3D printing has radically reshaped and revolutionized the manner in which manufacturing takes place, ensuring that the precision, clockwork and customized abilities reach their zenith. One of the materials that are available for this kind of manufacture is that one which is made using ABS (Acrylonitrile Butadiene Styrene) pellets. These have become more popular in the industrial sector. This is because they are strong, easy to work with, heat resistant and above all economical when it comes to producing the end product thereby clearing the usual bottlenecks that affect such industries. It is also essential to understand the nature of the work done by these materials over the years and notably the advantages of the ABS pellets within the ambit of 3D printing. The current need for lean manufacturing processes in which every activity across the value chain is optimized has increased the importance of incorporating efficiency improvements in 3D printing. Find out how incorporating ABS pellets could help you with industrial 3D printing demands, as there is an increasing TOWS analysis chart.

Understanding ABS Pellets and Their Properties

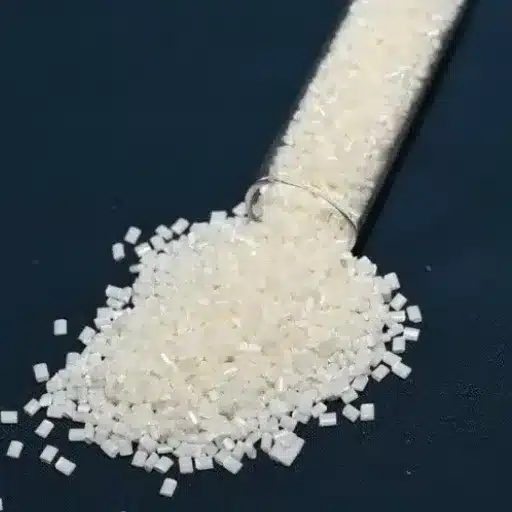

What are ABS Pellets?

Acrylonitrile butadiene styrene is a thermoplastic polymer of acrylonitrile butadiene, and styrene with remarkable physical properties and strength. It has a basic chemical compos4rose of ar19lonitrile, butadiene and styrene. The pellets are engineered to have the perfect balance of strength, flexibility and heat resistance. The presence of the acrylonitrile in the polymer is responsible for the chemical strength and resistance in the acrylonitrile butadiene styrene material. However, the butadiene makes the material tensile while the styrene enhances stiffness in the material leading to good surfaces. They are used in industrial 3D printing because of their low melting and molding temperatures, and they can form good particle-filled composites due to their very good inter-layer adhesion1. Moreover, the fact that they can be remolded and reshaped without significant loss of their physical properties explains why flexural forecast and short-run production activities usually favor utilizing the available material at the expense of iron and steel.

Physical Properties of ABS Plastic Pellets

ABS pellets, short for Acrylonitrile Butadiene Styrene Plastic, are a type of material that is of great significance in industrial set-ups because of its peculiar physical properties. One of the most prominent features is the ability to withstand a high level of sudden stress safely which, to a large extent, is fibrillated butadiene in the polymer compound…. This does not only mean that barrels and crack Propagation will not occur but that energy will be absorbed. Like in the case of development- prone structures: aspects of performance have been progressively explored.

ABS material also has the advantages of tensile properties, being 29 to 50 MPa normally depending on the composition. This confers its use in structural elements/ components even under variable or dynamic/fatigue loading conditions. On the other hand, as compared to other polymers, weight and transportation costs are reduced due to the lesser weight of the polymer with the approximate density ranging from 1.04to 1.07 g/cm3. The density is [quite critical] for production of quality components as it influences [the strength of the material] that can be achieved.

Another important feature is the dimensional stability of ABS. Most polymers shrink upon processing but in the case of ABS the shrinkage is low. One of the tangible benefits this possibility brings is a greater level of precision and infallibility in products that are moulded. So it goes without saying that the material also boast of thermal stability with test results showing that the heat distortion temperatures often reaches 90˚C or more under given conditions. This enables the material to withstand normal operating temperatures at moderate levels of temperature effectively.

ABS pellets provide beautiful surface finish upon processing as a result of the material, which is predominantly composed of styrene. Making them the best material for both low profile and decorative uses, as well as subsequent treatments such as painting and electro-plating. Moreover, large scale consumption of these continues as they do not swell in semiaquaeous solutions of basic and acidic inaculum, and several hypodermic oils.

