We encounter plastics every day, from drinking water out of a plastic bottle to using construction materials and electronics. Despite these examples, not all plastics serve the same purpose. Polycarbonate (PC) and Polyethylene Terephthalate (PET) are two commonly used forms of plastics that serve different purposes due to their unique properties. Whether you’re choosing to package something, design a product, or work toward eco-friendly goals, knowing the differences of these versatile materials will aid in making proper choices. In this article, we focus on the differences that PET and PC plastics have in their characteristics, applications, and environmental effects. This thorough guide will help you make proper choices while factoring in the material’s safety, durability, and recyclability.

What is PET Plastic and Why is it Commonly Used?

Polyethylene terephthalate, also referred to as PET, is a strong and light plastic that can be employed in various industries, especially in containers and packaging for food and drinks. Its popularity comes from the fact that PET can come into contact with food without danger of breaking and is safe, durable, and recyclable. PET plastic is clear, so it maintains the image of the product inside rather than hiding it, which makes it useful for containers and bottles, and food storage. Moreover, PET’s recyclability complements an eco-friendly attitude towards the environment.

Characteristics of Polyethylene Terephthalate

Lightweight and highly durable, Polyethylene Terephthalate (PET) has dynamic mechanical and thermal properties that make the material suitable for a variety of applications. PET’s outstanding features allow thinner and lighter packaging without loss of strength, making it easier to transport. It is also known for its superior barrier properties, making it critical for preserving the quality and shelf life of food and beverages. Its maximum operating temperature without change in form is between 250 and 260 degrees Celsius, meaning that it can sustain high temperatures in a lot of applications without resultant deformations.

From an ecological point of view, PET is a leader because of its recyclability. Industry reports say that about 57% of PET bottles globally produced in recent years were recycled, underlining their contribution towards battling plastic wastage. Moreover, PET recyclables can be transformed into new products like carpet textiles and even reprocessed into new food-grade containers. Its ease of identification makes it easy to recycle because PET plastics have the resin identification code “1.” This increases PET’s appeal as an eco-friendly solution when considering the positive environmental impact.

Applications of PET in Food Packaging

- Bottled Beverages

PET is common plastic type employed for packaging bottled beverages such as water, soft drinks, and juices. Its lightweight structure, durability, and ability to maintain contents freshness makes it an ideal choice for manufacturers. Over 500 billion PET bottles are produced annually for beverage storage globally. That amount of bottles is a huge waste of plastic and fills landfills worldwide, and it is a hazard for the environment as a whole.

- Food Trays and Containers

As an example, PET is frequently used in the production of microwaveable and ready-to-eat meals, and is even found in food trays, clamshell containers, and deli containers. Its excellent thermal stability enables use in refrigerated and heated places without compromising food safety. This is extremely helpful for transport and storage of products.

- Snack Packaging

PET is also employed in flexible films used to package snacks, candies, and chips. Its strong oxygen barrier properties aid in the preservation of spoilage-prone foods, thereby guaranteeing shelf-life longevity.

- Sealable Jars

These PET jars are clear and allow consumers to see the product inside, hence are mainly used for peanut butter, jams, sauces, and other condiments. PET jars are extensively employed for packaging other items also. This enhances buyer trust.

- Specialty Food Packaging

Aside from that, being made of PET makes it easier to achieve specialization without the risk of moisture and gas damage, making them ideal for specialty food packaging. Vacuum-sealed food items or even condiments through PET greatly benefit from its superior barrier properties.

PET’s uses for food packaging highlight versatility in aiding technology, safety, consumer demands, and, in particular, product convenience.

The Benefits of Using PET for Disposable Products

Disposables have become rampant in this modern era. Polyethylene terephthalate (PET) was a single-use product that had good durability, safety, and was easy to recycle. Widespread attention came PET’s way after it became known as lightweight and easy to transport at lower costs. Some studies PROVED WITH EVIDENCE that disposable drink bottles and other packaging material became recycled 100%, and even in countries that claimed to recycle over 50% of PET containers was on the rise.

