Polyoxymethylene (POM), or acetal plastic, is a high-performance engineering polymer with various uses owing to its strength, stiffness, and low friction. POM can be found in everything from automotive parts to consumer electronics. However, with the increasing global focus on sustainability, the questions surrounding the recyclability and environmental impact of POM plastic have become critical. This article explores innovative waste reduction and circular manufacturing approaches by examining the challenges and opportunities POM recycling presents. We aim to clarify the role of POM in sustainability by addressing its complexities surrounding recyclability.

What is POM Plastic and Its Uses?

Polyoxymethylene (POM), or acetal, is a versatile thermoplastic with many engineering applications. Its chemical and physical properties make it resistant to moisture, chemicals, intense friction, and wear. POM is extensively used in the automotive, electronics, and manufacturing industries in the form of bearings, precision components, gears, and fasteners. Its strength and microstructural stability enable it to maintain its properties in stressed and fluctuating environmental conditions.

Understanding Polyoxymethylene and Its Properties

Polyoxymethylene (POM) ‘s exceptional mechanical and thermal characteristics have made it popular in many industries. POM’s melting point is 162 °C to 175 °C, indicating thermal stability during processes. The material possesses a high tensile strength of 60-70 MPa and a modulus of elasticity between 2.5 and 3 GPa, guaranteeing dimensional stability and durability under load. In addition, POM exhibits low creep and fatigue resistance, which is advantageous for applications involving repetitive motions in dynamic systems.

Also, POM exhibits low frictional resistance and self-lubricating traits, enhancing its effectiveness in its uses requiring wear mark reduction and smooth movement over time. In addition, POM’s resistance to solvents, oils, and weak acids assures chemical attack, preserving its function in chemically active settings. POM’s superior thermal properties and mechanical strength make it an ideal engineering plastic for challenging conditions.

Common Applications of POM Plastic in Industries

POM plastic is used in many industrial sectors because of its mechanical properties and chemical resistance. In automotive manufacturing, POM is used in fuel system parts, door locks, gear mechanisms, and seat belt components because of the mechanical stress they tolerate and fluid exposure. Moreover, POM’s low friction and high wear resistance make it ideal for precision bearings, bushings, and gears.

In the electronics industry, POM is widely used for inline plugs, switches, and other small parts needing size accuracy and electrical insulation. The material’s exceptional machinability and thermal stability make it reliable in demanding electronic assemblies.

POM is used extensively in the consumer goods industry to make zippers, handles for kitchen utensils, and conveyor belts because of its durability and long service life. These devices also require components such as pen casings for insulin and parts for surgical instruments, which need to be moisture resistant and protective against chemicals. Therefore, POM is suitable for such applications.

The same can be said of the material’s applications in manufacturing industrial machines and apparatuses. With POM, parts can be manufactured with critical accuracy, smooth surfaces, and long-term endurance in harsh conditions with high operational speeds and repetitive motion. The versatility and dependability of POM are still relied upon in contemporary manufacturing.

Comparison with Other Types of Plastic Materials

Compared to other plastic materials such as polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC), Polyoxymethylene (POM) has distinguishing features that set it apart. POM is exceptionally competitive for high-accuracy uses due to its superior mechanical strength, dimensional stability, and wear resistance. Unlike PE and PP plastics, which are considered generic, cost-efficient, and flexible, POM is specifically used where rigidity and low friction are required.

POM’s lower moisture absorption rate compared to another engineering plastic, nylon (PA), ensures steady operation in differing conditions. Nylon, for example, can lose mechanical strength when subjected to humid conditions. In contrast, POM plastics stand stronger in volatile operating environments. While PVC is excellent in chemical resistance applications, it does not have the strength or fatigue resistance that POM provides to mechanical parts stressed or used repeatedly.

POM’s characteristics are crucial for its use in highly precision-sensitive fields such as automotive, aerospace, and industrial manufacturing, where accuracy, dependability, and uniformity are pivotal.

Is POM Plastic Recyclable?

POM plastic can be termed recyclable, but the recycling process is limited due to collection, sorting, and contamination issues. It is recycled chiefly using mechanical methods, whereby clean POM waste is shredded, melted, and reformed into new products. Nevertheless, there are no widespread efforts to implement it on a larger scale, as the attempts to recycle POM rely heavily on dedicated facilities and programs for a specific industry.

Can POM Be Recycled Effectively?

