Plastic pellets, or nurdles as they are colloquially called, might as well be considered the bricks of modern industrialization. They slowly & powerfully drive an industry from packaging, textiles, automotive parts, to household goods, raising the issues that grow with their importance in modern manufacturing. This article delves into the versatility of plastic pellets as it attempts to describe their utility while highlighting some pressing environmental concerns. Stay tuned while we uncover present industrial approaches toward functionality versus sustainability and the future for these crucial yet hotly debated building blocks of modern industry.

Understanding Plastic Pellets

What Are Plastic Pellets?

Plastic pellets, or nurdles, are tiny granules of polymeric resin. They form the basis for the production of various plastic goods. They are a few millimeters in diameter and weigh lightly. They are uniform in shape and size and, thus, easy to carry from one place to another, making them favored across industries by manufacturers.

With advancements in polymer science, plastic pellets are now designed to suit particular applications, which may include greater durability, a fair degree of flexibility, or perhaps a high degree of thermal resistance. For example, polyethylene (PE) and polypropylene (PP) pellets are used in packaging. In contrast, ABS pellets are used where greater rigidity and high performance in automotive parts and electronic housings are required.

Statistics shed light on their growing importance; the global plastics market, estimated at just over $580 billion in 2022, suddenly sees a boost from these pellets. Their commercial potential is enormous, although increasing concerns are being raised about the environmental impact of accidental spills in transit, as one of the contributing factors to microplastic littering. Solutions toward sustainability and end-of-life management concerning this vital input for manufacturing would help solve these issues.

Common Types of Plastic Pellets

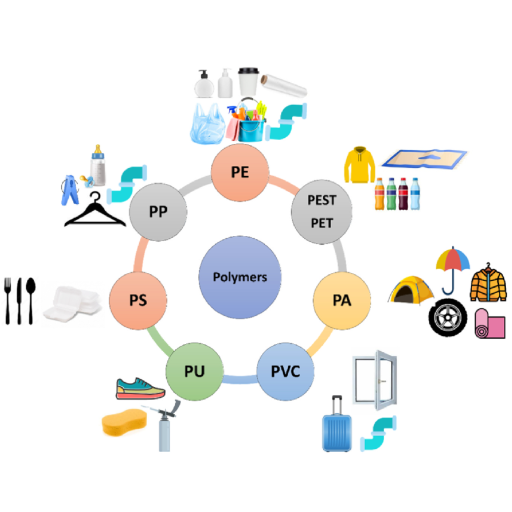

The fourth pellet type is mainly classified into plastic pellets or nurdles. These pellets serve as a primary instrument for the manufacture of most plastics. They come in several varieties, suited to specific industrial and commercial uses. Here are some of the most common types of plastic pellets, along with their applications and properties:

Polyethylene (PE) Pellets: Polyethylene pellets, including high-density polyethylene (HDPE) and low-density polyethylene (LDPE), are among the most widely used. They obtain value for their flexibility, chemical resistance, and durability. Plastic bags, bottles, and containers for packaging purposes represent some of their typical applications. The PE is in demand worldwide due to its versatility and economic considerations.

Polypropylene (PP) Pellets: This type of pellet, characterized by its ability to withstand heat, is employed in everything from automotive parts to medical instruments to food packaging. PP is valued for being light yet sturdy, making it a strong component for heavy industrial uses and a critical element in commercial applications.

Polystyrene (PS) Pellets: Polystyrene, commonly used for the clarity and rigidity of the pellets, finds applications for the manufacturing of disposable cutlery, foam packaging materials, and insulation. EPS, however, is an alternative listed for either construction or packaging protection.

Polyvinyl Chloride (PVC) Pellets: PVC pellets are more versatile and are mostly used in construction materials such as pipes, cables, and flooring. Depending on the plasticizers used, these pellets can be either rigid or flexible. PVC is aptly named for its excellent abrasion and moisture resistance.

Acrylonitrile Butadiene Styrene (ABS) Pellets: ABS polyplasters exhibit greater strength and impact resistance. They are probably the most common uses in electronics, automotive parts, and numerous household appliances. Because of their advantages in machining and good finish, ABS has also become a preferred choice for toys and 3D printer filament.