PET was also known to not shatter on impact and was 20 times more resistant than glass, making PET much more preferable for consumer use, especially for food and beverages. The inert nature of this polymer added more favorable attributes as it does not interact with the content within the container. PET has and still is an ideal alternative for eco-friendly disposable items. The carbon footprint for disposable PET items was also lower, which meant a lesser impact on the global warming problem. These all contributed to making PET invaluable in modern times.

Exploring Polycarbonate: A Different Plastic Type

Polycarbonate is a transparent, impact-resistant plastic with a variety of applications. It is used in the production of electronic parts, safety goggles, and automotive components. Unlike PET, polycarbonate isn’t singled out for one-time use; rather, it’s appreciated for its long life and reusability. Polycarbonate also possesses high-temperature resistance and shatterproof qualities, making it useful in harsh environments. Polycarbonate’s ease of molding into different shapes further boosts its applicability across different domains.

What Makes Polycarbonate a Strong Plastic Material?

Because of its molecular structure and how it distributes energy, Polycarbonate is one of the most durable and impact resistant polymers with tensile strength of about 9000 to 10000 psi. Additionally, Polycarbonate’s impact resistance is distinctive and often measured using the Izod Impact Strength test. In contrast to Acrylics or Polystyrene plastics, Polycarbonate’s impact strength of 16 ft-lb/in is unparalleled.

Moreover, polycarbonates aptitude to withstand extreme mechanical conditions are surpassed only by its optical clarity, which enables its more common applications in ophthalmic products like protective eyewear to ballistic shields.

In industrial conditions, the benefits of polycarbonates include enduring temperatures as high as 125 °C (257 °F) alongside their use outdoors, maintaining their mechanical properties and heat deflection exerted towards the polycarbonate, bullets, and high precision optics.

Along with being lightweight and highly moldable, polycarbonate also boasts a myriad of other properties—it ascertains engineers and designers the flexibility to construct intricate parts and shapes without jeopardizing strength. Because of qualities like these, polycarbonate is a preferred material in construction, automotive, aerospace, and electronics industries.

Polycarbonate’s Role in Automotive Parts

A polycarbonate headlamp lens, for instance, has a high impact and scratch resistance, providing safety, and precise light regulation improves aesthetic value as well. Along with being versatile, polycarbonate is ultra-strong, lightweight, and plays an important role in modern auto design. It is used in various components like: the transparent and durable headlamp lens, interior trim, and even panoramic roofs.

As stated recently in the industry, the global market for auto polycarbonate is set to witness growth due to the aid of novel inventions in the EV and fuel-efficient market. Polycarbonate is fundamental in improving and reducing vehicle emissions, which further improves the economy. One study proposes that by switching from traditional materials to polycarbonate, there is the potential for a 50% reduction in weight. Furthermore, since polycarbonate is heat resistant and dimensionally stable, it can be safely utilized in the components under the hood and battery housings of EVs that require thermal management. Thus, proving its importance in improving novel vehicle technology and its role in the automotive sector.

Understanding the Heat Resistance of Polycarbonate

Polycarbonate is well known for its exceptional heat resistance, with its most common use being in applications that involve high temperatures. Generally speaking, polycarbonate possesses a heat deflection temperature (HDT) of 120-135 °C while under a load of 1.8 MPa. With the incorporation of some flame retardants or stabilizers, polycarbonate’s temperature tolerance can be further improved, enabling the polymer to endure harsher conditions without deformation or loss of structural integrity.

The material’s glass transition temperature (Tg) is about 147 °C, and continues to rise after which the material begins to soften from a rigid to a malleable state, but still remains functional for most automotive and industrial applications. Moreover, polycarbonate has a low thermal conductivity, which aids in its insulation, most notably useful in EV battery compartments. This safeguards and ensures dependability in situations where heat exposure is prolonged or intense. The polymer’s flexible thermal characteristics make it easier for engineers around the world to adopt polycarbonate in high-temperature applications.

Comparing the Physical Properties of PET and PC Plastics

Although PET (polyethylene terephthalate) and PC (Polycarbonate) are both tough materials, they differ in several key areas.