We see that the plastic under consideration is the thermoplastic as it is classified as ABS that also is an amorphous type of plastic and it has moderate tenacity against the ultraviolet rays as tat is the case with most plastics, and possesses a number of desirable qualities which include being a good insulator especially for extrusion projects of an electrical nature as well as for outdoor products components thereof. It is important to note, that when all of the above indicated characteristics are combined, they make the ABS pellets to be the best material for almost all industries.

Comparison with Other Plastic Pellets

While comparing ABS to materials like PP, PE, and PC, the specific characteristics of the ABS plastic become more and more prominent. It is easier to work with, has more toughness, and is stiff as opposed to other materials which are usually chosen for their durability and economy. However, the known polycarbonate or PC offers both a better impact strength and optical clarity, there, on the other hand, this introduction of lower cost and less difficult to process material – ABS makes more sense and is more social among injection mold users since it is easier and cheaper to use.

In addition, ABS has better performance compared to less rigid thermoplastics such as PE in terms of dimensional stability and thermal resistance. Indeed, ABS has the advantage, for example, of not losing strength in the presence of heat and is ideal in automotive or electronic compartments while PE would tend to yield or break down under the same conditions. When compared to PC, ABS becomes more attractive even for applications that do not demand much absolute toughness or complete transparency such as 3D printing and parts for a microwave oven.

All these various qualities illustrate the value of ABS plastic grade as an extremely important materia, managing to occupy a middle position between cost and performance measures for an extensive assortment of customer and Medical services.

Applications of ABS Pellets in 3D Printing

Industry Use Cases for ABS Filament

ABS Filament has proven to be a popular material in a rather wide range of industries because of its characteristics including strength, robustness and ability to resist heat. Among the most common applications is the creation of final functional parts and prototype development. For example, in their cars, vehicle manufacturers use ABS filament to create durable display pads, instrument boards and custom components which are significantly lighter yet no less strong. The easy manipulation of the material ensures additional processing such as sanding or painting which allows various tailored finishes to be created for use within the relevant industries.

This field of consumer electronics industry freely churns out casings, housing and internal parts out of T shaped objects of plastics which can easily break with regular use yet they do not loose their shape so easily. Proper application here ofcourse means that such parts as fixtures, blocks or even replacement parts made out of ABS have to be properly designed since they will for sure have to work under reasonable temperatures for a long period of time.

Adding more value to the servlet experience, particularly those outsourcing manufacturing, is the fact that high-quality finished products, say smartphone skins, will be produced. These products, which include the design of the top-notch stereo systems, shoes as well as car parts, are bound to be very popular among end users. What should be noted is that the technology does not only apply to industries as persons in academic fields and institutions find the material fit for their practices.

But of course, ABs filament’s popularity is only understandable, provided the excellent quality performance ratio and ease in use connect it with 3D printing, with those who work in this field.

Benefits of Using ABS Pellets in FDM Printing

The inclusion of ABS pellets in the technique of Fused Deposition Modeling (FDM) has several advantages, especially in projects that require high volumes and cost optimizations. The provision of ABS pellets, as opposed to already manufactured filament, allows for a remarkable cost saving due to the fact that raw pellets can usually be procured in larger quantities at a lower price. This is a major plus especially for companies or sectors that undertake quick dispense operations. Finally, pellets are better because they allow for easier modification like the addition of other components such as additives, modifiers or even changes in colors, which can be done before extrusion and hence permit enhancement in the mechanical strength, heat resistant properties or effect of finishes in the completion of the project.

Introduction to pellet-fed and other extrusion systems as opposed to the filament-fed processes allows better, much more accurate distribution of material that is also crucial for its directionality in the sample layering regime. The said also benefits extrusion processes in terms of print quality with less frequent incidences of the nozzle tip getting blocked and most outstandingly it is generally more productive than the filament-fed processes on account of the high speed of production. Besides, industrial-grade 3D printers which are normally mixed with pellets assist in reducing waste levels since a proportion of the material is not immediately converted into products and thus could still be recycled to meet set objectives. This, together with the proven performance of ABS pellets and their value positions in the 3D printing sector further drive the progress of FDM (Fused Deposition Modelling) to use more ABS pellets.