Biodegradable Plastic Pellets: Biodegradable plastic pellets, such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA), are gaining in importance as sustainability concerns grow. Produced from renewable resources, these pellets provide a truly environmentally beneficial alternative to conventional plastics by readily facilitating their decomposition in the environment.

These various types of plastic pellets, therefore, not only satisfy diverse industrial needs but also stress the importance of performance versus environmental considerations. Continuing advancements in biodegradable and recycled pellets may, hence, be setting the course for a more sustainable future for plastic manufacturing.

Manufacturing Process of Plastic Pellets

Manufacturing plastic pellets is a multi-step process designed for uniformity, efficiency, and quality. Usually, the process begins with raw material preparation, where natural resources such as petroleum, natural gas, or biomass are converted into monomers through chemical processes such as cracking or fermentation. These monomers are then polymerized into long-chain polymers, the building blocks of plastics.

After polymerization, the polymer enters extrusion, where it is melted and mixed with additives like colorants, stabilizers, and fillers to provide the desired property. The molten mass is then forced through a die to shape the material into strands or sheets. Thermal and mechanical consistencies throughout extrusion are fundamental as they determine the ultimate quality of the pellets.

Following extrusion, the material is again cooled in water baths or air-cooling systems. During this step, strands are solidified and cut into uniform pellets by specialized pelletizing equipment. Depending on the type of plastic, the shape of pellets can vary, but the focus is always on utmost precision in their manufacture for optimization in further applications.

Innovation is of utmost importance in achieving a better pellet conversion facility. Advances in automation, precision monitoring, and energy-efficient technologies have resulted in more efficient manufacturing with reduced environmental footprints. Moreover, vendors now embrace clean practices, with many using secondary materials or producing biodegradable pellets to meet the rising demand for sustainability. These steps increase operational efficiencies, fully realizing the overarching goal of the global community to address issues concerning plastic waste.

Thus, through stringent manufacturing processes, the production of plastic pellets will continue evolving towards satisfying industrial requirements and environmental accountability.

Types of Plastics Used in Pellets

Polypropylene and Applications

Polypropylene (PP) is one of the most versatile and widely used thermoplastics. It is known for durability, chemical resistance, and adaptability. Being lightweight, this polymer is suitable for applications across industries, such as molding complex shapes.

Industrial Applications: Polypropylene is also used for packaging materials, such as containers for food and utensils, and plastic films, because it is cheap and resistant to moisture and chemicals. Due to its sturdy yet lightweight properties, the automobile industry uses PP for automotive interiors, bumpers, and battery containers to attain vehicular efficiency. Polypropylene can produce textile fibers for ropes, carpets, or even geotextiles, which are considered for their high strength-to-weight ratio and abrasion resistance.

Emerging Innovations: Novel innovations at the processing stage yield innovations. Modern manufacturing methods, like injection molding and blow molding, make producing fully customized and inexpensive components possible. Moreover, considering the aggravation of environmental problems, research in sustainable polypropylene alternatives led to recyclable and bio-based grades of PP, competently solving the two-dimensional problem of performance versus environment. In working toward these innovations, polypropylene is growing ever more adaptable to meet current market needs and environmental demands.

Market Insights: The global polypropylene market has undergone sustained growth, with increased pressures from the packaging and automotive sectors. As attempts are made to make a circular economy a reality, recycled polypropylene is seeing greater usage. This trend is projected to continue, with mounting regulatory pressure and rising consumer preference toward environmentally friendly products.

High-Density Polyethylene (HDPE) Overview

High-density polyethylene (HDPE) is a widely used thermoplastic polymer known for its high strength-to-density ratio. Depending on the needs of the end-user markets, it is used in packaging, construction, agricultural, and consumer goods applications. The material’s massive advantage is durability, resistance to moisture, chemicals, or impact, i.e., its ability to carry out these functions well: in short, making pipes, containers, geomembranes, and some other household items.

The global HDPE market is still witnessing significant growth, fueled by the increased demand for sustainable and lightweight materials. This growth is also supported by HDPE production technology advancement through improved polymerization techniques that make HDPE more efficient and have better properties. Moreover, recent data predict a strong CAGR over the coming decade in HDPE markets, supported by a surge in infrastructure development and packaging solutions.

