In industrial applications, PTFE and PFA are often emphasized as specialized materials because of their remarkable performance and versatility. Although they have some things in common, these two fluoropolymers differ in specific ways, which makes them more suited for different applications. Identifying the distinctions in PTFE and PFA can enable engineers, manufacturers, and even interdisciplinary professionals to make decisions with regard to using specific materials for particular applications. This article discusses the fundamental features, benefits, and practical applications of PTFE and PFA in the hope of helping you distinguish between them, unlocking their potential according to your requirements.

What are the differences between PFA and PTFE?

Although PTFE (Polytetrafluoroethylene) and PFA (Perfluoroalkoxy) are both high-performance fluoropolymers, their structural composition and applications are distinct:

- Temperature Resistance: PTFE is slightly better than PFA when it comes to extreme heat environments; hence, it has a comparatively higher operating temperature.

- Flexibility: PFA is better suited for processes involving complex shapes because it is more flexible and easier to mold compared to PTFE, which is rigid.

- Chemical Resistance: PFA offers greater resistance to stress cracking in harsh chemical environments compared to PTFE, making PFA the material of choice in this context.

- Surface Finish: In scenarios where low friction and minimal contamination are essential, PFA’s smoother surface compared to PTFE gives it an advantage.

- Cost: PFA is more expensive than PTFE due to being structurally more flexible and having better overall qualities.

Choosing either PTFE or PFA materials depends greatly on the operational conditions, the intricacy of the design, and even the financial constraints.

What are the unique properties of PFA?

Due to its advanced technology construction, PFA or Perfluoroalkoxy Alkane, exhibits a wide array of merits including high resistance to heat, solvents, and other chemicals alongside superior dielectric properties, making it suitable for harsh applications in various industries. The following are the important distinguishing qualities of PFA:

- High-Temperature Resistance: PFA is capable of withstanding operating temperatures of around 260°C (500°F). This continuous temperature defies other materials at high temperatures.

- Chemical and Corrosion Resistance: PFA is of immense value to chemical processing industries due to its exceptional resistance to strong bases, acids, organic solvents, and a myriad of other chemicals.

- Flexibility and Toughness: Enhanced mechanical strength and greater flexibility make PFA more advantageous than PTFE. PFA maintains structural integrity under pressure and is complex in geometry.

- Transparency: Laboratory and medical facilities greatly benefit from the use of PFA due to its naturally translucent nature, which permits monitoring of the internal flow of liquids in tubes and other transparent parts.

- Electrical Properties: PFA is an outstanding insulating material for electrical and electronic devices due to its low dissipation factors, excellent dielectric strength, and efficiency in high-performance applications.

- Non-Stick and Low Friction Surface: Due to its non-stick and low-friction surface similar to PTFE, PFA is smoother and less prone to contamination, ensuring smoother, cleaner operations.

- UV and Weather Resistance: Components otherwise exposed to outdoor conditions have an extended lifespan due to PFA’s remarkable resistance towards UV radiation and environmental degradation.

The unparalleled advantage PFA showcases in aerospace, electronic, pharmaceutical, and chemical processing industries is due to its distinctive characteristics. These features, in particular, make it useful as a material in cases where extremely harsh environments are present and remarkable performance along with dependability is needed.

How does PTFE compare in terms of chemical resistance?

Polytetrafluoroethylene (PTFE) remains one of the most chemically resistant materials known. It can sustain intense chemicals like acids, bases, and even solvents without any degradation or reaction, making it the top choice for use in aggressive chemical environments. PTFE is also able to withstand chlorine and sulfuric acid even at elevated temperatures. It can withstand hydrofluoric acid as well as sulfuric acid. It’s amazing that chemical PTFE still holds its structural integrity under extreme conditions where other materials would fail.

For instance, PTFE can withstand a broad range of pH levels while withstanding a chemical attack, making it appropriate for check valves in the chemical processing and high-purity fluid handling industries. PTFE parts can operate in sustained 500°F (260°C) environments and still be devoid of any chemical attacks that would destroy other materials. Its strongest application is in gaskets, linings, seals, and pipe fittings in highly reactive processes because no other fluoropolymer comes close to PTFE’s unmatched chemical resistance.