- Strength and Durability: Given that PC generally possesses greater strength and impact resistance, it is more suitable for higher-demand applications that require significant toughness.

- Transparency: Although their transparency compares, PC tends to give better optical clarity which is advantageous in applications requiring high-quality light passage.

- Heat Resistance: Compared to PET, PC’s greater heat resistance makes it better suited for prolonged exposure to heat.

- Weight: In applications that require weight to be minimized, PET has the upper hand as it is lighter than PC.

- Flexibility: PC is more flexible and less likely to suffer cracking, while PET’s rigidity causes it to outperform in flexibility.

Every material has benefits based on its unique application case and the surrounding conditions.

Impact Resistance: PET vs Polycarbonate

When it comes to impact resistance, I find polycarbonate to be the superior choice. PC is known for its exceptional toughness and ability to withstand significant force without breaking, making it ideal for applications requiring high durability. PET, while durable, does not offer the same level of impact resistance as polycarbonate, which is why I would prefer PC for applications where impact strength is a critical factor.

Transparency and Clarity in Different Plastics

Clarity and transparency are critical characteristics when assessing plastics used for packaging, lenses, or displays. Both polycarbonate (PC) and polyethylene terephthalate (PET) exhibit good optical features, although their performance differs significantly. Polycarbonate’s exceptional optical clarity makes it ideal for eyewear and electronic screens where light transmission is crucial, boasting a rate of 89%. Slightly better than polycarbonate, PET achieves ultra-clear, gloss-dominated, rigid thin films. PET clarity is often preferred in food and beverage packaging because it allows for excellent visibility while preventing hazy obscurity.

Moreover, PC displays enhanced resistance to discoloration, particularly long-term UV light exposure, suggesting better suitability for outdoor uses. In contrast, PET’s superior chemical resistance and ability to resist surface scratches make it a better candidate for protective coverings and containers designed for reuse. Both materials balance performance, aesthetics, and intended application, which accounts for their widespread use across numerous industries.

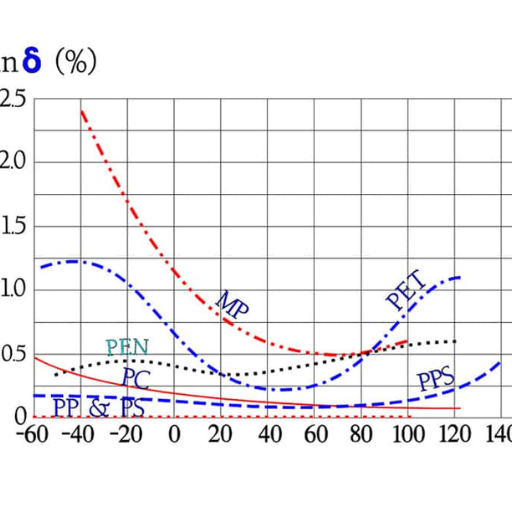

Which Plastic Type Offers Better Thermal Stability?

When assessing the comparative thermal stability of polycarbonate (PC) and polyethylene terephthalate (PET), the two materials possess distinguishing characteristics suitable for different uses. Polycarbonate displays greater structural stability. PC has a higher glass transition temperature of 147°C (297°F), which enables it to sustain its structural integrity during heating. Thus, polycarbonate is used in applications such as electrical components, automotive parts, and laboratory equipment that require heat resistance.

On the contrary, PET has a lower transition temperature of about 70°C (158°F) and a melting point of around 250°C (482°F). Although PET can endure certain amounts of heat, it has deformation and degradation thresholds that are attainable with prolonged exposure to elevated temperatures. Nonetheless, some of PET’s thermal properties can be improved by modifications such as crystallization processes applied to certain packaging materials to enhance heat resistance.

Research indicates that polycarbonate is more appropriate than PET while considering high-temperature surroundings. On the other hand, the lightweight nature and chemical resistance of PET deem it more suitable for certain applications. Choosing the right material can be guided by the focus requirements set for functional and thermal heating demands.

