Rock tumbling: when you take rugged rocks sand turn them to shiny and color stones is not something only artisans and jewelers fancy but it is likewise a dear process that has been appreciated over time. Nevertheless, perfection is not easily obtained and sometimes it is the choice of rocks to wear and the quality of the stones in question which becomes the pivotal difference. Out these plastic pellets have emerged as a very key inflating factor offering unique advantages for accelerated production, stone protection and fine work. This piece will therefore delve into the enabling technology i.e. plastic pallets, also gives the advantage and the essence of how they are acquired as well as they help in creating jewelry, Typically the potential of plastic which is so crafted, and so found, is much. No matter the classification one puts you in, be an old-time knower or a novice ready to dive in, an appropriate recognition of the importance of this neglect stuff might even give your artistic works an extra something of these worrying consequences that measures up those previous reckonings_worth less.

Introduction to Rock Tumbling and Its Materials

What is Rock Tumbling?

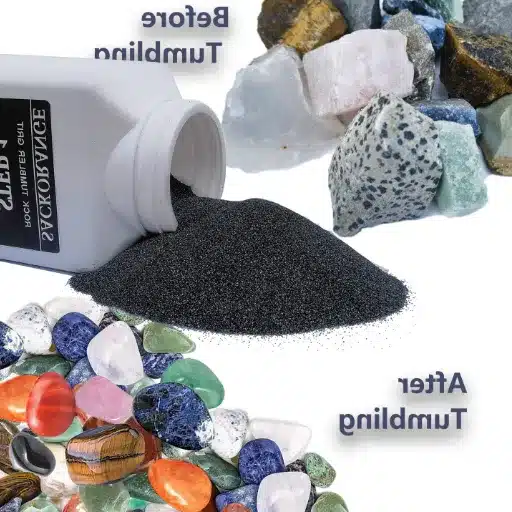

The process of rock tumbling refers to a method that is used as a part of the process of shaping and polishing raw rocks into beautifully shaped stones. It is turning to be such a popular way that widely involves randomly shaped rocks being placed inside a tumbler together with water and grains wearing the rocks in the process of rotation. This is a method that is used in nature when stones that are in riverbeds or along the shores of bodies of water are polished. And the way it usually proceeds in the case of stone tumbling, a standard cycle follows that includes three stages of grinding as well as one stage of polishing, respectively. However, as each state has increasingly smaller particles in it, the grinding material becomes finer. While using this method, it is actually quite possible to work with rocks by increasing their gloss and smoothness enough for them to be used as gems, art pieces, or a hobby. It is important to note that rock tumbling not only relies on certain apparatus – rotary or vibratory tumblers but also requires a knowledge of materials which include rock suceptibilities and particle sizes and other materials such as plastic pellets, which helps fabricate and protect the surface while obtaining consistent results.

The Role of Tumbling Media

In the effective completion of a tumble finishing process, much emphasis is placed on the utilizations of the tumble media. These may be elements in various shapes chemical bodies in ceramics, and polymer pellets; and/or metal shots, which powers can serve for a variety of purposes during tumbling. One of the core functions of the tumble media is helping to introduce and spread the abrasive grit and ensure continuous interaction with rock and stones so that all parts are uniformly worn. Different cleaning options are there, and they focus on slighty abrasive cleaning phase. Just like the use of media in tumbling serves a purpose also, that is the absence of contact and that there is something soft between the hard stones, risking breaking them or chipping them. The need for that includes the strength of the stone being processed, the acceptable grade of finish, and the step of stone transport, whether there is stock removal, polishing or burnishing. The problem of association and functional integration of media, grits, and stones in question has to be thoroughly resolved to meet targeted precision and repeatability of performance, inevitably bringing attention to the critical importance of a well-guided approach to selection and use of media.

Overview of Different Types of Tumbling Media

While ceramic tumbling media is not the only appealing substitute; it can be considered a prevalent type, as it boasts of numerous lovable characteristics and quality. Combined from various morphologies of clay plus an array of abrasives, it removes material quite well in various techniques from super heavy burr removing to super noiseless polishing. Ceramic media is not only made in the shapes of cowries; it comes as prisms of various types such as pyramids, cylinders or cones to account for the given surface forms on specific parts. The degree of density and powder purity of the media materials can be adjusted to suit what is being processed. Moreover, the mediaretaining grooves and wrinkles can be altered to accommodate a whole range of asperity materials such as metal, plastics and even ceramics themselves. Solving the problem of very rough and uneven surface finish of the item being polished, hypothetical down to machine level, can be a real trial and even impossible unless the perfect combination of the grit sizes and shapes is found. Ceramic media also has a high recycling potential and the wear and tear properties are also purposeful making tiles and gemstones much more useful to those willing to part with some money for longer operations.

