Some businesses or industries heavily rely on certain plastics for their parts; however, not all materials used for that purpose are identical. Different types of plastics exist, and among them are plastic pellets, which are vital in the processes of production. These granules are extremely useful because they can be applied in the manufacturing of many items, such as car parts and packaging. In this blog post, we explore the specifics of plastic pellets and analyze how they differ from other types of plastic materials. This article would be beneficial to professionals in design and manufacturing, as well as those interested in material science, since it discusses the benefits and issues associated with plastic pellets, in addition to sustainability aspects.

What Are Plastic Pellets and How Are They Made?

Plastic pellets are just small round pieces of plastic and serve as nurdles or resin, all depending on context. Manufacturing makes use of these as materials for tools and products. These pellets are made through polymerization, which is a type of chemical process. Firstly, polymers are created through the mixing of various raw chemical compounds. To ease transport and administration, the polymers are cooled and sliced into consistently shaped pellets, known as polymer pellets. These base materials of different kinds are all melted, boiled, and shaped in order to change their wording and boundaries.

Understanding the Manufacturing Process of Plastic Pellets

Currently, the processes in producing plastic pellets have been improved in terms of efficiency and sustainability. More Advanced technologies like precision extrusion and automated pelletizing systems allows for consistent size while reducing waste of material, Studies show that incorporating automation in these processes can increase production rate by 30% while lowering operational costs in Wenhsin.

Shifting to use of recycled plastics is another advancement in the industry when it comes to pellet production. These modern recycling methods produce high quality pellets from post-consumer plastic waste which reduces the need for virgin materials. About 25% reduction in greenhouse emission can be blamed on recycled content in manufacturing the pellets making it leaner alternative.

The eco-conscious initiatives gave rise to bio-plastic pellets. These bio-plastic materials aim to satisfy the increasing demand for environmentally friendly plastics. Research predicts the bio-plastics market to experience a 21.7% CAGR from 2021 to 2030 signifying the industry is gradually adopting more sustainable initiatives. These changes show a remarkable enduring commitment to innovation and environmental sustainability in manufacturing plastic pellets.

Types of Plastic Pellets and Their Uses

Based on their compositions and uses, plastic pellets or resin pellets come in different forms. Each of those has a particular function in an industry, including but not limited to automotive and packaging industries.

- Polyethylene (PE) Pellets

Polyethylene is one of the most widely manufactured types of plastic, and it comes in two forms: high-density (HDPE) and low-density (LDPE). The industry values HDPE pellets for their strength, as they are used in the manufacture of milk jugs, detergent bottles, and heavy-duty containers. Alternatively, LDPE pellets are relatively flexible and are heavily utilized in films such as plastic bags and shrink wrap. According to new industry data, the polyethylene market size is forecasted to grow from USD 207 billion in 2023 to USD 207 billion by 2030.

- Polypropylene (PP) Pellets

Polypropylene pellets are extremely durable when it comes to mechanical stress and heat. They are widely used in motor vehicle components, foods, and even in textiles. Its lightweight, editable form allows for the swift drafting of new models with little additional bulk while maintaining product utility. Most industry reports point to a significant increase in the need for polypropylene pellets, predicting a market value of over 165 billion by 2030.

- Polystyrene (PS) Pellets

Polystyrene pellets find extensive application in the creation of packaging materials, disposable cups, and even insulation material due to their rigid makeup and polystyrene’s superior level of insulation. Lightweight and shock-absorbent, expanded polystyrene (EPS) is sought after for protective packaging.

- Biodegradable and Bio-based Plastic Pellets

These plastic pellets are produced from renewable materials such as corn starch and sugarcane which are more environmentally friendly than traditional plastics. They are being adopted for use in compostable bags, food packaging, and agricultural films. As companies shift towards adopting greener measures, the biodegradable plastics industry is projected to grow to $7.9 billion by 2027.

- Polyethylene Terephthalate (PET) Pellets

PET pellets are best known for their use in manufacturing bottles and food containers because of their durability and freshness-retaining properties. With recycling programs in place, the use of recycled PET (rPET) pellets has grown tremendously and is anticipated to further increase along with the rPET market as eco-conscious consumers and manufacturers increase demand.

Every type of these plastic pellets is customized to meet particular applications, serving different industry requirements and simultaneously inviting innovation and sustainability. An emphasis on recycling and bio-based approaches clearly indicates a change in production practices towards greener and more environmentally friendly solutions.