What is the chemical structure of PTFE?

Polytetrafluoroethylene (PTFE), commonly known as Teflon, has the formula (C₂F₄)ₙ. The compound consists of a chain of carbon atoms, which is the backbone, wherein each carbon is attached to two fluorine atoms. This structure creates some of the strongest bonds known in organic chemistry, notably the carbon-fluorine bond which contributes to PTFE being chemically stable and an extremely chemical resistant.

Because of the strong C-F bonds, the backbone of PTFE is effectively shielded from external reactions, rendering PTFE nonreactive and inert to most chemicals. Its characteristics include ultralow frictional resistance, nonstick, as well as a low coefficient of friction, which all can be traced back to its molecular structure. PTFE contains a density of 2.2g/cm³ and a melting point of 600K (327°C), but PTFE stays stable structurally over an even wider scope of temperatures. The fact that PTFE is capable of withstanding harsh temperatures while still performing is what makes it irreplaceable in certain industries.

How do PFA and PTFE perform in high-temperature applications?

Both PFA and PTFE excel in high-temperature situations because of their thermal stability and impermeable degrading properties. PTFE can keep its properties up to 260°C (500°F) which is perfect for extremely hot environments. PFA also provides comparable high temperature performance, resisting 260°C (500°F) while also having better chemical resistance. These features make both materials dependable for working with high temperatures for a long time.

What is the maximum working temperature for PTFE?

Polytetrafluoroethylene, or PTFE, is praised for its unrivaled resistance to heat, retaining its mechanical and chemical properties even at high temperatures. The most widely accepted operating temperature limit for PTFE is approximately 260°C (500°F). Anything above this limit would result in gradual material degradation, leading to loss of structural integrity. While not advisable, PTFE can withstand short-term exposure to temperatures exceeding 260°C, up to around 327°C (620°F), which is its melting point. Its unmatched PTFE resistance to high temperatures makes it essential in industries such as aerospace and chemical processing, where materials are constantly subjected to extreme temperatures.

Can PFA withstand similar temperature ranges?

Yes, PFA tolerates temperature ranges almost as much as PTFE, with a maximum continuous service temperature at approximately 260°C (500°F). However, just like PTFE, PFA’s sustained exposure to extremes close to its threshold would impact its functional and structural integrity.

What are the applications of PFA and PTFE in semiconductor manufacturing?

Semiconductor manufacturing makes extensive use of PFA and PTFE because of their high chemical resistance, thermal stability, and non-reactive properties. They assist in the construction of components within chemical delivery systems and help minimize the risk of aggressive chemical infiltrations in the system, durably serving in the tubing, valves, and fittings. Additionally, both materials serve as the linings of process equipment, such as tanks and wafer carriers, to maintain purity and avert contamination during critical manufacturing processes. The reliability of these materials enables the stringent requirements of semiconductor production to be met.

How is PTFE used in semiconductor lining?

Polytetrafluoroethylene (PTFE) is of utmost importance in semiconductor linings because the material meets the specific requirements of the industry. PTFE is widely used as a lining for chemical storage tanks, pipes, and reaction vessels. It does not chemically react with severe acids such as hydrofluoric acid and sulfuric acid; therefore, aggressive contaminants do not corrode the containment systems and chemical clarity is not compromised.

Moreover, PTFE possesses unrivaled thermal stability because it can endure operational temperatures from -328°F to 500°F (-200°C to 260°C). PTFE is also suitable for processes that have extreme changes in temperature, like those present in semiconductor manufacturing. PTFE linings have an ultra-low friction coefficient, which increases precision and reliability while also reducing wear particles in sensitive environments.

Studies show that PTFE-lined systems can increase component lifespan by as much as 50% relative to non-lined counterparts. The reduction in system downtime avoids excessive maintenance cycles, thus improving operational cost-efficiency. The combination of chemical resistance, thermal endurance, and purity underscores the need for PTFE in semiconductor fabrication.

What advantages does PFA offer in semiconductor applications?

