Get in touch with us

Leave a message

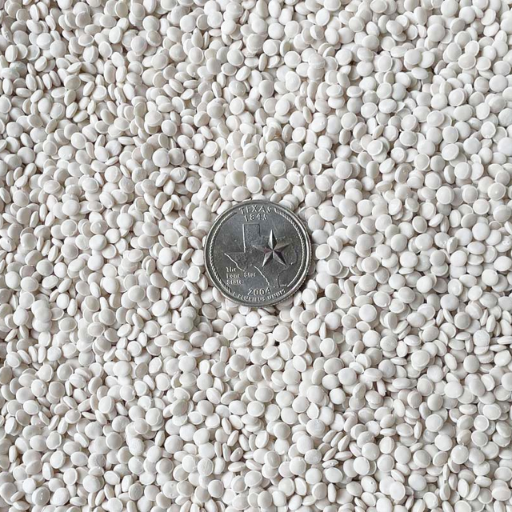

We supply premium polyphenylene oxide (PPO) plastic pellets known for high heat resistance, dimensional stability, and electrical insulation. Perfect for automotive, electrical, and industrial applications, our materials ensure superior performance and reliability. With a focus on quality assurance, cost-effective solutions, and global delivery, we’re committed to empowering your manufacturing needs with reliable, high-quality products tailored to demanding applications.

Polyphenylene oxide (PPO) plastic offers exceptional heat resistance and dimensional stability, making it a game-changer across industries. Its electrical insulation, durability, and chemical resistance ensure reliable performance in demanding applications, driving innovation and efficiency for your business.

PPO plastic can be used for a long time at temperatures up to 120°C without deformation or loss of performance. It is very suitable for automotive parts and electrical equipment housings that need to withstand high temperature environments, ensuring reliability under harsh conditions.

PPO has high dielectric strength and low dielectric loss, showing excellent electrical insulation properties. It is widely used in electrical and electronic components such as switches, sockets and circuit board brackets to ensure safe and efficient electrical performance.

PPO has extremely low water absorption (about 0.07%), which can maintain dimensional stability even in humid environments, avoid expansion or contraction, and ensure high precision and long-term consistency of precision parts (such as electronic connectors).

PPO can resist a variety of chemicals, including acids, alkalis and some solvents, extending the service life of the product in corrosive environments, such as maintaining performance when exposed to detergents in industrial equipment or household appliances.

| Property | Typical Value | Advantage |

|---|---|---|

| Tensile Strength | 50-70 MPa | High strength for structural applications like electrical housings. |

| Impact Resistance | Moderate (Notched Izod 100-200 J/m) | Good toughness for industrial components under stress. |

| Light Transmission | 0-50% (Opaque to Semi-transparent) | Suitable for non-transparent uses; adjustable for aesthetics. |

| Heat Deflection Temp | 100-120°C (at 0.45 MPa) | Resists deformation under heat, ideal for hot environments. |

| Operating Temperature | -40°C to 120°C | Reliable performance across a wide temperature range. |

| Density | 1.06-1.10 g/cm3 | Lightweight, reduces material costs in manufacturing. |

| Refractive Index | 1.57-1.59 | Moderate clarity, suitable for semi-transparent applications. |

Polyphenylene oxide (PPO) pellets offer exceptional heat resistance and dimensional stability, making them a game-changer across industries. Their electrical insulation, durability, and chemical resistance ensure reliable performance in demanding applications, driving innovation and efficiency for your business.

PPO Plastic Pellets are widely used in electrical housings, switchgear, and connectors due to their superior electrical insulation properties (high dielectric strength and low dielectric loss) and heat resistance up to 120°C, ensuring reliable performance in high-voltage environments like power distribution systems.

PPO is ideal for under-hood automotive parts such as pump housings, fluid reservoirs, and battery casings, thanks to its excellent thermal stability (up to 120°C) and resistance to automotive fluids like oils and coolants, providing long-term durability in high-temperature engine compartments.

PPO pellets are used in industrial fittings, valves, and pump components due to their strong chemical resistance to acids, bases, and cleaning agents, as well as their dimensional stability, ensuring precision and reliability in harsh industrial environments like chemical processing plants.