Simultaneously, greener manufacturing procedures are reopening development for recycled HDPE. Many key players invest in the closed-loop recycling program to generate high-grade, recycled HDPE that fits sustainability goals worldwide. Hence, these developments highlight the material’s role in fulfilling industry requirements and facing environmental challenges.

Comparing Polyethylene and Polypropylene Pellets

Polyethylene and polypropylene pellets are the most commonly used thermoplastics in many industries because of their versatility, durability, and cost-effectiveness. Although certain similarities exist between these two types of pellets, they vary significantly in their properties, applications, and performance under different conditions.

Physical Properties: Due to their inherent softness, polyethylene pellets tend to be flexible and have a lower melting point than polypropylene. This property makes PE suitable for applications that require durability at low temperatures, such as piping and flexible packaging. Polypropylene, on the other hand, exhibits rigidity and tensile strength with a higher melting point, creating applications such as automotive parts and containers designed to withstand heat and pressure.

|

Property |

Polyethylene (PE) |

Polypropylene (PP) |

|---|---|---|

|

Melting Point |

~239–275°F (115–135°C) |

~320–340°F (160–171°C) |

|

Density |

0.910–0.970 g/cm³ |

0.855–0.946 g/cm³ |

|

Flexibility |

High |

Moderate |

|

Tensile Strength |

Fair |

High |

|

Resistance to UV Degradation |

Moderate |

Low (requires stabilization) |

Applications and Use Cases: Polyethylene is used for all things requiring flexibility, such as plastic films, shopping bags, and tubing. Due to its cost-effectiveness and chemical resistance, it is favorable in manufacturing containers and industrial liners. Conversely, polypropylene pellets are used for rigid goods owing to their light weight and strength, including caps and closures, textiles (such as reusable tote bags), and automotive components.

Chemical and Environmental Factors: Both PE and PP materials decompose under acidic, basic, or organic solvent conditions, which provides a trait of chemical resistance. While PE can resist cold temperatures, PP tolerates high heat better. Environmentally, the recycled grades of either material have gained popularity, with newer methods now able to create high-quality pellets from post-consumer and post-industrial scraps to give them a USP worthy of a circular economy.

Industries today use materials to maximize cost optimization, high production outputs, and specific application needs. By understanding the unique properties and applications of every kind, a manufacturer can base its selection of the material on specific performance and sustainability criteria to ensure the desired balance of functionality and eco-responsibility.

Environmental Concerns Related to Plastic Pellet Pollution

Sources of Plastic Pellet Pollution

Plastic pellet pollution, infamously called “nurdle” pollution, occurs in many stages of the plastic production and supply chain. Pellet spillage can arise from various unintentional circumstances during the production process. Improper handling and inadequate storage procedures are two common reasons pellets escape their containment systems. Transport and shipment form another category that sees many pellets lost during loading, unloading, or transit, with many transported in bulk and therefore not contained by any significant measure: trucks, trains, marine vessels, etc. Poor packaging, the pilferage, or accidental tearing of the containment bags accounts for the rest.

Industrial plants processing plastic resin also dump plastic pellets in water bodies due to substandard filtration or accidental release into stormwater systems. Such manners of dumping constitute another significant source. Incompetent waste management only adds to the risk of nurdles contaminating the environment; for example, facilities lacking reasonable waste containment regulations may be a polluting medium through pellet leakage into the nearby soil or water bodies.

A recent assessment indicates that up to 230,000 tons of microplastic pellets find their way into the oceans every year, thus seriously threatening marine ecosystems. Once plastic pellets are introduced into the natural environment, wind and water current variations help them cover long distances, thereby making the clean-up operations ridiculously difficult. Wide dispersion threatens marine species that may ingest pellets, mistaking them for food; this also harms human populations that depend on these ecosystems for livelihood and sustenance.

Advanced technologies and more stringent regulatory standards are now being instituted globally to reduce pellet loss. However, collaborative efforts among manufacturers, transporters, and policymakers are still required to crack this environmental hazard.

Impact on Marine Life and Ecosystems

The familiar presence of plastic pellets in marine environments spells destruction for aquatic life and ecosystems. Ingested pellets inflict internal injuries, cause blockages, and cause many species to starve to death. They include fish, seabirds, and marine mammals. In addition, plastics act as carriers of toxic pollutants by adsorbing poisonous chemicals such as pesticides and heavy metals from the surrounding water. When ingested, these toxins can accumulate in marine food chains, thus increasing their damage to top predators and finally human beings who depend on these species for food.