Semiconductors greatly benefit from the unique properties that Perfluoroalkoxy alkane (PFA) offers – its versatility makes it an essential component. Below are its key advantages, summarized;

- Exceptional Chemical Resistance: PFA is extremely effective against a variety of corrosive chemicals like semiconductor grade sulfuric acid, sulfuric acid, and strong alkalis. This makes it useful for protecting and preserving equipment within harsh environments.

- High Thermal Stability: PFA guarantees ultra-clean performance without the risk of contaminants within the microfabrication required during semiconductor assembly. Maintaining device performance and yield is crucial, making its unparalleled cleanliness critical.

- Ultra-High Purity: Withstanding extreme temperatures ranging from -200°C to 260°C, PFA does not deteriorate, meaning thermal processes requiring harsh conditions aren’t an issue.

- Non-Stick Properties: Its low surface energy inhibits adhesion and particle build up, ensuring uninterrupted smooth operations during the processes of wafer fabrication and within chemical delivery systems.

- Durability and Longevity: The efficiency of PFA as a non-stick lining material is attributed to its ability to resist cracking, abrasion, and mechanical stress which increases time between scheduled maintenance activities. Research has shown PFA lined components outperform unlined ones by up to three times in harsh operational conditions.

- Superior Electrical Insulation: Its dielectric strength is unaffected by high frequencies, making it feasible to insulate delicate electronic elements during semiconductor fabrication.

- Versatile Application: PFA can be fabricated into several forms like tubing, fittings, and coating,s which enables it to meet particular application needs.

- Stable Performance in Ultra-Clean Environments: PFA does not leach contaminants or degrade with time because of its non-reactive nature, maintaining consistent performance in cleanroom conditions.

This mixture of traits enables PFA to be an exceptional material which aids in attaining the precision, ruggedness, and hygiene paramount for semiconductor manufactures.

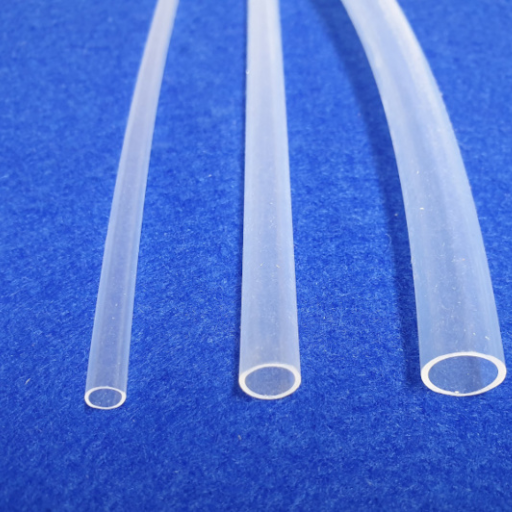

How does PFA vs PTFE impact tubing choices?

The comparison of PFA and PTFE for tubing remains dependent on certain application needs:

- Flexibility: PFA is generally more flexible than PTFE tubing, hence, it is easier to work with during installations involving tight bends or intricate shapes.

- Clarity: PFA is transparent and allows visual inspection of flow, while PTFE is opaque.

- Temperature Resistance: Both materials do well in withstanding high temperatures, but PFA is more flexible compared to PTFE hence has a slightly higher maximum operating temperature.

- Chemical Resistance: Both PFA and PTFE offer excellent chemical resistance; however, due to the smoother surface of PFA, the chances for contamination are lower in some applications.

- Cost: PFA does tend to be more expensive than PTFE, leading to some difficulty when a budget is involved.

In this regard, PFA is more often used in services with greater flexibility and clarity, whereas PTFE is better suited for more cost-sensitive, higher temperature applications.

What are the benefits of using PFA tubing?

PFA (Perfluoroalkoxy) tubing is commonly known for its remarkable properties, which make it favourable in many fields. Its nonstick cover reduces material accumulation, ramping up the level of cleanliness for sensitive applications in the chemicals, pharmaceuticals, and food industries. Strongly aggressive chemicals like strong acids, bases, and organic solvents are no match for PFA tubing also provides exceptional chemical resistance.