Environmental Impact: PET and PC Plastic Waste

The concern regarding the environmental consequences emanating from PET and PC plastic waste is notable. PET is commonly recycled because it is easy to process and has well-developed recycling infrastructures, which mitigates its negative impacts when appropriately managed. Nevertheless, when PET is not recycled, it has the potential to persist in the environment for centuries, thus exacerbating pollution. Conversely, PC plastics have a higher tendency not to be recycled due to the complicated processes involved in recycling them. This gives rise to greater concerns regarding their environmental impact, including the possibility of leaching hazardous chemicals if carelessly dumped. To lessen their ecological footprint, it is necessary to reduce usage, adopt new alternatives, and heighten recycling initiatives.

Recycling Challenges of PET and Polycarbonate

Though PET (Polyethylene Terephthalate) is one of the most commonly recycled plastics, recycling it does come with challenges. For instance, estimated figures show that globally, around 54% of PET is recycled made even more complex due to differences in regions. PET bottle recycling in the European Union goes as high as 60%, while other countries, sitting at a 20-30% mar,k tend to struggle because of infrastructure and public awareness. Moreover, leftover food and non-recyclable labels add to contamination, making the recycling streams complicated to work with. Additionally, other forms of contamination can be present in PET waste streams, such as leftover food or labels that cannot be recycled, which make recycling more difficult. Processing PET requires a significant amount of energy, which diminishes efficiency.

Polycarbonate is less recycled compared to other materials because of its intricate chemical construction and specialized usage. Medical equipment, electronics, and durable containers are some of the most common devices that utilize PC plastics, resulting in lower segregation and collection rates. In addition to this, compared to mechanical recycling, the chemical recycling process uses far more resources and advanced technology when dealing with PC, rendering it unfeasible for many recycling plants. Research states that less than 10% of polycarbonate is recycled worldwide, highlighting the need for policy changes to enhance the recovery and reusability of the material.

Plastic Waste Management and Sustainability

The uncontrolled problem of plastic waste has triggered a global effort towards improving management and sustainable practices. According to yearbook estimates, approximately 400 million tons of plastic waste are produced every year on a global scale, and the accounted figure of single-use plastic waste amounts to over 50% of the figure. Miserably, out of this waste, only 9% is recycled, and an estimated 22% is mismanaged and pollutes the ecosystem, especially the oceans. Studies suggest that roughly 11 million metric tons of plastic waste make their way into the oceans every year, and without sufficient measures, this number could triple by 2040.

An interdisciplinary approach is being taken to mitigate these issues; amazing innovations stem from chemical recycling and the creation of biodegradable plastics, which are extremely high in cost efficiency and consider the environmental effects of their creation. An example of this is the emerging development of enzymatic recycling, which breaks plastic down at the molecular stage to limit degradation and hence, new materials produced would be of much higher quality. Along with this, countries around the world are becoming more progressive in passing laws restricting the usage and manufacturing of single-use plastics; more than 120 countries have passed laws aimed at countering plastic pollution and are actively participating in lessening the problem of pollution on our planet.

The circular economy model as it pertains to plastic waste management is slowly gaining attention. This model seeks to minimize the need for new plastic by designing plastics that can be reused or recycled or even composted, aiding in diversion of used plastics from landfills. Awareness initiatives along with government, business, and environmental group coalitions have proven essential towards garnering support for this model. With the integration of policy change, appropriate technologies, and active participation, there is hope for improvement in sustainable global plastic waste management.

How to Choose Between PET and PC for Consumer Products?

For consumer products, choosing between PET (Polyethylene Terephthalate) and PC (Polycarbonate) requires consideration of the following:

- Safety and Food Use: PC may be strong and heat-resistant, but its inclusion of BPA may make some consumers avoid it. On the other hand, PET is lightweight and associated with food safety which can easily place it as a favored option.

- Durability: PET is less resistant to heat when compared to PC. On the other hand, PET works perfectly for single-use items, while PC offers better resistance for refillable items with added durability,such as water bottles.

- Environmental Impact: If put in the context of sustainable packaging, PET comes out on top by being widely recyclable. But PC provides lower value when it comes to waste management and recycling.

