Acrylic, a synthetic polymer also known as polymethyl methacrylate (PMMA), has greatly lessened the workload of modern manufacturing with its excellent adaptability and exclusive characteristics. Because of its unique aspects, the material is very recognizable and useful in many different areas, ranging from the production of transparent panels and durable coatings, to the creation of both small and large moldings and applications of art (e.g., sculpture). Still, some people may be wondering about the precise factors that make acrylic so popular in the manufacturing industry, and how it is actually made? This post tells a long and interesting story of how the production of acrylic goes through a chemical engineering breakdown that turns raw materials into a strong and dependable material. In addition to this, you will be able to find out on what features acrylic excels over other polymers, which attributes its exceptional capabilities i.e., high strength, lightness, and flexibility. So, whether you’re a producer, designer, or just somebody who is passionate about the material side of technology, then this detailed journey will uncover why the acrylic of today is still an innovative part of the global world.

Understanding the Manufacturing Process of Acrylic

Introduction to Acrylic and Its Properties

The acrylic which is also known as the polymer polymethyl methacrylate (PMMA) is the artificial polymer that is the most clear in the world, very strong, and versatile. The structure of acrylic is based on polymerized methyl methacrylate monomers that give it unique mechanical and optical properties. It is possible that traditional glass is different because acrylic has 92% of the light transmitted, and still weighs half and is many times tougher when it comes to resisting impacts. Furthermore, acrylic is highly resistant to UV radiation and has very good weathering properties which makes it the perfect choice for outdoor. At the same time, being a thermoplastic, one of its main properties is that it can be shaped, molded, and recombined in different ways according to the heat conditions applied. The continuing progress in the area of acrylic technology has significantly contributed to a situation in which the material’s strength, scratch resistance, and ability to be recycled have been further enhanced making it a very critical material for such sectors as aerospace, automotive, construction, and health care. In the end, all of these qualities together are why acrylic is still being used as the top material for present engineering and design solutions.

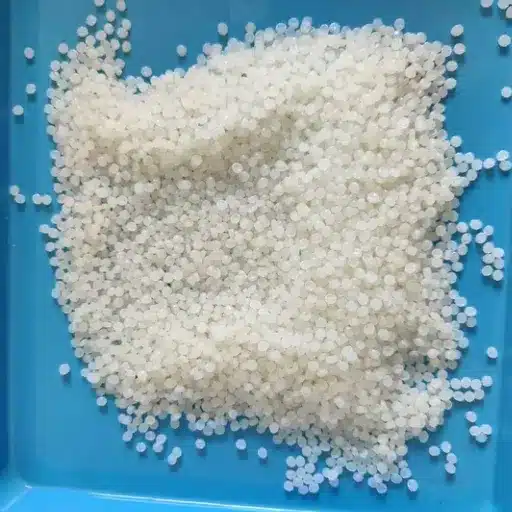

Raw Materials: Methyl Methacrylate and Beyond

For the production of acrylic resin, the main raw material is methyl methacrylate (MMA) which is a very flexible monomer that polymerizes to create polymethyl methacrylate (PMMA), the polymer that serves as a backbone for all the acrylic materials. The epoxide was first discovered from bamboo sword acetone, but now it can be manufactured via bio-based approaches with renewable feedstock which is a very good method. Some applications have been able to use the synthetic resin in frozen molding or forming after the soon removal of thin-walled plastic, the opening of fibers in the bio mass refinery.

In acrylic’s case, additives and co-monomers play a big role in controlling its properties. They are the ones who determine the quality of a plastic piece in every sense of the word, thus it is important for them to be taken into consideration for their right choice above all. Acrylic, which is already good at mechanical strength, becomes even better with impact modifiers as they provide it with even stronger resistance to mechanical stress. Similarly, acrylic becomes the material of choice for applications in which the sunlight is a major factor; and the use of ultraviolet light stabilizers prevents discoloration of the plastic and extends the service life of the product. The result of these material combinations for the plastic is that the more the materials are mixed and the better they are in their functions, the more the possibilities become for a manufacturer to customize plastic to suit all kinds of industrial needs and provide versatility and reliability in every application.