The Role of Plastic Pellets in Injection Molding

Injection molding remains one of the most common manufacturing procedures that plastic factories use today. This is due to the role of plastic pellets in the efficiency and versatility of the procedure. The process starts by feeding plastic pellets into a heated barrel where they are melted and injected into a mold to create the desired figure. The attributes of the plastic pellets have a profound effect on the quality of the product in terms of strength, flexibility, and durability.

The most recent data from industries shows specific types of plastic used in injection molding to be on the rise. Polypropylene (PP) pellets, for instance, are very popular because they are lightweight and very resistant to chemical substances, making them highly durable. Market analysis suggests that the polypropylene market size is estimated at a whopping $117.3 billion in 2022, with an expected increase of 3.5% CAGR between 2023 and 2030. Also, the use of recycled PET (rPET) pellets in injection molding is gaining steam, signifying an industry shift towards eco-friendly materials. With new recycling technologies emerging, the global rPET market is estimated to be at $13.1 billion by 2027, growing 8.5% CAGR.

Moreover, engineering-grade plastic materials, like polycarbonate (PC) and acrylonitrile butadiene styrene (ABS) pellets, support applications needing greater mechanical strength or heat resistance. These materials are essential in the automotive, electronics, and medical industries. There is also a growing development of eco-friendly plastics, such as biobased polylactic acid (PLA) pellet,s which broadens the scope of sustainable injection molding.

Advanced technologies and developments in engineered bio-resin materials exemplifies the increasing importance of choosing the right plastic pellets which not only affect operational efficiency during injection molding but also the sustainability and overall impact of the end products.

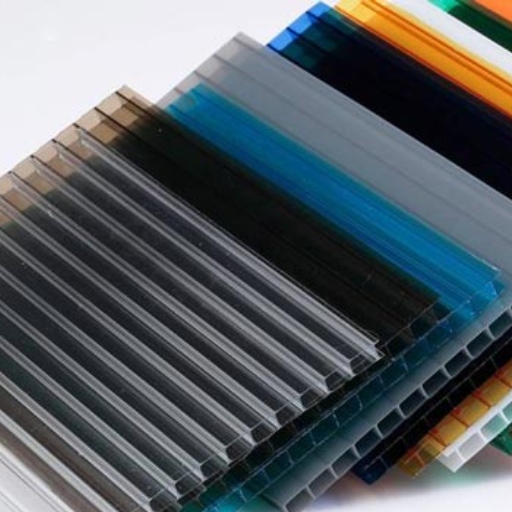

Comparing Polycarbonate to Other Plastic Materials

Polycarbonate differs from other plastic materials owing to its tremendous strength, resistance to impact, and clarity. Unlike acrylic, polycarbonate is tougher and more resistant to stress-induced cracking. In comparison to ABS, polycarbonate’s greater heat resistance and optical clarity render it suitable for applications that require both strength as well as visibility. What’s more, polycarbonate’s lower weight compared to glass, while still maintaining its transparency, makes it the preferred material for protective barriers, windows, and casing for electronics.

Key Physical Properties of Polycarbonate

Polycarbonate is a thermoplastic that is light, yet incredibly strong, known for its remarkable versatility and impact resistance. Its density is around 1.2 g/cm³, making it lighter than metals like aluminum and offering comparable strength for many applications. Additionally, one of its defining physical properties is the high impact strength of polycarbonate, often measured at about 850 J/m, making it virtually shatterproof. This allows polycarbonate to be used in protective equipment, safety glazing, and even in bullet-resistant windows.

Polycarbonate’s high transparency features a light transmittance value of approximately 88-90%, which makes it rival glass for its optical clarity in use for preservative materials, safety goggles, and protective visors and shields. The glass transition temperature of polycarbonate is around 147 °C, showing that is also has great heat resistance. This, paired with the ability to withstand harsh environments, places polycarbonate above other materials for protective coverings. In comparison with other materials, polycarbonate remains easy to mold in the injection molding process, which allows for the production of complex parts.

Another key feature is its electric insulation property, which is marked by high dielectric strength of approximately 17-22 kV/mm. This property makes it useful in electronics and electrical equipment where safety and ionization are crucial. Along with UV resistance, polycarbonate is well known as an outstanding multi-purpose engineering plastic throughout many industries due to its combination of polymers, crystalline polycarbonate, and its ability to resist UV radiation (particularly when treated with stabilizers), along with its resistance to cracking under stress.

