Thermoplastic elastomers (TPE) and silicone are two materials used in numerous industries and offer considerable versatility in applications. This difference often becomes an issue that confuses the user, a few characteristics that distinguish them, yet their essence, structure, and functionality are entirely different. This article addresses a common question: Is TPE the same as silicone? By understanding the origins, properties, and applications of both materials, this article attempts to provide a more lucid comparison of them—concerning their similarities, differences, and best uses. Thus, of interest in product design or manufacturing, or just having some background info on materials, that will render you an equally discerning patron while making the decision for your particular need.

Understanding TPE and Silicone

![]()

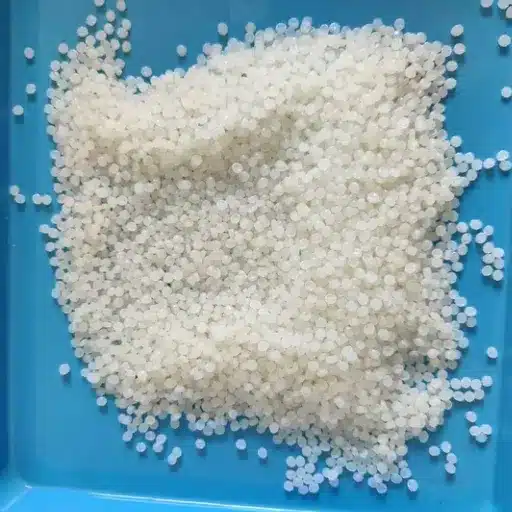

What is TPE?

Thermoplastic elastomers (TPEs) are a class of polymers that combine rubber-like elasticity with plastic-like processability. Compared to thermosetting rubbers, TPEs can be melted and reshaped repeatedly, a trait that contributes to their very high versatility and recyclability. Structurally, a TPE consists of hard and soft segments intertwined along its molecular chains, which provide a flexible yet strong material. Hence, these rubbers are particularly resistant to fatigue and provide variable tensile strength and hardness. Being lightweight and moldable with precision, while still compatible with multiple additive technologies for performance enhancement, TPEs are used in the automotive, medical, and consumer goods industries.

Characteristics of Silicone

Silicone is an immensely variable synthetic polymer, celebrated for its extraordinary thermal stability, chemical resistance, and median elasticity. The backbone structure consisting of alternate silicon and oxygen atoms makes it extremely stiff and resistant to environmental degradation. Silicone performance is far superior among a wide temperature range, commonly from -55°C to 300°C; as a result, it tends to suit highly demanding applications. Repellency to water, and thus electrical insulation, is rendered by its inherent hydrophobic nature. Besides, it is inert and biocompatible, thereby finding wide use in medical devices such as implants and tubing.

The mechanical properties of the silicone may be tailored by varying the level of crosslinking to produce anything from soft elastomers to hard resins. Further usefulness in a particular case may be provided by fillers or additives, such as the ability to contract under tension or to improve thermal conductivity. Being noted for its moldability and durability, silicone finds application in areas where performance assurance is required, including the aerospace, electronics, healthcare, and construction industries.

TPE Vs. Silicone

Thermoplastic elastomers (TPEs) and silicones are both plastics, but they possess very divergent properties and performance characteristics, making them suitable for different applications. The term TPE refers to a hybrid material possessing elastomeric and thermoplastic properties, hence providing some level of flexibility and processability, and being recyclable in nature. TPEs are less expensive to manufacture and hence are preferred for high-volume manufacturing industries such as automotive, consumer goods, and medical devices through injection molding. However, the thermal resistance properties of TPEs are generally lower than those of silicones, which limits TPE’s use in extreme temperature environments.

Whereas silicone is thermosetting, giving it a name for its temperature stability across a huge range of approximately -60°C to over 200°C and remarkable resistance to UV interference, ozone generation, and environmental factors. Silicone has excellent biocompatibility and chemical inertness, making it an ideal choice for critical healthcare applications such as implants and tubing. It finds uses in electronics, construction, and high-performance industrial applications due to its dimensional stability under stress and durability.

Key Takeaway: While flexible and strong in their own ways, the decision between TPE and silicone depends on specific application needs, such as thermal endurance, cost constraints, and environmental exposures.