Its nonstick cover reduces material accumulation, ramping up the level of cleanliness for sensitive applications in the chemicals, pharmaceuticals, and food industries. Strongly aggressive chemicals like strong acids, bases, and organic solvents are no match for PFA tubing also provides exceptional chemical resistance.

In comparison with other fluoropolymers such as PTFE, PFA tubing can be recognized for its better optical clarity. This added clarity enhances visual flow inspection making it ideal for processes that require monitoring. Additionally, PFA tubing’s flexibility makes it easy to install in intricate systems while still being tough, resistant to cracking under repeated stress, and maintaining the required durability.

Minimal permeability ensures that the risks of gas or vapor leakages are greatly reduced, making this safe for the environment and compliant to regulations during industrial use. PFA Tubing has multi-layered features as to why it’s considered trustworthy and safe in critical and complex tasks. This makes it the go to option in those types of applications.

Why choose PTFE tubing for certain applications?

PTFE (Polytetrafluoroethylene) tubing is well known for its usefulness in meeting the requirements of several services at once. This is because of its unique properties. Below is a detailed list of the key advantages of PTFE tubing.

- Exceptional Chemical Resistance

PTFE is nearly inert which means that it can resist almost all chemicals including strong acids, bases and solvents. This makes it an excellent choice for use in chemical processing and transport application.

- Wide Operating Temperature Range

PTFE tubing can work from -328°F (-200°C) all the way to 500° (260°C). The thermal stability allows ptfe tubing to withstand extreme temperatures without degrading.

- Low Friction Coefficient

PTFE is one of the lowest friction coefficient materials when it comes to solid materials. This helps wear and flow efficiency in fluid and gas transport systems.

- Non-Stick Surface

The non-stick property of PTFE makes sure that there is no residue that can build up and lead to clogging. This is very useful in cleaning and maintenance. This is invaluable in foodprocessing, pharmaceutical, and laboratory settings.

- Excellent Electrical Insulation

PTFE works as an excellent insulator across a broad spectrum of frequencies and temperatures, aiding its use in electrical and electronic components.

- High Flexibility and Durability

Although PTFE tubing is stiff under ordinary conditions, it displays remarkable flexibility, which allows it to be installed into complex configurations without failing due to stress cracking over time.

- Minimal Permeability

PTFE tubing’s low gas permeability is very important in applications where the environment is controlled, such as in gas sampling and containment systems.

- FDA and USP Compliance

PTFE tubing is often verified as food grade or medical grade and complies with FDA and USP regulations making it safe in food production, biopharmaceuticals, and medical devices.

- UV and Weather Resistance

Because of the strong resistance PTFE has against UV and weather, it can withstand harsh environments without losing effectiveness.

- Longevity and Cost-Effectiveness

Though PTFE tubing is relatively more expensive than other materials, it is cheaper in the long run due to its low maintenance and long-lasting durability.

Aerospace, medical technology, industrial processes, and incredibly sensitive fields where reliability and performance are crucial are some of the sectors where PTFE Tubing is used because of its unique properties.

What is the difference between PTFE and FEP?

Both PTFE and FEP are fluoropolymers that share the same non-stick properties and chemical resistance, but differ in:

- Flexibility

Flexibility FEP is easier to bend, unlike PTFE, which is more rigid.

- Transparency

Transparency FEP allows visibility through the material as opposed to PTF, E, which is opaque.

- Temperature Resistance

Temperature Resistance PTFE has higher temperature tolerance than FE, P, which has a lower maximum working temperature.

The differences aforementioned make PTFE apt for rigid and high temperature applications while FEP is better for applications that require flexibility and some kind of visibility.

How do the chemical properties compare?

Thermal expansion occurs as a result of changes in composition. In comparing PTFE and FEP thermal properties, both materials resist sudden environmental disturbances; however, FEP lacks the versatility offered by PTFE under thermal sources. PTFE is fully inert and resistant to corrosive environments, while also offering strong acids, bases, and organic solvents with amazing endurance. Thus, PTFE is preferable for extreme corrosive working conditions. FEP is also highly resistant, although its performance in extremely corrosive conditions is limited; it is better than PTFE in less severe environments.

