Current state of the art in development of advanced and sustainable engineering polymers has made Polyphenylene Sulfide (PPS) plastics a fast emerging material in the field. High-performance attributes such as a very good thermal stability, excellent chemical resistance, and superior mechanical properties of PPS, make this material most applied in various sectors including, but not limited to, automotive and electronics. However, its benefits are not only confined to the structural features of the material and it is now well-appreciated that PPS, owing to its distinctive properties further entails that its use facilitates in such that there is reduced weight in addition to energy savings and enhanced product life. In this article, we will focus on understanding how pps plastic has been instrumental to such innovation within design as well as causes and effects of such advancements on the environment. We will be answering questions like what makes it a wonder material and how it is worth to be used from the perspective of the industrial changes happening at the time as well as preparing for a future influenced by eco-materials technology.

Understanding PPS and Polyphenylene Sulfide

What is PPS Plastic?

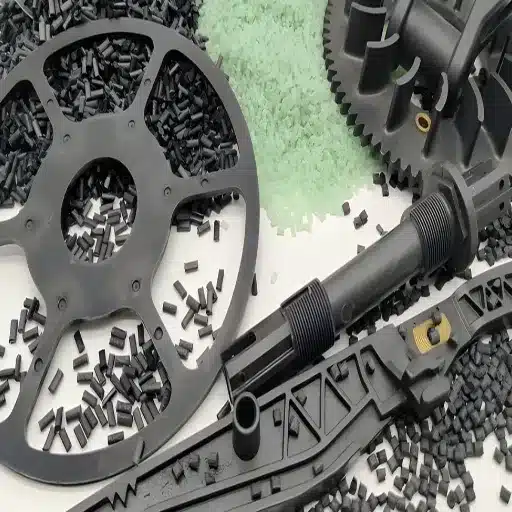

Polyphenylene sulfide (PPS) is a high-performance engineering plastic that is known for exceptional rigidity, superior chemical weathering resistance and superior high temperature resistance. This material is partially crystalline, extremely tough, and resistant to chemical breakdown as it is made of a heavily cross-linked molecular chain. Such a feature allows the polymer to keep all its strength and shape at excessive loads. In addition, due to the history of chemical production it is known that PPS plastics can withstand any chemicals, including all acids, alkalis, and organic solvents. It should be noted that PPS has advantages of good dielectric strength and low coefficient of friction which further extends its compatibility. It is these exceptional properties which make the plastic so indispensable in other industries like automotive, electronics, aero-space or/and chemical industries which demand maximum stability and efficiency for their components.

Chemical Structure of Polyphenylene Sulfide

A semi-crystalline polymer, polyphenylene sulfide (PPS), is known for its molecular structure that consists separately of phenylene rings with connections of sulfur atoms. This polymer has a chemical composition of (C6H4S)n, where the degree of polymerization is defined by “n”. In the PPS structure, the used aromatics appear to be perfectly conjugated and, therefore, very stable, whereas sulfur containing groups act as connecting bridges rendering the structure flexible and robust apart from the side chains that are also attached. Particularly, highly crystalline regions of PPS enable the production of materials for use at temperatures exceeding 200oC and under good thermal stability. The resultant balance of structure and properties, expression of percentage of crystallinity and presence of aromatic rings, also contribute to this resistance and toughness property of PPS and as a result it is commonly used in high performance requirements.

History and Development of PPS Materials

A historical perspective conveys the early days of PPS in the 1960s in which the new polymer was synthesized and put on the market as a high-tech material. This material was first made available by the Monsanto Company in 1967, and under its own brand; this polymer was pioneered as Ryton®. This involved the copolymerization of p-dichlorobenzene with sodium sulfide in a high boiling solvent (N-methyl pyrrolidone) at high temperature to achieve the polymer in a highly crystalline and essentially rigid state. It turned out to be one of the first thermoplastics with high performance characteristics comparable to conventional thermosets. In the very beginning, polyphenylene sulfide target sectors concentrated electrical and automotive due to convenience in use and exceptional aging properties – thermostability, resistance to chemical agents and fire inhibitor activity.