Composition of TPE and Silicone Rubber

Chemical Structure of TPE

Thermoplastic elastomers are polymer materials that combine the advantages of both individual thermoplastics and elastomers. Structurally, TPE has a segmented block copolymer structure with hard and soft segments. The hard segments usually consist of crystalline or glassy domains formed from polyamides, polyesters, or polyurethanes, which provide mechanical strength and thermal resistance to TPE. The soft segments are amorphous polymers with low glass transition temperatures and give TPE its elasticity and flexibility.

Owing to its two-phase morphology, TPEs are reversibly elastic, with hard segments acting as physical crosslinks at lower temperatures, while the soft segments delaminate and flow when heated. Such behavior recycles TPEs as thermoplastics since there are no chemically-bound crosslinks such as in vulcanized rubber. Progress in polymer technology has, however, provided a wide variety of TPEs that are specifically modified by changing the molecular makeups of the hard and soft phases, respectively. This controllable chemical structure makes TPE a versatile material for use in automotive, consumer products, and medical devices.

Silicone Rubber Composition

The primary component of silicone rubber is a backbone chain of alternating silicon and oxygen atoms, linked by a siloxane bond (Si-O-Si). This very stable bond gives silicone rubber its characteristically high thermal and chemical resistance, setting it apart from organic rubber compounds. Usually, the polymer chains are end-capped with methyl or other organic groups that can be modified to effect properties such as flexibility or adhesion.

Additives are important for shaping silicone rubber into a material suitable for certain applications. Fillers such as silica improve mechanical properties like tensile strength and elasticity. Crosslinking agents create a three-dimensional network during curing through addition or peroxide processes, thus endowing the silane rubber with improved durability and thermal stability. Other ingredients such as pigments, flame retardants, or process aids may be mixed in in conformity with the performance criteria required.

Note: From this nature, silicone rubber became so popular for the applications in equipment comprising aerospace, electronics, and healthcare, where it encounters very high temperatures, chemical degradation, and biocompatibility; therefore, the general capability of remaining functional from a very low temperature of usually -75°F up to over 400°F, excellently facilitates the use of the material wherever applications need higher performance under extreme conditions.

Properties of Synthetic Materials

Synthetic materials may be defined as those prepared by manipulating their chemical structures to optimize certain properties. High synthetic materials, such as thermoplastics, offer horizontal tensile strength and durability due to the polymer chain arrangement, while thermosetting plastics provide dimensional stability and resistance to deformation during heating. In other words, synthetic fibers such as Nylon and Kevlar have the highest tensile modulus, often exceeding that of natural fibers, making them indispensable to industries such as textiles and aerospace.

Chemical resistance is an important property for synthetic materials. For example, Teflon, a synonym for polytetrafluoroethylene (PTFE), is one of those synthetic materials that resist chemical corrosion to a high degree and remain stable even under extremely high temperatures. Teflon is, therefore, used in high-performance coatings and in applications where stick resistance is required. Moreover, in electronics, synthetic materials such as polyimides and epoxy resins have laid the foundation for present-day developments through their dielectric capabilities, serving as insulating media and enabling high-frequency operations.

With such properties, synthetics stand at the crossroads of technological development, as each industry demands ever-increasing levels of precision, reliability, and performance.

Differences Between TPE and Silicone

Mechanical Properties

Thermoplastic elastomer and silicone are very different from each other as silicone specimens have different mechanical properties, thus the difference in suitability for application. TPEs are flexible and resilient to tensile failure, making them universal for applications that require flexing or stretching repeatedly. On the other hand, they are very abrasive and can withstand mechanical loads for some time without permanent deformation. Since it falls within a lower hardness range, it can be molded into very complex parts, and the level of precision attained by this process is quite consistent.

In comparison, silicone is well known for its excellent flexibility and strength. It offers very high thermal stability and compression-set resistance; therefore, it is the preferred choice for sealing in harsh environmental conditions. While silicone offers high elongation, it exhibits excellent stretchability and remains durable until extreme elongation. These properties make silicone desirable for high-grade sealing, medical applications, and insulation systems. The differences in mechanical properties are why these materials would be better candidates for high-end industrial, medical, and consumer applications.