Gas permeability is another area where they greatly differ. FEP has a higher gas permeation rate compared to PTFE, meaning it serves as an inferior barrier for gases and volatile chemicals. Other than that, PTFE is better for tensile strength; features such as lower flexibility make PTFE easier to withstand hostile chemical attacks.

Both materials remain non-reactive with water, making them suitable for a wide range of applications. FEP, however, offers more ease of use in dynamically adaptable applications, where movement or vibration modifies the working conditions.

What are the unique applications for FEP?

Prized for its flexibility and thermal stability, FEP (Fluorinated Ethylene Propylene) also has thermal and chemical resistance, allowing it to excel in specialized applications across various industries. One of its prominent uses is in the manufacture of chemical-resistant tubing and piping, and in other functional areas such as the pharmaceutical industry and chemical processing industry,y where aggressive handling of chemicals is a necessity. Because of its non-stick and low-friction properties, FEP is also very useful in wire and cable insulation, particularly in high-performance electrical systems where heat resistance and dielectric properties are critical.

FEP is very useful in the medical field for creating catheters, surgical tools, and other devices which require biocompatibility, sterilizability, and precision under challenging conditions. In addition, it can also serve very well in the production of optical components and protective coatings for solar panels due to its transparency combined with UV radiation resistance.

FEP’s ability to withstand a broad range of temperatures (-200°C to 200°C) and its growing applications in the aerospace and automotive industries make it an industry essential for insulating components exposed to extreme conditions. These defining traits give FEP engineers the tools to meet the demands of dynamic and innovative applications where other materials tend to fail.

What are the non-stick properties of PTFE and PFA?

Because of their low surface energy and high resistance to chemicals, both PTFE and PFA are well known for their astonishing non-stick characteristics. These materials stop substances from bonding to their surfaces, which makes them ideal for use in the manufacture of cookware coatings, industrial molds, and tubing. One widely recognized example is Teflon, which provides excellent durability and non-stick performance. PFA has similar properties but is more flexible and transparent, which may make it better suited for applications that require these qualities. Both materials are effective in retaining non-stick properties in harsh conditions for a long period of time.

How effective are PTFE and PFA as non-stick coatings?

The supreme chemical properties of PTFE and PFA enable both of them to serve as exceptional non-stick coatings. PTFE, one of the very few materials with a frictional coefficient between 0.04 and 0.1 (one of the lowest in solid surfaces), achieves a near-adhesion frictional surface repelling substances like grease, oils, and other adhesives. Because of its non-stick properties, it is primarily preferred in cooking vessels and industrial tools with smooth surfaces that require low-friction interactions.

In contrast, PFA incorporates the anti-adhesive attribute of PTFE along with more flexible and temperature resistant properties. Even after 260°C (500°F) of heat for a long period of time, PFA retains its structural integrity as well as non-stick capabilities. Its transparency enables its utility in situations where close observation is needed, such as some processing or laboratory tasks.

Both PTFE and PFA possess chemically inert properties, which greatly aids in their utility in corrosive environments like chemical processing equipment and pipe linings. Industrial metrics and studies show that these coatings greatly aid in extending the lifespan of surfaces heavily exposed to abrasive conditions while increasing maintenance costs. Versatile non-stick performance coupled with high durability ensures utility across numerous industries.

What industries benefit from these non-stick properties?

The non-stick properties offered by these coatings are useful in many different fields. In the food and beverages industry, these coatings are used in the production of non-stick utensils such as pots and pans, ovens, baking molds, and even conveyor belts, which eliminates problems with food sticking while promoting clean production. The automotive and aerospace sectors use these coatings to protect parts that incur wear and tear, such as bearings, gaskets, seals, and other components, and improve their overall energy efficiency and durability.