Advantages and Disadvantages of Polycarbonate

Advantages:

- Impact Resistance: Polycarbonate is famous for its remarkable impact resistance, as it is 250 times stronger than glass and 30 times harder than acrylic. These factors make it a perfect material for bulletproof glass, helmets, and other safety equipment.

- Transparency: Polycarbonate has a high level of transparency and transmits up to 89% of visible light which rivals glass. This characteristic is crucial in the construction of greenhouses, skylights, and optical lenses.

- Lightweight: Robust polycarbonate is significantly lighter than glass, making handling, transporting, and installation easier in the construction and aerospace industries.

- Thermal Resistance: Polycarbonate’s ability to withstand temperature fluctuations, functional in a range from -40°F to 248°F, ensures reliable performance in extreme conditions without losing its properties.

- Chemical and Weather Resistance: Polycarbonate undergoes certain treatments. Such polycarbonate materials have excellent weather resistance to UV radiation, yellowing, and degradation, which expands their use and lifespan.

- Ease of Fabrication: Polycarbonate can be easily cut, molded, or thermoformed and thus can be used for a range of applications.

Disadvantages:

- Scratch Susceptibility: Polycarbonate is durable, but scratches can be an issue. It needs special coatings or treatments if used over a long period for specific applications.

- High Cost: Polycarbonate is fairly expensive in comparison to other plastics such as acrylic or PVC, because of its sophisticated properties.

- UV Sensitivity: In the absence of stabilizers, polycarbonate will deteriorate and turn yellow with prolonged UV exposure, weakening its clarity, as well as its strength.

- Chemical Vulnerability: Polycarbonate is susceptible to some chemicals like benzene, acetone, or alcohol which may cause it to fracture or weaken upon contact.

- Recycling Challenges: Polycarbonate is technically recyclable, but recovery and reuse are often more complicated and costly than with other materials, limiting its eco-friendly applications.

These particulars concentrate on the balancing tradeoffs regarding ease-of-use and care instructions with polycarbonate’s high-performance utility.

Common Applications of Polycarbonate

- Electronics

-

-

- Applications: Integrated in the casing of smartphones and laptops and other electronic devices owing to impact resistance and low weight.

- Key Data: Represents about 25% of polycarbonate consumption globally in the electronics sector.

-

- Automotive

-

-

- Applications: Due to its strength and transparency, it is used in the headlamp lenses, dashboards, and glazing panels.

- Key Data: Polycarbonate aids in lowering the overall vehicle weight, compared to glass, by as much as 50% thus increasing fuel efficiency.

-

- Construction

-

-

- Applications: Its strength and resistance to UV rays lends it to the roofing, skylights, and protective barrier industries.

- Key Data: With proper UV inhibitors, it can last outdoors for up to 10-15 years.

-

- Medical Equipment

-

-

- Applications: Its compatibility with sterilization makes it useful for medical syringes, issuing them, and surgical instruments.

- Key Data: The annual growth rate for the use of polycarbonate in medical equipment is approximately 3.5%.

-

- Optical Needs

-

-

- Applications: The clarity and scratch resistance of these materials makes them suitable for eyeglass lenses, safety glasses, and optical discs.

- Key Data: Polycarbonate lenses offer about 10 times greater impact resistance than glass or plastic lenses and are thus more durable.

-

- Packaging

-

-

- Applications: Its lightweight traits which also contribute to its shatter resistance make polycarbonate suitable for use in reusable water bottles and food containers.

- Key Data: Polycarbonate bottles can endure high-temperature sterilization for extended reuse.

-

These applications demonstrate polycarbonate’s versatility in different spheres, along with practical merits that make it popular for both common and specialized uses.

The Environmental Impact of Using Plastic Pellets

When mismanaged, plastic pellets dubbed as nurdles can pose a hazardous threat to the environment. They are a major contributor to microplastic pollution as they are often lost during manufacturing, transport, or spillage. These pellets can be devoured by sea creatures, which can result in dire consequences for the fauna’s health. Furthermore, these durable plastic pellets add to the already existing multi-faceted problem of plastic pollution since they resist decomposition. To alleviate the impact on the environment, better containment and disposal methods should be used.

