As the coating material, the choice profoundly affects the performance, durability, and working efficiency. Polyphenylene Sulfide (PPS) and Polytetrafluoroethylene (PTFE) stand among frequently applied coatings and have their own set of various properties, making them suitable for specific use. But what separates one from the other? The following article illuminates the major contrasting features of PPS and PTFE coatings and walks through their distinctive properties, uses, and advantages. Suppose you want heat resistance, chemical resistance, or things with very little friction. In that case, you need to be conversant about these two highly advanced coatings and go deep into their differing properties, allowing you to examine and decide which is more suitable for your project.

Introduction to PTFE and PPS

What is PTFE (Polytetrafluoroethylene)?

The polymer known as PTFE or Polytetrafluoroethylene is an advanced synthetic fluoropolymer manufacturing material, noted for its excellent non-stick properties and chemical resistance, with some genuinely unique mechanical properties. PTFE is marketed popularly as the Teflon coating. The most remarkable ability to reduce wear and ensure smooth functioning in industrial applications is given to the material with the least friction coefficient, PTFE. Its temperature stability range goes from -328°F to 500°F (-200°C to 260°C) and may be employed in environments requiring the utmost demands on aerospace, electronics, and chemical processing industries.

Aside from temperature resistance, PTFE possesses exceptional chemical inertness, resisting almost all corrosive materials, including strong acids, bases, and solvents. These applications, therefore, demand coating solutions that emphasize durability and hardly any contamination. It is also hydrophobic and has sound insulation against electricity, making it all the more versatile for medical devices and semiconductor components. Its characteristics adapt to ensure performance when needed, particularly in applications wherein precision and cleanliness are critical.

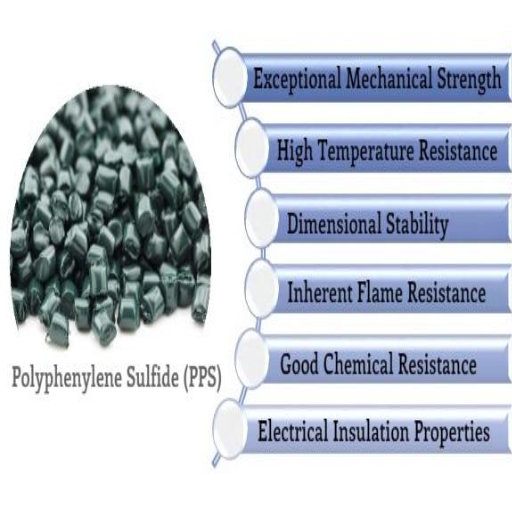

What is PPS (Polyphenylene Sulfide)?

Polyphenylene Sulfide (PPS) is a semicrystalline, high-performance polymer primarily distinguished by its thermal and chemical resistance. Its unique molecular structure of aromatic rings joined by sulfur atoms allows the polymer to resist stress at high temperatures, often exceeding about 200°C (392°F) and above. Thus, it is suitable for demanding industries, including automotive, electronics, and aerospace.

The polymer has excellent dimensional stability, low moisture absorption, and chemical resistance to acids, alkalis, and organic solvents. Owing to its flame-resistant nature and electrical insulation, PPS is a material of choice for electronic components such as connectors and circuit board parts. As PPS may be combined with glass fiber or other fillers to achieve mushrooming mechanical properties, applications requiring enhanced mechanical strength and stiffness are possible.

The PPS has been used more for injection molding and extrusion, producing complex precision components requiring tight tolerances. Durability behind versatility lends itself to fuel system components, medical devices, and industrial machinery while ensuring they perform in harsh environments.

Overview of Their Uses in Industry

Polyphenylene sulfide (PPS) is the material of choice in different industries for its many advantages, such as thermal stability, chemical resistance, and mechanical strength. In the automotive industry, for instance, PPS is prominently used to manufacture fuel system components, electrical connectors, and under-the-hood parts, which endure high-temperature applications and chemical attacks. PPS further aids in weight reduction and better performance in aerospace as it replaces metal components with lighter counterparts while not compromising durability.

In electronics, PPS is found in areas demanding good dimensional stability and flame resistance, such as circuit boards and insulation parts. The field of medicine uses PPS to build sophisticated surgical instruments and diagnostic tools where biocompatibility and sterilization resistance are paramount. From industrial machinery components to water filtration systems, the adaptability of PPS offers highly efficient solutions to modern engineering problems. This flexibility upgrades manufacturing processes and drives innovation across fields needing reliable, high-performance material solutions.