Over the course of numerous years, an array of notable improvements and refinements in PPS production technologies has seen the light of day. Among significant accomplishments are the introduction of PPS modifications including crosslinked-and linear type in order then to cope with particular operational conditions, which has resulted in an advance in impact strength and processability of the material. It is the glass-fiber and mineral-filled grades that have made the material suitable for use in such industries as aerospace, medical, and semiconductor manufacturing. Along with new approaches to assembling processes-continuous polymerization, for instance, PPS conversions for the future have also been reconsidered in such a way that the processing of the product is cheaper and the quality is more repeatable. In the present time PPS can be safely said that it continues to be an important material at easily a higher than normal temperatures that is impermeable to causing gases, for stress service industries.

PPS Material Properties and Advantages

Thermal and Chemical Resistance of PPS

Polyphenylene Sulfide (PPS) is often considered to be among the best due to its excellent temperature and corrosive resistant tendencies which make it the appropriate material for unfriendly surroundings. Even when exposed to high temperatures, PPS retains its shape and performs excellently in this area with most applications considering 200°C (392°F) as the upper radial. There are certain special conditions where the temperature allowed rises since enhanced grades are fabricated having an extended operation window which offers more mechanical and thermal shielding properties.

PPS, on the other hand, with respect to its chemical properties, has been found to be be remarkable in withstanding a wide range of organic and inorganic solvents, acids and alkalis. This resistance has been attributed to the type of the polymer which is the poly aromatics and the linkages of the polymer that contain S in nature, that are high energy, have great chemical bonding and weakens the material even less on exposure to a corrosive substance. Additionally, because of PPS reduce corrosion and oxidations; it is beneficial in regions wherein it is constantly explosed to elements like water and excessive air such as vehicle exhaust stystems and in chemical plant.

The material’s ability to withstand simultaneous exposure to high temperatures in aggressive chemical solutions has helped improve its usage in several sectors. This has been underlined by the durability of the material in withstanding thermal and chemical effects in such conditions and contributing to the extended use of these materials in several industries. PPS compounds from this century and PPS reinforcement in such resistance additive technologies are making great strides in boosting performance for latest high-tech applications and can now be considered almost essential.

Mechanical Properties of PPS Polymer

A material that is polyphenylene sulfide (PPS) is largely known for having commendable properties in terms of Eing. Some of such include tensile with a higher rank in most other materials (applaud). Typically ribs ranging from 70 – 110 MPa can be found with reinforcing. The fibers like glass or carbon will in most cases increase the tensile strength. Haus stiffness and shapes of the polymer grades after reinforcement is that included surpasses 3 GPa.

One major exceptional quality about PPS is its excellent temperature-related creep as well as its high strength within the proposed peak load or temperature threshold. This makes it suitable for use in applications where long term holiday exists in the load obly. Added to the fact that this polymer can handle such loads released at 115 C or even higher present load and it do not impose restrictions and warpage can also be controlled; there is water attacked or moisture conditions. In fact, during environmental testing such as the soak test it was found that the polymer had only absorbed 0.02% of the total volume of water present in the test materials. Its impact toughness and resistance to fatigue add to the qualities that assure they will be rate of within limit (safe) dynami load conditions.

These material performance characteristics, in addition to the good thermal behavior of the material itself, consolidate Polyphenylene Sulphide (PPS) as a key polymer for automotive, spacecraft and other engineering fields. Future developments in fiber and polymer improvements keep on increasing their outlook with success in the evolving industrial sectors.

Lightweight Characteristics of PPS Products

Polyphenylene sulfide, otherwise known as PPS is a polymer that has a thin frame and whose structure needs a low density, this increases the efficiency of its application in any development work. It is because of the materials low density of 1.3-1.4 g/cm³ makes it favorable in comparison to traditional metallic materials that can weigh up to fifty percent more, for instance, and have the density of the likes of aluminum and stainless steel. This material reduction is known for its advantages in industries such as space, and land transportation where there is less energy consumption to do work and self-weight reduction means the real displacement capacity will be almost equal to the paid displacement.

Growth in the usage of PPS based components is also as a result of the improvement in manufacturing technique. Incorporation of glass or carbon fiber reinforcement results in a reduction in the thickness of the component being produced without losing or even increasing the mechanical strength and stiffness required. Such modifications allows for the use of less material hence less cost to the manufacturers and eventually consumers while offering better quality solution.

Aside from being lightweight, the PPS products I also filled with also match the sustainability pronouncements of today. The percentage of material and the amount of energy needed in production and servicing the goods and materials is decreased – so the ‘liquid’ carbon released to create these items is mitigated enabling the population to feel the comfort of such materials un sparingly; as a result, such materials are being more and more employed in environmentally responsible engineering. This feature explains why PPS is more sought after in industrial models of the day devoted to weight saving technological evolution.

