Get in touch with us

Leave a message

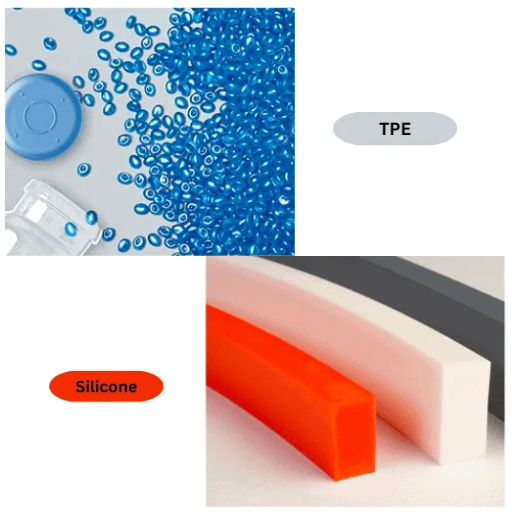

We supply premium thermoplastic elastomer (TPE) plastic pellets renowned for flexibility, impact resistance, and soft-touch feel. Ideal for medical, automotive, and consumer goods industries, our materials ensure excellent performance and adaptability. With a focus on quality assurance, cost-effective solutions, and global delivery, we’re committed to meeting your manufacturing needs with reliable, high-quality products tailored for diverse applications.

Thermoplastic polyester elastomer (TPEE) pellets provide exceptional versatility and resilience, revolutionizing applications across industries. Their flexibility, chemical resistance, and thermal stability ensure consistent performance in challenging environments, fostering innovation and efficiency for your business.

Provides excellent elasticity and is suitable for dynamic applications.

Resists a variety of chemicals and extends service life.

Maintains stable performance in high temperature environments.

Easy to shape, suitable for complex designs and efficient production.

| Property | Typical Value | Advantage |

|---|---|---|

| Tensile Strength | 5-20 MPa | Offers good flexibility with sufficient strength for dynamic applications. |

| Impact Resistance | High (Notched Izod >500 J/m) | Superior toughness, ideal for impact-prone uses like automotive parts. |

| Light Transmission | 0-50% (Opaque to Semi-transparent) | Suitable for non-transparent applications; can be adjusted for aesthetics. |

| Heat Deflection Temp | 50-100°C (at 0.45 MPa) | Maintains shape under moderate heat, good for consumer goods. |

| Operating Temperature | -40°C to 120°C | Wide temperature range, versatile for indoor and outdoor use. |

| Density | 0.89-1.2 g/cm3 | Lightweight, reduces material costs and eases handling. |

| Refractive Index | 1.4-1.5 | Moderate clarity, suitable for semi-transparent applications. |

Thermoplastic elastomer (TPE) pellets offer exceptional flexibility and resilience, making them a game-changer across industries. Their elasticity, chemical resistance, and thermal stability ensure reliable performance in demanding applications, driving innovation and efficiency for your business.

Used in flexible tubing and seals due to biocompatibility and sterilizability.

Ideal for gaskets, seals, and soft-touch grips with high durability.

Applied in soft grips for tools, toys, and sporting goods for comfort.

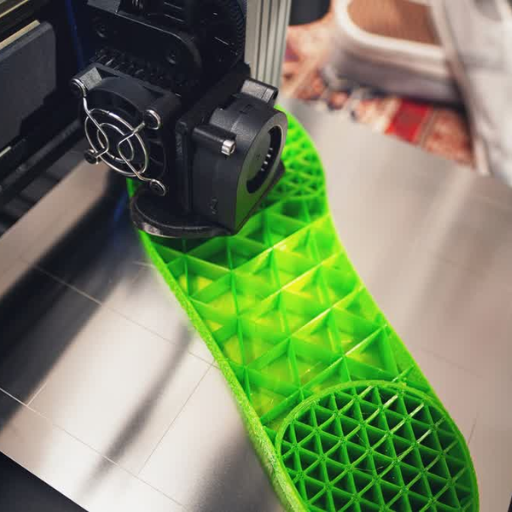

Utilized in soles and insoles for flexibility and shock absorption.

Employed in flexible films and seals for food-grade applications.

Used for cable insulation and overmolding due to flexibility and insulation properties.

Suzhou Yifuhui New Material Co., Ltd. delivers premium TPE plastic pellets with advanced manufacturing and strict quality controls. Products are tailored for diverse applications such as medical, automotive, and consumer goods, providing exceptional flexibility, resilience, and performance to enhance competitiveness. With a robust global supply network, competitive pricing, and dedicated support, seamless delivery and customized solutions are assured. Focused on innovation and precision, Suzhou Yifuhui ensures reliable partnerships that exceed expectations, supporting long-term client success in dynamic markets.

Understand from our clients what they say about doing business with us and the unique value addition we provide.

No, TPE (thermoplastic elastomer) is generally non-toxic and safe for many applications, including medical and food-contact uses, as it is often free from harmful substances like PVC or phthalates. However, always check specific formulations for compliance with safety standards.

TPE is ideal for injection molding due to its excellent flexibility, easy processability, and good adhesion in overmolding. It offers durability, chemical resistance, and a soft-touch feel, making it perfect for diverse applications while being cost-effective and recyclable.

The injection molding process with TPE involves heating the pellets to a molten state, injecting them into a mold under pressure, cooling the material to solidify, and then ejecting the finished part. TPE’s low viscosity ensures smooth flow and precise molding.

Identify your application requirements, such as flexibility, durability, or chemical resistance. Consider hardness (Shore A/D), operating temperature, and processing method. Ensure compliance with industry standards (e.g., FDA for medical use) and consult suppliers for tailored grades.

Yes, TPE is generally waterproof and resistant to moisture, making it suitable for applications like seals, gaskets, and outdoor products. However, water resistance can vary by grade, so confirm with the specific formulation for your needs.

Stay inspired and innovative by following our blog, where we share the latest best practices, techniques, breakthroughs, and insights in the field.

Explore Yifuhui, a trusted supplier among TPE Plastic Pellets suppliers in China. With precision manufacturing and competitive TPE Plastic Pellets prices, we deliver high-quality TPE pellets tailored for diverse industries. Partner with us to enhance your production efficiency and materials performance today.

A: TPE offers flexibility, durability, chemical resistance, and easy processing, ideal for diverse applications.

A:Yes, many TPE grades are biocompatible and meet FDA standards for medical devices.

A:Yes, TPE is recyclable, supporting sustainable manufacturing practices.

A:Automotive, medical, consumer goods, and packaging industries frequently use TPE for its versatility.

A:TPE operates well from -40°C to 120°C, depending on the grade, ensuring reliability.

A:Yes, TPE resists oils, greases, and many chemicals, but compatibility varies by grade.

Discover premium plastic pellets and engineering resins, including PC, ABS, PA66, POM, PMMA, HDPE, and more at Yifuhui Plastic.