Durability and Toughness of ABS Prints

ABS (Acrylonitrile Butadiene Styrene) is popular for its high durability and toughness, with material components that are very suitable for high toughness and resilience applications. Its plasticity is due to a variety of unique features, but again its activities do not result in cracks or wear and tear, which helps in the manufacture of defied parts. The nominal tensile strength of it is usually between 30-50 MPa, with the ability to bear some repeated loads without noticeable decline. Moreover, the plastic deformation of the ABS is greatly impeded over a wide range of terrors, i.e., 20°C to 80°C, leading to a recovery which is more steadfast in various working conditions. ABS is quite long-lasting and that is why ABS prints are usually intended for the functional modeling and construction of machine parts and final products for diagnostic or household goods industries, namely cars aviation. ABS is subjected to similar in-service exposure in AM, the application of the same proven technology in the manufacture of precision plastic components, also demonstrating improving service results under difficult conditions, all advantages that make this material an ideal choice for the additive technology process, modifying mechanical properties of the material.

Processing and Delivery of ABS Pellets

Best Practices for Handling ABS Plastic Pellets

Proper storage of ABS pellets is critical in order to sustain the quality, performance and value of the material during downstream processing. To preserve quality and enhance performance, the recommended practice is to store the ABS pellets in a place that is both clean and dry with no attendant exposure to serious humidity changes. Most of all, common practice is to store the ABS material in accompany of no moisture in the air, i.e. in moisture-proof bags or in closable vessels within the environs of 20–25°C (68–77°F).

While processing, the most critical step where ABS pellets need to be dehydrolysed with use of pre-dryer in order to prevent hydrolysis and related defects in the end-product. For ABS however, the recommended drying conditions are 80-90C (176-194F) in the range of 2-4 hours in a desiccant dryer to achieve moisture content of less than 0.1%. Doing this harmonizes the melt flow pattern and minimizes chances of aesthetic defects like blisters or lack of adhesion.

Material should also adhere to the standards of cleanliness by avoiding its contact with impurities such as greasy substances, dust or oils which can compromise its performance. By applying the guidelines mentioned above, we minimize the variation in material properties, reduce waste, and have improved results with production runs of ABS. ABS material can also be voltage and mileage resistant with careful storage and drying practices also utilized.

Temperature Settings for Optimal Printing

Appropriate temperature regulation is necessary when working with Acrylonitrile Butadiene Styrene to ensure smooth and efficient printing activities. Using this material, it is recommended that printing temperatures vary between 220∘C and 250∘C, depending on the resin formulation. At these temperatures, the flow behavior of the ABS is at its optimum preventing issues related to bonding of the layers like warping and weak interlayer adhesion.

Absolutely critical in this regard is the heated bed temperature, typically set in the range of 90∘C to 110∘C so as to improve bed adhesion and prevent the dislodging of parts from the bed upon cooling. Such controlled temperature levels; such as in an enclosed printer or a chamber with temperatures between 45∘C and 60∘C, reduce such effects that mainly result from ABS warp and shrinkage. These aspects are extremely relevant in 3D printing and especially in industries that demand fine engine parts because they will require precision in the process of production.

Bulk Delivery Options for Industrial Applications

Bulk delivery alternatives exist for businesses procuring industrial-grade materials, helping them in their respective markets, while also maintaining efficiency in the system. Moreover, for 3D printing, manufacturers who deal with materials such as ABS or other thermoplastics often offer bulk supply often in terms of pellets or as spools for the purpose of use either in high volume consumption, or in certain specific settings. Certain aspects have to be in place in the design of these delivery options amongst the considerations very essential in such cases are material storages to wall safety as well as protection and damage free storage, packing material could be packed in customized packs to meet space requirements hence enhancing operational gains along with effective transportation services within narrow timelines for the material use in production.

Advanced procurement strategies frequently concentrate on traceability and adherence to specifications, insisting on materials approved by certain standards, such as ISO or AS9100 for aerospace or automotive components. Furthermore, there are suppliers who supply modern solutions which work with inventories and consumption statistics on various materials allowing the manufacturers to accurately control the consumption of materials and anticipate any wastages that might provide challenges as to the level of the factory as well as this of the level in the period. Regardless of whether such facilities are high-output assembly lines or bound manufacturing plants, the choices offered in this section support the improvement of the economics and dependability nevertheless of the kind of industry.