PPS Manufacturing Process

Overview of PPS Polymer Production

High quality and performance without any deviations in such attributes, were thus very important in the production of it. This polymer is mainly made as a result of the reaction between sodium sulfide and dichlorobenzene in a polar solvent like N-methyl-2-pyrrolidone (NMP). This reaction results in sulfur based polymer, which is responsible for the PPS’s resistant to heat and chemical attack.

With modifications to the manufacturing process due to technological advancements, the production efficiency has greatly improved including the maximization of polymer purity and reducing atmospheric pollutants. Such improvements would incorporate the use of alcohol extraction systems, and the focus on application of exact parameters for minimizing undesired side reactions. Moreover, various technologies are applied for the purpose of bettering strength characteristics to conform to specific requirements of the fuse locations in cars or high-tech gadgets with the least mass content. These enhanced techniques have been formulated not only to the quality expectations of the performance of PPS but more importantly its impact in the environment.

Injection Molding and PPS Applications

Polyphenylene sulfide (PPS) is a specialized engineering polymer that is often referred to as a high-performance engineering plastic. It is used in a wide range of demanding applications due to its excellent properties such as high temperature capabilities, flame retardation, high chemical resistance, high dielectric constant etc. The unique features of PPS which make it very suitable for molding or extrusion applications are its good mechanical properties especially the flexural and tensile modulus.

The implementation of an efficient programming system (PPS) is applied across a multitude of sectors related to injection molding as the material is very resistant to chemicals, and operates at elevated temperatures, and the mechanical performance is of high quality. Specifically, in the automobile industry, PPS is commonly used for the production of components for the engine, its fuel and electrical systems sections that are designed to withstand long hours of working conditions even in the case of changes in temperature. Likewise, when it comes to the electrical and electronics industries, PPS is employed for molding effortlessly molded, non-brittle pieces like connectors and housings for mother boards, which are at least a flame retardant. As a bonus, it is resistant to aggressive chemicals which is good for such water systems and pump materials. All these applications speak volumes about its suitability for use in demanding areas, characterized by numerous challenges.

Advancements in PPS Manufacturing Techniques

Over the previous years, a lot of effort has gone into improving the properties of polyphenylene sulfide, which has turned out to be the rate-limiting label in respect of adaptability of these materials among engineering plastics. One of the most noticeable improvements regarding the construction process of these compounds is the introduction of continuous polycondensation technology, which gives an opportunity to regulate the top layer and the polymer lattice across perfectly. The contemplated modifications in the process geometry equally resulted in a robust increase in the tensile and high temperature properties of the PPS resins to most of the end users. Lastly, the precision of flexible manufacturing systems with regard to the design and manufacture of moulds, sub-assemblies and the subsequent assembly process capability improvements has had a dramatic impact in the reduction of non-usable parts in each of these activities.

There is an additional development that demands special attention as it represents the application of reinforcing fibres and so forth during the compounding process that significantly improves the strength-to-weight ratio and impact resistance of PPS. Especially, this introduction has significantly made the light weight without durability compromise necessary materials in the aerospace and automotive sectors economically efficient in social use. Also improvement in the additives and the fillers, as well as compatibilization of their composition, has favorably helped in expanding the application of PPS to new environments while introducing advanced new mini blends that last longer and can withstand rough use in situations such as high frictional and high moisture areas.

Moreover, continuous advancements and developments in eco-friendly solvents and catalysts aimed at diminishing the environmental implications of PPS production is an area of interest. These developments also fall within the context of international endeavours to encourage sustainable industrial development without undermining the high level of precision and quality control. Taken together, these advancements can be judged as comprising of a step ahead in PPS technology and even go further to portray the advantages of such a modern material in the engineering applications.

PPS Applications Across Industries

Aerospace and Automotive Uses of PPS

In the fields of aeronautical engineering and automotive construction, polyphenylene sulfide (PPS) has become a most common substance due to its high thermal integrity, barriers against chemicals and high mechanical properties. At the same time furthermore, in the aerospace industry use the same PPS, but it is incorporated in the case of high temperature electrical connectors, airplane, wall panels, roofs and columns, hot and hazardous material chambers as wel and others. Indeed, the very reason why it istonsorbents and can be used in the fabric of skin sample inflatables, is its ant-threfous, flame and restraint quality at very high temperatures, where foiled failure is not an acceptable scenario.