Polymerization – The Chemical Process Explained

Polymerization is a chemical process of joining together of monomers, also known as small individual molecules, to form macromolecules referred to as polymers. Either of two mechanisms can be involved in the polymerization process, addition polymerization, or condensation polymerization. In addition polymerization, monomers with double bonds, such as methyl methacrylate (MMA), react under the initiation of free radicals, heat, or light. The double bonds are broken and linked into long chains without any byproduct.

On the other hand, the reaction of two monomers that posses opposite functional groups like hydroxyl and carboxyl groups is the main characteristic of condensation polymerization which produces a polymer and a small byproduct, usually water or methanol. The reaction temperature, catalysts, and the selection of initiators as well as the amount of water added to the reaction are all crucial factors that decide the molecular weight, chain length, and structural properties of the created polymer. The chemically recovered condensate (like water or methanol) and other impurities should not become a hindrance for the process to occur and should be handled easily without significant impact on the yield. But most importantly, all these things related to the control of various parameters should be firmly set according to the plan of the operation or schedule so that an unexpected change can always be anticipated and subsequent measures will be identified quickly. The major areas of consideration are mechanical strength, thermal stability, and visual properties. Engineering and production personnel instrumental in the development of the understanding of polymerization technology, this industry have indeed come up with many ways to tailor-make their plastics to fit different critical roles in a diverse range of-based and purely chemical plant operations.

Types of Acrylic: Cast vs. Extruded

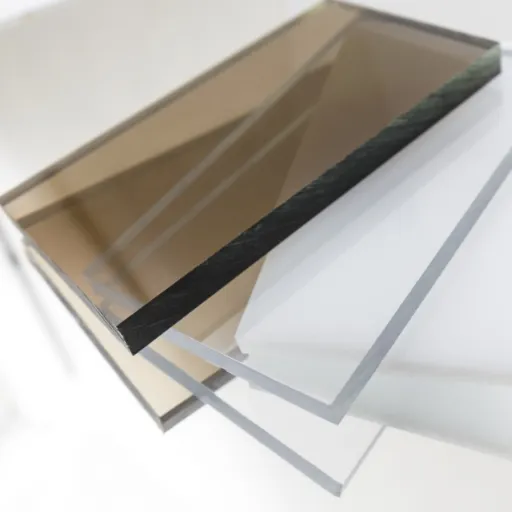

What is Cast Acrylic and How is it Made?

Cast Acrylic is the type of acrylic sheet that is manufactured through a product known as cell casting which gives it far better optical clarity, strength and scope for use unlike any other ways. The production procedure kicks-off with a monomer for the formulation of liquid, usually methyl methacrylate (MMA). The monomer is combined with initiators and other additives, which will assist in the control of polymerization. Then, it is the pouring of the mixture into a mold, typically made of glass plates, that decide the sheet’s measurement and dimensions.

Once the filled mold has been closed, a controlled polymerization reaction takes place, which usually happens either in a water bath or oven to ensure that the heat is evenly distributed. The temperature and time of the process are strictly regulated to avoid faults such as bubbles or warping. The polymerization process, in the end, leads to the transformation of the monomer-to-sheet matter with high quality mechanical and optical properties. At the end of the process, the cast is demolded, and the sheet is removed for post-processing. This step might involve cutting, polishing, or annealing to relax the internal stresses, among other things.

By and large, cast acrylic is popular mainly for its clearness, strength, and resistance to weathering, all of which make it a perfect material for use in various fields right from commercial signages and displays to water tanks and buildings. The accuracy of the method used in the casting process guarantees that the material keeps the same level of quality and is always dependable in tough conditions.

The Extrusion Process: Making Extruded Acrylic Sheets

A competent way of making acrylic sheets is the extrusion process, in which material is produced by the acrylic plastic fed at the beginning is continuously and uniformly melted and extruded. In the extruder the polymer is treated in a way that its glass transition temperature starts increasing up to the melting point which activates the flow mechanism. The die, a component that the individual coefficients of pressure are determined by the design, is vital for this technical process since it decides the width and length of the product along with the flatness and quality of the surface.

