Polyamide and polyester are two of the most commonly used materials when it comes to synthetic fibers, but their properties are different and this often raises the problem of determining the appropriateness of each type for a given application. The following piece will thoroughly discuss these two materials in terms of polymer properties and other characteristics. This will, in turn, shed light on which of the two is preferable based on the most important factors such as durability, moisture resistance, texture, and environmental impact. Either you are one of the manufacturers who is looking for materials for their new product or a person who is in fabrics and wants to know the textile performance or maybe a consumer faced with a myriad of a kind of cloth with different quality but does not know what to choose, this article will clear things for you. Eventually, you will be confident in making the right material choice because your new material will now be based more on your specific needs and priorities than the availability of other types.

Introduction to Synthetic Fibers

Tell me about Polyester and Polyamide

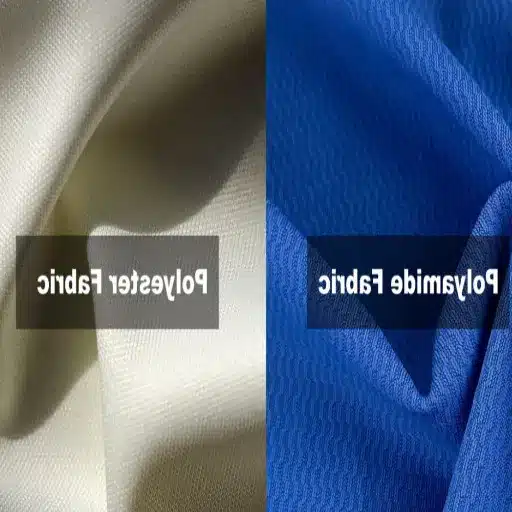

Polyester and polyamide are man-made polymers that are very important in the textile industry and also in the manufacturing industry because of their flexible characteristics and high performance. Polyester, which is made up mostly of polyethylene terephthalate (PET), is a family of polymers. They are made using the classical method of polymerization by the use of chemical feedstock from crude oil. It is one of the most widely used polymers in the world and is known for its durability, resistance to elongation and reduction in size, and ability to dry quickly, thus, being one of the most preferred choices in the garment, household, and industrial areas.

Polyamide, which is otherwise known as nylon, is a material that gets its characteristics from the molecular structure made up of repeating units held together by amide linkages. Together with polyester, polyamide is one of the materials being synthesized through chemical machineries and exactly like polyester it is dependent on petroleum derivatives, which are among the main sources of carbon–based feedstocks for chemical processes of polymer fabrication. The material is on top of the ranks for its incredibly high breaking strength, resistance to abrasion, and extensibility. The usage of Polyamide is very much in trend for the areas like; activewear, ropes, and technical textiles where the durability remains the dominant feature.

Both polyester and polyamide are strong materials with unique characteristics, and may be selected for many different reasons like, for example, the intended usage, the environmental factors, and the terms of use. Synthetic fiber, which is the type of fiber found in both polyester and polyamide, has always been an area of intensive research and development especially in the textile and clothing industry because it is a man-made fiber with characteristics similar to those found in the natural ones. Also, the way in which the fiber is produced can determine the functional properties of the fiber such as the dye absorbency, shape, diameter, etc.

Overview of Synthetic Fibers in Textiles

Synthetic fibers are carefully designed materials that have specific features to improve their functionality and suit various applications. High tensile strength, softness, resistance to the abrasion, and susceptibility to the environmental degradation such as mold or UV are the main attributes of synthetic fibers. Therefore, different synthetic fibers are of great importance in the industries including but not limited to the fashion, automotive, aerospace, and healthcare sectors. One of the most commonly used synthetic fibers is Polyester, which is the most commonly used fiber in the industry. It is most associated with its resistance to wrinkles, its being dirtcheap, and one of the most durable fibers and therefore serve as one that is extensively used in the form of its apparels, home furnishings, etc; Polyamide, nylon’s common name, is known for its superiority in terms of being elastic and being resistant to abrasion and thus, not getting affected by moistures, which makes it a very good pick for wear-resistant applications such as sportswear, carpets, and

Acrylic is another important fiber. It imitates wool’s characteristics and is frequently used in the production of knitwear, upholstery, and thermal insulation. Furthermore, the use of spandex, or elastane, enables the garments to be best stretched and restoring, thus making it ideal for activewear and compression garments. Flame retardancy and water repellency are a couple of the special treatments that these fibers usually undergo, giving them a broader range of functionalities that comply with the specific needs of both producers and consumers.

