HDPE pellets are not just another type of plastic; they represent a vision for sustainable manufacturing. With over 350 million tons of plastic produced annually worldwide, there is increased demand for materials that can be recycled and are tough enough for further applications. At the same time, these HDPE pellets manage to keep manufacturing costs down without compromising quality or performance. Understanding HDPE pellets and their uses is vital to manufacturers, procurement professionals, and sustainability managers who want to have their material selections based on concrete knowledge. This comprehensive guide will discuss how these amazing pellets, from their fundamental properties to their role in the circular economy, are transforming industries worldwide.

Introduction to HDPE and Its Significance

What Are HDPE Plastic Pellets?

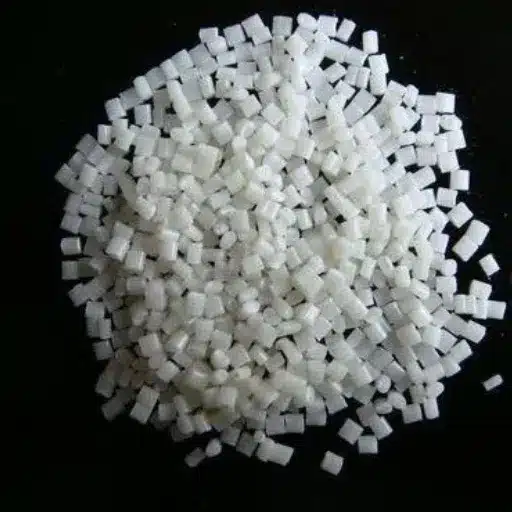

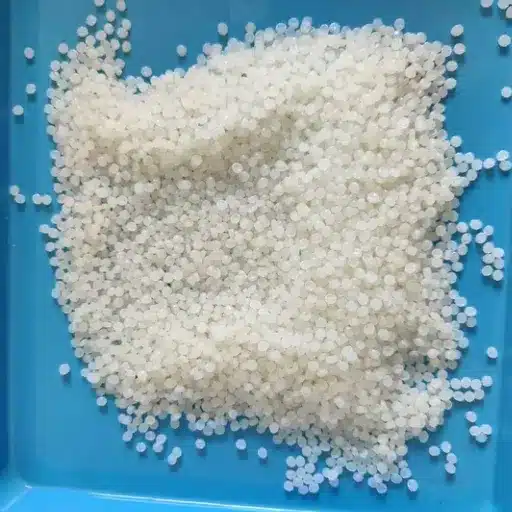

HDPE plastic pellets are the fine and medium-grained particles of high-density polyethylene used as raw material for innumerable manufactured goods. These pellets vary in diameter from 2 to 4 millimeters and appear as vertically or horizontally inclined cylinders, or sometimes as spherical beads, ranging in color from a natural translucent white to myriad colors for specific applications.

Once ethylene gas is polymerized under controlled conditions with initiation, the resulting polymer chains will be the longest and confer HDPE its strength and flexibility. This material is then pelletized by extrusion and cut into uniformly sized pieces that will melt uniformly during welding in the manufacturing process.

The Importance of Density for HDPE Pellets

Density plays an essential role in HDPE performance characteristics. High-density polyethylene has densities that usually fluctuate from 0.94 to 0.97 gram per cubic centimeter. A higher density means stronger intermolecular forces, resulting in higher tensile strength, chemical resistance, and durability than its low-density counterpart.

Density affects how HDPE pellets behave during processing: pellets with higher density require more energy to melt but yield stronger products in the end. The strength of the formed products makes them suitable for applications where structural integrity is essential, including tubing, containers, and automotive applications.

An Overview of HDPE Properties

Key Properties of HDPE Pellets:

- Chemical Resistance: Withstands exposure to acids, bases, and solvents without degradation

- Low Moisture Absorption: Well-suited for harsh environmental conditions

- Excellent Impact Resistance: Maintains integrity at low temperatures

- Climate Adaptability: Performs reliably from arctic pipelines to desert storage tanks

Given their properties, HDPE pellets have found myriad applications across multiple industries. The pellets resist the effects of chemicals, as they withstand exposure to acids and bases, as well as solvents, without showing signs of degradation. Such resistance, together with their low moisture absorption, makes them well-suited for applications in harsh environmental conditions.