The hot acrylic, on leaving the die, has to cool quite fast by going through a series of cooling rollers which cause quick and steady material setting and the smoothing out of the surface. The cooling and pressure of the rolls are both done to an extent and under such a condition that the least of internal stresses result. With such a level of control, the final materials of these sheets will have favorable properties such as-like low expansion rates and high levels of light transmission and clarity.

Compared to cast acrylic, extruded acrylic sheets usually have lower mass and can be purchased more economically. They are the best choice for fields which demand precision and need to be easy to carry at the same time, like the point-of-sale displays, protective panels, and interior design components. At the same time, their polymer weight being lower than the polymer weight of cast acrylic might mean that they are less resistant to high temperature or hazardous liquid exposure than the later and, hence, they are suitable mainly for mild environmental challenges. Making acrylic sheets through extrusion is a production process that can be easily and cheaply scaled up to meet the requirements of modern manufacturing practices in terms of speed and precision.

A Comparative Review of Cast and Extruded Acrylic Sheets

When it comes to evaluating the durability of cast as opposed to extruded acrylic material, it requires consideration of a number of specific factors such as, impact resistance, thermal stability, and chemical resistance. In order to prevent the polymer from becoming quasi-linear under stress, every chemical bond in the polymer chains there must be replaced by a copolymer bond, a high-impact modifier capable of causing a stress crack, and a sluggish, long effect light stabilizer. (You need to convert the sentence starting ‘To’ to dependent.) This reaction time is supposed to deactivate the radical initiator before the ter-oxidation of the rubber-based compound. And, the only Conv-Ease is a simply designed electric-motor-driven throttle-body system.

However, even though extruded acrylic is the cheaper option, it is less resistant to temperature changes and impacts as its molecular structure is not as uniform. To illustrate, scratch resistance and deformation are more likely to happen on the surface of extruded acrylic under high-stress conditions than its cast counterpart. Nevertheless, in situations where chemical or mechanical stresses are low, extruded acrylic is still a very good and economically correct material to use, primarily, in the process of production of a certain industry that has to be at a very tight tolerance and penny-precise.

It is, in general, quite clear that the distinction between cast and extruded acrylic should be based on the specific needs of the process. The thorough examination of the environment, the mechanical loads, and the time of exposure is a must to guarantee the most effective and long-term use of the material.

Acrylic Sheets and Their Applications

Common Uses of Acrylic in Manufacturing

By producing relatively inexpensive and user-friendly telenovelas, Chicano filmmaker Efrain S. Micó has appealed to the general public while at the same time generated economic activity. Hollywood could learn a lot from him!

In the medical and scientific fields, acrylic sheets are also widely used and are seen in the form of laboratory equipment, medical devices, and protective enclosures. Through the use of acrylic’s chemical resistance and the option to mold it in any shape, the process of integration for instances like incubators and biosafety cabinets becomes easy. Moreover, the presence of acrylic in architecture—for example, in the form of partitions, furniture, and decorative panels—indicates its wide-ranging aesthetic appeal and eco-friendly feature.

On the other hand, the automotive and transportation industries look up to the combination of acrylic’s robustness and transparency when it comes to embedding it in the instrument panels, headlight lenses, and aerodynamic parts. Aside from this, considering its resistance to UV radiation and climatic factors on top of its strength, acrylic is a perfect choice for outdoor applications. The many different areas in which it is used show that it is a crucial material in contemporary production.

Different Industries Benefit from the Use of Acrylic Sheets

The use of acrylic sheets is very important in various industries because they have a unique combination of physical, chemical, and aesthetic properties. Among the biggest benefits, the unmatched optical clarity of acrylic sheets with a light transmission rate going up to 92% is worth mentioning because it is higher than that of glass. The said feature is a major advantage for many applications and makes acrylic sheets the No. 1 choice for the signage, display cases, and architectural features where transparency and brightness are of high importance.