Similarly, in the Automotive field, various vehicle components such as fuel system elements, network compartments, and transmissions among others have been doing a lot of work using PPS. This material, exempt from any effect of the most commonly used in vehicles oils and coolants, such as PPS, totally guarantees that its workings will be resilient under harsh conditions. In the same respect, PPS has been instrumental in the design of technological components with particular emphasis on functionality for a new greener era car designs which affect weight distribution and fuel consumption. Its use in advanced driver-assistance systems (ADAS) and electronic control units (ECUs) on the other hand just goes to show how it goes a long way to meet the current trends in the motor industry; more and more consumers are looking for technologically powerful and robust automotive solutions. In this context, the absence of these properties greatly constrains the utilization of PPS in the field of aerospace and automotive engineering.

Electronics and Electrical Applications of PPS

Users found a modern printed circuit board, medium and high voltage switches and high frequency electrical circuits that solidified its main use so far. What properties of this polymer which makes it ideal for pressure bore applications such as in pipelines and jacketing is reiterated. This has enormously experienced a boost in the quest to maintain high electrical conductivity of the systems. Surpassing the limitations of a basic physical x-ray it involves 3D imaging of the body in any plane rather than just the trans-axial plane as in CT and PET.

It is evident that the development of advanced thermoplastic materials, engineering thermoplastics in particular, is the most productive progress in the field of material science within the past 20-30 years. Such advances have allowed for the production of PPS reinforced with glass and carbon fibers ensuring increased stiffness and strength specific to the material. With the extended use of these composites in electronics, particularly the more fragile components such as circuit boards, power devices and LED enclosures, where reduction of weight and heat is of extrene importance, it is very important according to the offer provided. In addition, PPS materials are also used in the cleantech and automarket segments – renewable power generation and EVs, fabrication of battery packs, transformer cooling, motor design, etc. – and here ensuring the suitable performance under conditions of high current intensity and voltage is a must. From the practical point of view, PPS is meeting the growing needs of the contemporary electronic systems, offering unapproached performance, dependability and versatility, and thus is crucial for the traditional systems and those which are just emerging.

Medical Applications of PPS Plastic

The use of Polyphenylene sulfide (PPS) plastic in medical applications is essential as this material fascinates to everyone with its excellent mechanical, chemical and biocompatible properties. Medical device manufactures often use PPS in the most challenging and performance demanding applications. The ability of PPS to resists repeated sterilization, including autoclave and gamma radiation, does not only ensure proper functionality for a longer time, but also reduces risk of medical accidents. Also, another application is the making of surgical tools, diagnostic equipment, and fluid management systems due to excellent resistance to dimension changes and capability to withstand even very aggressive chemical disinfectants. Thanks to all these properties, PPS material is highly ranked when it comes to servicing in high-risk healthcare facilities, promoting treatment results, and increasing effectiveness of healthcare facilities.

The Future of PPS Plastic and 3D Printing

Innovations in 3D Printing with PPS Materials

Elucidation of this; manipulating Polyphenylene sulfide (PPS) within 3D printing has met with a number of possibilities which are quite ground-breaking in the pace of technology’s manufacturing development and ideal for certain advanced materials. PPS does possess notch (high thermal, chemical, and flame) features but it is majorly used in such industries like aerospace, automotive, healthcare, etc. It is thanks to the researched establishment of PPS-containing filaments and progressive bonding material and additive technologies that it is possible for manufacturers to utilize distinct chemical features of PPS and build specially designed items of intricate shapes with durable PPS having functionality that was not possible previously with conventional technologies.

One of the more significant advancements I observed is the way in which printer equipment and materials are managed to accommodate the elevated operational temperatures demanded by PPS filament. For now, the industrial grade 3D printers used for processing high performance thermoplastics are only introduced with advanced heating chambers and nozzle with suitable accuracy enabling no material cracking and high adherence force of layers. Besides that, attention has been paid to issues that could potentially cause complications – an example of such issues includes the development of warping and cool-down stress in PPS.

Various techniques and strategies have been implemented to enhance the quality of these advanced 3D products. For example, computer modeling is now used to optimize the component’s design and eliminate as much of the PPS component as possible. Instead PPS morphologies that are readily employable as engineering components are formulated by combining several polymer chemistries as mixtures, reactive blends, and fillers. With these changes, the mechanical properties of their 3D printed articles will be significantly better than of the parts made only of the neat PPS.

