Material selection is a major decision that has a lot of influence on how long a product will last and on the profit of a company. Among the options, High-Density Polyethylene (HDPE) is the one material that now is getting a lot of attention as a universal one for many of the applications, mainly because of the injection molding industry. The unique mix of power, flexibility, and affordable price is the reason HDPE is the most popular one for the production of high-wear and -tear products.

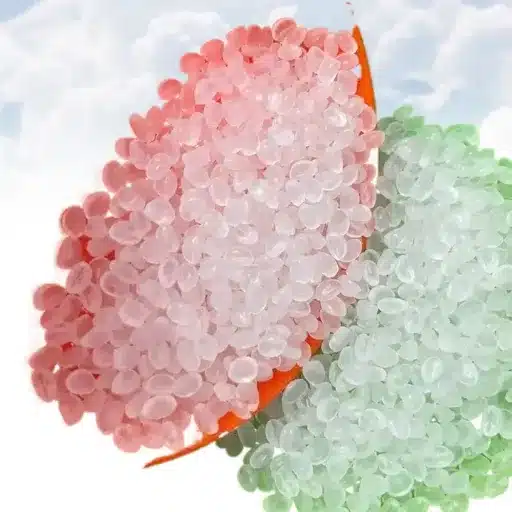

The main purpose of this manual is to explain the profit of using the HDPE in the form of plastic injection molding resin pellets. We will mostly concentrate on the vital properties of HDPE, its proceeding over other polymers, and the registration of the plastic part to be produced. Through this, interested parties like manufacturers and product developers can experience being on the top of the game; thus, they can provide better quality products and produce them with less effort. Actually, no matter whatever things you are making, if it is consumer goods, industrial components, or packaging, through this post you may get to know HDPE resin pellets are the best solution to your needs.

Introduction to HDPE and Its Applications

What exactly does HDPE stand for?

HDPE stands for High-Density Polyethylene, a thermoplastic polymer derived from the ethylene monomer. The material has been known for it’s extremely high strength/density which is one of the reasons for it to rule the market. The only way to produce HDPE is through a catalytic process; the result is a linear polymer with the fewest branches possible. Therefore, the polymer chains are more likely to make close packing. The material made as a result of this process is solid, firm, and not at all affected by chemicals or water, being highly crystalline.

When it comes to the manufacture of HDPE, the process includes a mixture of ethylene gas being brought to high temperatures and pressure in the presence of a catalyst such as Ziegler-Natta or Phillips catalysts. The catalyst (the third element in the mixture) produces the polymer chains that have the least number of branches. The outcome is a polymer that can be melted and shaped into so many different things that the end product is a very versatile plastic.

Common Uses of HDPE in Industry

The adaptability of high-density polyethylene (HDPE) is one of the main reasons for its wide use in a number of industries. The combination of its strength, chemical resistance, and low cost makes it a preferred material for many industries.

Below are a few of the most common industrial applications:

Packaging: HDPE is very common material for making bottles (milk jugs, shampoo bottles), containers, and caps. Being capable of resisting chemicals and moisture, it provides the necessary protection for the products accordingly.

Pipes and Fittings: The use of corrosion-resistant HDPE pipes is leading the water mains, gas distribution, and agricultural irrigation systems. The pipes are strong, flexible, and can handle high loads.

Automotive Components: HDPE has a widespread application as the material for fuel tanks, bumpers, and other parts in the automotive industry where crash safety and longevity are the top concerns.

Consumer Goods: HDPE offers the necessary ruggedness and safety for the seemingly easy products ranging from toys and playground equipment through cutting boards and outdoor furniture.

Industrial Containers: The usage of HDPE drums, crates, and pallets for the transportation and storage of a wide variety of materials, including hazardous chemicals, is a result of its excellent resistance to chemical reactions.

Comparison of HDPE with Other Plastics

If you have to pick up a material, then the first thing you would probably do is compare HDPE with other common plastics to find out what its unique strengths are.

HDPE versus LDPE (Low-Density Polyethylene): Both of them are polyethylenes and have close connections. Nevertheless, LDPE possesses a more piston-like structure, so it has a spongy nature and quite a good stretch. As a result, it is mainly used in the production of films and bags. In the meantime, HDPE is more rigid and stronger and hence, it is typically used for structural parts.