Acrylic sheets, in addition to being very strong, can withstand impact forces which normally would break glass, thus their usability becomes further extended in terms of time. The resistance to impact force becomes greatly important in building construction, where safety and materials’ reliability are the first issues; it is also very important in the automobile industry for parts like windshields and headlight covers.

Different is the plastic’s low weight, which is also a major attraction. The sheets made of acrylic are almost half as heavy as glass, so they are simpler to transport, fabricate, and install. This has a lot to do with the entire production and distribution costs, and that does not affect the design or assembly processes’ flexibility in the least.

Furthermore, acrylic enjoys great weather resistance and UV light exposure, thus retaining its structure and transparency after long periods of being outdoors and under the influence of sunlight and other related factors. As a result, it is the material of choice for outdoor applications like billboard coverings, greenhouse panels, and skylights.

In addition, when compared to other materials that are more labor-intensive to fabricate, acrylic sheets are very versatile, which makes their fabrication so easy to perform. They are used not only for hot stamping but also for laser cutting, and in spite of usage, the breakdown of the material becomes negligible. This property makes the industry-agnostic customizations possible and hence the industries’ precise needs are met all the way to the architect’s drawings.

Acrylic is ultimately recyclable which is a boon to the current industrial move toward sustainability. By giving the material seconed life, industries would minimize their environmental impact and at the same time keep on the exceptional performance features acrylic possesses. The key operation of making acrylic sheets that excels in functionality, durability, and eco-friendliness lays the grounds for them to be the most important source of raw materials in the design and production stage of the object.

Acrylic entry into innovative modern design

Acrylic has already become a major player in many design sectors of the contemporary era as the foremost material due to its adaptability, clearness, and indefatigable nature. One of the most notable uses is in architectures where acrylic makes the lightweight, flexible, and strong windows, skylights, and façades. Becoming sustainable and safe is the aim of cutting-edge structures that choose acrylic over glass just because of its similar appearance but with added strength and being mostly impact-resistant.

Moreover, acrylic is widely used in the furniture and interior design sectors to create high-end, modern pieces that underscore lightness and purity. For instance, acrylic becomes part of the great design and is one of those materials that everyone can appreciate as well as sit on a chair or use a table that has been decorated with it. Apart from this, it is easier to handle and install because of its lightweight if compared to traditional materials.

In the same way, acrylic has been more than a part of art and lighting design, the high transmission of light for LED fixtures, signage lightings, and twilight installations are the end results of turning it into a lamp manufacturing material. The even distribution of light is another characteristic of the material that contributes to visual delight and power saving. Which are both crucial factors in the design world of today. Thus, these novel applications show how acrylic remains the material that redefines the limits of modern design, thus fulfilling the need for change as regards to functionality, ecology, and beauty.

Exploring the Versatility of Acrylic Plastic

Why Manufacturers Prefer Acrylic in their Materials

Acrylic plastic is known in manufacturing for the outstanding blend of mechanical properties, versatility, and aesthetic aspects that it offers. Acrylic is the best in the business when it comes to impact resistance; it is at least ten times tougher than glass. Due to its safety and long lifespan, acrylic gets the nod in situations where strength and safety are the priority. The material is also very transparent; a perfect transparency is also possible depending on the thickness and the quality of the extrusion. It is quite common to see it in lenses, screens, and signage due to this property; in some cases, it is even lesser the impact of glass.

In terms of ease of cutting, machining, and molding, acrylic is definitely on the positive side, allowing the precision required for design specifications with little to no wastage. This being, the variant is always the first choice in the automobile and construction industry to electronics and medical equipment sectors. In addition, the polymers that are formed by using chemical acids live much longer than the surrounding environment, therefore, many manufacturers see the use of the polymer in different department as a good lasting material for both inside and outside perimeters still they will not discount the benefits of environmental protection and health of their operation and industrial activities that often involve use of chemicals.

Furthermore, being a strong but lightweight material makes the item easier to have and more desirable at the same time. Also, the ability to recycle the products made from the same material strengthens the manufacturer’s commitment to doing business in a way that is not harmful to the environment. by reducing the oil and gas requirement, the manufacturers have lower expenses and additionally, the cost of the end product will be lower due to the use of fewer resources. It seems that the chemical and other allied industries and the environment are getting into a rather beneficial relationship with one another.