Material Properties of PTFE and PPS

Thermal Properties of PTFE

With its unique thermal stability, PTFE is considered a material of choice for applications involving extreme temperatures. Possessing a sufficiently large melting temperature, generally around 327°C (620°F), it is, thus, capable of retaining its structural form under intense heat. The continuous service temperature of PTFE is rated between -200°C (-328°F) and 260°C (500°F), hence making it suitable for applications ranging from cryogenic to elevated temperature ones, thus testifying to its versatility.

Besides, PTFE would have a thermal conductivity of approximately 0.25 W/m·K, indicating its aptitude for heat insulation under high-stress conditions. It curtails thermal degradation, assuring that it loses very little of its performance even when exposed to prolonged temperature variations. This fine conjunction of thermal resistance and stability makes PTFE the preferred material in aerospace, automotive, electrical insulation, and other industries where precise temperature requirements make or break the facility of operation.

Thermal Properties of PPS

Polyphenylene sulfide (PPS) is a high-performance thermoplastic with breathtaking thermal properties. PPS has a melting point of around 280°C (536°F), with a usual continuous use temperature above 200°C (392°F), and is thermally very stable, hence fitting best in environments where product specifications need to be held at high temperatures. Its low thermal conductivity of about 0.30 W/m·K offers PPS another advantage, often considered an insulation material, from its resistance to thermal degradation. On the physical side, under prolonged heat exposure, PPS stands the test of time in staying dimensionally stable, not warping, cracking, or deforming in any other manner.

Flame resistance is another characteristic. A PPS holding UL 94 V-0 classifications can self-extinguish when removing the flame source. This is so much appreciated in the automotive industry and in electrical and industrial equipment manufacturing because safety and fire standards are considered. It also stands up to thermal cycling, meaning its properties undergo negligible changes when exposed repeatedly to alternating high and low temperatures. Having such properties as high resistance to temperature and flame retardancy has glorified the essentiality of PPS in various industrial activities.

Comparison of Mechanical Properties

Polyphenylene sulfide (PPS) boasts superior mechanical properties and, thus, is selected for high-performance applications. The generally recognized tensile strength range for PPS is between 70 and 110 MPa; this strength assures resistance to mechanical stress under environmentally demanding conditions. Now, the flexural modulus of PPS, varying from about 2.5 to 4.5 GPa, denotes its rigid nature, capable of maintaining an excellent dimensional stability under load.

Compared to other high-performance polymers, PPS is globally famous for being highly resistant to creep, even under elevated temperatures and prolonged stresses. Its low coefficient of thermal expansion provides reliability in plants where tight tolerances are necessary. Increased impact strength is an additional feature to ensure resistance under dynamic load without compromising their other mechanical features. These make the polymer Foster points in sectors where durability, precision, and consistency are vital.

Coating Applications of PTFE and PPS

PTFE Coatings: Benefits and Applications

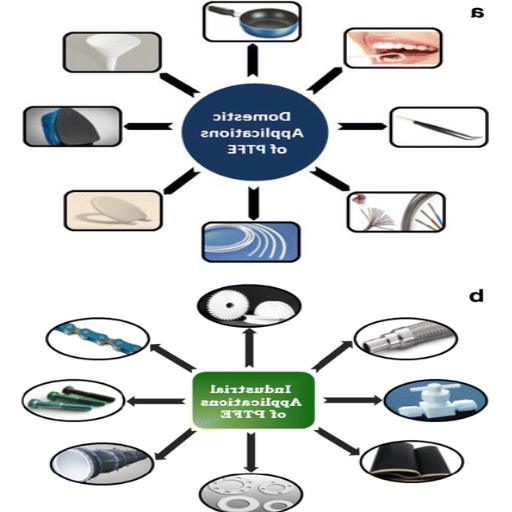

PTFE coatings showcase a particular mixture of chemical resistance, low friction, and thermal stability, hence their immense versatility across engineering disciplines. These coatings are mainly used in cases that demand non-stick applications. They can be used on cookware or for industrial machinery. In cases where there are extremely high or low temperatures, usually from -328°F to 500°F (-200°C to 260°C), PTFE will withstand the heat with ease. Another aspect of PTFE coatings that aids in the efficiency of mechanical systems is their low imposition of friction, limiting wear and energy losses.

These coatings have good applications in the automotive, aerospace, and food industries. In automotive applications, PTFE can coat gaskets, seals, and bearings to increase durability and decrease the need for maintenance. In food processing, its non-stick characteristics determine hygiene and operational convenience. Additionally, PTFE proves a better alternative in chemical processing plants where the equipment must resist an array of acids and solvents.

