industries. Its durability, thermal resistance, and reliable performance in challenging conditions make it a key material for driving innovation and efficiency in your manufacturing processes.

Ideal for engine parts, gears, and connectors due to high heat resistance and strength.

Used in bearings, bushings, and rollers for its excellent wear resistance and durability.

Perfect for connectors, housings, and circuit breakers with strong dielectric properties.

Applied in durable products like zippers, sports equipment, and appliance parts.

Utilized in fibers for carpets, ropes, and nets due to its toughness and flexibility.

Employed in non-implantable tools and housings for its reliability and chemical resistance.

Suzhou Yifuhui New Material Co., Ltd. supplies premium PA66 plastic pellets, leveraging advanced production techniques and rigorous quality standards. Our pellets are engineered for demanding applications in automotive, industrial, and consumer sectors, delivering superior strength, heat resistance, and reliability to boost your operational efficiency.

With an extensive global distribution network, cost-competitive pricing, and tailored technical support, we ensure seamless delivery and customized solutions. Committed to innovation and excellence, fosters trusted partnerships that drive success, meeting your needs in ever-evolving markets.

Understand from our clients what they say about doing business with us and the unique value addition we provide.

PA66 plastic, also known as polyamide 66 structure, is a type of nylon pa 66 formed by the polymerization of hexamethylenediamine and adipic acid. This creates Polyamide 66 Plastic Pellets with a strong, semi-crystalline structure, offering excellent mechanical strength, heat resistance, and durability. The composition makes pa66 plastic ideal for demanding applications, though its cost, such as the nylon 66 price per kg, can vary based on market demand and additives.

PA66 plastic pellets are widely used in injection molding due to their versatility. Nylon 66 pellets are melted and injected into molds to produce precise components like automotive parts, gears, and electrical connectors. The process benefits from PA66’s high strength and thermal stability, though proper drying is essential to avoid moisture-related defects. The pa66 plastic pellets price can influence production costs, making it a key factor in manufacturing budgets.

Polyamide, specifically nylon pa 66, is a plastic, not a rubber. PA66 plastic, derived from the polyamide 66 structure, is a thermoplastic known for its rigidity, strength, and heat resistance, unlike the elastic properties of rubber. It’s commonly used in forms like Polyamide 66 Plastic Pellets for industrial applications, with costs like the nylon 66 price per kg reflecting its quality and grade.

Nylon 66 pellets are generally not considered food safe unless specifically formulated and certified for food contact. Standard pa66 plastic may contain additives or processing agents that aren’t FDA-approved for food applications. However, food-grade nylon pa 66 variants can be produced, often at a higher pa66 plastic pellets price, ensuring compliance with safety standards for items like kitchen utensils or packaging.

Yes, pa66 recycling is possible, as PA66 plastic is a thermoplastic that can be melted and reprocessed. Nylon 66 pellets can be recycled into new products, though the process may degrade some properties, requiring additives to restore quality. Recycling helps manage costs, like the nylon 66 price per kg, and supports sustainability, making Polyamide 66 Plastic Pellets a viable option for eco-conscious manufacturing.

Stay inspired and innovative by following our blog, where we share the latest best practices, techniques, breakthroughs, and insights in the field.

Ready to enhance your production with high-quality PA66 plastic pellets? Contact us now to request a personalized quote and discover competitive pricing tailored to your needs. Let’s power your innovation!

A: PA66 has higher heat resistance (melting point ~260°C) and mechanical strength than PA6, making it better for high-stress applications, while PA6 is more flexible and cost-effective.

A: Yes, PA66 plastic pellets can be recycled, retaining up to 90% of their mechanical properties, making them suitable for non-critical applications and supporting sustainable practices.

A: PA66 pellets require drying to <0.2% moisture content and processing at 260-290°C for injection molding to prevent defects and ensure optimal performance.

A: Industries like automotive, electronics, industrial manufacturing, and textiles benefit from PA66 due to its durability, heat resistance, and versatility in demanding applications.

A: Yes, PA66 pellets can be customized with additives like glass fiber for added strength or flame retardants to meet specific industry standards, such as UL94 V-2 for electronics.

A: The price of PA66 plastic pellets generally ranges from $2 to $5 per kilogram, depending on grade, additives (e.g., glass fiber), and market conditions.

Discover premium plastic pellets and engineering resins, including PC, ABS, PA66, POM, PMMA, HDPE, and more at Yifuhui Plastic.