It also shows excellent impact resistance at low temperatures. This property ensures the integrity of products from HDPE pellets under various climatic conditions, depending on the environment (arctic pipelines would be stored in desert tanks).

Applications of HDPE Pellets

Industrial Applications of HDPE

Of prices of HDPE pellets, far away, industrial sales figure among the largest markets. In pipeline manufacturing alone, millions of tons are used annually. An HDPE pipe has the highest corrosion resistance among metal alternatives. As such, the pipe could serve for a couple of decades in water distribution, gas transportation, or chemical processing applications.

Chemical Storage Tanks and Containers for Handling Aggressive Chemicals: HDPE pellets provide a chemical storage solution for aggressive chemicals. The material is inert and will not react with the substances stored in it, while providing a durable structure that will not leak or fail structurally over the long term.

The automotive market is still expanding as HDPE manufacturers seek lightweight, durable materials. HDPE components reduce weight, allowing the vehicle to be more efficient in fuel consumption and less in emission.

Major Industrial Applications:

| Application | Key Benefits |

|---|---|

| Pipeline Manufacturing | Corrosion resistance, decades-long service life in water/gas distribution |

| Chemical Storage Tanks | Inert material, no reaction with stored substances, leak-proof structure |

| Automotive Components | Lightweight, improved fuel efficiency, reduced emissions |

Application of Eco-Friendly Packaging Solutions

The packaging industry has welcomed HDPE pellets as a sustainable alternative to traditional raw materials. Containers made from food-grade HDPE pellets maintain freshness while being fully recyclable. Such containers may be recycled through trays or curb-side programs, thereby decreasing landfill waste and supporting the circular economy.

Bottle manufacturing is a prominent use, with HDPE pellets used to produce containers ranging from milk jugs to detergent bottles. Barrier properties ensure that contents are not contaminated while also allowing at least partial recycling for their benefit.

Films and bags are fabricated from special HDPE pellet grades for use in flexible packaging. They give the best puncture and moisture barriers while being recycled through special collection programmes.

To make Items with HDPE Pellets

Some items made from HDPE pellets belong to consumer products in different categories. The strength and ease of maintenance of HDPE make it ideal for household items such as cutting boards, containers, and garden furniture. Also, being stain-resistant and odor-free, it serves as an excellent choice for food-contact applications.

The playground equipment and outdoor furniture are designed to achieve weather durability and UV resistance using HDPE. While wood and metal alternatives require treatment chemicals and ongoing maintenance over the years, HDPE products do not require such maintenance to maintain the aesthetics and structural integrity of the product through years of outdoor exposure in an unfavorable environment.

Environmental Impact and Sustainability

Recycling and Life Cycle of HDPE Pellets

HDPE pellets support the principles of a circular economy thanks to their high recyclability. The material can withstand a handful of recycle operations without undergoing any considerable degradation in its properties, thus making it amongst the most sustainable types of plastics. There are collection programs worldwide specifically targeting HDPE products, thereby forming well-established supply chains for recycled content.

The recycling process encompasses the collection of used HDPE products, cleaning operations, and reprocessing them into pellets. Such recycled pellets may be used outright in the production of secondary products or, in instances where there is a particular emphasis on achieving distinct performance characteristics, blended with virgin HDPE; in either case, this reduces the adverse impact on the environment.

Life cycle assessment clearly shows that HDPE products have a lower environmental impact than many alternative materials. Also, due to their longevity, they require less frequent replacement, and being light in weight, they result in reduced emission of pollutants during the supply chain.

The HDPE Recycling Process

Collection

Used HDPE products gathered

Cleaning

Thorough cleaning operations

Reprocessing

Converted back into pellets

Reuse

New products manufactured

Natural vs. Colored HDPE Pellets

Since they do not contain any colorants that could limit recycling applications, natural HDPE pellets are considered the most recyclable. These translucent pellets can be colored at the manufacturing stage, providing flexibility across various applications while remaining recyclable.