Developments in polymer science and fiber development are making synthetic fibers more and more diverse in terms of their types and applications. Thus, the global market is in the process of entering a new era of innovation in the field of materials and their use.

The Need for Full Comprehension of Fibre Properties

The textile manufacturing business in the age of fiber knowledge globalization demands that key variables be acknowledged in the development of materials, product, and the manufacturing process that shows industry leadership in textile innovation. Fibers are endowed with unique characteristics viz., tensile strength, elasticity, moisture absorption, thermal resistance, and durability which affect directly their specific use in the market. Thus, one fiber may not specifically show the same properties as another fiber and on this notion proper selection will require exercising the attribute of one fiber over another based on the two main characteristics. As a result, it is technically impossible to find a good compromise point for just one property of interest. They are variables that have been used in the market for a long time. Fiber A will be moisture-laden before Fiber B at 100 percent RH. During the same period(under high humidity conditions), Fiber A can be pulled with a required effort for upsetting the lagging step. Fiber B can shelter your body for only a very small area when compared to the rest. But little kids often look cute wearing them. In August Fiber A, Fiber B, and Fiber C were higher in entire dog days than in July. Fiber D was the opposite though. Fiber E was the big surprise in August. Fiber manufacturers and suppliers are the entities to be interested in circumventing the confusion. That is why they will put the fibers in the market with tags that say they are made to be used for very cold environments like those in Siberia. They are difficult to handle! The worst part of it is aesthetic values! At the beginning of August, a customer walkling would say if he was paying for a void. Why is it so extremely concentrated in the latter half of the year? One could go on learning and working to know more of the properties.

Key Differences Between Polyamide and Polyester

Chemical Composition and Structure

Though right up the street from each other, polyamide and polyester are two-dimensional polymers with the same synthetic nature, but a totally different make-up of chemical composition and molecular structure. However, due to their different properties and uses, it is a common and notable thing. At the same time, one of the main characteristics of polyamides is their condensation reaction between dicarboxylic acids and diamines, with the result being amide bonds (-CONH-) in the polymer chain backbone. This quite unique structure of polyamide is one of the main platforms that make the polymer have a high thermal stability, chemical resistance, and strength. In addition, hydrogen bonding among the chains of polymer molecules can also be seen to be a main property that the polymer chains are elastic and hard.methods of forming the polyamide that are taken as the overall characteristics of nylon are not less than the formation of the nylon itself. High temperature, extreme chemical exposure, and extremely high loads are some of the conditions that polyamides withstand very well. The other admiring properties of nylon are the low friction co-efficient and high toughness.

On the other hand, polyester is frequently made from the polymerization of dicarboxylic acids and diols, where ester bonds (-COO-) are formed in its molecular structure. This typeset gives polyesters a very strong, non-stretching, and water-repelling quality. The fact that there are no hydrogen bonds in the case of polyamide makes it have a lower melting point; however, it also means better processability, especially in the textile and industrial fields. The differences in chemical structures are the main reasons behind their performance in various applications since the polyamide is the best for stressful conditions, and the polyester is very good for light and moisture-resistant application the same time.

Durability and Mechanical Properties

The intertwining of the durability and mechanical characteristics of polyamide and polyester is attributed to the molecular structures of the materials and to the applications they are subjected to. Polyamides, including nylon, are very strong, elastic and resistant to abrasion. Consequently, the use of such materials in the manufacturing process is tantamount to resistance to the effects of high tensions and multiple loads. The material also performs very well, if it has been put through enough cycles, by keeping the structural integrity even under the harshest conditions, e.g., high strain or continuous motion.