In terms of performance, the coatings have proven to extend serviceability duration while making smooth movement possible, accruing cost savings over time. For instance, the non-stick properties of PTFE would significantly reduce downtime due to buildup in industrial molds, thus enhancing the throughput cycles. Because of its ability to coat hundreds of types of substrates and retain its characteristics in the harshest testing conditions, PTFE remains one of the absolute coating systems in the realm of advanced coating technologies.

PPS Coatings: Advantages in High-Performance Settings

PPS coatings have a reputation for being tough, so they flex against chemicals and high stresses in application. They are also very heat-resistant up to an operating temperature of 220 degrees Celsius (or 428 degrees Fahrenheit), beyond which they start to lose their integrity. As for chemicals, PPS coating is not readily interactable with acids, solvents, and the like, and so it should be used on metal equipment that is further engaged in aggressive industrial processes.

They absorb very little moisture to perform in wet and humid environments. At the same time, affording abrasion resistance to the components protects them from wear and thereby increases product longevity. They are considered secure for parts like exhaust systems and engine components in the automotive and aerospace industries when steadily exposed to heat and friction that require superior protective properties.

In addition to the coatings, they also bestow energy efficiency to the surface of the moving parts by having a very smooth coat that reduces friction loss. Given that these coatings serve more extended periods under adverse environmental conditions with very little need for maintenance, the PPS coatings are one of the best investments for any industry wanting to save on operational costs in the long run.

Choosing the Right Coating for Your Needs

Choosing the right coating is pivotal in ensuring performance for an extended period, durability, and efficiency in your application’s service. Different coatings are offered, and while choosing, one must consider various factors such as environmental conditions and operational requirements, including the specific materials that need to be coated. The PPS coating would be their choice for industries that are high on heat resistance because it will withstand very high temperatures while providing frictional and wear resistance.

Ask yourself about the operating environment. Chemical attack, moisture, or abrasion is usually detrimental to the life of a coating. Where chemicals are involved, fluoropolymer coatings may offer more resistance; corrosion-resistant coatings such as epoxy or polyurethane might work best where salt or humidity values are high.

Other considerations you must take into account are friction and wear. Applications like automotive engines or industrial machinery benefit from coatings that reduce friction losses and promote energy efficiency. Low-friction coatings can help improve energy efficiency up to 15 percent in moving elements, thus adding invaluable value to the whole operational process.

Maintenance and operating life costs come next. A highly durable coating will reduce downtime and maintenance, even though it may be a bit costlier, because it was designed specifically to cope with various challenges, such as temperature variations on one hand and heavy-duty service on the other. Aligning the properties of the coating with your specific application will not only improve performance and safety but also assist in maximizing lifespan and operational sustainability.

Comparative Analysis: PTFE vs. PPS

Cost-Effectiveness of PTFE and PPS

From a cost-effectiveness perspective, involving the costs of raw materials and giving due importance to possible long-term cost benefits, we must determine which one to select. Some consider PTFE slightly expensive; however, with its live-serviceability, less wear and tear in tough environments, it bodes well over time, making it a worthwhile investment in industries such as chemical processing and food processing.

PPS, on the other hand, competes for attention with its semi-affordable and mechanical properties. Chemical resistance, thermal stability, and dimensional accuracy make an attractive proposition for those working with moderate to high temperatures requiring uniform performance. In addition, the lower density of PPS compared to PTFE may allow for some cost-saving potential in intermediate or end applications without compromising hard-surface performance.

The choice of either of the two depends on application demands. Industries that require extreme temperature resistance or ultra-low friction might go for the massive upfront investment in PTFE for ultimate durability and performance. However, the selection could tilt indisputably towards PPS on cost-sensitive operations demanding superb precision and chemical stability. By assessing the operational requirement vis-à-vis total lifecycle costing, a decision could be carefully reached that would suit both budget and performance expectations.

Durability and Longevity of Each Polymer

When judging enhancer and sustainer, resistance to wear, atmospheric conditions, and chemical exposure are reasonable criteria. PTFE possesses an immensely prolonged lifetime, especially in environments of extreme heat, differing from harsh pressure or corrosive chemicals. Owing to its lower coefficient of friction, it withstands wear and abrasion very well, thus being preferred for applications where it must produce lasting results with a minimum of investment in maintenance and repairs. Regarding mechanical properties, PTFE is resistant enough to hold its own even after an arduous 6-month mechanical exposure to a temperature of 260°C (500°F), thereby delivering good structural integrity in high-temperature industries.