HDPE vs. PET (Polyethylene Terephthalate): PET is the usual choice of material for the production of beverage bottles and food jars due to its perfect transparence and high barrier properties against oxygen and carbon dioxide. Nonetheless, the outstanding feature of HDPE is its ability to resist impact and chemicals better than PET, and hence HDPE is the more preferable option for containers that carry chemicals or detergents.

HDPE vs. PVC (Polyvinyl Chloride): PVC has always taken charge in the plastic world as the most adaptable material for pipe, window, and flooring application. In spite of that, the durability and stiffness of PVC cannot compete against the same HDPE attributes. Moreover, as the PVC-chlorine link is a main concern from an environmental viewpoint, many endeavors choose HDPE.

HDPE vs. Polypropylene (PP): The melting point of PP is higher than that of HDPE, so it is practical to use it in cases where sterilization is required such as medical equipment and microwave-safe containers. Yet, HDPE has a much higher impact strength and is the winning material when it comes to freezing temperatures.

The Advantages of HDPE Resin Pellets

Durability and Resistance

It is famous for its precious and excellent durability and HDPE is one of the most durable qualities of the products. The objects produced from HDPE can be impacted remarkably and in spite of this, it won’t break and its surface won’t crack. The stuff made from it will be of the highest quality and long-lasting and the same for the people that need them for the purpose every day, for people that need to transport, and for customers that are out in the environment.

Moreover, HDPE is very protective against a plethora of different kinds of chemicals that include irritants, bases, and different kinds of solvents. This is very important in the case of packaging where the plastic should not react with the substances it contains, e.g., bottles of cleaning agents, containers for motor oil, and in the case of industrial chemicals, among others. It also has very low humidity absorption rates, which secure the very stable and uninterrupted exponential phase of the product when there is exposure to water.

HDPE is not only a superior performer on environmental stressors but also to a great extent an earth-friendly material. It is mildew and rotting resistant, features that make it a solid choice for either domestic or industrial outdoor applications such as pipes, decking, and playground equipment.

Cost-Effectiveness of HDPE Resin

From the perspective of a company, HDPE is a material of very high desirability mainly due to its productivity effect. The materials which are utilized for the production of HDPE are also rather cheap and, at the same time, easily obtainable throughout the world. On top of it, the manufacturing process itself is very efficient due to which the production cost is greatly minimized.

Because HDPE is less weighty, it can result in a great reduction in cost both in transportation and handling. Sending lightweight products costs less as the material’s sturdiness lessens the losses incurred through damage in transit. HDPE products’ long life also means fewer replacements which in the end equals a hassle-free and value-for-money situation for the customers and adds to the manufacturer’s name in terms of the quality side and reliability alike.

Environmental Impact of HDPE

When the topic is about the choice of materials, the issue of sustainability is getting more and more significant. As compared to other plastics, HDPE has the advantage of being a more environmentally friendly material that also has several other benefits.

It is true that HDPE is a very recyclable material. This kind of plastic is assigned a recycling number of “2” and is among the polymers that are easiest for recycling process. The recycling of HDPE makes it possible to come up with diverse new products like non-food bottles, pipes, lumber, and outdoor furniture. One more vital point on the list is the lightening of the load to be carried for virgin plastic production, conservation of energy, and landfill waste diversion.

The long lasting and tough nature of HDPE products also have a positive impact on the environment. When products are this durable, they need not be replaced frequently, and so, the total consumption and waste generation cut down.

Injection Molding Process with HDPE

Injection Molding Process in Brief

The most important stages of the polymer injection are the following:

Clamping: A smaller and a larger part of the shape are locked together by the clamp.

Injection: The plastic is entered into the heated container in the form of tiny pellets. A plunger heats the plastic and at the same time mixes it, then it injects the molten plastic under high pressure into the mold cavity.

Cooling: When the mold is filled, the solidification of the plastic and its cooling process start at the same time. The length of time that it takes for the cooling to happen depends on the thickness of the part and on the properties of the plastic.

Ejection: After the plastic hardens completely, the mold is opened, and the product is taken out with the help of an ejection system.

