High-density polyethylene (HDPE) pellets play an essential and integral role in modern industry and commerce: in the manufacture of resilient packaging materials and sturdy construction elements. But the quality of HDPE pellets from the supplier can certainly affect product performance, efficiency, and price. This blog is intended to assist you with finding the best HDPE pellet suppliers in the industry. We discuss what makes a quality HDPE pellet and a trustworthy supplier, and some critical considerations for sourcing. Whether you are streamlining your supply chain or simply want to enhance your product quality, this article provides you with all the knowledge you need to choose among suppliers to fit your needs.

Understanding HDPE and Its Applications

What Is HDPE?

High-Density Polyethylene (HDPE) is a widely appreciated thermoplastic polymer because of its robust structure and general adaptability in use. Due to its high strength-to-density ratio, HDPE is a robust yet light material that finds applications ranging from piping and packaging to geomembranes and household goods. This polymer is very resistant to impact, chemicals, and moisture, so it gives long services to industrial as well as usual use. The high recyclability of HDPE puts it in good standing with an ever-growing desire for sustainable materials in manufacturing. Since it is adjustable and environmentally friendly, this polymer is preferred amongst industries that wish to produce high-performing products with sustainable solutions.

Uses of HDPE in Industry

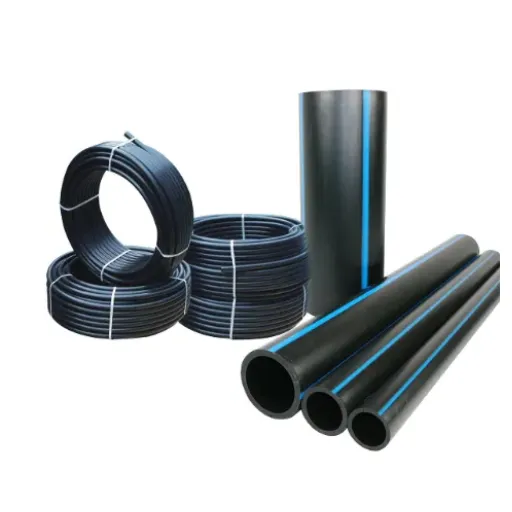

Due to its versatility, high-density polyurethane has made its mark in almost every industry. One primary application is packaging, where HDPE offers an ideal solution for creating bottles, containers, and plastic bags due to its lightweight nature and adequate strength. The construction industry also directs the use of HDPE in piping systems, such as water and gas supply lines, because it is resistant to corrosion, chemicals, and environmental stress.

These plastics, known for their high impact resistance and low weight, are widely used in the automotive industry for applications in fuel tanks, seat components, and body panels to enhance durability and reduce weight. Likewise, HDPE is an important material in agriculture, mainly for irrigation piping, greenhouse films, and protective covers. In addition to this, HDPE’s enhanced recyclability makes it a green choice increasingly preferred by markets that operate above circular manufacturing models to reduce waste. Innovations continue to enhance its properties, allowing HDPE to meet performance requirements for industries with its newfound sustainability.

Benefits of Using HDPE Granules

HDPE granules offer various advantages that industries worldwide consider in preference for each application area. One of the special advantages is their durability and impact resistance, which can provide longevity and reliability to applications under adverse conditions, such as in piping systems and industrial containers. They are lightweight, so they can be easily handled with little transportation cost, yet they are strong.

The second key advantage is chemical resistance—they withstand harsh chemicals and corrosive substances, making them suitable for use in chemical storage tanks and agricultural solutions. HDPE granules also provide excellent weather resistance, which prevents the products from being damaged by long exposure to UV, extreme temperatures, and keeps them moist.

HDPE granules can be recycled completely, aligning with industries increasingly adopting eco-conscious practices and circular production based on the main sustainability principle. This recyclability decreases pollution and supports curbing industrial waste. Finally, the HDPE granules are versatile, allowing manufacturers to provide customized solutions to meet the specific requirements of construction, packaging, or consumer goods. Thus, a combination of these advantages places HDPE granules as high-performance, sustainable, and cost-effective materials for modern production requirements.