Colored HDPE pellets from colors due to the pigments or dyes inside them. Though they are technically recyclable, colored pellets may have limited application in recycling streams because they cannot be lightened. However, colored pellets will save manufacturers’ processing energy and cost that would have been spent on colorants.

The natural or colored choice tends to depend on the end-use requirements in question and sustainability goals. Manufacturers favor natural pellets for their versatility and recycling advantages.

| Type | Advantages | Limitations | Best For |

|---|---|---|---|

| Natural HDPE Pellets | Most recyclable, no colorants, can be colored during manufacturing, versatile | Requires coloring process for specific applications | Maximum recycling potential, flexible applications |

| Colored HDPE Pellets | Saves processing energy, reduces colorant costs, ready to use | Limited recycling applications, cannot be lightened | Specific color requirements, cost efficiency |

Benefits of HDPE for the Environment

Several mechanisms enable HDPE to drive an environmentally sustainable development. Durability being one allows for less frequent replacement of products, so less raw materials are used. Being chemically resistant, it would circumvent the coatings or treatments that may pose environmental concerns.

Energy-efficient production and processing reduce carbon emissions during manufacturing. HDPE is processed at lower temperatures than most other plastics, so less energy is required. Lower emissions and costs result from this manufacturing efficiency.

Another environmental advantage is water conservation, for which HDPE offers resistance to both moisture and chemicals, thereby reducing the water-intensive cleaning or maintenance required by other materials.

Environmental Benefits Summary:

- Durability: Less frequent replacement reduces raw material consumption

- Chemical Resistance: Eliminates need for potentially harmful coatings or treatments

- Energy Efficiency: Lower processing temperatures reduce carbon emissions

- Water Conservation: Minimal cleaning and maintenance requirements

- Manufacturing Efficiency: Lower emissions and reduced operational costs

Buying and Sourcing HDPE Pellets

Where to Buy High-Quality HDPE Pellets

One must identify reputable suppliers with unwavering quality control and timely delivery to source high-quality HDPE pellets. Developed global distribution networks help major chemical companies maintain a consistent supply for high-volume applications. Suppliers generally extend technical support to customers and may customize their formulations to meet specific application needs.

Regional distributors provide invaluable services to small manufacturers, handling smaller quantities and offering localized support. The benefits of these distributors include maintaining stock to ensure speedy deliveries and even offering blending services to meet very specialized needs.

Large-volume buyers gain preferential prices and assurance that their current supply agreements will be guaranteed through an extended direct relationship with the manufacturers. In turn, this kind of relationship entails working together technically to develop and optimize applications.

Supplier Options:

- Major Chemical Companies: Global distribution networks, consistent supply, technical support, customized formulations

- Regional Distributors: Smaller quantities, localized support, maintained stock, speedy delivery, blending services

- Direct Manufacturer Relationships: Preferential pricing, guaranteed supply agreements, technical collaboration, application optimization

Price of HDPE Pellets: Influencing Factors

HDPE pellet prices depend on several factors, with raw material costs being the most significant. Ethylene prices vary with petroleum markets and the dynamics of worldwide supply and demand. These changes then trickle down, directly affecting pellet prices with varying time lags depending on the stocks kept by suppliers.

Further processing can also increase value, with certain grades fetching much higher prices. Food-grade certification, special molecular weight distributions, and color matching all amount to higher prices.

The demand level for a product can significantly influence price changes during peak manufacturing seasons or when supply disruptions occur. An area will affect prices due to varying transportation costs and other factors influencing regional markets.

Volume conditions certainly play a significant role in pricing negotiations. Typically, large-volume purchasers enjoy substantial discounts, whereas smaller quantities incur handling fees and minimum order requirements.

| Price Factor | Impact | Considerations |

|---|---|---|

| Raw Material Costs | Most significant factor | Ethylene prices vary with petroleum markets and global supply/demand |

| Processing & Certification | Increases value significantly | Food-grade certification, special molecular weights, color matching |

| Demand Level | Fluctuates with seasons | Peak manufacturing seasons, supply disruptions |

| Regional Factors | Location-dependent | Transportation costs, regional market dynamics |

| Volume | Major role in negotiations | Large-volume discounts vs. handling fees for smaller quantities |

Evaluating Sellers and Quality of HDPE Products

Quality assessment starts with purchasing and supplier control systems and certification review. A certification like ISO 9001 suggests that the supplier has quality control processes in place, while an industry-specific certification may indicate compliance with regulatory requirements, e.g., an FDA certification for food-grade materials.