Polyester, on the other hand, shows better dimensional stability and is less affected by environmental degradation, its special characteristic being able to keep its strength and shape to a great extent in the presence of UV radiation and water. This property not only makes polyester ideal for outdoor applications but also throws light on the fact that it is a perfect material for places where weather is a predominant factor. Hence, both the mentioned characteristics of the materials are actually almost the same, while the differences in the performance are visible in dynamic loading for polyamides and in almost no changes in the case of polyester. Additives and different manufacturing processes further contribute to the qualities of end products and make them suitable for all possible industrial applications. Advanced processing techniques and material blends further enhance these characteristics, providing tailored solutions for diverse industrial requirements.

Abrasion Resistance and Wearability

The main thing in characterizing the performance of a certain material would be the level of abrasion resistance and wearability particularly in the case of the most demanding industrial, automotive, and customer applications. Polyamides, such as nylon, are greatly resistant to wear by their very nature of being tough and by having a low friction coefficient. Thereby, They are very proper for the making of gears, bushes, and bearings that goes through long mechanical interaction int the operation. In contrast, polyethylenes in this case, are very good with resisting surface erosion which is brought about by the friction created from the rubbing and for that reason they can keep their shape and colour looking the same as new for long[].

If we mention only a couple of the significant impacts of modern abrasion tests, it can be said that they are a great help in determining the abrasion resistance of various materials by the tested standard methods. The test results in the industry-textile area indicate that self-lubricating property of polyamide is one of the main reasons behind the toughness improvement of polyamide under dynamic conditions while facing very high wear rates that come with direct impacts. For example, the polymer of polyester presents strong links in a three-dimensional bond structure of the molecule that only gives slight movement, thereby making it difficult for mechanical stress to effect the fabric and coatings; thus, polyester is an important part of such things as protective textiles and heavy-duty upholstery, being the favored material.

Use of these as well as the other materials and manufacture of composite solution or constructions with them bring the industry a choice of very specific means to produce economically and sustainably. The continuous improvement of the additives and coatings, through which both the polyamides and polyesters’ abrasion resistance getting even more excellent and expanding to be used widely in modern technological developpement and ecological approaches, leads to the remarking of these two as the leading ones in the aforementioned application field.

Applications of Polyamide and Polyester Fabrics

Sports Apparel and Activewear Usage

Use in activewear and sports apparel is enormous due to the outstanding mechanical and beng unlimited, the adaptability of Polyamide and polyester fabrics. Polyamide is, with its exceptionally superior elasticity, and wear and tear, as well as lightweight, the most suitable material for clothes that need both flexibility and durability, including leggings, sports bras, and compression gear. On the other hand, polyester is mostly known for its moisture-wicking properties, the nature which is quick-drying, and resistance to ultraviolet (UV), which makes it the best choice for outdoor and performance apparel, such as running shirts and jackets.

The use of the most modern technology and methods ensures that textile engineering is up to date with the latest trends and that the materials are getting better for the purposes of sport. This is true for the microfiber technology and polyester fabrics, which will eventually bring about a combination of the two which will be soft and excellent in capillary action; thereby, they will be helpful in the process of sweating during stressful physical activities. Elastane and Polyamide are the best combination that will give one the best of both worlds, which are shape retention and perfect fit, so crucial for those people who do high-impact moves. The story is not yet at its end; a lot of work in the industry has been done in the areas of the dyeing and finishing processes so the colors stay longer and the anti-odor properties are being introduced to the performance part, which are tried but failed conditions.

Not only that, the technical aspect, as well as the introduction of “green” processes, has positioned polyamide and polyester as pillars in the sportswear field. These materials are children of strict standards in the business world and pro-environmental measures companies take, and this is an assurance to stay on the market and maintain the trend of the new without being left behind.

Textile Industry Trends: Polyester vs Polyamide

One of the current trends in the textile industry will be the use of polyester and polyamide. These new varieties from combining polyester’s strength and economic feasibility with polyamide’s stretchiness and coziness are they need the best of both worlds. Fabric manufacturers are the main operators in this new system by positioning this product in very well between the two extremes of being strictly functional and marketing oriented. For example,; these kind of fabrics are more and more used in sportswear of best quality because of the feeling of dryness that they give and the less friction, and such yet very light also.