Select PET for products requiring low weight, food safety, as well as recyclability. Choose PC when the primary concerns are strength and heat resistance.

Factors to Consider in Packaging Materials

As with any other aspect of business packaging, companies have to integrate the strategic requirements of marketing when designing and selecting packaging materials. In addition to the strength, recyclability, and heat resistance, these factors also need attention:

- Environmental Regulations and Compliance: Legislations are increasingly being put in place to curb the use of plastics and foster eco-friendly practices. These would include the European Union directive on single use plastics that favors biodegradable or recyclable materials. Knowledge of local laws and compliance standards assists in ensuring that there is no contradiction between the packaging and the environmental objectives.

- Life Cycle Analysis (LCA): Assessing the life cycle of a particular product shows the stages it goes through right from the creation stage to disposal. This assessment also sheds light on how the environment will be impacted by the different stages, hence the term eco-life cycle assessment. For example, while aluminum and glass containers are touted to demand tough plastic PET, they are far easier to recycle or reuse.

- Consumer Preferences: Trends and survey results reveal an increasing preference toward green packaging. More than 62% of consumers consider sustainable packaging when making purchases and prefer biodegradable, reusable, or recycled materials.

- Cost and Scalability: There is growing interest in materials such as bioplastics and new biopolymer blends; however, they tend to be more expensive than PET and polypropylene. Companies must consider sustainable targets, pyrotechnic precision, and sharp cost margins while strategically competing in the market.

Packaging manufacturers can thoughtfully balance consumer interests, policies, and ecological footprints alongside materials and these considerations to devise an effective strategy.

Cost Efficiency of Different Plastic Types

The efficiency in spending on plastic materials differs dramatically according to the type, application, and scale of production. More traditional plastics, such as PET (Polyethylene Terephthalate) and polypropylene, are considered some of the more affordable options due to their availability, established production methods, and widespread use. A good example is PET, which is used in packaging and bottles because it is lightweight and recyclable; it is therefore saturating the market as industries try to reduce costs and simultaneously fulfill corporate social responsibility.

In contrast with the former group of plastics, newer types of plastics, such as polylactic acid (PLA) and polyhydroxyalkanoates (PHAs), are more expensive because of the high cost of production and sourcing raw materials. PLA can be manufactured using corn starch or sugarcane, but its price tag is 2-4 times higher than those of traditional plastics because the production chain is complicated and the supply chains are limited. There is, however, developing innovation in its production technology which is enhancing its affordability.

Another dimension regarding cost consideration is found in recycled plastics. Brands are increasingly willing to pay the higher cost of recycled PET (rPET) due to the environmental benefits and regulatory pressures, even if it sells for a higher price than virgin PET. Recycled polypropylene is usually cheaper, but its availability can be volatile depending on the recycling rate and demand among consumers.

In hindsight, companies are paying more attention to lifecycle costs instead of just the upfront prices. To achieve cost effectiveness while maintaining sustainable practices, businesses consider a material’s lifespan, ease of recycling, and environmental compliance in their construction.

Suitability for Food Containers and Bottles

Polypropylene (PP) is commonly accepted as an appropriate plastic for food containers and bottles because of its excellent properties. Its resistance to chemicals, heat, and moisture makes it safe for food and beverage storage. One of the main benefits includes the exposure to high temperatures which allow for microwaving and dishwashing without degradation of the containers. Furthermore, food grade polypropylene is permitted by FDA and EFSA which means that there are no safety concerns regarding food contact.

The latest data suggest that polypropylene makes 16-20% of all plastic produced in the world, and a large share is used for food packaging and bottles. For manufacturers looking to lower costs and carbon emissions, the low weight of polypropylene is an appealing feature. In addition, improvements in recycling technologies have made it possible to reuse polypropylene more than single-use plastics like polyethylene terephthalate (PET), making it more environmentally friendly. This increase in usable and food-safe materials indicates a shift towards sustainable approaches, which is a growing issue regarding polypropylene’s practicality and safety.