Almost 690 marine species suffer from plastic pollution, and pellets comprise a considerable portion. Even coral reefs, which are of utmost importance for biodiversity and livelihoods for coastal communities, are affected by plastic pollution that impedes their growth and increases their susceptibility to diseases. Microplastics derived from degraded pellets penetrate even deep-sea sediments, which clearly indicates how far-reaching the impact of this pollution is. Dealing with these ecological threats requires not only the respite offered by preventing further degeneration but also sustained efforts by the involved stakeholders to rehabilitate the affected areas in an all-encompassing approach.

Mitigation Strategies for Pollution

Some strategies for pollution require an all-around attack, mixing innovative technologies and their application, strategic policy, and public action. One is reducing the usage of single-use plastics by implementing measures to ban or set taxation on them. For instance, several countries have seen tremendous benchmarks in curtailing the use of plastic bags. Promoting circular economy principles to industries creates an opportunity to reduce waste by designing products with reutilization, recycling, or biodegradation in mind.

Now it is time for the large scale: technical ingenuity to advance waste treatment, environmentally safe waste treatment, and bioremediation, which uses microorganisms to break down pollutants, will undoubtedly become one of the key tools for ameliorating environmental pollution. Coupled with renewable energy such as solar and/or wind power, one can expect a significant reduction in air pollution and greenhouse gas emissions.

Education is also paramount. Public awareness campaigns promote waste reduction, reuse, and recycling, encouraging change at the individual and community level. For example, on occasions where recycling education programs have occurred, engagement and waste diversion have increased.

Further investment in monitoring and data collection technologies, such as satellite imagery and IoT-enabled sensors, is key to tackling pollution. These tools allow authorities to pinpoint hotspot areas for intervention and devise targeted approaches to address the pollutants. Together with the other pathways, they present a practical hope of efficiently confronting the very long-term implications of pollution.

Applications of Plastic Pellets in Various Industries

Packaging Industry

Plastic pellets are vital in packaging by providing the raw materials for hundreds of packaging products, such as bottles, containers, and films. The combination of durability, easy transportation, and low costs makes packaging solutions functional and eco-friendly. For instance, in response to a demand for sustainable options, biodegradable or recyclable plastic pellets have been developed to eliminate dependence on conventional materials and support circular economy goals. Another use of plastic pellets comes through its versatility and ability to customize and mold the plastic according to a particular request, for example, from manufacturers needing food-grade packaging to those requiring heavy-duty industrial containers. New developments in material sciences have also stimulated the commercialization of advanced materials, while production processes have been improved to enable greater outputs with less wastage in the manufacturing procedure.

Automotive Manufacturing

As companies seek to meet demands for sustainability, performance, and efficiency, the automobile industry is increasingly using newer techniques and materials. Such plastic pellets have also become an integral element of the manufacturing process in contemporary automotive construction by being lightweight, durable, and cost-efficient. The use of plastic components from a weight perspective presents an alternative to metal components, whose weight and volume would inhibit fuel efficiency to quite a great extent, and the attendant emission of greenhouse gases, which are now being considered heavily by the industry with a shift towards stricter environmental laws. Moreover, plastic materials can allow manufacturers to express creativity in shapes that are difficult to achieve with conventional materials and integrate performance features critical to vehicle safety and performance, including impact resistance, thermal stability, and acoustic absorption.

With automotive manufacturing in transition, we thus cannot deny a growing emphasis on electric mobility and the ensuing exciting material requirements. Plastic pellets are instrumental in this metamorphosis by forming such high-performing components as battery housings, wire coatings, and lightweight interior parts. The materials contribute to extending the EV range and counteract passenger safety with properties like fire resistance and non-conductivity. Moreover, advanced injection molding techniques have hastened the manufacture of plastic parts with greater accuracy and decreased production time, which will be critical to accommodating the demand for EVs shortly.