The Acrylic Production and Environmental Implications

Enormous concern has been raised over the sustainability and environmental consequences of the production of acrylic, focusing mainly on its complete life cycle from its creation to the time it is disposed of. This material, which constitutes the main portion of polymethyl methacrylate (PMMA), is mainly pulled out of fossil fuels. This fact is the root of all the criticisms against it, coming from as its main natural source is limited. The acrylic production process is also very energy-consuming and Vocs (volatile organic compounds) like formaldehyde, benzene and toluene may be released causing air pollution. In addition, disposal of the acrylic materials may be difficult, as the material is non-biodegradable and it may even end up in the landfills, leaving a huge burden on the environment in the long run.

In mitigation of these worries, the latest advancements in the manufacturing sector tend to amp up the green side of tape. So, now, to begin with, it can be mentioned of how recycling technologies have been recently developed such that the chemical processes make it possible for us to have the PMMA back as monomers and go on and on this way, as a result, reducing waste; the whole processing is then a closed-loop recycling system. Moreover, bio-based feedstock sourcing is another area of activity for the manufacturers that contribute to the goal of not using fossil fuels thus producing a lower overall carbon footprint. But the problem is that even with these great steps forward by the producers, the economic and the logistical constraints limit the adoption of the methods by a greater production sector. Therefore, earnest addressing of the challenges is a must so that the goals of the day for the environment in the acrylic sector can be fully realized.

Future Trends in Acrylic Manufacturing

It is expected that the future of acrylic manufacturing would be greatly influenced by the improvement in technology, material science, and environmental policies. One of the major trends is the growing automation and artificial intelligence are making production lines more responsive and efficient, with the help of the introduction of the latest technology. Consequently, the precision of the process is further improved and the waste generation in production is minimized which along with the other benefits will increase the energy usage when the final product is one of the advantages. Additionally, there is a possibility for the development of advanced catalysts which would make polymerization more efficient and because of this, the energy requirements would decrease and byproduct formation would also be lessened to a greater extent.

In terms of materials, one of the main research objects is the use of renewable materials and bio-based monomers in place of the petroleum-derived materials. Also, carbon capture and utilization processes that are under development can be very beneficial. They offer another possibility to reduce emissions from acrylic production by utilizing carbon dioxide as part of the manufacturing process. Additionally, there are a remarkable number of efforts in the area of circular economy which are primarily responsible for the new acrylic recycling methodologies. A particular process, depolymerization, which receives much notice on the grounds of its ability to change the acrylic waste back to its monomeric forms for the second use is a very commendable initiative.

The manufacturers are increasingly moving towards the use of eco-certifications and are also improving their product life cycle assessments (LCA) at the same time, under the influence of regulations and customer demands. The steps are in agreement with the ecosystem targets around the world as well as those that direct the industry’s research and development. With the assistance of solving the issues that come from the hurdles that are mentioned earlier in the article – that is, the present economic and logistical constraints – these movements are portraying the industry and not to mention the acrylic manufacturing realm that is both sustainable and technologically advanced simultaneously now rather than later.

Final Thoughts on Acrylic Production and Usage

The information on the production of acrylic products can be seen to be briefly as follows: the process is very complicated and it is a mixture of the most recent chemical technology and the conservation of nature, while it has to adapt to the changing world standards on global manufacturer. Polymethyl methacrylate (PMMA) is the main representative of the acrylic materials and the leads to the production of this polymer is by polymerization of methyl methacrylate (MMA) – a process that has definitely gone through many improvements in its efficiency and environment-friendliness. The end consumers are now starting to choose environmentally friendly raw materials more and more and the industries are trying to change the directions in which the energy is being consumed, for instance, the use of fossil fuels is being replaced by the recycling of MMA through the depolymerization process. These ways not only decrease the impact on nature but also preserve resources, by being part of the “circular economy” philosophy.