PPS, conversely, entails another dimension to the durability spectrum, catering to precision parts in harsh chemical environments. Dimensional stability is retained throughout applications with severe temperature variations or exposure to aggressive chemicals such as acids, bases, or hydrocarbons. PPS can resist maintaining its mechanical properties for long periods, experiencing continuous exposure to temperatures of about 200°C (392°F). The hydrolytic stability of PPS greatly promotes longevity, particularly in moist environments.

In an appraisal, considering that both polymers undergo extreme durability, the factors of long-term performance should weigh heavily on the specific purpose your application will serve. When industries concerning thermal endurance and resistance to friction take the limelight, PTFE lessens the wear rate in correlation with time. Conversely, the PPS methodologically outperforms precision, chemical resistance, and operational costs throughout longevity. The criteria that guide decision-making thus have to include the degree of performance from each material at the onset and the long-term operational requirements of a particular use case. Analyzing these will yield consistency in financial returns or predictability in lifecycle results.

Environmental Impact and Sustainability Considerations

In this age, environmentally friendly and sustainable material choices have become paramount in manufacturing and product design. These two materials, carbon fiber and PPS, concerning pollution, can vary depending on how energy-intensive their production may be, the possibilities of recyclability, and usage as disposal alternatives. Carbon fiber’s very nature offers good performance and product life in contrast to the difficulty in dismantling it for recycling because of its complex construction. Then came the newer ways of recovery, which, through thermal or chemical means, are helping to promote carbon fiber recycling when earlier it left almost 100 percent in landfills.

PPS is believed to be a better choice in some settings for being more environmentally friendly because of its durability and lower energy consumption rates during manufacture. This means the material lasts long without degrading greatly in performance and drastically lessens the need for replacement, thereby conserving resources overall. Further, with an excellent resistance to harsh chemicals, PPS does away with additional coatings or treatments that might otherwise be disposing of environmentally harmful substances.

Companies increasingly use lifecycle analysis tools to evaluate the full range of ecological costs associated with their material choices. A more holistic analysis considers factors other than production, such as emissions due to transportation and energy efficiency during use, thereby aiding them in undertaking well-informed decisions that work toward sustainability. Considering these discriminants will ensure that material choices contribute to operational effectiveness and prominently play a role in an enormous push toward environmental consciousness and sustainable practice.

Conclusion: Making the Right Choice Between PTFE and PPS

Summary of Key Differences

In the case of PTFE and PPS, each material exhibits certain advantages according to the application. PTFE, with its high chemical resistance and low friction, would be used when the heat-resistant surface needs to be non-reactive. This versatility gives it application areas in chemical processing and the food industry. On the contrary, PTFE can sometimes limit applications due to its low mechanical strength and high costs, especially where durability under heavy loads or cost-saving measures are considered a priority.

PPS is good for resisting chemicals and high temperatures, being mechanically strong and dimensionally stable, and being more cost-friendly than PTFE. Thus, it is best used for components that undergo a high degree of temperature and mechanical stress, such as automobile parts and electrical applications. Yet it does lack PTFE’s ability to offer ultra-low friction and extreme chemical inertness, which in some cases might be imperative.

Ultimately, the decision between PTFE and PPS would depend on the specifics of the project requirements, expected operating conditions, and budget constraints. These factors should be considered when weighing one material against the other in terms of functionality and sustainability support.

Future Trends in Coatings and Polymer Use

From my point of view, the rise of sustainability and performance will heavily influence the future of coatings and polymer technology. Environmental consciousness has triggered the climb towards focusing on bio-based and recyclable polymers. Manufacturers are increasingly innovating coatings and polymers from renewable resources, while their durability and high performance are equivalent to traditional materials. Reducing the emission of greenhouse gases and promoting circular economies foster this transition, with businesses trying to keep up with regulatory obligations and consumer clamor for green products.

Another significant development would be using nanotechnology while applying polymers and coatings. Nanomaterials could improve properties like strength, wear resistance, thermal stability, and perhaps self-healing. This frontage can advance new opportunities in industries requiring utmost reliability and precision, such as aerospace, automotive, and medical devices. Nanotechnologies can provide a particular singular advantage: ultra-thin coatings that are highly effective in protecting the substrates, thus optimizing resource use and maximizing performance simultaneously.

The growing innovative coatings and polymers are absorbing. They dynamically respond to their environment by regulating temperature, changing colors, or self-cleaning. With the advancement of AI and IoT, I expect these innovative materials to contribute significantly to energy efficiency, extend product lifetimes, and augment user experience. By following these trends and identifying their practical applications, I want to maintain applicability in innovative fronts while addressing the pressing needs of project work and sustainable development.