PPO is employed in microwave oven components, coffee maker parts, and other appliance housings that require heat resistance and dimensional stability, maintaining structural integrity and performance during exposure to high temperatures and repeated thermal cycles.

PPO is utilized in medical trays, instrument handles, and sterilizable equipment due to its ability to withstand repeated sterilization processes (e.g., steam or chemical sterilization) and its chemical resistance, ensuring durability and safety in healthcare settings.

PPO is applied in plumbing fittings, water pump impellers, and valve components because of its low water absorption (0.07%) and resistance to hydrolysis, ensuring long-term performance and dimensional stability in water-handling systems, even under constant moisture exposure.

Suzhou Yifuhui New Material Co., Ltd. delivers premium PPO plastic pellets with advanced manufacturing and strict quality controls. Products are tailored for diverse applications such as automotive, electrical, and industrial sectors, providing exceptional heat resistance, dimensional stability, and performance to enhance competitiveness. With a robust global supply network, competitive pricing, and dedicated support, seamless delivery and customized solutions are assured. Focused on innovation and precision, Suzhou Yifuhui ensures reliable partnerships that exceed expectations, supporting long-term client success in dynamic markets.

Understand from our clients what they say about doing business with us and the unique value addition we provide.

Yes, PPO plastic is generally safe for most applications, with low toxicity and compliance with regulations like RoHS. It’s stable and safe for electrical, automotive, and medical uses when processed correctly.

PPO offers high heat resistance (up to 120°C), excellent dimensional stability, superior electrical insulation, and strong chemical resistance, making it ideal for demanding applications in electrical, automotive, and industrial sectors.

PPO has high heat resistance (up to 120°C), low water absorption (0.07%), excellent electrical insulation, good dimensional stability, and strong chemical resistance to acids and bases, with a tensile strength of 50-70 MPa.

PPO is highly resistant to a wide pH range, including acids and bases, maintaining its mechanical properties and stability in both acidic (low pH) and alkaline (high pH) environments, except in extreme conditions.

PPO is an amorphous polymer, lacking a crystalline structure, which contributes to its excellent dimensional stability, low shrinkage, and consistent performance across a wide temperature range.

Stay inspired and innovative by following our blog, where we share the latest best practices, techniques, breakthroughs, and insights in the field.

Explore Yifuhui, a trusted supplier among PPO Plastic Pellets suppliers in China. With precision manufacturing and competitive PPO Plastic Pellets prices, we deliver high-quality PPO pellets tailored for diverse industries. Partner with us to enhance your production efficiency and materials performance today.

A:PPO Plastic Pellets provide high heat resistance up to 120°C, exceptional dimensional stability with low water absorption (0.07%), and excellent electrical insulation with high dielectric strength, making them ideal for demanding applications like electrical housings and automotive parts.

A:

Yes, PPO’s superior dielectric strength and low dielectric loss make it an excellent choice for electrical components such as switchgear, connectors, and insulators, ensuring reliable performance and safety in high-voltage environments like power distribution systems.

A:

Yes, PPO can operate continuously at temperatures up to 120°C without significant deformation or loss of mechanical properties, making it suitable for high-heat environments like under-hood automotive components or appliance parts.

A:

PPO is widely used in the automotive industry for under-hood parts, the electrical sector for connectors and housings, and industrial applications for fittings and valves, leveraging its heat resistance, chemical stability, and electrical insulation properties.

A:

Yes, PPO resists a wide range of chemicals, including acids, bases, and some solvents like alcohols and cleaning agents, making it suitable for industrial equipment and consumer appliances exposed to chemical environments, though it may be less resistant to strong aromatic solvents.

A:

Yes, PPO’s extremely low water absorption rate of 0.07% ensures excellent dimensional stability in humid conditions, preventing swelling or warping, which makes it ideal for plumbing fittings, water pump parts, and other applications exposed to moisture.

Discover premium plastic pellets and engineering resins, including PC, ABS, PA66, POM, PMMA, HDPE, and more at Yifuhui Plastic.