The potential of using PPS to 3D-print a part is not only about shrinking costs- it also includes cutting the lead time and achieving a level of flexibility in supporting different processes. I anticipate this tool to develop further especially as improvements in materials and innovations in the field of 3D printing happen, enhancing the applications of PPS in sectors where high performance and high dependability are vital.

Potential for Sustainability in PPS Manufacturing

Based on the data I obtained, I can make a statement that the concept of sustainable development in polyphenylene sulfide production is gaining popularity as manufacturers strive to address new standards with minimum pollution of the environment. New recycling techniques appear favorable; because they make it possible for PPS to be salvaged and reused that would have otherwise gone into the ground as garbage. More importantly, there are manufacturing and processing techniques such as the closed-loop systems which allow reprocessing PPS waste into usable material for the manufacturing of new parts thereby minimizing virgin material use. This improves with tol sustainable yard. No need to discuss biological feedstocks in this information.

Given the above, it is here that we consider the improvement in the manufacturing sector, also in terms of the reduction in energy use, which is obtainable through energy efficient houses. Thanks to precision extrusion- and polymerization techniques tailored for the effective use of the energy seevral pps producing activities begin to decrease in carbon dioxide emissions. These developments are working hand in hand with 3D printing and other attempts to minimize waste through what is termed green manufacturing – allowing PPS materials in formulation to further benefit in enhanced environmental performance. I am expecting that incorporating these kinds of advances with the global push to develop responsible supply chains will result in increasingly ‘greener’ methods of PPS manufacturing without sacrificing the qualities of the material.

The future requires cooperation among stakeholders in the field of materials, production and legislative discourse to successfully implement sustainable practices. Increased funding in research and innovation mechanisms, especially when coupled with new awareness and support from the administration for eco-friendly production systems, can only expedite the change. PPS can enhance sustainability in technology and shift the impulse beyond clean technologies to sustainable engineering of mineral and raw materials.

Challenges and Opportunities in PPS Plastic Development

Talking from personal experience, I think that one of the issues associated with the PPS type is achieving the right balance between elemental properties and the environmental and other impact aspects. Polyphenylene Sulfide, or PPS, is a material well-known for its strength at high temperatures and resistance to attack by solvents and chemicals, and is used in extreme applications such as automobile parts, aircraft sections, and electronic devices. The PPS is also identified as being an environmental problem because the methods used for its manufacturing involve particular substances, and energy uses, which make environmentalist wbdo recognize the negative effects of PPS, particularly at a time, the world wants to practice more of green technology. This article argues that there is a need for more research in order to identify other sources of PPS and include recycled contents without sacrificing the performance requirements in view of its high performance in the specific uses or applications such as those mentioned above.

Besides the challenges discussed above, there are issues having to do with easy expanding and making products at a reduced cost. Though this new material is very much needed in a number of businesses, costs associated with PPS manufacturing can restrict large portion of the industries where cost of materials is crucial. In order to address that, the use of production techniques permitting faster and more efficient environments, such as rentless processes and their automation can reduce the costs and increase the market. Policy actors can also be part of achieving this goal by promoting greener substitutes for PPS which will also rank I the market and with sustainable technical progress.

In contrast, there are plenty of outstanding prospects to look forward to. The enhanced need for products with greater technological properties especially in respect of the automotive and aerospace industries is beneficial for PPS plastics since light materials are developed which help to save fuel and also account for reduction of carbon footprints. Furthermore, the tendency to make electronic systems smaller also contains scope of PPS solutions wherein its dimensional stability and electrical resistant properties have the optimum performance. Elimination of possible drawbacks alongside enhancing further development and feasibility of PPS materials in environmentally friendly cost effective manner, especially in products that have a high level of performance features is what I am convinced PPS polymers can bring.

Reference Sources

- A Review on Research, Application, Processing, and Recycling of PPS-Based Materials | Academia.edu – Explores the properties, applications, and recycling of PPS plastic in engineering.

- Innovative Use of Wood-Plastic-Composites (WPC) | Harvard ADS – Discusses sustainable materials, including composites that incorporate PPS plastic.

- Biodegradability of Plastics | Arizona State University Library – Examines the environmental impact and sustainability of various plastics, including PPS.

Frequently Asked Questions (FAQs)

What are the important PPS characteristics when it comes to thermal stability and heat resistance?