There are distinct possibilities and difficulties in recycling POM (Polyoxymethylene), primarily associated with its chemical characteristics and its use in industry. One major challenge in efficient POM recycling is contamination; any slight impurities may affect the physical properties of the material during processing. Also, the most common mechanical recycling method has been known to sometimes cause irreversible decline in material quality over successive cycles, which further affects the recyclability of the material and the ability to use it for performance-grade applications.

Recent breakthroughs, though, offer new solutions to these challenges. Newer chemical recycling methods seek to depolymerize POM into its constituent monomers for potential reconversion into pristine second-generation polysaccharides. Thus, they can reduce both process sustainability and final product quality. Also, these approaches are being pursued under closed-loop systems, which have recently gained popularity in the automotive and manufacturing sectors with a heavy POM penchant. These systems simplify the capture and reprocessing of POM waste, increasing material recovery rates.

The steps above, however, have not aided in the global adoption of effective POM recycling systems. A technological shift coupled with investments and a policy change will need sustainable cross-industry collaboration to scale these practices and minimize the environmental burden of POM.

Recycling Process for Polyoxymethylene

POM (Polymer of OxyMethylene) is a semi-crystalline thermoplastic, and its recycling revolves around a few distinct steps to fully retain the material’s structure and performance. The first step is obtaining POM waste from a collection of manufacturing waste, obsolete goods, and industrial by-products. After gathering the material, POM undergoes a first sorting step, where it gets cleaned from contaminants and other polymers UNEP/SETAC.

POM waste recycling begins with sorting, followed by complete mechanical recycling, which includes washing, shredding, and drying the waste. Such extrusion processes remelt the POM pellets meter by meter. The recycled POM can be reused in manufacturing, furthering the closed-loop mechanism while improving cost efficiency. Precise mechanical engineering and automotive applications for POM demand critical features like compressive tensile strength and low friction, which advanced mechanical recycling preserves.

POM depolymerization is being explored to complement and improve basic mechanical processes, further enhancing the scope of polymethyl methacrylate recycling. Depolymerization involves breaking polymers into formaldehyde components, allowing for purification and repolymerization into new POM material. Such an approach aims towards fewer production steps, enabling closed-loop recycling and minimizing quality degradation.

These goals can be further pursued with new and emerging innovative technologies like pyrolysis or solvent-based purification for POM. Widespread industry collaboration is needed to tackle issues of high production costs and work towards better scalability.

Challenges in POM Plastic Recycling

One issue that arises in the recycling of POM (Polyoxymethylene) plastics is the material’s excessive thermal sensitivity. When POM is processed at higher temperatures, it tends to degrade and give off formaldehyde, a toxic substance. This means conventional over-temperature recycling techniques cannot be applied, and either low-temperature methods or other techniques must be developed to provide environmental and occupational safety.

POM waste streams mixed with other polymer variants and additives are another complication that can lower the quality and properties of the recycled material. NIR (Near Infrared) spectroscopy and automated systems play an important role in solving these problems, but their implementation on a large scale can be very costly.

Recycling is often hampered by the absence of properly defined, organized collection systems and infrastructure for POM waste. In contrast to more widely used plastics such as PET and HDPE, POM is not supported by a strong post-consumer recycling market, which, in turn, discourages plentiful retrieval. Forming partnerships within the industry and providing strong regulatory policies could facilitate the adoption of POM-specific closed-loop recycling systems.

What Are the Methods for Recycling POM Plastic?

Recycling POM (polyoxymethylene) plastic primarily involves two methods:

- Mechanical Recycling: This process includes collecting, cleaning, and shredding POM waste into smaller granules, which can be melted and reformed into new products. However, mechanical recycling can degrade the material properties over successive cycles.

- Chemical Recycling: This involves breaking down POM into its monomer components through processes like depolymerization. The recovered monomers can then be purified and reused to produce high-quality POM, maintaining material integrity.

These methods continually evolve to enhance efficiency and align with environmental sustainability goals.

Mechanical Recycling of POM

Mechanical recycling of polyoxymethylene (POM) is focused on reusing and reshaping the polymer without changing its chemical composition. The typical procedure is collecting, sorting, cleaning, shredding, and processing into pellets that can be molded into new products. One of the significant drawbacks of mechanical recycling for POM is the reduction in material properties like tensile strength and thermal stability over polymer chain degradation in multiple recycling loops. It has been shown that the degradation is less severe with the addition of stabilizers and chain extenders, increasing the usability of recycled POM.