In this way the same product and a big number of them can be produced by the same process in a short time span at a high rate.

Choosing the Most Suitable Mold for HDPE

Successful HDPE injection molding requires a good mold design. The cooling of HDPE leads to a high shrinkage rate so the mold must be designed to take this into account. The molds for HDPE are usually made of hard steel to be able to cope with the high injection process pressures while also having a longer service life.

For HDPE, the gate and runner design are also important factors. The gate is the hole through which the plastic goes inside the cavities of the mold, and the runner is the channel through which the gate is reached. If this is designed in an optimal way, then the mold will fill evenly and completely and there will be minimum defects like weld lines or voids.

Factors Influencing Quality of Injection Molding

In the production of high-quality HDPE parts, many variables have to be kept under strict control in order to give good results:

Melt Temperature: It is necessary to heat HDPE to the right melt temperature for easy filling into the mold. If the temperature is too low, it will not be possible for the plastic to fill the mold thus the performance. If the temperature is too high, the material will degrade.

Injection Pressure and Speed: The pressure and speed of the injection process determine how the mold will be filled and the quality of products. These parameters need to be set properly to avoid faults and to get the part with a uniform density.

Cooling Time: The transformation of the HDPE from a viscous state to a solid state depends to a considerable degree on the cooling process. HDPE is a thermoplastic, and it will eventually be the same as the mold if cooled entirely properly. Moreover, warping and shrinking might appear if cooling is not sufficient,。

Mold Temperature: The temperature of the mold is another key factor as it can be dependent on the surface finish and the crystallinity of the part. A warmer mold will give better surface characteristic that is a trade-off as the cooling time will be longer.

Understanding Density and Its Importance

What is Density in Plastic Resin?

Density is a measure of how much material is there for a given volume. In the case of plastics, the density is very much affected by the polymer’s molecular structure. Among linear-chain polymers that can be tightly packed, for instance, HDPE is the one having the highest density. In a contrast, the LDPE with highly branched chains would have comparatively a lower density due to the chains outwardly arranged all over making less close a package with one another.

How Density Impacts the Product Performance?

Changing only the plastic density can often affect directly the plastic physical characteristics:

Strength and Hardness: Generally, a higher density of the polymer material corresponds to a greater tensile strength and hardness, which is the reason that HDPE is even more rigid and tougher than LDPE.

Stiffness: Plastics with more molecules that are densely packed are usually stiffer and cannot easily be bent or deformed.

Chemical and Moisture Resistance: High-density plastics have very closely arranged molecules that serve as a very effective barrier making the materials resistant to chemicals andmoisture.

Melting Point: In most cases, plastics having higher density also have a higher melting point.

Comparing High Density and Low Density Polyethylene

It is very easy to realize how significant the material’s density is in the selection process by means of comparing HDPE and LDPE:

HDPE: Its high tensile strength, rigidity, and excellent resistance to chemicals are typical attributes. It is not transparent and can withstand heat better than LDPE. Thus, it is the material of choice for different applications such as structural components, durable containers, and pipes.

LDPE: Its foremost characteristics are flexibility, clarity, and toughness. It is a more pliable material and the melting point is lower. Among its applications are plastic bags, films, and flexible lids, which are widely distributed.

The decision of whether to use HDPE or LDPE lies solely on the requirements of the final product. If a very strong and rigid material is needed, HDPE will be the best option. On the other hand, when flexibility is the prime issue to be dealt with, LDPE would be a better choice.

Finding Reliable Suppliers for HDPE Resin Pellets

Essential Components To Be Mindful Of When Selecting A Supplier

In selecting the best suppliers for your business one has to keep in mind several variables:

Quality and Uniformity of Material: Make sure that the supplier will present detailed technical sheets for their resin and pledge to provide the same quality from batch to batch. Differing materials can result in not only production issues but parts with defects as well.

Dependability and Delivery Times: By having a reliable supplier, you can avoid very expensive production stops that delays in the deliveries of the materials can cause. You should ask them concerning their mean lead and delivery times.

Technical Support: A supplier is considered a great one if they can provide proper technical support. The support can include the optimization of the injection molding process for the material. This help is much important for the problems’ solving and the productivity improvement.

