Get in touch with us

Leave a message

We supply premium polycarbonate (PC) plastic pellets known for durability, optical clarity, and thermal stability. Perfect for automotive, construction, and electronics industries, our materials ensure superior performance and precision. With a focus on quality assurance, cost-effective solutions, and global delivery, we’re committed to empowering your manufacturing needs with reliable, high-quality products tailored to demanding applications.

Polycarbonate resin offers unmatched versatility and strength, making it a game-changer across industries. Its durability, transparency, and thermal resistance ensure reliable performance in demanding applications, driving innovation and efficiency for your business.

Built to endure tough environments, polycarbonate resin resists impact and cracking, ensuring products withstand stress while maintaining optimal functionality.

With glass-like clarity, polycarbonate enhances product aesthetics and functionality, perfect for protective screens, optical devices, and display materials.

Polycarbonate resin excels under extreme temperatures, maintaining stability for heat-exposed applications such as automotive and electronic components.

Highly recyclable and long-lasting, polycarbonate resin supports sustainability goals while delivering superior, cost-effective performance.

| Property | Value | Advantage |

|---|---|---|

| Tensile Strength | 55-75 MPa | Withstands high mechanical stress without deformation |

| Impact Resistance | 600-850 J/m (Izod) | 250× more impact-resistant than glass, even at low temperatures |

| Light Transmission | Up to 89% | Crystal-clear transparency for optical applications |

| Heat Deflection Temp | 132-138°C | Maintains structural integrity at elevated temperatures |

| Service Temperature | -40°C to 125°C | Performs reliably in extreme environments |

| Density | 1.20-1.22 g/cm³ | Lightweight alternative to glass and metals |

| Refractive Index | 1.584-1.586 | Excellent optical properties for precision applications |

Polycarbonate resin offers unmatched versatility and strength, making it a game-changer across industries. Its durability, transparency, and thermal resistance ensure reliable performance in demanding applications, driving innovation and efficiency for your business.

PC plastic pellets provide automotive components with excellent impact resistance and thermal stability to withstand extreme temperatures while maintaining structural integrity. Their lightweight properties improve fuel efficiency without compromising safety standards.

Excellent flame retardancy and electrical insulation properties make PC pellets ideal for electronic enclosures, providing excellent protection against electrical hazards while offering superior clarity and UV resistance to maintain a long-lasting appearance.

PC particles are biocompatible and sterilizable, maintaining optical clarity and mechanical strength during repeated autoclave cycles while meeting the stringent regulatory requirements of healthcare applications.

PC pellets provide unparalleled impact resistance to protective equipment and safety shields, combining optical clarity with lightweight durability to create comfortable and long-lasting protection that meets international safety standards.

PC particles have excellent light transmittance that hardly turns yellow over time, with excellent heat resistance and electrical properties that extend the service life of LED lamps while enabling innovative lighting designs.

Food-grade PC pellets create durable, dishwasher-safe containers that maintain clarity and structural integrity through hundreds of use cycles, offering excellent thermal resistance for both refrigeration and microwave applications.

Suzhou Yifuhui New Material Co., Ltd. delivers premium PC plastic pellets with advanced manufacturing and strict quality controls. Products are tailored for diverse applications such as automotive, electronics, and construction, providing exceptional durability, clarity, and performance to enhance competitiveness.

With a robust global supply network, competitive pricing, and dedicated support, seamless delivery and customized solutions are assured. Focused on innovation and precision, Suzhou Yifuhui ensures reliable partnerships that exceed expectations, supporting long-term client success in dynamic markets.

Understand from our clients what they say about doing business with us and the unique value addition we provide.

Select based on application needs like impact resistance, optical clarity, or heat resistance. For example, PC/ABS blends are ideal for automotive, while food-grade PC is suited for containers.

Yes, food-grade polycarbonate exists and is FDA-approved for food preparation and storage. It’s commonly used in water bottles, baby bottles, and food containers.

The "7" indicates the recycling code for polycarbonate and other plastics. It signifies that the material is a mixed or non-standard plastic, often including polycarbonate.