Understanding Plastic Pellets for Rock Tumbling

What are Plastic Pellets?

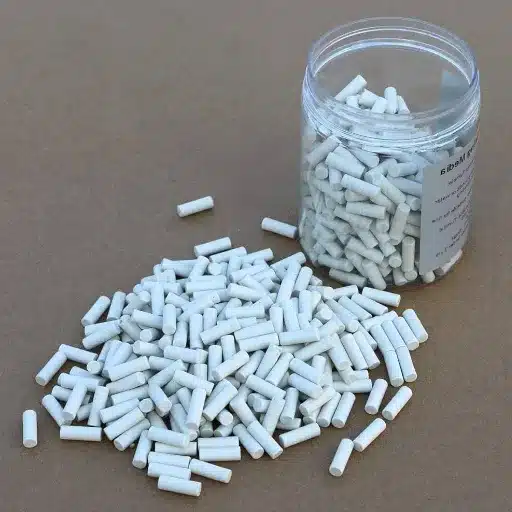

Under normal circumstances, the plastic pellets that always occurs are found in the form of small beads encased in cylindrical rubber form spaces. These pellets have multiple properties, although their primary purpose is to minimize bumping of the rocks and thus effectively reduce overworking of the machine and ensure that the tumbling rubbles are coated fairly. Made out of materials for instance polyethylene or polypropylene, these are plastic spheres possess light weight and are dense. Moreover, the application of water in this process is not an issue because they are made of aqueous material. There are many other reasons why in particular those size of the stones I que they adore are not suitable. For instance those plastic pellets that are only used for the tumbling of jewelry are thin, light, and easy to wash and re-use. By improving chips distribution, the poly beads however helps in even grinding and polishing especially once in a while where bigger stones are concerned.

Types of Plastic Pellets Used in Tumbling

Material type, size, the exclusion of some properties but presence of others appropriate for particular technique such as tumbling are the possible features differentiating plastic pellets for tumbling. Polyethylene pellets and polypropylene pellets are rolls usually used in the process for the fact that they cover a wide surface because they are durable.

Polyethylene Pellets: Whereas Polyethylene pellets tend to be lightweight and that is the use where they are rather flexible for there use.[Informative Sentences 2] These are suitable for instances where soft or otherwise less aggressive stones are being employed, yanga it helps in milimilising the damage caused. [Informative Sentences 3] Besides it chemical resistance enhances the use of polyethylene in certain tumbling applications among them in fine specialized pollution blends.

Polypropylene Pellets: These are especially valued for their increased density meaning that it also has a relatively much higher melting point as compared to its common competititors. For this particular reason, they are preferred for heavy duty operations that involve high friction forces especially in cases where the component can be in use and then taken out and re-used. They are commonly used in instances where harder stones are being tumbled or where more abrasive components are being polished, the high wear resistance property stops these from wearing out the first few cycles.

High Density Plastic Pellets: it is particularly for heavy duty operations, needed to add a greater weight onto the rolling stones for the tumbler to remain balance and steady. Thick enough material to keep the stones surface cells from jumping into all the small gaps where the water only saturates some of the stones in the metal pot.

Recycled Plastic Pellets: The following incorporates certain operations employing separation tactics aimed at the achievement of plastic pellets recycling for tumbling purposes. Human-driven systems using apparently recyclable materials could easily be re-designed; a composting program is one direction that could be looked at to manage this excess.

As mentioned earlier all these different groups result from the unique properties of the granules, which further encourages the manufacturers to improve the material feedstock parameters.

Benefits of Using Plastic Pellets as Tumbling Media

When it comes to the plastic pellets used in tumbling, they have such certain advantages as being of a light weight, having uniform composition and also being flexible. It’s the fact that their weight is low serves this processing particularly well when the parts are fragile or any other quoted materials are of such sensitive nature that they can be broken or cracked by heavier surfaces such as glass and ceramics. Besides, plastic pellets are of relatively the same sizes and shapes such that they can be spread over a surface in an average way without getting thick anywhere on the contour- resulting in even and predictable removal or polishing of matter.