Besides, the recent advancements in fiber engineering have more and more zeroed in on the eco-consciousness of these fabrics. The latest trends like using post-consumer waste polyamide and manufacturing the fabric from recycled polyester have been very user-friendly, and at the same time they are eco-friendlier. These not-so-newly-fiber-introduced high-quality blends correspond with the eco-friendly-products and tough-environmental-rules to which most of the industries seem to adhere. As a result, this will not only place the polyester and polyamide blends as a trend-setter but also be the reflection of a bigger scope of moving to the earth responsibly by sourcing and producing materials properly.

Innovations in Fabric Blends: Combining Nylon and Spandex

Nylon and elastane are among the best combos for creating fabrics with extraordinary features such as stretch, durability, and comfort. One of the most popular applications of nylon is in fabrics because of its strength and wear resistance. Elastane gives textile its desired elasticity. Hence, the combination of these two leads to excellent adaptability and shape retention. This combination is even more exciting for the manufacturers because it is already being adopted as one of the key fabric blends for sportswear, swimwear, and athleisure- all of which need the smallest possible weight and maximum versatility under different kinds of stresses.

An important factor of the innovation chain has been the introduction of microfine yarns and seamless knitting techniques in the mixture, which produce thin and breathable fabrics that at the same time allow the free mobility of the person and have a high tensile strength. Another point to consider is that the colorfastness and vibrancy of the dyed fabrics have been much improved by the new dyeing methods, thus meeting the very strict aesthetic requirements of today’s consumers. These improvements along with the fabrics’ moisture-wicking and quick-dry properties have turned nylon-elastane blends into the most preferred material for creating both functional and stylish clothes.

The production of nylon-elastane fabric for these and other purposes is non-stop, with its share in the fabric market growing rapidly and researchers also exploring newer ways to make this fabric more ecofriendly by, for example, increasing its recyclability and minimizing the related environmental impact.

Recyclability of Polyester and Polyamide

Getting to Know Recycled Polyester and Its Positive Aspects

It is not uncommon to see recycling as rPET. In this manner, recycled polyester becomes an eco-friendly choice to raw polyester and is the result of the summonsing of such things as the plastic waste from the recycling of PET bottles and other post-consumer plastics. The method is to collect, clean, and shred the plastics into small pieces, which are then melted and made again into polyester fibers. Refining fossil fuels, recycled polyester becomes part of the reduction in greenhouse gas emissions and the preservation of the resources of the earth.

Recycling polyamide (nylon and other synthetic fibers) has taken a very long road to reach the point of commercial feasibility. However, the industry still faces several obstacles, including high costs, low quality, and environmental concerns associated with recycling processes. Additionally, the new challenges in recycling polyamide fabrics can be connected with the expansion of the availability of other recycling technologies, such as biological recycling of polyester. This way, a combined technology can be exploited and it will make processes less dependent and more efficient.

Challenges with Recycling Polyamide Fabrics

The reclamation of polyamide materials through recycling is faced with intricate challenges, mainly because of the molecular structure and the existence of additives or mixtures in the material. Polyamides, like nylon, are frequently employed in textiles as blends with other fibers: elastane or polyester, for the later case, so as to extend durability of the final product and the wear comfort. But these blends make the separation much longer and more difficult and in all cases the yield and quality of the output are adversely affected by the recycling method in a mechanical or chemical way.

Additionally, chemicals used in dyeing and finishing of polyamide fabrics often cause residues and produce more chemicals that can be barriers to the recycling processes and reduce the quality of created substance. Nonetheless, technologies like depolymerization may provide a method for breaking down plastic to the level of the monomers that can be re-polymerized if it is possible to overcome the technical and economic hurdles these methods have. The problem even can be more difficult because of poor systems for collection of used polyamide and the fact that the consumer is not well informed about the proper way of disposal. It is only through technological upscaling of recycling, the establishment of tight supply chains, and the increased collaboration in the value chain among the different partners or stakeholders in the value chain that the issues can be dealt with, thus making polyamide fabric processing more sustainable.