In addition, the non-stick coatings used in the chemical processing industry are quite helpful because they protect machinery from harsh chemicals, which reduces equipment and downtime, cutting costs. Medical technology also uses these properties for the tools used in surgery, containers used to hold prescription drugs, and even in some implanted devices to greatly reduce the risks of bacterial infection. Industrial non-stick coatings in these sectors have been reported by experts to improve efficiency and reduce maintenance, therefore promoting sustainable industrial practices.

Reference Sources

- Surface Characterization of Fluorinated Polymers (PTFE, PVDF, PFA)1:

- This study analyzed the surface properties of PTFE, PFA, and PVDF using microscopy techniques.

- Key Findings: PFA exhibited the lowest nano-roughness, making it ideal for ultrapure liquid storage and transport in industries like microelectronics. PTFE, due to its sintering process, showed less favorable surface quality.

- Methodology: Techniques like light microscopy, scanning electron microscopy, and atomic force microscopy were employed.

- Overview of the Development of the Fluoropolymer Industry2:

- This review provides a historical and technical overview of fluoropolymers, including PTFE and PFA.

- Key Findings: PFA’s lower crystallinity compared to PTFE enhances its processability, while PTFE remains dominant in applications requiring high chemical resistance and thermal stability.

- Applications: PTFE is widely used in chemical processing and electrical insulation, while PFA is preferred for high-purity and chemical-resistant components in semiconductor manufacturing.

- Performance Properties and Applications of Polytetrafluoroethylene (PTFE)—A Review3:

- This review focuses on PTFE’s performance enhancements through the use of nano and micro fillers.

- Key Findings: Modified PTFE demonstrates improved wear resistance, thermal stability, and mechanical properties, making it suitable for diverse industrial and domestic applications.

- Methodology: The study surveyed various casting and processing techniques for PTFE.

- Top PFA Resin Suppliers in China

Frequently Asked Questions (FAQs)

Q: What are the main differences between PTFE and PFA fluoroplastics?

A: The main differences between PTFE (polytetrafluoroethylene) and PFA (perfluoroalkoxy) fluoroplastics include their processing methods, with PTFE being used in applications like extrusion and PFA being melt processable. Additionally, PFA has a lower maximum operating temperature compared to PTFE, making PTFE more suitable for high-performance applications.

Q: How do the properties of PFA fluoroplastics compare to PTFE?

A: PFA fluoroplastics have similar properties to PTFE in terms of chemical resistance and temperature stability; however, PFA offers better melt processability and lower viscosity, which makes it ideal for certain applications like medical tubing.

Q: Can PFA be used in the semiconductor industry like PTFE?

A: Yes, PFA is used in the semiconductor industry due to its high-performance characteristics and similar properties to PTFE, making it suitable for applications that require chemical resistance and temperature stability.

Q: What is the impact of the difference between PTFE and PFA on their applications?

A: The differences between PTFE and PFA impact their applications significantly; PTFE is often used in high-performance settings such as heat exchangers, while PFA is preferred for applications requiring easier processing, such as in medical tubing and chemical equipment.

Q: Is PFA a version of PTFE or a different polymer?

A: PFA is considered a version of PTFE, as it is a type of fluoropolymer that shares many similar properties with PTFE but has distinct features that allow for different processing methods and applications.

Q: How does the temperature stability of PTFE compare to PFA?

A: PTFE generally has a higher continuous working temperature compared to PFA, which has a lower maximum operating temperature, making PTFE more suitable for extreme thermal environments.

Q: What makes PFA suitable for medical tubing?

A: PFA is suitable for medical tubing due to its ability to be melt processed, which allows for precise manufacturing, as well as its excellent chemical resistance and temperature stability, ensuring safety and reliability in medical applications.

Q: Are there applications where FEP is preferred over PFA or PTFE?

A: Yes, FEP (fluorinated ethylene propylene) is sometimes preferred in applications that require lower processing temperatures and where its specific properties, such as salt spray resistance and weathering resistance, are beneficial, particularly in the chemical industry.

Q: What are the considerations when choosing between PTFE and PFA for industrial applications?

A: When choosing between PTFE and PFA for industrial applications, considerations include the required processing method, maximum operating temperature, chemical resistance, and specific application needs such as whether injection molding or extrusion is necessary.