How Plastic Recycling Influences Environmental Impact

Recycling plastics saves energy, resources, and emissions, which reduces the environmental impact. Recent data shows, recycling one ton of plastic saves around 5,774 kWh of energy, 16.3 barrels of oil, and conserves 30 cubic yards of landfill space. Also, recycling lowers the dependency on new plastic, which is costly to make and uses lots of fossil fuels. Additionally, recycling reduces waste when there is no space to store it, like oceans and landfills, in turn protecting ecosystems along with endangered wildlife. That said, recycling can be beneficial if done efficiently while being accessible. In this era, technology such as chemical recycling and better sorting systems tackles the long-standing problem of managing plastic waste, which reduces plastics impact on the environment.

The Plastic Waste Challenge

The annual global plastic production is over 400 million tons. This means plastic waste is among the most concerning environmental problems we are dealing with today. What’s worse is that only a shocking 10% of plastic is actually recycled, meaning most of it is lying around in landfills and polluting ecosystems. With an additional 11 million tons of plastic added to the oceans each year, the already disrupted marine life is at risk. If current estimates are correct, this number is projected to triple by 2040—if nothing changes, of course.

Microplastics pose another threat; fragments smaller than 5 millimeters have appeared in soil, oceans, and, more worrying, the air and bloodstream of humans. With the current figure of plastic waste and consumption trends, it’s evident that an immediate intervention needs to be implemented on a global scale. Systemic change is essential to reduce the production and consumption of single-use plastics, alongside introducing more advanced recycling, biodegradable materials, and better solutions overall. The good news is that global policies and collaborations are finally stepping up to the plate to fight for future generations by addressing these profound issues.

Sustainable Alternatives to Plastic Pellets

Industries are embracing sustainable alternatives to the traditional plastic pebbles as they seek eco-friendly solutions for countering plastic pollution. One such alternative material is polylactic acid (PLA), a biodegradable polymer made from renewable resources such as corn starch or sugarcane. PLA degenerates in industrial composting facilities within a couple of months, hence providing an option for reducing reliance on petroleum-based plastics.

Polyhydroxyalkanoates (PHA) are another hopeful substitute, and they refer to bioplastics produced through bacterial fermentation of organic feedstocks like agricultural waste. PHAs decompose completely in both marine and terrestrial environments, thus addressing the growing concern regarding oceanic plastic debris. The global production capacity for PHAs will reach nearly 250,000 tonnes by 2025, according to recent studies indicating their increased popularity.

Besides that, mycelium-based materials derived from the root structure of fungi are being developed to replace some forms of plastics, such as packaging. These materials decay easily without environmental degradation effects and toxic residues left behind. Companies using mycelium have expanded their operations, with reports indicating a significant decrease in carbon emissions during manufacturing compared to synthetic polymers.

The research is also focused on upcycled natural fibers such as hemp, jute, and bamboo that are not only strong but also compostable as part of its strategies for minimizing environmental damage. Legal measures in various fields and corporate pledges have been used to inspire investment in such green materials, thus providing concrete steps towards a circular economy, where plastic pollution becomes a thing of the past.

How Do Plastic Pellets Perform in Different Plastic Polymers?

The performance of plastic pellets is according on the type of polymer being used. The pellets melt easily and mold without stress for thermoplastics such as polyethylene and polypropylene, providing agility and strength for different applications. An engineering plastic example would be ABS polycarbonate, where strips provide greater strength and heat resistance. This is ideal for more demanding applications like automobile parts. Biodegradable plastics such as polylactic acid (PLA) use pellets that balance usability and eco-friendliness since they will break down under certain conditions. Best said, the performance of the pellets is balanced with the characteristics of the polymer in terms of intended use.

Performance in Polyethylene and Polypropylene

Thermoplastics include Polyethylene (PE) and Polypropylene (PP), which are used globally due to their versatility and productivity. Impact resistance, tensile strength, chemical endurance mechanical durability of HDPE grades make high-density polyethylene an optimal choice for piping, containers, and liners. An example of polyethylene’s usefulness is HDPE, which has a high tensile strength between 20 to 37 megapascals and withstands temperatures from fifty degrees Celsius under nominal conditions.