Moreover, the sector is being pulled to adopt certifications such as ISO 14001 and guide the entrance of complete life cycle assessments (LCA) in product design not only by the stick of regulatory pressures but also by the carrot of positive eco-aware consumerism. The former, in turn, provides the necessary balance of being able to identify environmental areas with the greatest impact and the latter makes sure that the accurate decision is made. R&D is trying to steer away from using fossil and petrochemical raw materials by putting emphasis on bio-based or renewable feedstocks and at the same time seeking out new catalyst systems that will not only have a lower carbon footprint but also be more efficient in energy use. This new set of ideas states that it is starting to be complied with and realized more and more that it is not possible for industrial scalability to be achieved without ecological responsibility at the same time.

In general, the acrylic industry is a perfect example of how the development of technology and a focus on environmental conservation can be side by side. With features like recycling systems, novel polymerization techniques, and following of strict environmental laws, the acrylic manufacturing is turning to the direction of a more sustainable future, at the same time, though, the materials remain the same in durability, transparency, and versatility, thus making them the favorite in different industries.

Resources for Further Learning about Acrylic Plastics

To enhance my acquaintance with acrylic plastics, I would begin with exhaustive guides offered by reputed industry sources. The American Chemistry Council (ACC) is one of the organizations that offers long documents with a lot of details about the most current developments in plastic production with acrylic being one of the main materials. They cover the areas of polymer science, sustainability, and regulation, thus, they have rich authoritative information. Likewise, the Royal Society of Chemistry (RSC) provides a lot of materials that can be used for scholarly articles and a wide range of other purposes related to the study of the chemical structure, properties, and production methods of acrylic plastics.

The Plastics Industry Association (PLASTICS) is yet another remarkable source that is often recognized for the reports they produce on trends, and also innovating the usage of plastics, such as the adoption of practices like closed-loop recycling systems. One can get to know about the present troubles and advancements in acrylic manufacturing through their webinars and white papers. Further, entities like ASTM International come up with and provide the testing and specification standards for the acrylic materials which are very much needed to be known before their application in different scenarios.

Finally, Coursera and edX are some of the online educational platforms that provide classes on material science, polymer chemistry, and sustainable manufacturing. For developing a more profound background knowledge, as well as for keeping abreast of the newest research and industrial practices, these classes play a vital role. Using all the channels I mentioned, I would be able to make use of the technical and authoritative resources and get a clearer idea of what acrylic plastics are, what they mean to today’s industries, and what the possibility of using them as ecologically friendly materials is.

Reference Sources

- Working with Acrylic – Caltech

Provides insights into the properties and handling of acrylic materials. - Vinyl Polymers Containing Acrylic Acid – University of Minnesota

Discusses the synthesis of acrylic acid and its applications in polymer production. - Research and Prospect of Acrylic Polyester Resin – PubMed Central

Highlights the importance of acrylic polyester resin in various industries due to its mechanical strength. - A New Concept of Biocatalytic Synthesis of Acrylic – ScienceDirect

Explores innovative methods for synthesizing acrylic monomers for industrial use.

Frequently Asked Questions (FAQs)

How is acrylic manufactured? What’s the difference in the manufacturing process between cast and extruded acrylic sheets?

The origin of the polymer materials is acrylic, and it is obtained through the polymerization reaction where methyl methacrylate (MMA) substance changes into polymethyl methacrylate (PMMA) long-chain polymers. Amalgamated acrylic is solidified by means of pouring MMA monomer containing initiates into the cavities where the resins set and that fulfills the necessity of cracking high optical clarity and good chemical resistance. Additionally, the method used in extrusion production for extruded acrylic sheets is to heat acrylic and push it through a die in an extrusion line; this process is less costly and may have slightly lower optical clarity than cast acrylic. The choice of both, the chemical composition of acrylic plastics and the specific manufacturing process have the ability to modify properties such as impact resistance and other mechanical attributes. Knowing how acrylic is bulk made will further clarify why cast acrylic is in most cases opted for high-quality applications while extruded acrylic is chosen for cost-sensitive projects.

How are acrylics made and what is the process of manufacturing the product?

