Get in touch with us

Leave a message

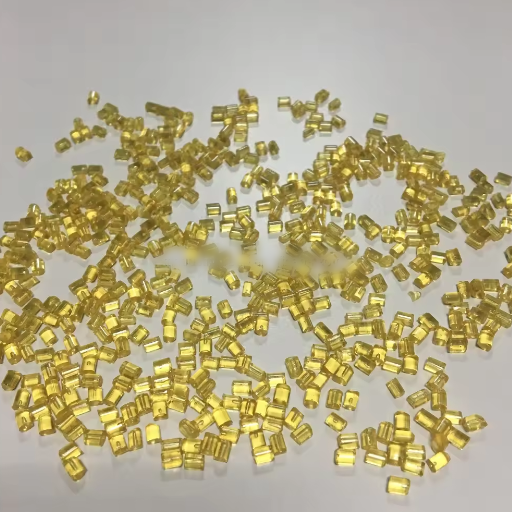

We provide high-performance PEI (Polyetherimide) Plastic Pellets, renowned for their exceptional heat resistance, mechanical strength, and flame retardancy. Perfect for aerospace, medical, and electronics applications, our PEI pellets offer superior dimensional stability and transparency, ensuring precision and reliability in demanding environments. With a commitment to quality, competitive pricing, and global delivery, we support your manufacturing needs with tailored, high-quality solutions.

PEI resin provides exceptional strength and thermal stability, transforming applications across diverse industries. Its durability, flame retardancy, and reliable performance in high-temperature environments make it an essential material for driving innovation and efficiency in your manufacturing processes.

PEI pellets maintain integrity at temperatures up to 200°C, ideal for extreme environments.

These pellets offer superior tensile strength, ensuring durability in demanding applications.

PEI provides natural flame resistance, meeting safety standards without additional treatments.

PEI pellets combine optical clarity with dimensional stability, perfect for precision components.

| Property | Value | Advantage |

|---|---|---|

| Tensile Strength | 55-75 MPa | Withstands high mechanical stress without deformation |

| Impact Resistance | 600-850 J/m (Izod) | 250× more impact-resistant than glass, even at low temperatures |

| Light Transmittance | Up to 89% | Crystal-clear transparency for optical applications |

| Heat Deflection Temp | 132-138°C | Maintains structural integrity at elevated temperatures |

| Service Temperature | -40°C to 125°C | Performs reliably in extreme environments |

| Density | 1.20-1.22 g/cm3 | Lightweight alternative to glass and metals |

| Refractive Index | 1.584-1.586 | Excellent optical properties for precision applications |

PEI Plastic Pellets deliver exceptional versatility and strength, revolutionizing applications across industries. With superior durability, crystal-clear transparency, and excellent thermal resistance, they ensure reliable performance in challenging environments, empowering innovation and efficiency for your business.

PEI’s high strength-to-weight ratio and thermal stability make it ideal for lightweight, durable parts like aircraft interiors and structural components.

Its biocompatibility, sterilizability, and transparency are perfect for producing reliable medical instruments and device housings.

PEI’s heat resistance and impact strength suit it for under-the-hood components, such as connectors and sensor housings, that endure high temperatures.

With excellent electrical properties and flame resistance, PEI is used in insulating components like circuit board parts and electrical connectors.

Its high light transmittance and refractive index make PEI suitable for precision optical lenses, lighting covers, and display components.

PEI’s mechanical strength and ability to perform in extreme environments make it a go-to material for gears, bearings, and other industrial equipment parts.

At Suzhou Yifuhui New Material Co., Ltd., we offer premium PEI plastic pellets, crafted through advanced manufacturing and rigorous quality control. Our products are tailored for diverse applications, including aerospace, medical, automotive, electronics, optics, and industrial uses, ensuring exceptional durability, transparency, and performance to boost your competitive edge.

With a robust global supply network, competitive pricing, and dedicated support, we guarantee seamless delivery and customized solutions. Committed to innovation and precision, [Your Company Name] fosters reliable partnerships that exceed expectations, driving long-term success in dynamic markets.

Understand from our clients what they say about doing business with us and the unique value addition we provide.

Ultem, a high-performance brand of polyetherimide plastic, enhances the performance of PEI plastic pellets by providing superior thermal stability, mechanical strength, and chemical resistance. As a type of Ultem PEI plastic, it ensures that polyetherimide plastic pellets maintain structural integrity in demanding applications like aerospace and medical devices, making them ideal for industries requiring durability and reliability.

The quality of raw materials is critical in producing high-grade polyetherimide plastic pellets. Using premium-grade PEI plastic material ensures that the final PEI plastic pellets exhibit excellent properties like transparency, strength, and heat resistance. Consistent raw material quality also impacts the PEI plastic pellets price, as superior inputs lead to better performance in applications such as PEI plastic sheets for industrial uses.

Polyetherimide plastic pellets perform exceptionally well in high-temperature environments, with a heat deflection temperature of 132-138°C. This makes PEI plastic material ideal for applications like automotive and electronics, where components must maintain integrity under heat. For instance, a PEI plastic sheet made from these pellets can reliably function in service temperatures up to 125°C without deforming.

PEI, or polyetherimide plastic, is highly durable, with a tensile strength of 55-75 MPa for polyetherimide plastic pellets. This strength allows PEI plastic material to withstand significant mechanical stress without deformation, making it a robust choice for demanding applications like PEI plastic sheets in industrial machinery or aerospace components.

Ultem and PEI are closely related but not identical. PEI refers to polyetherimide plastic, a high-performance polymer, while Ultem is a specific brand of Ultem PEI plastic developed by SABIC. Ultem is a type of PEI, often used to produce polyetherimide plastic pellets with enhanced properties. So, while all Ultem is PEI, not all PEI is Ultem, and this distinction can influence factors like PEI plastic pellets price depending on the formulation.

Stay inspired and innovative by following our blog, where we share the latest best practices, techniques, breakthroughs, and insights in the field.

Ready to elevate your projects with high-quality PEI Plastic Pellets? Contact us today to get a personalized quote and discover competitive pricing tailored to your needs. Let’s drive innovation together!

A: PEI Plastic Pellets are used in industries like aerospace, automotive, medical, electronics, optics, and industrial manufacturing for applications such as aircraft components, medical devices, automotive parts, electrical insulators, optical lenses, and machinery parts due to their durability and thermal resistance.

A: PEI Plastic Pellets offer a unique combination of high tensile strength (55-75 MPa), excellent heat resistance (up to 138°C), and crystal-clear transparency (up to 89% light transmittance), making them ideal for high-performance applications compared to many other plastics.

A: Yes, PEI Plastic Pellets perform reliably in high-temperature environments, with a heat deflection temperature of 132-138°C and a service temperature range of -40°C to 125°C, maintaining structural integrity in demanding conditions.

A: PEI Plastic Pellets are highly durable, with a tensile strength of 55-75 MPa and an impact resistance of 600-850 J/m (Izod), making them 250 times more impact-resistant than glass, even at low temperatures.

A: Absolutely, PEI Plastic Pellets have a light transmittance of up to 89% and a refractive index of 1.584-1.586, making them perfect for optical applications like lenses and lighting systems requiring crystal-clear transparency.

A: While pricing varies based on quality and supplier, PEI Plastic Pellets are a cost-effective choice for high-performance applications due to their durability, versatility, and ability to replace heavier materials like glass and metals, reducing long-term costs.

Discover premium plastic pellets and engineering resins, including PC, ABS, PA66, POM, PMMA, HDPE, and more at Yifuhui Plastic.