As for polypropylene, it is less flexible, more fatigue resistant, heat stable, and useful for automotive interiors and medical equipment such as food containers. With a flexural modulus of 1200 to 1800 megapascals, polypropylene does possess high stiffness, however, some grade withstands up to 130 degrees Celsius. Not to mention, the low density of 0.91 grams per cubic centimeter gives an edge on weight without losing strength.

Both materials have an equally good processability when molded into complex shapes ensuring efficient manufacturing. Current UV resistance flame ignition overhaul needs is possible due to evolution of polymer and PE and PP composite parts.

Utilization in Polyvinyl Chloride (PVC)

Polyvinyl Chloride (PVC) is used in construction and electric cables across multiple industries due to its flexible nature and cost efficiency. Roughly 70% of the PVC produced is used in construction for pipes, window frames, fittings, and flooring. Water and sanitation infrastructure also relies on its resistance to corrosion and chemical exposure.

Plasticizers make PVC more flexible which makes it easier to use when designing medical devices and other consumer products. Additionally, the insulating properties of PVC makes it ideal for use in electric cables.

Eco-friendly methods for producing PVC are on the rise, along with the increase in developing economies, which has led to a higher demand for construction materials. This trend is primarily driven by the introduction of bio-based plasticizers, which lower the environmental impact of manufacturing PVC. These factors are expected to increase the value of the plastic market to $78.9 billion by 2027.

Compatibility with High-Density Polyethylene (HDPE)

Among a variety of widely used plastics, both PVC and HDPE are used in many industries, each having its own set of benefits. In the case of HDPE, it is known to be a thermoplastic polymer that is prized for its strength-to-density ratio, making it appropriate for piping, geomembranes, bottle manufacturing, and more. Compared to PVC, HDPE has lower impact resistance and is more resilient to environmental stress cracking. On the other hand, blending PVC and HDPE is easy with the use of other additives/compatibilizers as they differ in chemical composition and melting point.

Deriving from modern literature in material science, it is now possible to design composite materials of PVC and HDPE for certain applications. For example, hybrid pipes utilizing the flexibility of HDPE and the strength of PVC have been made possible through added compatibilizing agents. In the infrastructure market, there is a greater need for sustainable solutions, which is predicted to make this type of composite in demand by 4.5 percent annually through 2030. This highlights the ingenuity emerging with the industrial approach seeking to increase the compatibility between PVC and HDPE.

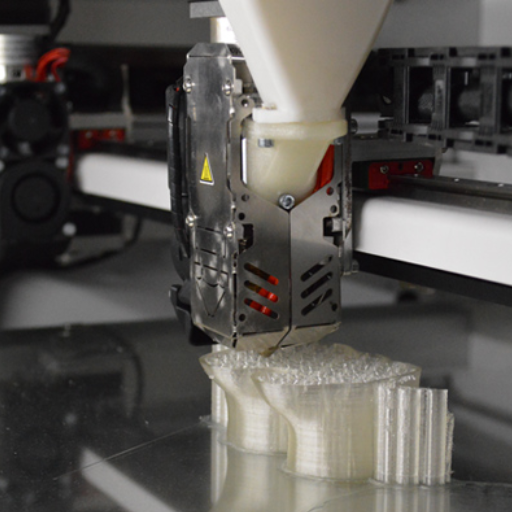

What Is the Role of Plastic Pellets in 3D Printing?

War on waste actually identifies plastic pellets as 3D printing raw material in processes such as pellet-based extrusion. 3D objects are constructed via a sequential process where these pellets are melted and extruded one layer at a time. When compared to filament based 3D printing, plastic pellets are often more readily available and cheaper which lowers the total production costs. Pellets also enhance the sustainability of the process as they allow the use of recycled plastics in 3D printing.

Benefits of Using Plastic Pellets in 3D Printing

- Cost-Effectiveness

With their low pricing, plastic pellets are more cost-efficient than traditional filament materials, which lowers the 3D printing cost for manufacturers. Pellets are, on average, priced 50-90% lower per kilogram than filament, especially when purchased in bulk, which makes pellets economically feasible for prototyping as well as large-scale production.

- Material Versatility

The use of pellets broadens the material options available. Thermoplastic materials such as PLA, ABS, and PETG, including engineering grade ones like nylon and polycarbonate, are feasible for use in pellet based 3D printing systems. Moreover, pellets enable the use of advanced composite materials such as carbon fiber reinforced composites for improvement of mechanical strength.