Characteristics of High-Quality HDPE Pellets

Density and Stiffness of HDPE Pellets

High-quality HDPE pellets feature an excellent density and stiffness that confer significant mechanical strength and durability. Usually, the density of HDPE lies anywhere between 0.93 and 0.97 g/cm³, giving it the advantage of being both light and strong, a coveted property when durability without extra weight is required. The significant density, combined with its crystalline structure, enables it to bear heavy loads and resist high impacts, enhancing the product’s durability.

Stiffness is another essential property exhibited by HDPE pellets and is governed by the molecular constitution and processing parameters. A very high tensile modulus, along with bending strength, permits these pellets to be used in operations where retention of shape under stress without deformation is desired. This rigidity helps in selecting applications such as pipes, containers, and structural components requiring stability and durability. By adequately balancing density and stiffness, HDPE pellets provide a versatile and reliable solution for various industrial and consumer applications, without affecting quality and performance.

The Resistance Properties of HDPE

HDPE is famous for its strong environmental and chemical resistance, which all foster the potential of this plastic for use in the industries. The HDPE plastic resists corrosive chemical atmospheres by strongly resisting acids, bases, and alcohols, thus retaining its performance. It also resists water and moisture very well, which places it high on the list for water pipes and storage tanks.

With one of its special features being resistance to UV radiation when appropriately stabilized, it lowers the possibility of degradation due to sunlight exposure. When coupled with HDPE’s outstanding impact resistance and retention of mechanical properties at low temperatures, great performance under extreme weather conditions is assured. All these make it an undeniably durable and economical option for industries that require super-strong materials geared for extreme environments.

Virgin vs. Recycled HDPE Pellets

Understanding the key differences between virgin and recycled HDPE pellets is essential for making the right decision based on specific applications. Being made straight from petrochemical feedstocks makes virgin HDPE pellets pure in materials and consistent in mechanical properties. These attributes stand out in industries that require high-quality standards, such as food packaging, medical supplies, and critical infrastructure components.

On the contrary, recycled HDPE pellets are synthesized from post-consumer or post-industrial plastic wastes. Recycling in this manner indeed plays a vital role in sustainability by reducing plastic waste and conserving natural resources, but the material properties may vary depending on the source and processing method. New technologies have been developed to ensure the supply of high-quality recycled HDPE, allowing it to be used for non-food containers, construction, and outdoor furniture.

Ultimately, the choice of HDPE pellets-whether virgin or recycled-depends on the importance of performance versus environmental considerations. Industries that consider themselves more environmentally friendly can go for recycled HDPE wherever possible, but those that demand the highest precision and uniformity usually need virgin HDPE.

Finding Reliable HDPE Pellets Suppliers

A Few Vital Factors to Consider When Selecting a Supplier

Selecting the right HDPE pellets supplier is essential for maintaining product quality and achieving long-term success. Here are critical factors to consider as you make your decision:

- 1.Quality and Consistency:

Evaluate the suppliers’ ability to provide pellets meeting certain quality and specifications consistently. Look for certifications, such as ISO norms, to ensure that these suppliers abide by certain high manufacturing standards.

- 2.Range of Offerings:

A good supplier should be able to supply all types of virgin and recycled HDPE pellets to ensure you can purchase the materials most suitable for your specific applications, in terms of cost and usefulness.

- 3.Sustainability practices:

A supplier that is in tune with sustainability issues tends to use environmentally friendly production methods and practices to source recycled materials thoughtfully. Engaging a supplier with these practices would help build credibility for your own environmental commitments.

- 4.Industry Experience and Reputation:

Suppliers with a long history in the industry are well aware of the subtleties of HDPE applications and can offer insights and recommendations tailored to your needs. Researching their reputation through reviews or testimonials can provide further assurance.