Using recycled plastics for manufacturing is another emerging trend in line with circular economic thinking. Thus, reducing the usage of raw materials and carbon footprints accounts for the inclusion of PCR plastics. Big-name manufacturers are partnering with material suppliers working toward creating sustainable solutions, either using plastics from ocean waste or closed-loop recycling of production scraps. This win-win situation supports worldwide sustainability goals and promotes better brand positioning that draws attention from environmentally aware consumers. The employment of such state-of-the-art methodologies and materials proves the development of manufacturing in the automotive industry in the direction of innovation and a responsible manner toward the environment.

Construction and Building Materials

The construction industry has made significant progress in sustainable building materials due to the desire to reduce environmental impact and simultaneously improve durability and efficiency. Materials such as cross-laminated timber (CLT) and prefabricated components are gaining acceptance for their reduced carbon footprint and efficient installation methods. Furthermore, these developments are increasing the lifespan of infrastructures while minimizing maintenance costs because of recent trends in self-healing concrete that incorporates bacteria or polymers.

The recycled plastic composites and reclaimed wood play another role in this emerging trend towards circularity in construction. Insulating materials based on natural materials, such as sheep wool and hemp, are also gaining ground for their superior thermal performance and biodegradability. Together with 3D printing advancements for construction, these illustrate how technology and sustainability are redefining the industry and will enable contractors to meet tighter environmental regulations while simultaneously cutting costs and project delivery time.

Future of Plastic Resins and Pellets

Innovations in Biodegradable Plastics

Regarding the perforation of biodegradable plastics, it is exciting to think about the possibilities that can address environmental considerations. One of such inventions has been towards developing plastics from renewables such as starch, polylactic acid (PLA), or even algae. These materials are easier to break down in natural surroundings than conventional plastics, avoiding additional waste in the long run. On the other hand, scientists are perfecting the quality of biodegradable plastics so that they may have specifications equal to or better than those of standard plastics, fulfilling requirements for a diversity of industrial uses and consumers.

Another big name for progress relates to enzymatic and microbial technologies that induce and accelerate degradation processes. These technologies enhance the efficiency of decomposition of biodegradable plastic beyond their natural decomposition setting, including circumstances in which composting or special facilities do not exist. Such innovations are up-and-coming and could see vast applications in packaging, agricultural, and medical uses, where concern over single-use plastics has been paramount.

As we advance, I believe integrating biodegradable plastics into the circular economy will be essential. For instance, if environmental materials are run in tandem with recycling initiatives or actualized into reuse designs, their ecological footprints can be significantly diminished. These new processes do not only take a side track from conventional plastic but speak full force toward a much broader, circular approach to material use that is also aligned with wider global strategies for tackling plastic pollution and conserving natural ecosystems.

Recycling and Circular Economy Initiatives

I remain steadfast in my beliefs that recycling and circular economy initiatives are vital to solving the pressing problems of how our society currently uses and maintains materials. Recycling, foremost, lessens waste entering landfills; secondly, it conserves primary resources by reusing materials. However, recycling is not enough; it has to move into the bigger framework of the circular economy that looks through the entire lifecycle of products. This means that waste disposal is out of the linear “take, make, dispose” form of existence; the way goes into closed loops inside which materials can be continuously used and regenerated.

I believe the actual shift will come from considering the two simultaneously: fostering innovation and fostering collaboration. We must invest in new recycling technologies while redesigning products to be more easily repaired or recycled. We must also promote collaboration across industries, governments, and communities so that programs supporting these pursuits can operate efficiently. Programs that encourage consumer recycling, e.g., deposit return schemes, could be introduced while businesses agree to increased use of recycled content in their products. This approach will ensure immediate reductions in environmental impact while setting the foundation for a sustainable economy and long-term transformation.

When all is said and done, adopting a circular economy outlook is a vast cultural and systemic paradigm shift; this begins with education and awareness. Educating individuals and organizations on the relevancy of materials and the value of waste avoidance can inspire participation in recycling programs and the beginning of innovative thinking about circular solutions. Together, these measures can lay the foundation for designing a sustainable future with positive outcomes for humanity and the environment.

Predictions for Plastic Pellet Usage Trends

I see the use of plastic pellets undergoing significant developments over the next few years, primarily due to advances in material science and the growing demand for sustainability. As industries globally work toward processes favorable to biodegradable and recycled resins, manufacturers must adopt suitable processes. This will offset a massive trend of circularity, putting plastic pellets derived from post-consumer waste and/or synthetic bio-based sources on a bigger focal point. Increased regulatory pressure, coupled with greater consciousness on environmental issues from the public, is speeding up the demand for greener alternatives, redirecting this industry line toward more ecologically viable solutions.