- Improved Sustainability

The incorporation of recycled materials into plastic pellets reduces the environmental impact plastic manufacturing has. Recycled plastic pellets not only minimize plastic waste, they also reduced the carbon footprint of the entire manufacturing process. This expedites making pellet-based extrusion methods significantly more environmentally friendly than traditional methods.

- Faster Production Speeds

Compared to filament based systems, pellet extrusion systems melt and deposit materials at an increased speed. Faster throughput results in more iterations and quicker production cycles, benefitting industries that prioritize high efficiency.

- Scalability for Industrial Applications

Due to the higher material volume that pellet-based systems accommodate, they are best suited for large-scale 3D printing and industrial applications. For example, in construction and automotive industries, bulk material processing capability results in the ability to manufacture large parts or components with significantly less downtime for material changeovers or resupply.

These benefits, lastile 3d printing cost reduction, environmental friendliness, speed, and scalability plastic pellets augement modern 3d printing technology, indicate the use of plastic pellets makes economic sense.

Challenges in 3D Printing with Plastic Pellets

Using plastic pellets in 3D printing offers many benefits but comes with unique challenges. One primary challenge is assuring a consistent flow of materials. Pellets, unlike filament, are not as uniform; they can be of a different size and composition. This can lead to irregular extrusion, which can jeopardize the quality of the printed part. With many processes, such as advanced hopper designs, precision printing, and careful temperature control, this issue can be alleviated. However, these additional processes can increase the complexity of the machinery.

Pellet-fed 3D printers also present hurdles in the maintenance and fine-tuning of the equipment. With the infusion of abrasive elements, these 3D printers require more frequent cleaning and adjustments to avoid blockages or wear at the nozzle. Unlike traditional filament-based 3D printers, these printers require more time for setup and tuning, impacting user-friendliness for small-scale operations.

Heat management also impacts 3D printed parts. Larger printers, along with thicker component parts, require more thermal management to stop problems such as warping, uneven cooling, and inconsistent layer adhesion from occurring. This also means using special pumped heating chambers and cooling systems, which, again, impact operational costs.

Finally, the sources of supply for plastic pellets have their own challenges. Although opportunities to obtain pellet materials are on the rise, they are not as diverse or as easily obtainable as filament options, especially for niche applications that demand specific mechanical or chemical attributes. Further investments in research and development will eventually help widen the selection, but the lack still remains a challenge for many industries searching for custom-designed products.

Innovations in 3D Printing Materials

Three-dimensional printing, also referred to as 3D printing, is undergoing a profound transformation in recent years thanks to advancements in study materials aimed at bridging gaps in various specialized sectors. For instance, provisions of bioplastic materials and composites have been added, making the entire 3D printing manufacturing undertaking sustainable and affordable. Unlike other materials that succumb to the manufacturing processes’ environmental impacts, these eco-friendly materials fulfill the required balance of maintaining strength as well as versatility, which can cater to a wide range of processes.

Research on metal powders has also achieved new heights over the years, now allowing for the inclusion of 3D printing with aluminum, titanium, and high-strength steels for creating complex manufactured components at a balanced center and economic scale without sacrificing durability. A report coming from the scope of additive manufacturing elucidates the projection for growth in the range of 3D printing using metals to reach 22.43% CAGR by the year 2030, brought forth by the aerospace, automotive, and medical sectors.

Advancements have been made in composite filaments with carbon fiber-infused materials, allowing for immense strength while remaining lightweight. These materials are becoming more common in industries trying to improve efficiency, especially in aviation and automotive, which need a drastic reduction in terms of aerospace, automotive, and medical industries.

Moreover, new frontiers of embedded electronics, sensors, or energy storage devices stand to benefit from the innovations brought by advanced low-resistance materials. Multidisciplinary approach of science towards such materials aims to induce finer control with respect to density and assure seamless integration with multi-functional components. At last, polymers such as PEEK and PEI are beginning to be used to manufacture parts for aerospace and medical sterilization systems. These materials have incredible chemical resistance and thermal stability, which allows for further application in different fields.

The chemical industry is specializing more towards separate 3D printed components. The new possibilities in design requirements are driving advances in more precise, functional, and sustainable 3D printing technologies.