Future of Sustainable Fabrics: Recycled Options

Advancements in chemical and mechanical recycling technologies have been making the increasing use of recycled materials in fabric production the way of the future, with the related fallouts of the two industries converging to the point that recycled polyester (rPET), a case in point, has taken the lead over virgin polyester as an eco-friendly fabric due to its lower carbon emission and decreased petroleum usage. Moreover, the breakthrough in recycling techniques for cellulose fibers, among others, the fibers present in cotton and viscose, has been providing the industries with the possibility of adopting closed-loop model, where the entire material can be recycled and reconstituted into new fibers with the least amount of degradation in quality.

Moreover, the emerging technologies in enzymatic recycling are showing a great deal of promise in the area of fiber recovery due to their ability to break through the old barriers. Engineers have the ability to manipulate enzymes in a way that they will only break down specific polymers such as PET or polyamide into their monomers, hence providing the material to be re-polymerized into new and quality materials. This sharp peaceful decomposition is not only a profit-making event but also opens up the fabric pool that can be recycled in a sustainable way.

Despite all this, the biggest hurdle is putting in the necessary money for the infrastructure and the many new rules and ways of working that will make it as easy as possible for the recycling method to be implemented. The success of recycling also significantly depends on the following: collection works, the simplification of the sorting process, and the reasons consumers should end-of-life garments properly. Using high-level data analysis including among other things AI-based sorting of textiles will have the advantage of linking up recycled fiber on a garment-to-garment basis thus improving the whole process even more.

If the textile industry was to combine these very advanced methods of recycling with the help of the whole sector and that of the law, it could change towards a circular economy model. In this way, the industry will greatly decrease the use of limited resources while meaningfully involving in the green textile production and waste impacts. In the long run, the fashion industry will be much more sustainable as a result of recycling fabric technologies that lead a sustainable change.

Conclusion: Choosing the Right Fabric for Your Needs

Factors to Consider When Choosing Between Polyester and Polyamide

I think of certain features and use of the fabric when the comparison of polyester and polyamid is in question. Polyester is very popular and the reason being such attributes as long lasting, not easily crumpled. Its fast-drying capacity, besides, it is most frequently employed in outdoor wear, sportswear, and home furnishings, also, among some cases where shrinking is not expected. Quality of the color is supposed to remain vivid forever, the chemical nature of the material would be another important issue in the case of wash resistance, nevertheless, the price would also be in the center of interest. Also, polyester is usually cheaper hence, it is also an economic indicator for a whole range of industries particularly in the case of mass production on an extensive scale.

However, polyamide, which is more commonly known as nylon, can stretch more, withstand abrasion better, and give softer touch against polyester, which is its peer. It is indeed these same properties that place the material over the top of a selection list for items which require the highest degree of flexibility and comfort such as hosiery, swimwear, and technical gear. Polyamide fabrics are also more absorbent than polyester, which could mean less sweating but, on the other side, longer drying. Nowadays, the environment is also a consideration; both fibers are made from petroleum feedstocks, which are synthetic materials, yet recycling of nylon is already in vogue and, thus, making it all the more eco-friendly.

It really comes down to these things plus the specific needs of the application that I am still debating the polyester or polyamide case for. It is a case of sturdiness, ease of use and low cost. With the materials, I just need to grasp the most significant ways in which they differ and thereby, I can go ahead and decide wisely about each and every individual project or need.

Final Thoughts on Fabric Selection for Various Applications

I always talk about how fabrics must be closely related to the use cases which they are intended for, when I am the one who selects the fabrics for the applications. Polyester with the problem of moth and polyamide (nylon) with the water and the other two bring the benefits of being distinctively different. Polyester is the one that has the upper hand in terms of light and water which means it is the first choice of the outdoor uses such as tents, and sportswear associated with the nature of the material. One of the major advantages of being non-polar is [that] polyester does not absorb water, which makes it [the] case for ever so many places like activewear or when there is wetness often. Besides, the extraction of the more environmentally friendly polyester has been made; the polyester which is used thereafter always has less [environmental impact], durability remains the same, and performance even increases, if at all.