Environmental Considerations of ABS Materials

Carbon Footprint of ABS Pellets vs. Other Materials

While determining the amount of CO₂ produced from the composition of ABS pellets in comparison to other materials, certain aspects must be taken into account including the energy requirements involved in production, the resulting emissions through its life cycle, as well as its disposal. Making of ABS is generally laborious because the polymerization particularly requires petrochemicals that are not renewable to be effective. While Still, it i sthe perceptions of some studies that manfacturing ABS is responsible for an estimated 3.5 to 4.5 kg of the global warming carbon dioxide equivalent VOC to each kg of the material manufacturered.

On the other hand, such as polypropylene (PP) or high-density polyethylene (HDPE) materials come along with slightly reduced effects on the environment, averaging from 1.5 to 3.0 kilograms of co2 per kilogram of the material, production process dependent. In contrast, the tough and non-brittle ABS is longer-lasting, which in this case helps to cancel out the emissions. Also, the improved methods in recycling are making the loop of ABS’s use smaller which results in less production of the virgin material, saving the environment hence.

In conclusion, the consuming ceiling of ABS is different from that of other materials not just because of the mechanisms at the end of each chain. It is also affected by the parameters these products are obtained by, logistics and disposition of waste used materials, waste stage and overall recycling system hierarchy, which underscores the relevance of detailed lcas focused on product choice.

Recycling Options for ABS Plastic

There exists a long history as process known as mechanical recycling in the utilization of ABS plastic waste. This operation entails the actual collection, separation, preparation, and comminution of ABS materials to granules or flakes that can possibly be fed back to the processing streams. As to mechanical recycling, it is necessary to remember that the quality itself of the material is expensive to build as cross contamination by other polymers or with additives will impair the performance properties of the recycled ABS. This is the reason why improved methods such as NIR and AI are now being used to achieve high yields in recycling. Here, construction and application of advanced sensors raise the major concern. Decking up the recycled materials with virgin materials such as ABS would become essential to reinstate specific mechanical properties but this approach would limit the application in the absence of a further development in new techniques of processing of these materials.

Future Trends in Sustainable ABS Manufacturing

Sustainable production of the ABS material has advanced greatly in recent printing methods, such as with the chemical recycling processes. ABS is a polymer that is deeper cut into its monomers and thus the resultant product obtained is more pure. In other words, the process has more overtures to circularity than the traditional mechanical reprocessing as there is little to no decrease in material quality at each run. In the creation of such resins, even the thermal degradation is minimized. The development continues on bio-based ABS plastic stemming from natural products like bioethanol seeking to reduce carbon footprints as opposed to ABS plastic produced from traditional petrochemicals. Other areas of concern are the search for low energy input polymerization techniques as well as the quest for the green solvents during the manufacturing process – all these aim at clearing the mess created upon the environment. This convergence of available technological advances and further motivation in the form of imposed regulations, industry is likely to change the way ABS is produced and maintained going into the next few decades.

The Future of ABS Pellets in Additive Manufacturing

Summarizing Key Benefits

ABS (Acrylonitrile Butadiene Styrene) pellets remain a key component in the 3D printing process, at least according to my research, owing to the near-perfect combination of mechanical characteristics, thermal resistance, and ease of processing inherent in them. One notable benefit of ABS is its high tensile strength: the material is highly resistant to external forces, which means that it can be applied even for designing rough looking models as it sustains such forces. The combination of its lightweight and yet strong form makes it applicable for various purposes like automobile parts, houseware, as well as other perfective organization means. ABS is also capable of finishing in detail as well as an application of high-gloss smooth surface that helps in different applied and the manufactured products.

An additional strengthening factor of ABS is that it can survive through the technical milling, painting or chemical polishing, which provides a higher degree of custom work quality. Rather, advances have been made in the development and production but without the inclusion of bio-based or recycled ABS. Due to the properties of ABS during packaging procedures, ABS promotes the application of newer films for energy efficiency consumption such as sheets additive manufacturing like the Fused Deposition Modelling; this enables to suppress a decrease in a process rate without the change of the material quantity. These developments show that despite the latest developments in modern efficient manufacturing, SLS is still as useful as it has always been, in promoting quick, high-quality, and environmental manufacturing.

Potential Innovations in ABS Technology

My observation of recent progress in an area of interest drives me to believe that among potential improvements in ABS there would be the most successful biobased ABS, ie acrylonitrilebutadienestyrene that is free from petrochemicals. By turning to resources of biological origin through such precursors as monomers synthesized from crops, the chemical industry help argues the case for lower carbon emission abs chips that still meet requirements of form, fit and function. Efforts are therefore directed at investigating possibilities of addition of abovementioned biologically sourced entities without compromising such desirable mechanical properties as resistance to deformation in engineering structures and tactile capability in clothing.