Thermal Resistance

Thermal resistance is the ability of the materials in question to contest heat flow, thereby allowing a design to perform stably under different ranges of temperature. Silicone has the best thermal resistance, and it can withstand temperatures from -75°F to beyond 500°F (-60°C to 260°C) without substantial degradation. The capability is associated with one of the factors, a unique molecular structure, providing thermal stability in the vast majority of applications. Such a property makes silicone an essential consideration for markets subject to harsh thermal conditions, including the aerospace, automotive, and electronics sectors. On the other hand, some elastomers are generally susceptible to thermal deformation or cracking at high or low temperatures, thus limiting their operational range. In fact, it is pertinent to understand and improve thermal resistance to ensure materials maintain functionality and reliability in harsh environments.

Flexibility and Durability

Its unique molecular configuration determines the highly flexible and durable properties of silicone, allowing it to withstand mechanical stresses repeatedly with negligible loss of performance. Unlike common polymers, which may fatigue or become brittle after repeated bending or stretching, silicone retains its mechanical integrity over time. These properties are highly useful in dynamic applications where the seals, gaskets, or flexible joints involved move or vibrate during regular intervals. It is, in fact, this silicone that rewards its users with UV (ultraviolet) radiation, ozone exposure, or weathering resistance and offers protection against material degradation in outdoor or highly exposed conditions. These characteristics make it an ideal choice for any industry requiring high durability and trustworthiness in their execution, from construction to healthcare. Silicone is a mate of durability and versatility, combining for a high-performance partner capable of withstanding even the worst operational environment.

Injection Molding Processes for TPE and Silicone

Overview of Injection Molding

Injection molding is an efficient manufacturing method for producing highly complex, precise parts from thermoplastic elastomers (TPE) and silicone. Injection molding involves forcing molten material under pressure into a mold, where it cools and solidifies to form the required shape. The method guarantees many advantages such as making identical parts with smooth surface finishes and fairly complicated arrangements along with tight tolerance setups.

For TPE and silicone, the injection molding process requires special considerations due to their material properties. TPE is thermoplastic, allowing remelting and reprocessing during manufacturing and providing economic advantages. Being thermoset, silicone becomes vulcanized on molding and attains its final state whose structure is irreversible. Both materials require precise temperature and pressure controls during injection molding to produce a product with optimal physical and mechanical characteristics.

Advancements in injection molding technology brought unprecedented perfection to production. Contemporary injection molding machines now come with sophisticated monitoring systems capable of real-time parameter changes to maintain periodic quality control. Moreover, the multi-material injection molding system can simultaneously process TPE and silicone, opening new horizons for producing complex, multifunctional components. These innovations present the reasons why injection molding is a basic process in almost all other industries like automotive, medical devices, consumer electronics.

TPE Injection Molding Parameters

Thermoplastic elastomer (TPE) injection molding stands as one specialized process combining in a way the versatile nature of plastics with rubber-like elasticity, making it highly suitable for industrial applications, quite a few of which may otherwise require specific methods of manufacture. One of the essential characteristics of TPE molding is the realization of complex, high-precision designs combined with good final product durability and flexibility. The processes undergo lesser pressures and temperatures than in the cases of conventional thermoplastics, allowing energy to be saved and equipment to last a little longer.

Trying to adhere flexibles onto rigid substrates of polycarbonates or ABS, advanced grades of TPE ensure good adhesion and simplify multiproduct manufacture. The market demands a successful and dependable product that offers superior properties like high impact resistance, UV resistance, and excellent chemical compatibility. Now that tooling and machinery technologies have made such progress, short cycles for TPE injection molding, disposals of bipolar wastes, and never-ending assurances of high-quality outputs are fast becoming a key manufacturing method in the realm.

Injection Molding Techniques for Silicone

The silicone injection molding process is a precision-driven manufacturing technique that produces high-quality silicone parts which have to comply with stringent industry standards. The process is especially suited for applications that require flexibility, durability, and resistance to extreme temperatures. The unique properties of LSR-it—its excellent thermal stability, transparency, and biocompatibility—provide a wide range of applications, from medical devices and auto parts to consumer goods.