Aside from that, plastic granules have high resistance to shattering and breaking in a state of stress, thus ensuring long service life and saving on operating expenses. They are applicable to either wet or dry process making it easier for the users to shift tasks. Recent development in materials sciences has given the new plastic granules added features and thus customized them to have a bit of hardness that can be work on at the industries floor almost without wearing out the manufactured product. Recycling and reusing plastic granules in production guarantees operational efficiency and environmental protection, reducing operational costs and ensuring operational and environmental compliance in place as soon as possible.

Comparing Plastic Pellets to Other Tumbling Media

Plastic vs. Ceramic Tumbling Media

In industrial finishing processes, plastic and ceramic media have their own unique functions to the parameters of usage and restrictions. Plastic ensures the vast malleability and weight compared to other media including ceramics. This property is most desirable when it comes to fragile parts even the ones made of less durable materials such as plastics or some other composites. The lower the abrasion is the less the chances of the part’s integrity being compromised significantly during the removal of burrs or sharp edges. Moreover, lower density leads to reduction in loads of machines as well, allowing to postpone the effects of depreciation on them.

Grinding and polishing grains are lightweight plastic media used in vibratory and mass finishing processes for deburring normally soft materials such as. Metallic ceramic media, on the other hand, has an edge with its much higher hardness and is preferred for more demanding applications such as, preparing and covering hard materials such as steel or cast iron. With a high degree of toughness, the material guarantees long service life even under extreme conditions, consistent with the expected lifespan of the material. Nonetheless, considering this, the increased mass as opposed to the less mass already present in plastic media may erode the machines faster. The use of plastic or ceramic procedural products will also be influenced by the composition of the materials that are under tooling, the standard of finishes desired, as well as the propensity to remove the finishing properties of devices and conform actual performance to the intended function. It is indispensable that both these media classes are applied in the realm of precision manufacturing to effectively cater for the needs of various industries.

Cost-Effectiveness of Plastic Pellets

When it comes to practicality, plastic media beads have become a popular choice for industrial uses, owing to their strength, ease of use, and application without limitations. In virtually every area of engineering, plastic washer/grommet/wedge pellets may be applied with a relatively high degree of deliberation. They are, more often than not, the expensive solution unless newly designed, for the entire processes targeting cost minimization. Besides that, they are also light in weight, thus further enhancing the cost reduction opportunities in their operation as there is little or no total aids in the operation dysfunction due to pushing and vibrations during the tumbling or vibratory finishing process. Plastic pellets also have extremely low wear Wear Levels lest as they are not really cataclastic in nature like ceramic media does and as such can be used with the softer materials of, for example, aluminum, brass, or plastic for finish purposes. Such durability makes it possible to save money since there is no term such as “economic life” for the product. Also, the amount of waste plastic shot is small and is easy to handle and hence, does not require much expense as far as waste disposal is concerned. All these compounded factors are what drives the preference of plastic pellets over any other alternatives for those who seek to also maintain financial prudence while maintaining performance.

Durability and Longevity of Plastic Pellets

The fact that plastic pellets do not easily break can be accounted for the fact that potentially, the type of polymer used in making the pellets as well as the pellets internal structure are so constituted that it maximizes its resistance to wear, pounding and reactions on the environment which can affect oils. Advancements in polymer engineering have also made it possible to prepare extreme energy absorption which is very essential and particularly suitable plastic composites. For instance, PEEK [Polyetheretherketone] and PTFE [Polytetrafluoroethylene] are some of the high-performance engineering plastics, which have high thermal and chemical resistance, and can be used even in harsh and difficult environments.

Moreover, many tests and surveys have come to a conclusion that over time, plastic pellets do not lose their functionality even while under continuous heavy loads. According to the studied data, parts worked out of a better quality plastic of the pellets’ level are less prone to material decay by about 30% within the styles, in comparison to the parts made out of traditional materials, such as metal and wood. Plastic pellets are the most excellent for use where parts are intended to be effective for a long time such as in the automotive, aerospace, or other manufacturing industries. Various applications progress the provisions of these granules through coevolution with material science advances which would enhance the efficiency and sustainability looks different from other cases or applications.