- 5.Customization and Technical Support:

Typically, the best suppliers will offer material customization that ensures an exact fit to your application. Expert technical support during the very early stages of your investigations may allow faster project development and better troubleshooting.

- 6.Production Capacity and Lead Times:

Assess the supplier’s production capacity and the ability to meet your demand over time. Deliveries of material need to be timely at all stages of production to avoid bottlenecks or delays in your operations.

- 7.Cost Efficiency:

It is vital to carefully evaluate pricing patterns so that good suppliers may provide competitive prices without compromising on material quality. Discounts for bulk quantity procurements are an additional advantage that can help diminish procurement costs.

- 8.Compliance and Certifications:

Ensure the supplier adheres to relevant industry rules and standards, particularly for safety and environmental compliance.

Before making your final decision, consider all these factors to help you secure an HDPE pellets supplier who stands true to operational and sustainability goals and with whom you can confidently rely for years to come.

Top Suppliers of HDPE Pellets in the Market

In selecting reliable suppliers of HDPE pellets, you must consider their market reputation, product range, and quality and sustainability measures. Here is a detailed account of some of the best suppliers in the industry:

| Supplier Name | Key Highlights |

|---|---|

| INEOS Olefins & Polymers | INEOS, being an eminent entity in the petrochemical industry, has a broad portfolio of HDPE pellets that finds uses from industrial packaging to highly specialized works of automotive parts. The whole range of their production processes is hinged on innovation, efficiency, and environmental compatibility. |

| LyondellBasell Industries | As renowned leaders in advanced polymer technologies, LyondellBasell produces high-quality HDPE pellets that meet industrial needs, from packaging to construction, and some consumer uses. Their materials prepared with performance and sustainability in mind. |

| SABIC | SABIC is a notable supplier of HDPE pellets and is known to have superior R&D capabilities. SABIC maintains a very strong focus on circular economy initiatives to provide solutions for industries where high chemical resistance and durability are essential. |

| ExxonMobil Chemical | HDPE products from ExxonMobil are engineered for reliability across a broad range of applications. They use advanced manufacturing techniques to produce materials that comply strictly with industrial standards at competitive prices. |

| Braskem | Being deeply committed to sustainability, Braskem stands as a major producer of bio-sourced HDPE pellets derived from renewable resources. These products are perfect for companies that wish to include greener materials in their supply chains. |

| Chevron Phillips Chemical | The company holds high-density polyethylene resins, which are marketed as a premium material for versatility and strength. Their extensive range of products accommodates more demanding applications, also considering environmental sustainability. |

Exploring opportunities with these reliable suppliers will help companies identify solutions that meet their production requirements and sustainability goals, ensuring secure supply chains and quality outputs.

Assessing the Quality and Reliability of the Supplier

In our assessment of supplier quality and reliability, we make an informed decision that leans more towards the supplier’s long-term success. This involves evaluating product quality, adherence to industry standards, and delivery performance. A high-quality supplier can produce a wide range of certifications that firmly attest to the materials of products, which should, in turn, comply with local regulation requirements and the company’s production goals.

In addition to this, studying suppliers’ on-time delivery records helps assess their reliability and instill trust in their ability to meet deadlines, especially during stringent schedules. Customer reviews and case studies from within the industry could provide pertinent insights into responsiveness, problem resolution, and adaptability concerning specific project requirements. Giving greater priority to these aspects improves supplier assessment methodologies, thus allowing companies to work with vendors that favor operational efficiency while maintaining high-performance standards.

HDPE Resin and Its Role in Injection Molding

Types of HDPE Resins Used in Manufacturing

Some HDPE resins find use in injection molding. In essence, with their associated versatility and durability, they permit infinite opportunities for all kinds of applications. The common types of HDPE resin found in manufacturing include:

Blow Molding Grade HDPE

This category is applicable mainly for manufacturing hollow objects such as bottles, containers, and tanks. It has excellent stress crack resistance and good processability, making it suitable for applications where the product requires uniform wall thickness and durability.