Final Recommendations for Industry Professionals

From my viewpoint, a proactive attitude toward emerging technologies and their applications is needed to step ahead of the game in the industry. Keeping a closer eye on innovative materials, AI, and the IoT is advisable to truly grasp their capabilities in pursuing efficiency and innovation. Short spells engaging with case studies and research on these technologies will show how they aid specific projects in energy efficiency and durability, or in making better user-centered solutions. Such knowledge would indeed arm professionals in making sound decisions based on the ever-changing sustainability and market demands.

Beyond these, collaboration and knowledge-sharing amongst the professional fraternity cannot be overemphasized. Through shared learning, problems can be jointly identified early, resources efficiently utilized, and cutting-edge solutions implemented. Industry events, specialized forums, and informal networking would all enhance broad perspectives and areas of expertise. AI-powered platforms would also optimize current workflows by automating repetitive tasks, allowing professionals more time to participate in strategic innovation.

Having such a mind-set forever is necessary. Technological advancements are happening at such a fast rate that ultimate success will go to those adaptable and willing to experiment with new tools. Ensuring that such innovations are always balanced with sustainability goals secures solutions for today’s pressing issues and lays a strong foundation for the industry. Doing so would make us leaders in an intensely competitive and ever-evolving arena.

Reference Sources

- PPS vs. PTFE – A detailed comparison of material properties for PPS and PTFE.

- The Difference Between PP, PPS, PTFE – Explains the differences in strength, toughness, and applications of PPS and PTFE.

- A Comparative Analysis of Characteristics of PPS and PTFE – A research-based analysis of the characteristics of PPS and PTFE.

- PPS / PTFE (Polyphenylene Sulfide / Polytetrafluoroethylene) – Discusses the applications and properties of PPS and PTFE coatings.

- PET Vs. PPS Vs. PAI Vs. PTFE Vs. PI – A broader comparison including PPS and PTFE, focusing on thermal conductivity and dimensional stability.

- Top PC Plastic Pellets Suppliers in China

Frequently Asked Questions (FAQs)

What are the main plastic properties of PTFE and PPS?

PTFE (Polytetrafluoroethylene) and PPS (Polyphenylene Sulfide) are prominent engineering-grade plastics known for their specific attributes. PTFE has low surface energy, chemical-resistance properties, and offers lubrication, making it suitable for use in the presence of organic solvents. Conversely, PPS endures strength, rigidity, thermal stability, and weathering at extremes of temperature and humidity without degradation to an appreciable extent. Both materials have good resistance to wear, but based on these properties, the applications intended for specific materials change.

How is the chemical resistance of PTFE and PPS compared?

PTFE is widely accepted as a chemical-resistant material in an aggressive chemical environment. Its performance hardly degrades in the presence of a wide variety of aggressive chemicals. On the contrary, PPS withstands resistance to some substances under consideration in high-temperature applications, but does not resist all organic solvents as does PTFE. This chemical stability difference is crucial in selecting the right material for a specific industrial application.

What about the temperature resistance of PTFE compared to PPS?

Temperature resistance is essential when deciding between PTFE and PPS. PTFE can stay stable at high temperatures, and with a melting point of about 327°C (620°F), it is considered appropriate for high-temperature applications. On the other hand, PPS can also retain its properties at high temperatures, typically within a temperature range up to 260°C (500°F). Both have excellent thermal stability, but PTFE will generally have a higher melting point and is a better choice under extreme thermal conditions.

How do the two plastics compare in terms of mechanical strength and hardness?

There is a drastic variation between PTFE and PPS concerning mechanical strength and hardness. In general, PTFE is less rigid and has a lower tensile strength than PPS, which is characterized by high tensile strength and hardness. Hence, applications that use PPS require durability and structural integrity, while PTFE is usually chosen for its low level of friction and material adhesion. Therefore, when factors of resistance to mechanical strength come into play, PPS is preferred, and PTFE is preferred when considering its special physical properties.

Could PTFE or PPS material be fit for automotive applications?

PTFE and PPS could be used in automotive applications for different purposes. PTFE finds application in seals, gaskets, and bearings due to its excellent wear resistance and low friction properties. In contrast, PPS is used for parts that must withstand high temperatures and aggressive chemicals, such as automotive components. The final choice in material, though, depends on specific automotive application requirements, such as heat resistance and mechanical strength.

What fillers can be used for PTFE and PPS?

The properties of both PTFE and PPS materials can be improved by the filler material. The common fillers used for PTFE are glass fibers and graphite, which enhance mechanical properties and wear resistance. Likewise, PPS can be filled with glass, carbon, or mineral fillers to improve its rigidity and mechanical strength. The choice of filler directly affects thermal stability and chemical resistance in general; thus, the selection of fillers for these engineering plastics should consider the intended application.