How to Use Plastic Pellets in Your Rock Tumbler

Setting Up Your Rock Tumbler with Plastic Pellets

One of the keys to getting the best possible performance from a rock tumbler is to put the plastic pellets in it appropriately. It is possible to do this by working out how much of the pellets are suitable to be placed alongside the stones in the tumbler with respect to its capacity. The suggested ratio is 30%-50% but, the waistline is well taken care of in that although they are healthy, they hardly tend to that extent. At the same time, check the cleanliness and the condition of the pellets before inserting them in the tumbler – cycolac pellets that have already been utilized must not have cracks or even any material stuck in them, which would spoil the effect of re-polishing.

Please be very careful to put sand and small stones into the tumbler in the right order and add a suitable abrasive or polishing powder depending on the tumbling phase. Also, make sure to screw in the barrel lid without any gaps because this is one of the best ways to avoid any spills while tumbling. Another important thing to do is to check the behavior during the rotation process as well as the sound levels associated with tumbling; due to this, if there is more than a little shake, consider increasing the rock-to-pellet ration to curb tumbler efficiency. It is planned that if such equipment is well maintained regularly and whenever it is not in use, together with the pellets, tumbling barrels will serve for a much longer time and have better results.

Best Practices for Effective Tumbling

It is imperative to get the rocks which will be used in making tumbling machines to be as close in hardness as possible when judged in terms of the MOHS scale. This will even the wear and tear on the rocks and prevent softer ones from being also spoilt on the inside. Another technical consideration is to always clean the rocks at the material limit and check if there are any cracks or contaminants before adding them in a tumbler.

As regards a reliable history, stick to a tumbling timetable by working for the correct amount of time on each stage from breaking in, to course grind, medium grind, fine grind, to wave or polish—that ranges from one day to a week depending on who is manipulating the material. Then before Teflon, be sure to check that the slurry is taking on the correct consistency so that the mandatory force is regulated while machining and the collecting of any waste is minimized.

The issue of excessive heat arises in an extreme case when the processing speeds lead to the generation of heat that weakens the barrel or changes polishing compounds. In order to prevent this, please ensure that the device is rested every now and then especially if it works for a long period of time. Applicable application of the mentioned side should help in improving the tumbling process thus making it perform better than them, giving finer finishing of products.

Cleaning and Maintaining Your Tumbler Media

It is important that a proper procedure is used while cleaning and keeping tumbler media in order to ensure its good working condition and a longer service life. When cleaning any medium, the media is carefully removed from the litter, soil or stoppage that may compromise the efficiency of the blending process. This should be done via a mesh kit or filter created to fit the size of the medium. When that is done the media is washed with sanitation until any cling compound is removed. There are mild detergent like dishwashing soap that can be used when the strains are obstinate overtime provided they change the nature of the media.

In addition, it is important that media is also checked regularly for wear and tear, to recognize any symptoms of the same. It should be understood that media which loses its shape that is, when it becomes round a hobnob, or is cracked or is excessively used, reduces the efficiency of the tumbling process and is required to be replaced. It is further suggested that care should be taken to store media in a dry place to avoid corrosion or the growth of mildew. Here the above maintenance measures will enable tumbler media to perform gel with less variations in operational performance and better outcomes and in the same breath they will also be able to extend the lifetime period in which they can fasten materials.

Creative Applications of Plastic Pellets in Crafting

Using Plastic Pellets in Jewelry Making

In my view, plastic granules have proved very well to be an inventive and revolutionary element in jewelry manufacture. They can be fused together and molded into any form necessary for example as hanging pieces, balls, or other decorations. These chips have a relatively low density which makes them an appropriate material for making eye catching necklaces and bracelets. Moreover, many are even enhanced such that they come with various rainbow variations good for drastic patterns or even non extreme, simple designs. Be it in its single material state or when partnered with the syndetic oppositions of metal or wood, infuses a whole new dimension into self-made jewelry.

There are lots of tricks that I liked, but one of them—apparently from the beginning—turned out to be the most effective in resin-based creatives. I find it more interesting to include simple little items such as flowers or leaves, metal foil, and other trivial items or small photographs in the resin along with the addition of plastic beads as the components of the material limiting the use of the material. In addition to their aesthetics, it is good to also remember this because the beads can easily be worn to make the jewelry last longer. Also, designers who work with plastic like this are the use of some plastic beads which are made out of recycled materials, hence they are safe environmentally and still of good quality.