Injection Molding Grade HDPE

More suited to specific needs, this resin type is used in the production of caps, containers, and household goods. Its main attraction is the strength of impact and dimensional stability, which ensures reliable performance in high-volume production.

Film Grade HDPE

Used widely in packaging applications such as plastic bags and liners, film-grade HDPE is regarded for its high tensile strength and puncture resistance. Being such a light material, skinny films aid in the reduction of materials used without compromising durability.

Pipe Grade HDPE

This variety is designed for use in pipe production, tying-in gas distribution, water systems, and irrigation. Its resistance to chemical damage, pressure, and environmental stress cracking ensures long-lasting performance under demanding applications.

Using these grades allows manufacturers to optimize the products they market in terms of both performance and production cost. Very much an industrial marvel, the ever-evolving technology of HDPE resins is constantly widening its application front to suit the ever-growing demands of modern-day industries.

Injection molding process for HDPE

Injection molding for high-density polyethylene (HDPE) is very efficient and adaptable, making it ideally suited for the manufacture of many different items. After melting HDPE resin pellets in a heated barrel, the molten material is then forced by pressure into a pre-designed mold cavity under controlled pressure and temperature. Advanced temperature control in this process ensures that the HDPE maintains its required viscosity, allowing it to flow evenly into the mold and thereby minimizing the occurrence of defects such as voids or warping.

Modern injection molders apply improved automation and monitoring technologies to ensure consistency and minimize production time. Real-time sensors, for example, allow manufacturers to monitor pressure and flow rates, thereby reducing potential material wastage and increasing cycle efficiency. After the material cools down and solidifies into the shape of the mold, the product can be ejected and, in its final form, is ready for use.

In other words, it is a process that heavily manufactures durable and complex components, such as caps, containers, and automotive parts, with very high dimensional accuracy. Meanwhile, innovations in mold design and automation continue to bring about tighter tolerances, faster cycles, and better energy efficiency, meeting the industry’s need for sustainability and cost-effectiveness.

Comparison of HDPE with Others in the Market

High-density polyethylene (HDPE) stands apart from thermoplastics in its phenomenal balance of durability and flexibility at an affordable price. Whereas HDPE is somewhat less rigid but very resistant to impact and cracking, PP is the preferred product in packaging, piping, and outdoor applications due to its rigidity and heat resistance. Polycarbonates (PC), on the other hand, are far more expensive and heavier than HDPE, but they offer optical clarity and extreme toughness for applications such as lenses and protective equipment.

An additional point worth comparing is vinyl chloride polymers. Whereas PVC shows better rigidity and resistance to fire, often plasticizers need to be used to confer flexibility, raising some environmental concerns. In contrast, HDPE is more flexible by nature and chemically inert, thus offering a good option in specific applications. Further to this, its moisture resistance and ease of recycling make HDPE a preferred choice for environmentally conscious applications where longevity is a desired property.

With advances in polymer technology, HDPE continually enhances its performance properties, including for food-grade applications and improved processability. This flexibility, together with its competitive pricing, keeps HDPE among the very top thermoplastic choices as the field continues to evolve.

Market Trends and Innovations in HDPE Pellets

Emerging Technologies in HDPE Production

This branch of HDPE production encompasses numerous front-line developments impinging on the industry. It would be paramount to think of a new technology based on the advanced catalytic systems, such as metallocene catalysts, that offer an unprecedented degree of control over the polymer chain structure. These systems acquired the HDPE pellets with very precise properties, imparting effects like strength, flexibility, or environmental-stress cracking resistance. Such catalysts can bring other advantages to the production process and enable lower energy consumption and waste generation, highlighting the growing demand for sustainability in manufacturing.