Reference Sources

- Eco-bricks Method to Reduce Plastic Waste2:

- Key Findings: This study explored the use of eco-bricks (plastic bottles filled with sand and/or plastic waste) as an alternative to traditional bricks. Eco-bricks demonstrated higher compressive strength (41.2 MPa) compared to red bricks (27 MPa) and concrete bricks (38 MPa). This makes them a viable non-structural material for construction.

- Methodology: The research involved compressive strength testing of eco-bricks made with varying compositions of sand and plastic waste. The results were compared to traditional building materials.

- Impact of Plastic Packaging Design on Recycling Sustainability3:

- Key Findings: The study highlighted the importance of Material Value Conservation (MVC) design principles in improving the economic, environmental, and social sustainability of plastic recycling. Implementing MVC principles increased the availability of high-quality recyclable plastic waste, enhancing the profitability of recycling plants.

- Methodology: The research used feasibility studies, expert interviews, and scenario analysis to assess the impact of MVC principles on recycling plant operations and sustainability.

- Filament for 3D Printers from PET Bottles4:

- Key Findings: This study developed a machine to convert PET bottles into 3D printer filament. The resulting filament (BPET) was tested for tensile strength, temperature resistance, and print quality. While BPET was slightly weaker than commercial PET-G filament, it showed potential for sustainable 3D printing applications.

- Methodology: The research involved designing and testing a filament production machine, followed by experimental analysis of the filament’s mechanical and thermal properties.

- Top PC Plastic Pellets Suppliers in China

Frequently Asked Questions (FAQs)

Q: What are plastic pellets, and how are they used in plastic production?

A: Plastic pellets, also known as plastic granules, are small, cylindrical pieces of plastic used to manufacture a wide range of plastic products. They are the raw material in plastic production, allowing manufacturers to create products like packaging materials, plastic items, and more.

Q: How do plastic pellets compare to other types of plastic materials?

A: Plastic pellets offer distinct properties such as ease of handling and consistency in quality, making them suitable for various plastic production processes. Compared to other forms of plastic, pellets provide efficient processing and uniformity, which is crucial in the material selection process for high-quality plastic products.

Q: What are the advantages of using plastic pellets over other materials like polystyrene or PVC pellets?

A: Plastic pellets, including PVC pellets, offer advantages like ease of transportation, consistent melt flow, and versatility. They are often preferred over materials like polystyrene due to their adaptability in manufacturing processes and their ability to be used in various applications, from packaging materials to plastic lumber.

Q: Can plastic pellets be used in recycling plastic processes?

A: Yes, plastic pellets can be used in recycling plastic processes. High-quality plastic pellets made from recycled materials help reduce waste, allowing discarded plastic to be transformed into new plastic products, supporting sustainable practices in the world of plastic.

Q: What is the role of plastic pellets in material selection for manufacturing?

A: In material selection, plastic pellets are favored for their uniformity and ease of processing. Their consistent quality ensures that manufacturers can predict the properties of the final product, making them a reliable choice for producing a range of plastic products with specific strength and rigidity requirements.

Q: How do plastic pellets contribute to the production of thermoplastic materials?

A: Plastic pellets are essential in the production of thermoplastic materials. They are heated and molded into desired shapes, allowing for the creation of various plastic products. This process is efficient and adaptable, enabling the manufacture of items with complex designs and specifications.

Q: Are plastic pellets used to manufacture HDPE plastic items?

A: Yes, plastic pellets are used to manufacture HDPE (High-Density Polyethylene) plastic items. These pellets provide the necessary properties for producing durable and lightweight products, commonly used in packaging, containers, and other industrial applications.

Q: What types of products are commonly made from plastic pellets?

A: Products made from plastic pellets include a wide range of items such as packaging materials, automotive parts, toys, household goods, and construction materials like plastic lumber. The versatility of plastic pellets allows them to be used in the manufacture of various plastic products with specific requirements.

Q: How do plastic pellets impact the environment compared to other plastic materials?

A: The environmental impact of plastic pellets depends on their lifecycle and recycling potential. When used responsibly, they can contribute to sustainable practices by facilitating the recycling of plastic materials. However, like all plastic materials, they must be managed properly to minimize environmental harm.

Q: What are the challenges associated with using plastic pellets in manufacturing?

A: Challenges include ensuring uniform quality across batches, managing the environmental impact of production and disposal, and adapting to different manufacturing processes. Addressing these challenges is essential to maintain the benefits of plastic pellets while minimizing their drawbacks in the world of plastic manufacturing.