I’ve got to say the larger part of glass ceiling simply decreased in a number of pieces, because now I can also use such material as plastic pellets for my jewelry. It doesn’t matter how the technique may be, as long as these plastic granules can be easily built into objects. They must have numerous thoughts or plans to start modern materials like plastic pellets, the limitless scope this proves in crafting.

Innovative Projects with Rock Tumbling Media

Rock tumbling media is perfect for all creative and practical purposes. I must say – and this is the professionals’ opinion – it is not just a polisher, however, it also has equal importance when practicing delicate precision work. In particular, ceramics or some other plastics, as pumice can be used to provide finishing to materials that want to achieve a balance between beauty and strength. About such media, it is easy to notice that they are very useful for small scale industries such as polishing of metal jewelry or removing burrs from metal parts. A selection mistake in this case is unacceptable as it affects the final result of the work.

Believe it or not, rock tumbling no longer takes place in rock shops and workshops strictly for the purpose of polishing, but also has found its way into home and art decoration in the best possible form of media. I know this because There are methods to use stones as decoration in a magnificent glass chest or as designed pieces which is the modern trend. Such designers and architects add these elements such as ceramics to the third dimension while working on sculptures and construction. Ceramic beads are hard wearing and at the same time lightweight. That is why they are excellent when it comes to rigid, yet flexible structures in the construction.

Taking advantage of the use of rock tumbling media also ties in with the principles of modern minimal computation crafting. They come in forms such as ceramics, plastics and much more and are quite reusable across other projects making it possible to eliminate the redundant materials. Well, for all those who love exploring artistic approaches that emphasize themes of usefulness, rock tumbling media opens up new exciting frontiers. The beauty of these substances is that they can withstand anything, making them a very good arsenal for every rising artist or crafter.

Combining Plastic Pellets with Natural Stones

When it comes to rock tumbling or similar crafts that involves both sand and gravel materials, I am quite certain of how I should combine the plastic pellets and natural stones, in order to employ the materials beneficially for both operational and aesthetic purposes. The pellets are used to protect the stones, which prevents the possibility of the stones being worn down, chipped or cracked during processing. An in addition to that, these pellets help in balancing the stones and materials within the drum from the tumbler and hence there will be even and less disturbing movements and undue noise. In this case the pellets are quite handy since when mixed with an abrasive grit there is less rapidness in the tumbling process, which is more important for supervisors too much grinding of stones especially the softer and/or fragile stones.

When working with the media T, both the size and type of plastic pellets utilized become an important factor or consideration. The advantage of small pellets is that they work well with the stages of polishing with a finer abrasive slurry which would penetrate into the small spaces between the stones. On the other hand, large size pellets are more applicable for the first processes when one needs to perform a thorough tumbling due to the good cushioning that these pellets offer. With that, I run a clean and tidy work environment by taking all necessary precautions to clean the plastic pellets in between steps. In principle, plastic pellets are resuable but they should be cleaned if only dust from other stages of processing has good potential to mix up and spoil the end result the consumer gets. That is, regular cleaning is important.

I combine plastic pellets and natural stones to enhance the efficiency of the tumbling process and to produce a higher quality finish and sheen. Casting these materials together allows me to work with the assurance that both raw stones are left in their natural form and the tumbler will work as it should. This presents a good proportion of doing the task correctly while showing off any craftsmanship, even though, as in other projects it maybe, all about coming out with new concepts.

Reference Sources

- Rock Tumbling Guide – Evergreen State College. This guide discusses the reuse of plastic pellets and their role in cushioning rocks during the tumbling process.

- Rocks Final Document – Evergreen State College. It highlights the environmental impact and alternative uses of plastic pellets in rock tumbling.

- Geology – University of Minnesota. This document explains how plastic pellets help maintain the volume and protect stones during tumbling.

Frequently Asked Questions (FAQs)

What are these Polishing Plastic Media, and how to use them in rock tumbling?

Other than their widely promoted names such as poly pellets or plastic poly pellets, the primary role of plastic polishing beads is that they cushion the weak points of the stones while they are turned over in the tumbler. They aid in the improvement of the tumbling action by expanding into all the open spaces in the rock tumbler, thus reducing the volumes of force and minimizing the cracking of fragile stones. These pellets are usually nontoxic and can be washed and reused; moreover, there is a big variety of pellets available that do not generate any heat so that they can be driable after washing. Use of plastic rock media also means you don’t have to use so much grit at certain stages, although you will still have to conserve grit for the finishing phase. Many tumblers use the measurements of lbs plastic media rock tumbling measurements to determine how much will fill the empty spaces for an equal tumbling effort.