Another significant development is the modification of additive techniques to maxime the use of ABS. Making technological advancements with the improvement of 3D printing—most notably advanced thermal management systems, such as heated build chambers and extruders with precise layer deposition—has shown it to be effective in preventing warpage and improving the surface roughness of printed ABS prints. Incorporating functional additives, such as carbon nanotubes or glass textile, in binary ABS filaments has further improved the use of this polymer by increasing its electrical conductivity, mechanical modulus and resistance to high temperature. Furthermore, the functionalized composite materials of ABS filled with these additives have also started to be produced, in particular they are in high demand in the aerospace, healthcare and electronics industrial sectors for fabricating engineering components.

Following novel advancements in chemical recycling, it is now possible to have a self-reliant system for the handling of ABS throughout its lifecycle. Currently, there are most plausibly two strategies developed to solve the issue, which concern the pyrolysis and regenerative methods. They are focused on the enhancement of the effectiveness of the collection of recyclable parts: waste in the form of polystyrene is being transformed and reprocessed preventing performance loss. In this way, the discussed ways also apply to the issues of recycled materials in terms of plastics and the cascading use of materials. All of the above allow to suppose that due to the progress in technologies in the near future ABS has a big and as yet unexploited potential to become a rather economic and more sustainable basic engineering polymer technology.

Final Thoughts on ABS Pellets for 3D Printing

The potential of ABS pellets in boosting 3D technology is very promising in relation to environmentally sustainable development and efficiency improvement within the industry. As there has been considerable advancements in the field of polymer science lately, these pellets are more flexible, cheaper and more eco-friendly than ever before. In this regard these pellets can now be easily molded to produce heat and weather resistant products that can also be reproduced with better are into more precise dimensions during the process of printing. Moreover, such innovative approach involves a mechanism that makes the destruction of ABS even more effective, hence allowing the material to be produced again without the loss of its original characteristics. This in turn allows companies to utilize the concepts of waste reduction and the tenets of a cyclical economy in practice.

Speaking of technical progress, it is to be noted that nowadays controlling thermal features of ABS pellets is expected to be easily done with assistance of advanced printer settings and filament extrusion systems. The point is that ABS terpolymer requires determination of the working temperature range for its successful printing in 3D due to the peculiar reasons like warping and poor rock adhesion and layer delamination. Also, hybrid formulations of ABS pellets, which incorporate such components as biodegradable compounds or fibers with reinforcing properties, make it possible to change it to an even more performance-based material. These milestones are indicative of the great plasticity of ABS, which can function in a wide range of activities, from making prototypes to making final products.

In the history of 3D printing’s development, it is apparent that ABS granulates will forever play a constructive role. This is because the art and craft of making cornstarch-based formulations will be enhanced which ensures the continued presence of ABS even as the industry continues to venture into other materials. However, for those who are looking for a tried and tested covid option, ABS plastic combines performance, robustness, and eco-friendliness aspects more effectively than any other in the existing field of prototyping materials that focus on the standard procedure of adding material layer by layer to form the part.

Reference Sources

EcoPrinting: Investigating the Use of 100% Recycled ABS | University of Texas – Explores the potential of recycled ABS for FDM 3D printing and its industrial applications.

Analysis of the Mechanical Properties of 3D Printed Recycled ABS | Clemson University – Highlights the thermoplastic nature and mechanical properties of ABS for 3D printing.

Mechanical and Aerospace Engineering Theses | University of Texas at Arlington – Discusses the use of ABS pellets combined with other materials for advanced 3D printing applications.

Frequently Asked Questions (FAQs)

Can I use ABS pellets with my printer or 3D printer setup?

Yes, ABS pellets can be used in conjunction with an appropriate filament extruder or a pellet-feeding system, but a standard 3D printer where it is designed to support the use of wires cannot use them. Examine such capacities and confer the required procedures to make the physical operable conditions of your equipment were is in the melt temperature of ABS polylactic acid. Such a method allows for tolerances in such adjustments of the equipment that allow relevant additives to act in the proper manner in the automated system. Users seek to transform pellets into filament prior to playing with the parts for fine dimensional print quality purposes. Pellet machines in an industrial scale are usually heavily adopted and are most preferably used locally or in production facilities as opposed to residential ones as they exist for greater efficiency in terms of the quantities processed and durable applications.