Use a fine-toothed saw or a utility knife for thinner sheets. Ensure the sheet is clamped securely to avoid vibrations, and cut slowly to prevent cracking.

When heated to extreme temperatures, polycarbonate can release small amounts of BPA and other fumes. Proper ventilation is essential during processing.

Stay inspired and innovative by following our blog, where we share the latest best practices, techniques, breakthroughs, and insights in the field.

Explore Yifuhui, a trusted supplier among polycarbonate pellets suppliers in China. With precision manufacturing and competitive plastic pellets prices, we deliver high-quality PC pellets tailored for diverse industries. Partner with us to enhance your production efficiency and materials performance today.

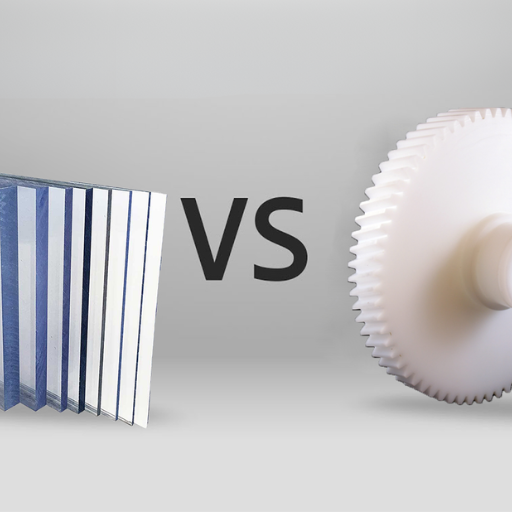

A: PC offers a unique combination of high impact resistance (250× stronger than glass) while maintaining excellent optical clarity (89% light transmission). Unlike acrylic (PMMA) which is brittle, or SAN which has limited temperature resistance, PC maintains its exceptional properties across a wide temperature range (-40°C to 125°C). This rare combination makes it ideal for applications requiring both transparency and durability.

A: The most common challenges include moisture sensitivity, potential for yellowing, and stress cracking. These can be overcome by thorough pre-drying (110-120°C for 2-4 hours), processing at appropriate temperatures (280-310°C), minimizing residence time in the barrel, designing parts with uniform wall thickness, and applying proper cooling rates. For outdoor applications, selecting UV-stabilized grades is essential to prevent premature degradation.

A: Yes, specialized food-grade and medical-grade PC pellets are available that comply with FDA, EU 10/2011, and USP Class VI requirements. These grades undergo additional testing for biocompatibility, extractables, and leachables. Medical grades can withstand repeated sterilization cycles (autoclave, gamma, EtO) without significant property degradation, making them ideal for reusable medical devices and food storage containers.

A: Standard PC grades can yellow and degrade when exposed to UV radiation. However, specially formulated UV-stabilized grades offer excellent weatherability for 5-10 years of outdoor exposure. PC maintains its mechanical properties from -40°C to 125°C, making it suitable for extreme temperature environments. For applications involving chemical exposure, it’s important to note that PC resists many chemicals but is vulnerable to attack by alkaline solutions, certain solvents, and aromatic hydrocarbons.

A: PC pellets come in numerous specialized grades including general purpose, high-flow, flame retardant (UL94 V-0/V-2), UV-stabilized, optical, medical, food-grade, glass-fiber reinforced, impact-modified, and custom-colored formulations. Selection should be based on specific requirements including mechanical properties, optical clarity, regulatory compliance, processing method, exposure conditions, and cost considerations.

A: PC is 100% recyclable and can be reprocessed multiple times with minimal property loss. Many manufacturers now offer grades containing post-consumer recycled (PCR) content, some achieving up to 30-75% PCR without significant performance compromise. BPA-free formulations are increasingly available for sensitive applications. While PC production is energy-intensive, its exceptional durability and longevity often result in a favorable lifecycle assessment compared to less durable alternatives that require frequent replacement.

Discover premium plastic pellets and engineering resins, including PC, ABS, PA66, POM, PMMA, HDPE, and more at Yifuhui Plastic.