Several recent studies emphasize the use of closed-loop systems and automation to enhance sorting efficiency and minimize contamination. POM is now being separated more precisely from plastic waste streams using NIR (Near-Infrared) spectroscopy. Moreover, studies focusing on the optimization of granulation processing parameters, such as temperature and shear, improve the performance of the material in question. Mechanical recycling continues to be one of the most important avenues for innovation toward greater circularity because it is widely used in industry due to the durability and precision of POM parts.

Chemical Recycling Options for Polyoxymethylene

Polyoxymethylene (POM) and polycarbonate chemical recycling can provide valuable methodologies for recovering raw materials and closing the loop on leveraging material usage. The process consists of the depolymerization of POM into its monomer, Formaldehyde, and other intermediate compounds, which can be reused to synthesize polymers. A forefront technique in chemical recycling is using thermal and catalytic processes, which have been shown to catalytically depolymerize POM within a temperature range of 200—350 °C. Furthermore, heterogeneous catalysts in zeolite and metal-based systems have shown greater selectivity and yield for these reactions.

Within the parameters of chemical recycling, reaction temperature, residence time, and even structural properties of the catalyst used all impact the success of the reaction. Moreover, new designs within the reactor also enable better control over the reaction conditions and therefore, reduce the unwanted by-products, increasing the monomer recovery rate, which is hugely beneficial for the highly contaminated POM waste streams that would otherwise prove too difficult to purify through mechanical means. The contribution of chemical recycling gracefully complements mechanical techniques and aids in improving the efficiency of resource usage, reducing the need for primary raw materials.

Innovative Recycling Solutions for POM Waste

To solve problems posed by POM waste, I merge sophisticated chemical recycling methods with standard mechanical methods. With the help of depolymerization techniques, I can convert POM into its monomeric units while separating them to a level of necessary purity, allowing the materials to be reintegrated into production cycles. I also focus on creating contamination-free, closed-loop systems that are more efficient in recovering resources, thus emphasizing more sustainable circular waste management practices.

What Is the Environmental Impact of POM Plastic Waste?

Waste in the form of POM plastics raises notable ecological concerns because of its persistent, non-biodegradable components. If POM plastic waste is not managed correctly, it contributes to long-term soil and water pollution. Also, the production and degradation of POM releases considerable volumes of formaldehyde, a toxic compound that is dangerous to the human population and civilization. The shallow recycling processes available for POM plastics result in most of this waste plastic being dumped in landfills or incinerated, defeating any potential to offset greenhouse gas emissions. Improving recycling processes and reducing the dependence on virgin POM are essential in minimizing their environmental repercussions.

Reducing Plastic Waste and Its Environmental Footprint

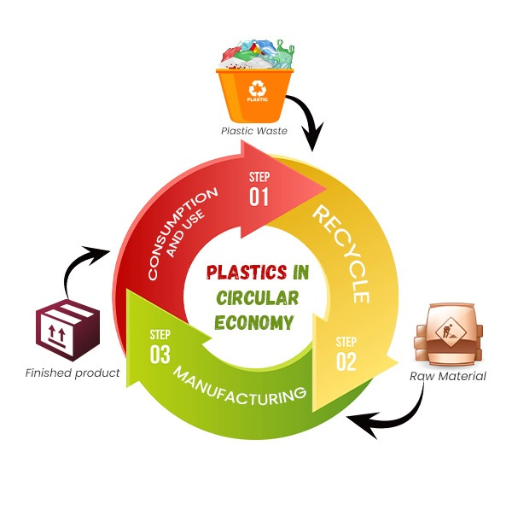

Reducing plastic waste starts with more efficient alterations in resource allocation. One example is the introduction of comprehensive waste management frameworks, as recycling POM plastic. One effective means to meet this target is the increasing utilization of biodegradable and compostable substitutes, which mitigates the volume of plastics introduced to the environment for decades. Moreover, implementing stronger EPR policies motivates producers to handle the complete life cycle of their products from production to disposal.

In addition, progress made in chemical recycling methods holds promise for recovering more valuable recycled outputs by reversing the process into monomers. For example, specific depolymerization methods could improve the recycling efficiency of some difficult-to-recycle plastics such as polyoxymethylene (POM) and polyethylene terephthalate (PET). Public awareness and education campaigns are essential for motivating consumers towards active participation, particularly in eliminating single-use plastics. Collectively, these approaches would aid in reducing the environmentally unsustainable impact of plastic waste and promote the principles of the circular economy.