Material data sheets and technical data provide helpful information on the different grades, properties, and performance characteristics of materials. Reliable suppliers provide an unabridged documentation package containing information for melt flow rates, and density, as well as mechanical properties data.

Testing capability is encouraged as determined by how a supplier approaches control of their product quality. If they do have their own proprietary testing laboratory, they are likely also able to perform quick quality verification and give technical support for application development.

Customer references and case histories provide evidence of suppliers’ experience and reliability. Long-term customer relationships point toward suppliers who consistently maintain their quality and services.

Quality Evaluation Checklist:

| ✓ Certifications | ISO 9001, FDA (food-grade), industry-specific certifications |

| ✓ Documentation | Material data sheets, melt flow rates, density, mechanical properties |

| ✓ Testing Capability | Proprietary testing laboratory, quality verification, technical support |

| ✓ References | Customer testimonials, case histories, long-term relationships |

The Future of HDPE in Various Industries

Innovative Developments toward HDPE Applications

Advanced HDPE formulations are thus widening the horizon of application possibilities. Metallocene-catalyzed HDPE has the potential to offer enhanced properties such as improved impact strength and better processability. These advanced materials help in producing thinner-walled products with performance intact-the thinner wall translates into less material consumption and a drop in cost.

Depending on the end use, additive technology is applied to either improve or modify the performance of these HDPE materials. UV stabilizers, for instance, are intended to extend the lifespan of these enhanced materials when exposed to outdoor conditions, whereas antimicrobial additives provide hygienic surfaces for medical and food applications. These enhancements give HDPE a way into markets that would otherwise be unsuitable for this material.

These composites, in which natural fibers are combined with HDPE pellets, are entry points to sustainable alternatives to traditional composites. These materials are in the uphill, lightweight, and green direction while maintaining structural performance in construction and automotive applications.

Innovation Highlights:

- Metallocene-Catalyzed HDPE: Enhanced impact strength, better processability, thinner-walled products

- UV Stabilizers: Extended lifespan for outdoor applications

- Antimicrobial Additives: Hygienic surfaces for medical and food applications

- Natural Fiber Composites: Sustainable alternatives with maintained structural performance

Energy Efficiency and Cost-Effectiveness of HDPE

Energy consumption of HDPE processing has been decreasing over the years mostly due to improvements in equipment and optimization of processes. Advanced extruders and molding equipment now operate with higher energy efficiency, using less energy per unit produced.

Maintenance requirements for HDPE products are minimal compared with other materials. By reducing maintenance activities, this feature also reduces lifecycle costs and the environmental impact of HDPE.

Being lightweight, these materials also benefit transport efficiency. They weigh much less than their metal or ceramic counterparts, generating less emissions during transportation from the manufacturing site.

| Efficiency Factor | Benefit | Impact |

|---|---|---|

| Processing Energy | Decreasing energy consumption | Lower energy per unit produced through advanced equipment |

| Maintenance | Minimal requirements | Reduced lifecycle costs and environmental impact |

| Transportation | Lightweight material | Less emissions compared to metal or ceramic alternatives |

Future Trend Predictions for the Demand of HDPE

Demand for HDPE worldwide will continue to expand as infrastructure development in emerging markets and sustainability initiatives from developed countries drive growth. Pipeline applications alone are expected to consume more quantities as replacement of aged infrastructure is required.

Applications of packaging will continue to grow as companies search for sustainable alternatives to non-recyclable materials. Regulatory pressures and consumer preferences are driving a shift toward recyclable packaging at the expense of HDPE applications.

Lightweighting trends in the automotive sector are driving the growth of HDPE applications as manufacturers juggle performance, cost, and environmental requirements. Particularly in the development of electric vehicles are lightweight materials that lend a helping hand on battery range.