Thanks to recent improvements in molding technologies, silicone injection molding has become more efficient and accurate. Some of these technologies include highly automated closed-loop systems that greatly reduce material wastage and increase process consistency. The cold-runner systems, along with flow-channel optimization, helped improve material utilization, which is extremely important for cost reduction and lessening environmental impact. All these advancements, combined with stringent process controls and quality assurance, make silicone injection molding essential for the production of complex, high-performance components.

Various Applications of TPE and Silicone

Common Uses of TPE

According to my findings, Thermoplastic Elastomers (TPEs) enjoy tremendous versatility across industries due to their unique combination of elasticity and processability. The most popular applications of TPEs lie within the automotive field that uses it for a number of interior purposes like seals, gaskets, airbag covers, and floor mats. TPE steps in as a lightweight alternative to traditional rubber materials, resistant to varying hostile environmental conditions. Moreover, its ability to be custom compounded enables manufacturers to tailor its performance in terms of UV stability, heat resistance, or abrasion resistance to the given application needs.

Also, typical fields of application for TPEs include the consumer goods and medical sectors. To be more precise, in items related to personal care, the TPE will be used for the designing of ergonomic and soft-touch grips for toothbrushes, razors, and tool handles. Due to its non-toxicity and skin-friendly properties, this material is also well-suited for medical applications such as tubing, stoppers, and seals that require biocompatibility. The possibility of creating color masters and color finishes makes these products even more visually and tactilely interesting, fulfilling consumer demands for aesthetics in the market.

To another equally important domain, TPEs are outstanding in their applications on electrical and electronic areas. They are used largely as insulations for cable sheathing, in making flexible connectors, and in providing cases where protection is necessary. They provide the necessary electrical resistance, flexibility, and flame-retardant properties to ensure safety and longevity for components designed into household or industrial systems. For these reasons, TPE retains its ability to address current material needs for sustainability initiatives, as recyclable grades and bio-based options are increasingly coming to the forefront. Through these different roles placed before it, TPE is on its way to sustaining a practical role in advancing material technology and resolving industrial challenges.

Applications of Silicone Rubber

Silicone rubber is very flexible and durable, and is found in many different industries because of its properties. From my professional understanding, silicone rubber offers the best thermal stability, flexibility, and chemical resistance—from chilling cold temperatures to demanding environments. Another vital use of silicone rubber is in seals, gaskets, and O-rings, a critical component in fluid integrity that automobile, aerospace, and industrial systems depend upon. Due to its ability to withstand temperatures between -60°F and 500°F, it is indeed the first choice for high-performance applications such as engines and heavy machinery.

In the healthcare and medical fields, the silicone rubber finds its foremost use in segments that require medical devices and prostheses that must be biocompatible and free of bacterial contamination. It is also used for tubing, catheters, and seals for medical equipment where cleanliness and quality are crucial. Beyond medical fields, silicone rubber is widely used in electronics to help protect sensitive components from moisture, dust, and heat, but this use limits its insulation performance and stability. It, for instance, is used to make keypad covers, gaskets for electronic enclosures, and silicone adhesives for circuit assembly.

Further to this, silicone rubber plays an absolutely critical role in construction and consumer goods. In building works, silicone sealants and adhesives are primarily used for waterproofing and bonding, thanks to their superior durability and weather resistance. Being non-toxic and heat-resistant, silicone in consumer products acts as a boon to cookware and bakeware as well as baby products such as bottle nipples and pacifiers. The ability of silicone rubber to resist property changes on aging has helped cement its place as a key industrial and consumer product.

Industry-Specific Uses

Adhesives, as per my study, truly do their job across industries because their formulation changes with each need. For instance, adhesives in the automotive industry have now become indispensable, bonding lightweight composites and metals to help reduce vehicle weight and improve fuel efficiency. They are formulated to withstand extreme temperature fluctuations, vibrations, and other environmental conditions, resulting in a long-lasting bond that enhances structural integrity. On the other hand, adhesives find applications in electronic assembly, for instance, in adhering components to circuit boards, because of their properties of electrical insulation and thermal conductivity.