In the HDPE production plants, the attraction is the use of combining digitalization and Industry 4.0 technologies. For example, many manufacturers implement machine learning and predictive analytics in their operations to fine-tune the production parameters, minimize downtime, and maintain product consistency. In addition to increasing overall efficiency, these technologies allow real-time monitoring of quality and environmental impact, ensuring compliance with stringent industry regulations.

Sustainability continues to be the prime mover for innovation in HDPE manufacturing, where chemical recycling and bio-based feedstocks have taken center stage in R&D. Chemical methods of recycling post-consumer HDPE waste break it down into monomers, allowing recycled pellets to be made, which are of such high quality that they can be used exactly as virgin ones. Similarly, bio-based raw materials come from renewable sources such as sugarcane, thereby cutting down on fossil fuel usage and carbon emissions. With such complementary technologies, efficient and green methods of HDPE production can be developed to meet ever-growing markets for high-performance thermoplastics.

Impact of Sustainability on HDPE Supply Chains

In my view, sustainability is transforming the HDPE supply chains and creating changes on two fronts: environmental and operational. Increasingly stringent regulatory interventions coupled with growing consumer consciousness now create more pressure on companies to ensure that eco-friendly practices are followed in their supply chains. By using recycled HDPE or bio-based materials, manufacturers reduce carbon emissions and ensure that upstream processes align well with the circular economy concept. They thereby transform the system into a closed loop for the reuse of plastic materials, minimizing the volume of waste going into landfills or the ocean.

Another crucial transformation arises from wanting to bring greater transparency and traceability to the supply chain. Advanced technologies such as blockchain and electronics can allow businesses to track materials in real time, trace origin, and ensure sustainability. These tools can also help determine the environmental impact of production and logistics activities, as well as create trust between manufacturers, distributors, and the end consumer. This high level of accountability is thus becoming a competitive advantage for industries that rely heavily on HDPE, such as packaging and construction.

It is, however, obvious that the scaling of sustainable practices within HDPE supply chains also faces challenges. Limited availability of quality recycled material or high upfront R&D costs for an eco-friendly solution might pose a challenge for some manufacturers. These challenges, however, are far outweighed by long-term financial and reputational benefits such as improved efficiency, compliance with sustainability regulations, and increased customer loyalty. If companies address them in advance, they will be competing as leaders for the establishment of an industry that is both resilient and environmentally responsible.

The Future of HDPE in Various Industries

We are looking at High-Density Polyethylene (HDPE), which offers significant hope for the future in various industries due to its versatility, durability, and environmentally friendly considerations. HDPE is becoming widely preferred by manufacturers in industries like packaging and construction because of its ability to be inexpensive and dependable, attributes attributed to its being light yet strong. Whatever sustains the world in the name of green initiatives further catapults the role of HDPE, which is highly recyclable and environmentally friendly. Closed-loop recycling systems are beginning to loom large in the circular economy, encouraging companies to implement HDPE in their long-term sustainability plans.

An exciting advance is the increasing use of HDPE in renewable energy systems. For example, HDPE pipes are commonly selected in geothermal heating-cooling applications since they resist temperature variation and harsh environmental conditions. Stocks’ irrigation application method in agriculture is considered a use of HDPE for water conservation and waste reduction. The automotive and consumer goods industries, on the other hand, have recently been investigating uses for HDPE that involve creating lightweight components to aid in vehicle fuel efficiency and reduce waste from product packaging, making this material an essential part of any modern environmental equation.

Planning further, the next stage of improvements in HDPE performance will be powered by technology and research. In other words, enhancements in the strength-weight ratio of the polymer are being sought. They are languishing in the laboratories to withstand high-stress environments and improve recycling technology for maximum reuse. Indeed, these developments will help the industries as they comply with the toughest regulations and go beyond consumer sustainability requirements. Today’s HDPE investments will lead to immediate commercialization and accelerate a future where sustainability and efficiency are the cornerstones of any primary industry.