Future Growth Drivers

Infrastructure Development

Emerging markets expansion and aged infrastructure replacement driving pipeline applications

Sustainable Packaging

Regulatory pressures and consumer preferences shifting toward recyclable packaging solutions

Automotive Lightweighting

Electric vehicle development requiring lightweight materials to improve battery range and efficiency

Reference Sources

- R-HDPE Pellets and Their Applications – Eco Recycling Today

Discusses the eco-friendly benefits of R-HDPE pellets across industries like packaging and construction. - Best Natural HDPE Pellets | 100% Strong & Sustainable Plastic

Highlights the durability and versatility of natural HDPE pellets for packaging and industrial uses. - Understanding HDPE Pellets: Properties and Applications

Explores the properties of HDPE pellets and their applications in packaging, piping, and other industries. - Recycled HDPE Plastic Pellets for Molding

Details common applications of recycled HDPE pellets, including automotive, industrial bins, and cable insulation. - HDPE Applications | Shell Polymers | Business

Provides insights into how industries are thriving using high-density polyethylene for various applications.

Frequently Asked Questions (FAQs)

❓ What is the raw material of HDPE plastic pellets?

HDPE is a thermoplastic polymer injection resin possessing strength and durability. It falls under petrochemicals; hence, this versatile material fits many applications because it is light and highly resistant to various forms of damage. These pellets find application; these can be colored, including black. They can be have-ability specifications very well suited for injection molding operations. The method of producing these natural pellets involves maintaining high quality and meeting industry standards. Using HDPE, manufacturers can develop designs that are very efficient for making bottles and containers.

❓ How are HDPE pellets used in injection molding?

HDPE pellets are primarily used in injection molding to produce a wide range of plastic products. When heated in an injection molding machine, the pellets melt and are formed into containers, bottles, and other products. Being a tough, heavy, and chemically resistant material, high-density polyethylene is used for items that need resistance against impact and chemical reaction. The versatility of HDPE enables it to serve a wide range of applications, from consumer goods to industrial components. The low cost of these natural pellets is another reason why manufacturers favor them.

❓ What do HDPE plastic pellets usually cost?

Plastics have no standard price; prices depend on several factors. However, the prices for HDPE pellets are generally quoted per pound, and they may be several dollars or much higher; the injection mold, for example, is the highest grade. The price may be more attractive when buying in bulk. Hence, it is advised that buyers compare prices from different suppliers to secure the best deals. Of course, being an eco-friendly material and thus being recycled very efficiently has sometimes supported upward price pressure, but that is a secondary consideration. In any case, shipping charges must always be factored in when considering the total cost.

❓ How does the use of HDPE pellets affect sustainability?

Using a high-density polyethylene pellet contributes to sustainability, as HDPE can be recycled across many applications. Allowing the repurposing of HDPE products throughout their lifecycle to create new ones will minimize waste and the need for raw materials. The processes involved in producing the pellets can be optimized, leading to energy and emission reductions and supporting an environmentally friendly approach. Manufacturers continue to look for ways to make their products more sustainable, paving the way for the use of recycled HDPE. In the final analysis, HDPE aligns with modern sustainable design principles.

❓ Where do I buy HDPE plastic pellets?

The raw material, HDPE pellets, can be bought from suppliers and manufacturers of thermoplastic materials. Today online portals give buyers the convenience to make price and specification comparisons for similar grades of HDPE pellets. A reputable supplier should be selected for serious buyers, and one that discloses all data on the product’s quality and compliance. One should consider all shipping costs, minimum quantity orders, and customer reviews. Through local distributors, they may also be available for bulk purchases by manufacturers engaged in injection molding applications.

❓ What are the main applications of HDPE pellets?

Though versatile and strong, HDPE pellets operate for various applications. They are commonly used to produce bottles, containers, and consumer articles that require durability and strength. Injection molding for hand tools is used for impact- and chemical-resistant applications. It also produces bags and protective packaging, making it vital in many industries. With increased demand for green products, the use of HDPE pellets has risen across several sectors.