Benefits of Recycling POM for Environmental Protection

The recycling of polyoxymethylene (POM), also referred to as acetal or polyacetal, is highly advantageous from an environmental sustainability perspective. The recycling of this particular engineering thermoplastic reduces the supply of POMs required, thus reducing the energy-intensive extraction and refining processes. This leads to a reduction in greenhouse gases and carbon emissions. Recycled POM also offers considerable mechanical strengths, including rigidity, low friction, and resistance to wear, and therefore finds use in the automotive, electronics, and construction industries.

Another significant benefit of POM recycling is reducing industrial and post-consumer waste that would otherwise contribute to landfills and incineration. Plastics, being non-biodegradable materials, pose a challenge during disposal because they result in long-term harmful effects on the ecosystem. However, POM can be chemically recycled to its monomers and then polymerized, which maintains material fidelity in a closed-loop system. Therefore, encouraging POM recycling proactively mitigates environmental harm, defies resource depletion, and implements circular economy principles into industrial practices.

Landfill Issues Related to POM Plastic Products

From an environmental standpoint, landfilling POM plastic products presents serious challenges. POM’s durability allows it to resist biological breakdown, permitting it to persist in a landfill for a long time, further perpetuating the problem of plastic waste and inefficient land use. Research also suggests that POM does not break down under landfill conditions, leading to mounting waste.

Moreover, due to moisture and microbial activity, the decomposition of POM with time may result in the liberation of formaldehyde, a hazardous substance. The chemical seepage can potentially permeate surrounding soils and groundwater, resulting in far-reaching contamination and expensive clean-up efforts. Research underscores the increasing application of such POM products in industrial and consumer domains as a growing contributor to waste that does not decompose, thereby putting a strain on landfills worldwide.

To address such landfill concerns, there is an immediate need to adopt more sustainable waste management practices. These efforts include, but are not limited to, improving existing infrastructure for POM recycling, developing substitutes that are easier to break down, and stricter enforcement concerning the disposal of plastics, all of which would help mitigate the environmental footprint and protect ecological systems.

How Does POM Recycling Fit into the Circular Economy?

Recycling polyoxymethylene (POM) is critical to the circular economy as it allows for the recovery and recycling of this rigid plastic, which otherwise calls for new material construction. Effective recycling technologies can help recover POM waste to manufacture new products and help conserve environmental resources. This approach is in line with the core tenets of a circular economy that focus on resource minimization, waste mitigation, and materials regeneration. POM is most commonly used in the production of engineering thermoplastics. Keeping POM in the production cycle enables industries to reduce their carbon emissions and aids in establishing a sustainable, closed-loop framework.

Creating New Products from Recycled POM

Recycled polyoxymethylene (POM) plastic is considered a multi-functional thermoplastic, performing better than classed virgin POM plastics. POM’s unique thermoplastic characteristics, high tensile strength, low friction coefficient, and excellent dimensional stability are preserved even after thorough recycling. Therefore, POM can manufacture precision mechanical parts such as automotive components and consumer products, including gears, bearings, and fasteners.

Recent progress in material science allows more functions to be added to POM’s recycled forms due to the ability to integrate it with other polymers or additives. For instance, adding glass fibers or other reinforcements into the recycled POM polymer significantly improves its wear resistance and thermal stability. This widens its application in high-temperature machines and heavy-load environments. This advancement shows that there is increasing potential for recycled POM to not only aid in reducing environmental impact but also serve as a high-performance industrial material capable of withstanding rigorous standards.

Role of POM in Sustainable Practices

Polyoxymethylene (POM) is essential in further encouraging sustainable practices because it adheres to the principles of the circular economy. A critical aspect of POM is that it can be recycled; therefore, manufacturers can retrieve and use it during end-of-life processing. This feature is crucial for numerous industries trying to reduce waste and the resources needed to source new materials. In addition, the continuous improvement of recycling processes helps the production of POM by increasing the grade of the recycled materials. As a result, reprocessed POM can retain up to 90% of its mechanical properties after several cycles.

An example of POM’s application in sustainable engineering is in the automotive and consumer goods industries, where POM is used for precision and durability. Integrating post-industrial or post-consumer POM into these industries allows manufacturers to reduce energy consumption by producing new plastic. Research also shows that recycled POM lowers greenhouse gas emissions than POM’s production through traditional polymer techniques, making it useful in climate change mitigation.