What impacts the print quality when operating at high temperatures, compared with an extendable gen1 batch of operation and adoption?

ABS offers higher heat resistance and thermal stability in relation to PLA leading to its being used in applications such as casings for household appliances and automobile parts. The development of the extrusion process, which factors in filaments extrusion properties; melt flow or rheological properties; and adhesion of layer to layer, depends upon the extrusion temperature, bed and enclosure heaters. Problems associated with poor temperature modulation levels include defects like warpage, air entrapment and even substandard powder formation of certain extruded elements. The deprivation of such a combustible heat impacts not only the danger of breakage, but also the frown resistance and creeping properties of the parts. It is necessary to adjust temperatures and convection cooling according to the metrics and composition of the ABS material or admixture in order to achieve reproducible results.

Will I be able to achieve good fracture toughness and overall strength on parts printed with ABS pellets for the filament or direct parts.

ABS pellets of unfilled grade produced parts show rather good resistance to impact and high toughness if printed accordingly and with the right parameters of infill, making the product suitable for producing service parts and equipment, including cosplay articles. The intensity and the elastic resistance largely depend on the interlayer adhesion, the infill rate, and some surface treatments; adjustment of the correct parameters of the extrusion process serves to change the degree and cohesion value of the corresponding interface as well the mechanical performance overall. Strength deflection and high resistance to fracture can be achieved by incorporating a special masterbatch, or strengthening with impact resistant modifiers such as PC. In comparison to PLA, ABS has some good features such as more resistant to temperature and tougher as to mechanical impacts. For those strict applications first test-printed samples should be assessed to check their suitability for the task.

How do color and color changes affect the final result – Can ABS pellets be colored or made translucent?

You can incorporate color masterbatches and pigments quite well into ABS pellets which makes it possible to make filaments or molded parts of the variety and hues, colors, shades (including transparent finishes). The presence of colors in general make the material become slightly stickier during the melting process in addition copper tube bending extrusion table will help with extruding them, so some adjustments in extrusion setup may be required to achieve the desired 3D print quality. It’s essential to note that usage of darker colors in a 3D printer filament may sometimes subject the support material to greater heat as compared to lighter colors and the design may be very noticeable, hence adjustment in setting of speed especially during 3D printing and/or adjustment of the thickness of the printing layer are very crucial. The use of a good quality masterbatch resolves the problems of uneven color distribution and formation of uncolored areas. In cases such as translucent signage panels of cosmetic purposes, conduct a pilot before proceeding to mass fabrication.cast parts Appearance of samples for further evaluation and approval is recommended for these requirements.

Will ABS be easily bonded with TPU, PC or Resin for multi-component projects?

It should be noted that ABS may be incorporated within various structures with other materials albeit connecting it directly with TPU or Resin – bonding is a challenging one and may sometimes require additional design as well as adhesives or mechanical fixings owing to the different levels of adhesion and thermal expansion. Alloying of PC and additives can enhance the heat and strength of ABS, warming up the hardening conditions, while the addition of TPU only different with processing conditions. Beware that co-printing and multi-material systems involve more than just changing the 3D printer settings: filament extrusion or direct extrusion and corresponding temperature should be restricted within the material audio characteristics. It needs to be noted, however, that within each mixed combination or geometry specifications, these materials would not meet required operating standards in in automotive or cosplay applications. Conduct adhesion and stress tests with one or more combined materials to test the combination.

How much ABS do I need — is 1 kg or a pound batch practical for prototyping?

Employing an ABS pellet batch with the weight of 1 kg (2.2 lb) is most beneficial when it comes to production of objects on small size using an extrusion-based 3D printer. However, when changing infill or speed, the usage of the pellets can have some variations based on the object size. Still, with the use of containerized materials disparities are done away with and variations in batch performance are minimized. There are respective disadvantages with such smaller quantities in terms of purchasing a larger volume of masterbatches, plastic additives or custom made extrusion dies for example. In order to accurately address the requirements of the fabrication process, ensure that proper storage is unprovided any circumstances so that the quality of the pellets will not deteriorate, which is cohly quality related. One can also recommend using desiccators and obtaining feedback from the suppliers more often when necessary, especially if the material is frequently used.