Pricing: While cost is always a factor, the cheapest option may not be the best. Pricing should be compared within the context of material quality, reliability, and support. Think about the whole cost, which also includes shipping fees and potential losses from poor-quality material.

Certifications: Go for the suppliers who are committed to industry norms and have certifications such as ISO 9001 ratifying their dedication to quality management.

Top Suppliers of HDPE Plastic Resin Pellets

The global marketplace for HDPE is controlled by some of the big chemical companies which are well known for their quality and reliability. Some of the key suppliers are:

- ExxonMobil Chemical

- Dow Chemical Company

- LyondellBasell Industries

- Chevron Phillips Chemical

- Formosa Plastics Corporation

These companies have been in the business for a long time and have a reputation for providing their customers with high-quality polymer products and very significant technical support.

Understanding Pricing: Cost per Kilogram and in pounds

HDPE resin pellets often come priced by the unit, i.e., either the pound (lb) or kilogram (kg). They are usually subjected to various factors that shape the market price, such as the cost of crude oil that is the main source for making ethylene, the global unbalance between supply and demand, and the fees connected to the transportation of goods.

Keep a close eye on the market.commodity price. Moreover, if you are in good terms with the supplier, probably he will offer you stable or even less costly terms of a contract. And also when you make purchases in bulk you save, though the question of storing that much till it is completely used may be the challenge.

Reference Sources

HDPE plastic injection molding – Yifuhui New Material

This article highlights the advantages of HDPE in injection molding, including its strength-to-density ratio, chemical resistance, and cost-effectiveness.

Understanding HDPE Pellets: Properties and Applications

Provides insights into the properties of HDPE pellets and their applications in industries like packaging, piping, and more.

The Ultimate Guide to HDPE Plastic Pellets

Explores the benefits of HDPE pellets for injection molding, blow molding, and other manufacturing processes.

Frequently Asked Questions (FAQs)

What is the reason behind thermoplastic resin pellets being made for injection molding?

Plastic injection molding resin pellets, like HDPE, are used for injection molding because they flow and melt under heat, then solidify on cooling, enabling the production of complex parts with precision. The molding process is maintained and controlled by key machines, such as injection molding machines. The strictness of the quality control is assured by the machines control of the melt flow and pressure. These resins, due to their high mechanical strength and impact resistance, are among the most popular choices for thermoforming bottles, containers, and tubing. The mechanical properties of high-density polyethylene are very close to those of polypropylene; they were found to have similar lower limits. Compounding raw materials is one method used to adjust the melt flow, color, and abrasion resistance of the adapted resin for the end application, such as automotive or healthcare. The suppliers deliver specification sheets with the values of the melt flow, lbs per bag, and processing recommendations thus they make the melt flow and lbs per bag limits essentially the same as in the case of the newer energy planning materials and solid wastes.

How do raw materials like high-density polyethylene compare to polypropylene for molded parts?

Polypropylene typically has higher stiffness and better chemical resistance than polypropylene (PP), making it a preferred resin for rigid containers and plastic bottles. Polypropylene offers good fatigue resistance and can be more flexible, which is why it’s often used for living hinges and some automotive interior parts. Both are standard thermoplastic resins typically used in injection molding applications and can be tailored for higher-impact strength or higher operating temperature as needed. In terms of processing, HDPE and PP have different melt flows and require different machine temperature profiles to optimize molding cycle time and energy consumption. Many plastics supplies and hdpe resin suppliers will recommend grades based on necessary end-use and specification, such as FDA compliance for food-contact bottles or medical containers.

Why is natural HDPE often specified for food-grade containers and bottles?

Natural HDPE is labeled as a high-density material that is not only preferred but for food-grade containers as well. The reason is that it is a pure, unpigmented material that can easily undergo the necessary testing and FDA approval. Because of its very low moisture absorption and chemical resistance, it is an excellent choice of plastic for the medical field and laboratories. Moreover, natural grades pave the way for subsequent processes, such as coloring or adding agents, without affecting performance characteristics, such as impact and wear resistance. During the pre-production stage, manufacturers assess the viability of natural hdpe grade for their moldings based on melt flow and tensile strength measurements. To ensure the reliability of the fabricating process on their injection molding machines, some manufacturers choose high-density pellets and evaluate them based on the mentioned values. Through this partnership, they are enabling themselves to reach the desired consistency in quality and service for the highly demanding application.