How do methods like the use of pellets dampen the tumbling process in comparison to just using particles of pebbles?

Involving plastic pellets while carrying out the tumbling process brings about more control of the motion. As a result, breakages can be reduced and the duration of tumbling fixed at certain stages is put an end. Tumbling media plastic fillers plastic pellets are possible to stop them from from banging against one another and causing unwanted wear and tear, especially with some types of sensitive stones. Nevertheless, it is important to still provide enough grit for cuts and the polish operation because pellets are primarily used for reducing friction rather than cutting agents. Some plastic filler pellets and bead plastic fillers can be used in a self or a floating sequence that allows for easy removal, but instructions are given regarding separation methods. On the whole, the practice of using grit alternatively and incorporating pebble media or pellets into the practice proves to be more beneficial and feasible.

Are acrylic acid-polymethacrylate-based abrasive media materials safe and biologically safe for personal use?

Although conclusions on the safety of plastic media in tumbling machines owned by hobbyists can be drawn, major concerns can be raised concerning plastic materials that might be undesirable for the purpose of hobby tumbling. First, this author has never used a tumbler for this purpose so cannot comment on its abilities or effectiveness compared to tumbling with silicon carbide grit. It is possible that using coarse grit cleaning teeth as a media for effective tumbling may be conducive to scratching, although it is certainly not ideal for anion-based media. Work in various fillers that have higher flatness or coarseness produced good surface finishes with other media, but in this case soft waxes or rubber flock will be utilized. Always remember to immediately rinse and dry the pellets sprayed with abrasives or grit, in order to avert converting these particles into chips rather than coarse debris.

Can you safely use plastic in your craft tumbler?

Often, plastics like the pellets used making tumblers are biodegradable. However, the majority of pellets contain polyurethane plastics. In case there will be any animals used, then dialysed urine is preferred. The use of polypropylene plastics also extends to production of glass beads. That is how crazy and beneficial the use of plastic has been! Moreover, when every other option except the purchase and installation of new sink top is untenable one than getting a stove top without a sink fitted isn’t also an attractive alternative. What about these instead of dreading that the granite countertops could be full of stains, scratches or that one would need to blemish the masterpiece of their kitchen by trying to match the kitchen appliances with the colors and lines of the granite?

How do I select the best plastic poly pellets and bead tumbling media for my rock tumbler?

Traditionally, pick the poly plastic pellets based on the capacity of the tumbler, the softness and compassion of the stones particularly the polish, and whether the filler is designed as one shot filler for re-use over multiple cycles. For small stones or stones of irregular shapes, smaller pellets rock tumbling media plastic filler will be more accommodating, while larger pellets will serve best as a general filler to aid in the preservation of the large stones. Look for pellets that are described non-static and non-residue and make sure that they are capable of standing up to moisture, harsh conditions and if they are safe to clean and reuse, dry, and predominantly non-toxic. Consider the run limit and if tanks having pellets that can be floated and “tipped out” are what you need or denser pellets to remain adhered in one position. With the recommended volumes—most articles recommend the use of rock tumbler fillers in a certain amount to comply with the maximum protection and the polishing requirement.

Will plastic pellets change the outcome of the one of the steps of tumbling, i.e. will pellets affect grit?

Platic balls, being soft when compared to abrasives, serve more as a filler rather than a replacement of e.g. grit or other abrasive. This means one should still use cutting / three-body abrasive or polishing grit instead of using only these beads. However, their use can be beneficial; for example, protecting the subject against high impact velocity crushing hence avoiding macro chip formation and enhancing better surface integrity suitable for a good final polish. As Dresser-type pistol as applied to chert and gypsum and including rock-abrasion during these activities is greatly reduced by the constant immersion of the sample in water, the rocks pull apart with minimum wear. Hence in some situations one discovers that if you use milder abrasives or more aggressive ones but for shorter stages, it is still possible to compromise between high performance and time. The method will also enable one to be less intensive in tasks of simple coarse grinding for pebbles, stones, or gravels. 이겁사라, translates to After each grade of grit use these, has a step to clear the stone and beads respectively of abrasive contamination and cleanness is essential to improve the performance of the beads and help in their effectiveness. Proper pairing of plastic balls with selected grading of hardness allows to prevent damage to fragile items while achieving uniform finish.