Reference Sources

- Characteristics of Ball-Milled PET Plastic Char1:

- Key Findings: This study explored the adsorption properties of ball-milled plastic char (BMPC) derived from PET waste. It demonstrated that BMPC effectively adsorbs aromatic organic pollutants like phenanthrene and phenol. The adsorption efficiency increased with higher pyrolysis temperatures, and mechanisms like π–π interactions and hydrogen bonding were identified.

- Methodology: PET waste was subjected to slow pyrolysis to create plastic char, which was then ball-milled. Adsorption experiments were conducted using aqueous solutions of pollutants, and models like Langmuir and Freundlich were applied to analyze adsorption isotherms.

- Exploring Plastic-Management Policy in China2:

- Key Findings: This paper reviewed China’s policies on plastic management, focusing on PET and other plastics. It highlighted the impact of the 13th and 14th Five-Year Plans, which improved recycling rates and reduced plastic waste. The study emphasized the need for integrated policies and better recycling systems.

- Methodology: A comprehensive policy review and material flow analysis were conducted using national data on plastic production, consumption, and recycling.

- Engineering Plastics: Market Analysis and Recycling Methods3:

- Key Findings: This research compared engineering plastics like PC and PET with commodity plastics, focusing on their market trends and recycling challenges. It underscored the importance of advanced recycling technologies to improve sustainability.

- Methodology: The study involved market analysis and a review of existing recycling methods for engineering plastics.

- Top PC Plastic Pellets Suppliers in China

Frequently Asked Questions (FAQs)

Q: What are the main differences between PC and PET plastics?

A: PC (Polycarbonate) is a durable and impact-resistant type of plastic often used in safety equipment and electronic housings. PET (Polyethylene Terephthalate) is a lightweight plastic widely used for plastic bottles and packaging. While both are thermoplastic polymers, PC is known for its good impact resistance, while PET is favored for its transparency and recyclability.

Q: Is PET plastic used in consumer goods?

A: Yes, PET plastic is often used in consumer goods, particularly for plastic bottles and food packaging, due to its lightweight nature and ability to preserve freshness. It is also a recyclable plastic, making it suitable for a wide range of applications.

Q: How does the recyclability of PC compare to PET plastic?

A: PET is more commonly recycled than PC plastic. PET’s recycling process is well-established, making it a popular choice for packaging. PC is less frequently recycled due to its complex structure and higher processing costs.

Q: Can PC and PET plastics be used in the automotive industry?

A: Yes, both PC and PET plastics are used in the automotive industry. PC is valued for its mechanical strength and impact resistance, which is ideal for interior parts and lighting. PET is used for lightweight components and as a type of plastic used in seat fabrics and belts due to its durability.

Q: Are there safety concerns associated with PC plastic?

A: PC plastic can contain BPA (Bisphenol A), a chemical that has raised health concerns. However, many manufacturers now offer BPA-free PC products. It is important to check product labeling to ensure safety, especially for consumer goods like water bottles and food containers.

Q: Which plastic is more suitable for medical devices, PC or PET?

A: Both PC and PET can be used for medical devices, but each serves different purposes. PC is often chosen for its strength and transparency, making it ideal for medical tubing and equipment housings. PET is used in products where flexibility and clarity are needed, such as in certain medical packaging.

Q: How does the environmental impact of PC compare to PET plastic?

A: PET plastic generally has a lower environmental impact due to its recyclability and widespread recycling programs. PC, while durable and long-lasting, is less commonly recycled, which can contribute to waste. When considering environmental impact, PET is often the preferred choice for single-use applications.

Q: What are some alternative types of plastic to PC and PET?

A: Alternatives to PC and PET include PVC (polyvinyl chloride), PP (polypropylene), PE (polyethylene), PS (polystyrene), and PMMA (polymethyl methacrylate). Each type of plastic has its own properties and uses, such as PE for plastic bags, PS for insulation, and PMMA for acrylic glass.

Q: Are PC and PET suitable for electrical cable insulation?

A: PC is not typically used for electrical cable insulation due to its rigidity. PET, on the other hand, is used in certain insulation applications, particularly where lightweight and flexible materials are required. However, other plastics like PVC are more commonly used for this purpose.