Can LDPE or low-density polyethylene be used instead of high-density polyethylene for certain injection-molded parts?

According to the statement, LDPE (low-density polyethylene) maintains larger elongation at break than HDPE, which allows it to be used in more flexible parts like squeeze bottles or plastic bags, while less effective for containers requiring high tensile strength. LDPE is advantageous for its impact resistance at low temperatures and the flexibility of tubing and extruded films, due to its lower crystallinity. Nonetheless, LDPE is not as stiff as high-density polyethylene and has a lower maximum service temperature, so designers will have to make a compromise between mechanical and thermal performance. If the goal is to make flexible rather than rigid injection-molded parts, LDPE or LDPE blends, which are sometimes only available through materials suppliers rather than resin manufacturers, may be the only way to achieve the desired performance. The process parameters like melt temperature and machine settings will change greatly between LDPE and HDPE in order to control the melt flow and the pricing if necessary.

How is the importance of the melt flow factor in the choice of the resin pellets and machine for injection molding identified?

Melt flow rate is a crucial quality that points out how a thermoplastic compound can be easily melted and sifted under given conditions which in turn affects filling, packing, and final part properties. One of the possible results with a high melt flow index resin is that it will fill thin sections with less difficulty by the use of lower pressures at injection and at the same time the mechanical strength to en.will probably be lower at the same time the lower melt flow index can give stronger parts but then more processing heat and pressure need to be applied. The injection molding machine must be equipped with the proper temperatures and the screw speeds are adjusted to prevent degradation and to have a good balance of energy consumption and time for the process cycle. Data supplied to the molder by resin suppliers normally also include processing temperatures, melt flow values, and lbs per bag and so on which may assist in the molding of the right grade for packaging, automotive parts, or laboratory ware. Pairing melt flow to the part design and the machine’s capability ensures a consistent production yield and reduces waste.

Which among polycarbonate (PC) and high-impact strength plastics is more suitable for applications with higher operating temperature requirements?

Polycarbonate (PC) is a better choice in terms of toughness and operating temperature than many polyolefins, so it is the right choice for such applications that require high-impact strength and also higher thermal resistance, for example, automotive or healthcare components of some kinds. It is also possible for PC to be formed into parts that are clear and dimensionally stable through injection molding, but it is usual that its material is expensive and the processing conditions applied are unique to the plastic as compared with HDPE or PP. For those demanding chemical resistance and low cost, high-density polyethylene or polypropylene are obviously a more preferred choice, despite offering a lower service temperature until their service temperature has been reached. The designers usually compromise between blends and reinforced grades when seeking a material with both abrasion resistance and thermal performance, and they ask material suppliers for plastics grades that meet the special requirements and, if needed, the Food and Drug Administration (FDA) requirements. The choice also influences energy consumption and machinery wear, so molders must strike a balance among performance, cost, and processing complexity.

A typical requirement is several tens of pounds of resin pellets. How do suppliers package HDPE and PP resins?

Typically, resin suppliers wrap HDPE plastic injection molding resin pellets and PP (polypropylene) in bags or bulk totes and assign different weights per bag, such as 25 kg (about 55 lbs) or 50 lb bags, depending on the region. Inaccurate material weight due to component weight and part cutting has paved the way for estimating part weight and the percentage of the part expected to be recycled. The process of deliveries for HDPE resin supplies is well managed to keep the production process flow uninterrupted. Raw materials aren’t limited to single-grade materials; any raw or compounded material can be used, such as black HDPE plastic suitable for making non-food parts, and FDA-compliant natural-color grades for food and health care products. The suppliers are supporting their clients by releasing complete product specification sheets including melt and flow properties, tensile strength and recommended processing conditions, making it easier for molding houses to prepare their injection molding machines and achieve the item’s performance qualifications. When the customers buy their resin pellets from the most trustworthy plastic suppliers, they are assured of getting the materials they need for their injection molding applications in the quantities they may require and thus are also supported to carry on their operations consistently and maintain the same quality during control steps