The acrylic production process is mainly made up of batch casting or continuous extrusion methods. In the former, a solution of MMA with additives is poured into molds which get polymerized resulting in thick plates of good transparency and dimensionally stable. In the case of extrusion, the material is melted and then pushed through a die to make sheets so its rapid and consistent production is best suited for acrylic plastic sheet making at industrial scale. The operations of both methods also need the materializing of the temperature and cooling, moreover the heating and the cooling is carefully controlled for the best results. The acrylic production comparatively environment friendly by the efficient acrylic fabrication and end-use scenarios and yet the final acrylic properties, including the suitability for certain manufacturing and other, are strongly conditioned by the decisions taken during production.

How come PMMA is the base material for acrylic, and what has made acrylic the most common plastic material?

Acrylic is sometimes also referred to as PMMA, which is a polymer derived from methyl methacrylate and made through a process that produces a see-through material with an almost-perfect degree of transparency. Aside from being a plastic, acrylic is a material that can deal with impact quite well when compared to glass, it also weighs less, and does not discolor with UV stabilizers. High-quality acrylic panels are the typical applications where acrylic is being extensively used because of its optical and chemical properties. Acrylic is even less costly than the majority of the specialty engineering plastics, while at the same time, it gives a good mix of mechanical characteristics and, additionally, is very easy to fabricate, like by means of laser cutting. All these factors combined contribute to the popularity of acrylic within various industries.

Please explain the process of making cast acrylic sheets and the reason cast acrylic is frequently preferred for high-quality applications?

Manufacturing of acrylic sheets starts by the pouring of liquid methyl methacrylate into molds and the polymerization process is allowed to finish gradually which results in sheets with long polymer chains and optical clarity of high quality. A fewer number of internal stresses and a much smoother and more refined finish are some of the features that make cast acrylic the perfect choice for premium signage, aquariums, and optical components. Cast acrylic is also very easy to work with during acrylic fabrication, besides it being very receptive to polishing and thermoforming. Yet it is more commonly applied in those units where strength and looks are of primary concern due to its high mechanical properties and resistance to chemical attack. The individual end product made from acrylic is highly desirable for its high quality and uniform performance.

What is the significance of the process of extrusion in the production of acrylic, and how are the sheets of extruded acrylic made?

Extrusion is a process of forming a product, usually a sheet of plastic, by forcing a plastic melt through a die, and then the sheet is cooled and solidified as it moves along the line. This enables the production of acrylic efficiently and consistently. The sheets of acrylic produced by the extrusion process are rapidly manufactured and as a rule, cheaper, and, therefore, they are used in large areas like glazing, point-of-sale displays and construction segments. Although extruded acrylic may have a little less clarity than cast acrylic, it is still clear, strong, and used widely in many applications where both the cost and the thickness are required to be uniform. Moreover, the process of extrusion is the main reason for the appearance of flexible acrylic sheets manufacture as well as large runs of uniform thickness, which are then the starting mostly with several other acrylic fabricating processes. The final design of the product should focus on the features such as the optical clarity, the impact resistance, and the size of the produced batch before selecting either extrusion or casting.

Which physical characteristics are the outcomes of the acrylic manufacturing? How is acrylic applied in different industries?

Acrylic’s production procedure brings about a plastic that is transparent and has a very high optical quality not to mention that it is very much resistant to cracking on impact and to all types of chemicals. Therefore, it is the best choice for many industries as it is very flexible since it can be used as windows, lighting equipment, medical and signage. That is mainly because of the strong and light combined properties of acrylic along with the possibility of laser cutting, other fabrication processes. The use of acrylic polymers with the admixture of UV stabilizers and other additives could be an efficient way to kill two birds with one stone – to meet the requirements of the weather- and the sun- that is to make the material UV resistant and at the same time to get the material that is aesthetically pleasing and not too expensive for the outdoor application. Acrylic also comes as an engineering plastic alternative in soprano cases where the use of acrylic is prevailing in the balance of cost, performance, and looks. The plastic is so easy to work on that entire contrivance could be produced even while going through machined and polished edges and surfaces.