Another key trend I do see coming is using more plastic pellets in advanced manufacturing technologies such as 3D printing. Pellets are lightweight and customizable, and provide efficiency across industries such as automotive, construction, and electronics with their innovations in materials to optimize their operations. We may also see more collaborative efforts from organizations in the coming years to create frameworks for plastic feedstock standardization and traceability to ensure that the standard of quality and sustainability is measured on a common platform.

All said, with the economic future of plastic pellets usage balanced between innovation and environmental obligations, the companies that pay attention to sustainable technologies and circular economy concepts will emerge to lead the market in setting a new precedent for material utilization and management of waste. This approach would, thus, not only serve water objectives but simultaneously create long-term economic value, ensuring that such a transformation fits with industry and global sustainability goals.

Reference Sources

- What are Plastic Pellets Used For? – Aceretech

- What are Plastic Pellets Used for? Applications and Uses – Pastillator System

- Innovative Uses of Plastic Pellets in Various Industries – Recycling Today

- 10 Surprising Ways to Use Plastic Pellets You Didn’t Know – Jiantai

- What is Pellets? Its Importance in Plastics Recycling – Sintac

- Top Suppliers in China

Frequently Asked Questions (FAQs)

What is the process involving the pellets of resin in plastic production?

Several terms are used regarding resin pellets: pre-production plastic pellets, pellet, or nurdle. These are raw materials required for conversion into a plastic product. The smaller granules derive from thermoplastics like HDPE and are necessary for several types of molding. Making plastic begins with resin pellets, which are heated and shaped inside machines via injection molding to form the final products. Knowing the importance of resin pellets may help assess plastic pollution issues and the environmental influence of the plastics industry.

How can plastic pellets become scattered in the external world?

There are several ways in which plastic pellets enter the external environment: production spills or transport spills, colloquially known as pellet spills. Endless tiny plastic pellets are littered on beaches and thrown into rivers, creating microplastic pollution. Losing millions of plastic pellets during production and shipment threatens marine ecosystems. International Pellet Watch and other bodies monitor these spills to lessen their environmental impact and inculcate best practices in the plastics industry.

What is the environmental degradation of plastic resin pellets?

The environmental degradation caused by the plastic resin pellets is beyond comparison, with the scale of their annual production soaring to trillions. Beaching in the ocean or natural environments is considered to be the spit of the pellets turning into microscopic pollutants which threaten marine life. Research also suggests that different species may ingest the granules, thus damaging marine ecosystems. A solution to the loss of plastic pellets must be found if we are to tackle plastic pollution along with the larger environmental crisis of plastic waste.

How does the density affect the properties of plastic pellets?

The density of plastic pellets, particularly HDPE, influences the molding process and the final product. Generally, matured products of higher density tend to be sturdier and are apt for use in products that require strength. Conversely, plastics of lower density provide more flexibility and are lighter in weight, making them fit for different kinds of products. Knowledge about the density of resin pellets helps manufacturers select the plastics necessary for a particular application, with consideration of the environment.

What is done in the plastics industry against pellet spills?

Operation Clean Sweep is one of the best instances of action set up to avert the aggressive effect of pellet spills on the plastics industry. The program tries to prevent plastic pellets’ loss during manufacture and transport by promoting good practices amongst companies. Among such good practices would be the handling, storage, and clean-up of materials that would further ensure that plastic pellet dust does not enter the environment. Implementing these measures will reduce the risk of marine pollution and save the ecosystem from the side effects of plastic waste.

What are the challenges associated with plastic pellet cleanup?

There are some challenges with the cleanup of plastic pellets or nurdles because they are small and scattered far and wide. These tiny plastic pellets are challenging to collect once they are in the waterways or gather on the beaches—the cleanup operation costs money and effort. Community acceptance and awareness are paramount for the cleanup to continue, as most organizations depend on volunteer assistance. These challenges continue to underline the need for better practices in the plastics industry so that incidents of pellet spills can be avoided in the first place.