POM’s lightweighting strategies contribute to sustainability from a different angle. POM’s strength-to-weight ratio makes it easy to substitute for heavier metals, conserving raw materials and improving energy efficiency in fuel-dependent sectors like transportation. The ability to replace heavier components with POM while supporting sustainable goals emphasizes its importance as an engineering thermoplastic.

Consumer Awareness and the Importance of Recycling

Recycling is directly tied to consumer awareness. Even today, a wealth of priceless recyclables like plastics, metals, and paper are rotting in landfills due to a lack of understanding regarding sorting and disposal techniques. Raising public awareness on this subject remains crucial.

There lies an eco-logical reason behind recycling that reduces greenhouse gas emissions, protects depleting natural resources, and saves energy when manufacturing. This motivates individuals to engage in restoratively proactive behavior. Municipalities with higher public awareness campaigns display better recycling rates. An increase in public participation and the technological evolution in recycling processes can help writers scope levels of managing waste operations while achieving the set goals for sustainable development.

What Alternatives Are Available for POM Plastic?

Proposed substitutes for Dow Chemical’s Polyoxymethylene (POM) include other plastics like polypropylene (PP), polyester (PET), or even nylon (polyamide) due to their mechanical strength and high durability. For high-end applications requiring reinforced engineering plastics, polyetheretherketone (PEEK) and polycarbonate (PC) can also serve as replacements due to their strength and high resistance to heat. Moreover, certain biobased plastics, namely polylactic acid (PLA), are considered environmentally sustainable alternatives for some applications that are non-critical structurally. Choosing a substitute is guided mainly by critical features like the permissible load, operation temperature, or ecological effects.

Exploring Biodegradable Plastics Like Polylactic Acid

Polylactic acid (PLA) falls under the category of biodegradable thermoplastics and is classified as a linear aliphatic polyester. PLA polymers have structural formulas derived from renewable sources such as corn or sugarcane, making them environmentally friendly. PLA also has several functional characteristics, such as being easy to process, having good biocompatibility, and being highly transparent, which means it can be used elastically. The tensile strength measures between 40 and 70 MPa, depending on its formulation and processing conditions. Additionally, its glass transition temperature lies at 55 to 65°C.

Industries such as packaging, agriculture, and 3D printing have extensively adopted PLA. For example, in the packaging industry, it is used to produce disposable cups, food containers, and films because it is biodegradable and has a low environmental footprint. In addition, PLA is dominant in the filament used in 3D printing because of its user-friendly nature and low warping characteristics during printing. Yet, while PLA’s mechanical properties are on par with petroleum-based plastics such as polyethylene terephthalate (PET), its relatively lower thermal resistance and susceptibility to hydrolytic degradation in moist environments limit its use in high-temperature or high-moisture conditions.

Recent shifts in the polymer science field focus on overcoming PLA’s limitations—such as low functionality and lack of copolymers—by blending it with other materials. Incorporating additives or composite structures seems to have promise in enhancing the thermal resistance and mechanical strength of PLA, thereby increasing its utilization as a structural and industrial material. The continued innovation underscores the resistant functionality of PLA as an advanced biodegradable polymer raw material for sustainable product design and green manufacturing.

Comparing POM with Other Engineering Plastics

Polyoxymethylene (POM), also known as acetal or Delrin, is one of the engineering plastics with the best compositional balance of stiffness, shape retention, and frictional properties, making it unique. POM outperforms nylon (PA) in terms of dimensional moisture sensitivity, as nylon absorbs water, which can lead to swelling and altered mechanical properties. Compared to Polypropylene (PP), POM has a much greater strength-to-weight ratio and wear resistance, making it an ideal plastic for high precision gears, bearings, and other mechanical components that undergo repetitive motions.

Moreover, POM is almost as tough as polycarbonate (PC) in impact strength. However, POM is often more cost-effective than PC and more straightforward to process, making it more advantageous when impact strength is not a significant requirement. Compared to Polyethylene Terephthalate (PET), POM is better suited for applications that require low friction and wear. However, PET outperforms POM in some environments due to its higher thermal stability and chemical resistance. These detailed distinctions highlight the broader application range of POM and strategic importance in industries from automotive to consumer electronics, where material selection plays a critical role on operational effectiveness and durability.