Polyphenylene Sulfide also known as PPS, is one of the high performance thermoplastics that exhibits a high level of thermal stability as well as heat stability with use temperatures of close to 200 degrees C and a high melting point. Fortunately, its molecular structure enables its proper functioning at elevated temperatures wherein both thermal and creep resistance properties are high even under stress. PPS is almost unique in its thermal properties as it has a very low CTE and exceptional dimensional stability giving very perfect tolerances in very high tech moulded parts. Several of the PPS grades have retardant properties such as meeting the average UL94 V-0 classification or its natural ability to just resist burning from the sides especially where V-0 rating is important for the electrical circuits and components. PPS is a class of material that is not only a good thermal insulation but also has the properties of inhibiting burning and as such it can be used in situations where there is heat resistance.

In which aspect is PPS used with regard to the electrical insulation and thermal performance?

PPS is known for its exceptional electrical insulating properties which makes it a choice material for many components with designed insulation capabilities even under very high temperatures; that is in elevated temperature applications. With rated flammability of V-O that compliances to Uli94 covers some of the mixture formulations that are essential for electronics and electric industry. The semicrystalline structure of PPS, accompanied with its high thermal stability, ensures that once the component is made, its electrical insulation qualities will be preserved even under the increasing effect of temperature over time. The use of some neat PPS resins provides moderate electrical insulation and mechanical strength to suits a targeted application. As a result, the PPS does not fail to offer high degree of electrical insulation while at the same time offering high thermal and flame resistances in the high end applications.

What are the properties that maintain the stability of PPS and that make it suitable for precise tolerances?

PPS is a semi-crystalline material which has no moisture absorption and has excellent dimensional stability, this greatly reduces moisture related swelling and any other variations. Low CTE (Coefficient of Thermal Expansion) and similar CTE (Linear Thermal Expansion Coefficient) values at various temperatures, respectively, provide consistency of dimensional stability. Such stability allows for the achievement and maintenance of tight tolerances besides enabling the provision of strength in precise components. In addition, the presence of the glass transition temperature as well as high melting temperature is essential to avoid any distortion in the component structures when subjected to thermal loads. For applications where performance standards in terms of tolerances and long-term stability are high, particularly in the automotive sector, PPS takes precedence as the preferred engineering plastic.

What kind of chemical resistance does pps resin have?

Despite its exceptional performance against chemical attacks, PPS is resistant to many solvents, fuels, and alkalies, as well as not participating in reactions with sodium sulfide in most cases. Due to its distinctive features, it can be useful in working conditions where the existing mechanical properties of the polymer need to be retained, and there is a strong presence of aggressive chemicals. PPS also reveals minimum moisture intake and lesser hydrolytic decumination as compared to several other polymer substances. Various grades of pps, ranging from virgin PPS to the pore grades in conjunction with specializing the chemical and thermal results for specific service, are available includes PPS glass filled. The outstanding chemistry resistance of PPS makes it a reliable choice for demanding industrial applications.

How are the processing methods of pps affected by its mechanical and thermal properties?

Processing of PPS is conducted under high-temperature conditions because PPS is characterized by a high melting point and a high thermal stability. Molding and extrusion, for example, are usually carried out at higher processing temperatures, stripe edges, however is rarely an appropriate solution due to poor final quality of the bond. In some applications Solvent or moisture absorption may be expected, and therefor drying of PPS is included in the process but PPS is not hygroscopic and does not absorb moisture. Processing under such tight tolerances and for such demanding applications means that processing parameters are optimized for the delivery of exceptional dimensional control and low coefficient of thermal expansion. The molecule morphology and the melting point of the semi-crystalline do matter in the crystallization, and consequently their effects on the tensile and wear properties are observed. An appropriate selection of pps resin and the sets of process parameters are directly related to parts with excellent structural and performance properties.

What are some examples of applications demanding in pps with supporting reason?

PPS is commonly employed industries such as metal applications and fabrics, gas and electric applications, platform and engines applications because it has high heat and high chemical resistances. Due to its synergistic fire retardancy, v-0 rating and superior insulation resistance, it does not melt, drip or produce toxic smoke in electrical/electronic applications. PPS also possesses high chemical resistance and all wear and tear, and can withstand heavy environments for a long time. On condition of various pps, including unfilled pps and wiff’ receiving grades this permit the optimization of mechanical characteristics (mield properties and resistance to deformation) with the needs of process requirements. Hence, PPS encompasses thermal, thermophysical, and mechanical exceptional polymer enhancing a good quality work for production.