Get in touch with us

Leave a message

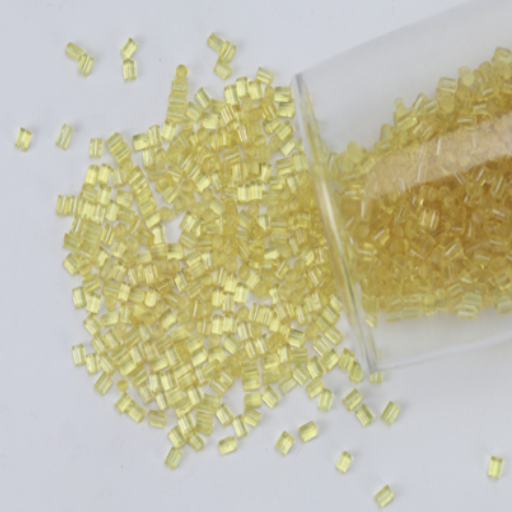

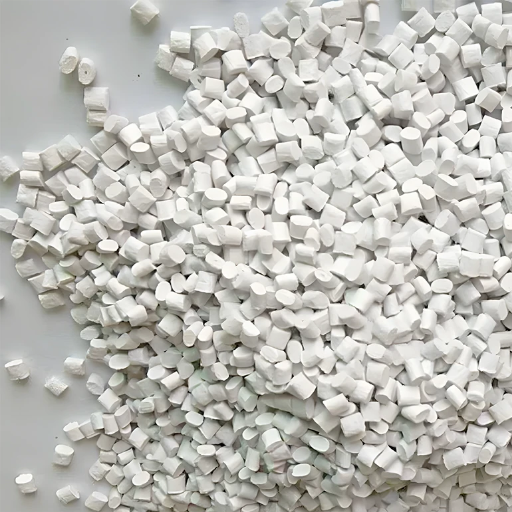

We offer premium Polyphenylene Sulfide (PPS) Plastic Pellets, engineered for superior thermal and chemical resistance, ideal for demanding applications in automotive, electronics, and industrial sectors. With excellent dimensional stability, inherent flame retardancy, and the ability to withstand temperatures up to 240°C, our PPS pellets ensure reliable performance and precision. Sourced with a focus on quality and sustainability, we provide cost-effective solutions to meet your manufacturing needs.

PPS resin delivers exceptional thermal and chemical resistance, revolutionizing applications across various industries. Its durability, inherent flame retardancy, and ability to perform in extreme conditions make it a vital material for driving innovation and efficiency in your manufacturing processes.

PPS pellets endure temperatures up to 240°C, ensuring performance in extreme heat applications.

PPS offers natural flame resistance, meeting safety standards without additional treatments.

These pellets resist acids, solvents, and fuels, ideal for harsh industrial environments.

With low shrinkage, PPS pellets provide accurate molding for intricate components.

| Property | Value | Advantage |

|---|---|---|

| Tensile Strength | 70-100 MPa | High durability for demanding applications |

| Impact Resistance | 20-50 J/m (Izod) | Moderate toughness for industrial use |

| Heat Deflection Temp | 200-260°C | Exceptional stability in high heat |

| Service Temperature | -50°C to 240°C | Reliable in extreme temperature conditions |

| Density | 1.35-1.40 g/cm3 | Lightweight for high-performance parts |

| Chemical Resistance | Excellent | Resists acids, fuels, and solvents |

PPS resin provides exceptional durability and chemical resistance, making it a transformative material across industries. Its high thermal stability, flame retardancy, and reliable performance in extreme conditions drive innovation and efficiency for your manufacturing needs.

Used in fuel system parts and under-hood components due to excellent heat and chemical resistance.

Ideal for connectors and sockets, leveraging inherent flame retardancy and electrical insulation.

Applied in pump housings and valves for its resistance to harsh chemicals and high temperatures.

Utilized in lightweight, heat-resistant components like brackets, benefiting from dimensional stability.

Found in fittings and filters, resisting corrosion in hot water and steam environments.

Employed in sterilizable equipment parts, thanks to its chemical stability and durability.

Suzhou Yifuhui New Material Co., Ltd. delivers top-grade PPS plastic pellets, manufactured with advanced technology and strict quality oversight. Our pellets are optimized for high-performance applications in automotive, electronics, and industrial sectors, offering unmatched thermal stability, chemical resistance, and flame retardancy to enhance your product reliability.

With a global distribution network, competitive pricing, and dedicated customer support, we ensure fast delivery and customized solutions. Focused on innovation and excellence, Suzhou Yifuhui builds trusted partnerships that surpass expectations, empowering your success in competitive markets.

Understand from our clients what they say about doing business with us and the unique value addition we provide.

Polyphenylene Sulfide Plastic Pellets are ideal for injection molding due to their excellent dimensional stability and flowability, making them a top choice among engineering plastics. The pps polymer ensures precision in complex molds for automotive and electronic parts, while the pps plastic price reflects its high performance, offering a cost-effective solution for durable, high-quality components.

Polyphenylene sulfide is manufactured through a polymerization process where p-dichlorobenzene reacts with sodium sulfide in a solvent like N-methyl-2-pyrrolidone under high temperatures and pressure. This produces pps plastic material in powder form, which is then pelletized into Polyphenylene Sulfide Plastic Pellets for use in applications like pps filament production, ensuring consistent quality for engineering plastics.

Yes, pps plastic can be recycled as a thermoplastic, allowing pps polymer to be melted and reprocessed into new products. However, recycling Polyphenylene Sulfide Plastic Pellets may slightly degrade thermal properties, so additives are often used to restore performance, making it a sustainable option despite the pps plastic price considerations.

PPS plastic material is suited for high-temperature applications due to its ability to withstand temperatures up to 240°C without losing structural integrity, a key trait of engineering plastics. The pps polymer in Polyphenylene Sulfide Plastic Pellets also offers low thermal expansion, ensuring stability in demanding environments like automotive engine parts, justifying the pps plastic price.

Yes, pps plastic is excellent for electrical applications because of its high dielectric strength and inherent flame retardancy, making it a preferred pps polymer in engineering plastics. Polyphenylene Sulfide Plastic Pellets are used in connectors, insulators, and circuit components, with pps filament also applicable in 3D-printed electrical parts, offering value despite the pps plastic price.

Stay inspired and innovative by following our blog, where we share the latest best practices, techniques, breakthroughs, and insights in the field.

Reach out now to request a tailored quote for premium PPS Plastic Pellets, designed to meet your high-performance needs with unbeatable quality and service!

A: Yes, PPS Plastic Pellets can withstand temperatures up to 240°C, making them ideal for high-heat environments like engine components.

A: Yes, PPS Plastic Pellets are recyclable as a thermoplastic, though recycling may slightly affect their thermal properties.

A: PPS Plastic Pellets are inherently flame-retardant, meeting safety standards like UL94 V-0 without needing additives.

A: Industries like automotive, electronics, aerospace, and water management benefit from PPS pellets’ durability and resistance properties.

A: PPS Plastic Pellets are typically processed via injection molding, requiring high temperatures (300-340°C) and proper drying to avoid moisture issues.

A: Yes, PPS Plastic Pellets resist acids, solvents, and fuels, making them suitable for harsh chemical environments.

Discover premium plastic pellets and engineering resins, including PC, ABS, PA66, POM, PMMA, HDPE, and more at Yifuhui Plastic.