Reference Sources

- HDPE Resin / Pellets – Order Online

Offers a variety of HDPE resin and pellets for extrusion and molding, with detailed product specifications.

- Premier Plastic Resins – HDPE

A Michigan-based supplier providing virgin, prime, and recycled thermoplastic pellets for injection molding.

- Plastic Resin Pellets Suppliers – Thomasnet

A directory of manufacturers and distributors offering plastic resin pellets, including HDPE, for various applications.

- Industrial Plastic Pellets | 100% Durable Recycled Resin

Features eco-friendly, high-strength industrial plastic pellets suitable for molding, packaging, and construction.

- Buy HDPE Granules | Polyethylene | CAS 9002-88-4

Provides HDPE granules with high strength and chemical resistance, ideal for research and various molding processes.

Frequently Asked Questions (FAQs)

What are HDPE pellets, and what are their uses?

HDPE pellets are tiny granules made out of HDPE resin. Various applications include plastic bottles, containers, and pipes. With HDPE, stiffness and impact strength can be applied to demanding applications such as automotive parts and packaging materials. The pellets are used as raw material in injection molding and blow molding to create finished products. Their versatility and durability make HDPE acceptable for many industries.

How are HDPE resin pellets manufactured?

HDPE resin pellets are produced through polymerization processes, where ethylene gas is converted into high-density polyethylene. Catalysts are usually used in the process, in combination with conditions favorable for the formation of a certain molecular weight and density. After forming, the polymer is cooled and cut into small granules or pellets. These pellets can undergo further processing for various applications, including injection molding and extrusion. The production of HDPE pellets primarily focuses on achieving a high degree of purity and good mechanical properties, which are necessary to meet industry standards.

What is the difference between HDPE and LDPE pellets?

The HDPE and LDPE pellets differ mainly in the molecular structure and properties. HDPE is characterized by high tensile strength, great impact resistance, and rigidity. This resin finds application when durability is required, such as in pipes and containers. LDPE, on the other hand, is more flexible and softer: it is used to make plastic bags and films. The two types of polyethylene have quite different characteristics and thus should be correctly selected for individual applications, especially in industries where they are heavily used, such as packaging and manufacturing.

What are some advantages of using virgin HDPE resin?

Virgin HDPE resin offers advantages in HDPE aggregates with enhanced mechanical properties and chemical resistance. Such resin is considered high-density, as opposed to its recycled counterpart, and is endowed with much higher tensile strength and impact resistance. Thus, virgin HDPE is predominantly employed in high-performance applications like automotive components and sturdy containers. From another perspective, virgin HDPE is less prone to contaminants, and thus, powder resin of a consistent quality and performance can be counted on in injection molding. This, however, poses environmental issues that the industry should address by looking into sustainability.

How good are recycled HDPE pellets in comparison to virgin pellets?

Performance-wise, recycled HDPE pellets can be very good substitutes for virgin pellets. They vary based on the quality of the recycling process. Generally speaking, recycled pellets are economical and sustainable, although they do not usually match the mechanical properties of virgin HDPE in applications requiring very high mechanical properties. In any case, with the advancement of recycling technologies, the quality of recycled HDPE has improved, and it can now be applied in many fields. It is about time for industries to face the major environmental impact of plastic waste, which has opened up to the need for recycled materials in products such as bottles and containers.

Which variables should be examined in an HDPE pellet supplier?

When searching for HDPE pellet suppliers, it is imperative to consider the quality of the product, its consistency, and the supplier’s reputation in the market. The OEM would prefer suppliers that offer high-purity pellets with the mechanical and thermal properties desired for their respective applications. Again, question the supplier’s production capacity and lead times. Will they meet the specific requirements for color or additives? Will they be environmentally friendly in their approach? If so, they might well support your company’s philosophy. Prices might be marketed well, yet should not affect the pellet quality.