Adhesives, too, are the lifeblood of the healthcare market, particularly in the making of medical devices and wearables. Of course, adhesives applied in this field must meet stringent biocompatibility standards to ensure that patient safety is always paramount. Surgical drapes, wound care products, drug delivery systems, and, in some cases, implantable devices are included. Now, manufacturers are increasingly paying attention to pressure-sensitive adhesives that are gentle on the skin yet can adhere firmly enough to be worn for days at a stretch.

In the aerospace and defense sectors, an opportunity arises to optimize adhesive technologies, with weight reduction and serviceability as top priorities. Structural adhesives are, in a broad sense, used to bond composite materials for aircraft and spacecraft, resulting in light yet strong and sufficiently fuel-efficient structures. Modern adhesives, because of their capacity to be tailored to any performance or set of functions, continue to evolve alongside the broader industry, and as their own platform opens new technological, safety, and environmental branches.

Reference Sources

- TPE vs. Silicone: Which is Better? – Timco Rubber

- All About the Differences Between TPE and Silicone – Xometry

- Silicone vs TPE: What are the differences? – EuroPlas

- TPE vs. Silicone: Key Differences and Applications – TechSci Research

- TPE vs. Silicone | Comparing Elastomers for Medical Parts – Protolabs

Frequently Asked Questions (FAQs)

❓ What is the meaning of TPE, and what is its relation to silicone?

TPE stands for thermoplastic elastomer, a versatile material with properties of rubber and plastic. Silicone, on the other hand, is a synthetic polymer known for its flexibility and heat resistance, but a TPE compound represents a cost-effective solution with excellent elastomeric properties. TPE materials are extrudable and moldable into various shapes for specific uses in fields like automotive and medical devices. When the Turner products perform well at high temperatures, the TPE ones are a good alternative in terms of quality, durability, and resilience.

❓ What are the major differences between TPE and silicone?

TPE and silicone differ mainly in their chemical compositions and physical properties. TPE is a thermoplastic elastomer, and because it can be reprocessed and recycled, it is more environmentally sustainable. Silicone, on the other hand, is a type of synthetic rubber that can hardly be recycled. Therefore, it can withstand very high temperatures and is an incredibly biocompatible material —a must in medical applications. TPE materials have lower melting temperatures, making them very easy to handle, especially when injection molding and blow molding are used. Hence, each material has its own advantages depending on specific application needs.

❓ What advantages does TPE offer to manufacturing processes?

There are multiple advantages TPEs offer to manufacturing processes in ease of processing and versatility. The material can be extruded, injected, and molded into any design for use across industries. The material TPE is known for its strong resistance to heat, chemicals and hydrocarbon exposure, which makes it indispensable in the automotive field and industrial applications. Another feature is its ability to retain its original shape at very high or very low temperatures, making it one of the materials preferred for rubber parts and gaskets.

❓ In terms of heat resilience, how does TPE stack against silicone?

Both TPE and silicone solutions exhibit good heat resistance; however, silicone operates at a slightly higher temperature range than TPE. This implies that silicone products can withstand extreme temperatures without losing structural integrity and are therefore preferable for medical device and high-temperature automotive applications. On the other hand, Thermoplastic elastomer materials show good heat resistance, with the specific formulation being a key factor affecting performance. Knowing how heat-resistant each material is will help you identify the right alternative when searching for your application and requirements.

❓ Can TPE be used in medical devices?

TPEs are primarily used in medical devices that require biocompatibility and chemical resistance. The properties of thermoplastic elastomers allow them to be sterilized and molded into intricate shapes, which is crucial for medical applications. Silicone is still preferred for certain medical devices due to its excellent biocompatibility and compliance with international standards. Nevertheless, TPE materials can accomplish tasks where a certain degree of flexibility and durability is required but do not justify silicone’s high cost.

❓ What are the typical applications of TPE materials?

TPE has diverse applications across industries, including automotive, consumer goods, and healthcare. Because of its elastomeric property, it is mostly used for durable rubber parts, tubing, and gaskets. A variety of goods like utensils and toys need TPE for flexibility and safety considerations. The material’s adaptability accounts for its wide use in applications that require rubber-like properties in conjunction with those of thermoplastics: easy processing and recyclability.