Future Trends in Plastic Materials and Recycling

The changes occurring within the plastics industry are centered around new technologies in material development and increasing societal requirements for sustainability. Developing bio-based plastics and biodegradable plastics is one new approach to fostering a balance between the new bioplastics and plastics obtained from fossil fuels. These new plastics should possess similar strength, flexibility, and durability. The bio PLA (polylactic acid) and PHA (polyhydroxyalkanoates) polymers are gaining acceptance due to their environmentally friendly nature and wide applications in packaging and the medical industry.

Rapid changes within recycling technologies are taking place at the same time. Newer, more efficient chemical recycling strategies, such as depolymerization and pyrolysis, allow near-total recycling of plastics by turning them into their monomer units. This approach works much more efficiently than mechanical recycling, which, to a greater extent, leads to the material losing its value. In juncture, the widespread adoption of machine learning and AI for sorting plastics by their resin types is propelling recycling rates to new heights.

Globally, pursuing circular economies rationalizes EPR regulations, spurring more ambitious recycling goals. Also, more research is being done on upcycling—transforming waste plastic into high-value materials, creating new opportunities in construction, renewable energy, and even aerospace. These advances may reshape the plastic material lifecycle toward sustainability.

Reference Sources

-

A Comparative Bibliometric Analysis on Plastic Waste Recycling (2023)

- Key Findings: This study explored global trends in plastic waste recycling, emphasizing the transition from a linear to a circular economy. It highlighted that while POM and other engineering plastics are recyclable, the lack of infrastructure and economic incentives limits their recycling rates. The study also discussed the potential of chemical recycling to recover valuable materials from POM.

- Methodology: A bibliometric analysis was conducted using Scopus and Web of Science data, analyzing over 2,000 articles published between 2014 and 2023. The study used tools like VOSviewer to map research trends and identify key contributors in the field.

-

- Key Findings: This paper examined the degradation and recyclability of POM under different processing conditions. It found that POM’s thermal stability and mechanical properties are influenced by its processing method, which has implications for its recyclability. Higher tonnage injection molding was shown to enhance POM’s thermal stability, making it more suitable for recycling.

- Methodology: The study used thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC) to evaluate the thermal and mechanical properties of POM samples processed under varying conditions.

-

- Key Findings: This research discussed the role of engineering plastics like POM in e-waste and highlighted strategies for their sustainable recycling. It emphasized the importance of urban mining and circular economy models in recovering valuable materials from POM and other plastics in electronic waste.

- Methodology: The study conducted a comprehensive review of global e-waste management practices, focusing on policy frameworks, technological advancements, and stakeholder collaboration.

- Top POM Plastic Pellets Suppliers in China

Frequently Asked Questions

Q: Can POM plastic be recycled?

A: Yes, POM plastic, also known as acetal, can be recycled through effective recycling methods, helping to reduce the environmental impact associated with the production of new plastic products.

Q: What are the recycling methods for polyoxymethylene?

A: Polyoxymethylene recycling methods include mechanical recycling, where used plastic is ground down and reprocessed, and chemical recycling, which involves breaking the polymer down into monomers.

Q: What are the benefits of recycling POM plastic materials?

A: Recycling POM plastic materials helps decrease plastic waste, lowers the carbon footprint, and conserves resources by reducing the need for virgin polymer production.

Q: What are the typical applications of recycled POM products?

A: Recycled POM products are commonly used in automotive parts, medical devices, and various consumer goods, benefiting from their high strength and dimensional stability.

Q: Is the recycling of polyoxymethylene a widely adopted practice?

A: While the recycling of polyoxymethylene is not as widely adopted as other kinds of plastic, like HDPE, efforts are increasing to promote the recycling of POM and its materials.

Q: How does the molecular weight of POM affect its recyclability?

A: The molecular weight of POM can influence its recyclability. Higher molecular weights may require more energy but also provide better mechanical properties for precision parts.

Q: Are there specific challenges in the recycling of POM plastic?

A: Yes, challenges include the presence of formaldehyde and the need for specialized recycling processes to maintain the quality and properties of the recycled polymer.

Q: What is the environmental impact of not recycling POM plastic?

A: Not recycling POM plastic leads to increased plastic waste in landfills, higher natural resource consumption, and a greater carbon footprint from producing new plastic materials.

Q: Can POM plastic be recycled into new POM products?

A: Yes, recycled POM plastic can be processed and remolded into new POM products, making it a sustainable option for creating new consumer products.

Q: How does the stiffness of POM influence its use in recycling?

A: POM’s high stiffness makes it suitable for precision applications, but it also means that recycling processes must be tailored to maintain these properties in recycled plastic.