Despite its beauty, polyamide is more popular than others in three aspects: strength, elasticity, and resistance to abrasion. Thus applying it in some areas where the strength is very important is favorites as for example industrial textiles, climbing gear, or high-performance sports equipment. By contrast, nylon neck and neck with other fibers is more comfortable to wear and more breathable. In fact, it is visible more in the soft delicate lingerie industry or in the very similar hosiery industry. This is absolutely a positive feature of nylon but actually the biggest advantage of this fiber is its comfort. The polymerization process for Nylon creates a very organized structure within the polymer network which ensures that the nylon fibers have very few defects and are very strong. Differently, polyamide is hard to process after the fibers in it have been oriented as they are not heated and are little flexible. Due to this effect but not only polyamide is a cost-effective and fast material used in the industry but also the process of its production is long and the electricity used for the subsequent stages of nylon production is not much greater either.

I base my actions on the unique requirements of every single project. It’s through using the very specific qualities of these materials and being well-informed about the latest advancements in recycled and bio-based technologies that I am capable of choosing the best functional, cost-effective, and environmentally responsible material. The textile innovation scenario which is in the process of further development steadily points out the right direction for my materials, thus, the most successful outcome is guaranteed for any application the fabric is intended for.

The Future of Synthetic Fibers in Fashion and Textiles

It can be concluded that one of the sources where the future of synthetic fibers in the fashion and textile industry is associated with is the use of environmentally friendly-advanced production methods and making the industry circular. To me, the breakthrough is in the development of fibers that not just copy the characteristics and applications of the traditional synthetics but also the great amount of cutting down their environmental impacts. The example of the already aforementioned different nature and properties of bio-based synthetic fibers, the cultivation of which is done using raw materials like corn or sugarcane, is an ideal demonstration of the enormous potential in this direction. The above-mentioned fibers are very much similar to their petroleum-based counterparts and apart from that, they also decrease one’s dependence on petroleum, which is the main energy source of the modern world. Moreover, the improvements in the recycling of the textile products show that through the combination of a wide variety of techniques, mechanical and chemical, it can now be possible to retell the old story of the synthetic textiles as waste, where maximum reuse is observed and the life of the products is prolonged.

The rise of another necessary consideration is the closed-loop systems in manufacturing techniques. Through these, the unused materials and waste are kept in a constant cycle or even turned into new products instead of being thrown away. Another sustainable feature of the production is that it’s not in the same magnitude of land usage, water pollution, and so on. They also include more and more renewable energy technologies. Through keeping up with all these technology advancements, I participate in the process of bringing the latest synthetic materials into my projects, making them environment-friendly along with being functional as a necessity.

I have come to believe that the collaboration of material scientists, industry leaders, and regulatory bodies is the key to setting the new standards for synthetic fibers. The rise in the demand for transparency, traceability, and eco-certification makes me think that the synthetic materials will develop into more environmentally friendly and not only do that but also fully satisfy the global sustainability goals. The implementing of the measures will not only present a technical issue but it is also an ethical necessity and so a more sustainable and responsible textile industry will come out of that.

Reference Sources

- 📚Polymers – Los Medanos College

Discusses the differences between polyamides and polyesters, including their chemical bonds and properties. - 📚Introduction to Polymers – OpenLearn by Open University

Explores the molecular structure and bonding characteristics of polyamides and polyesters. - 📚Structure and Applications of Polymers – Penn State University

Provides an overview of polyamides and polyesters, focusing on their structure and practical applications.

Frequently Asked Questions (FAQs)

Which yarn features play a big role in soft touch and comfort of a fabric?

The characteristic that really stands out when it comes to soft, comfortable, and kind of a second skin is polyamide. Nowadays a range of nylon yarns, namely nylon 6, can be designed with very fine filament structures giving the yarn a smoother feel compare to the rough feel of polyester yarns. However, polyamide tends to be somewhat firmer than polyester yet this can be improved by finishing. Apart from this, the durability and fabric softness of polyamide vis-a-vis polyester are also relevant points of reference. Moisture regains and hydrophilicity are especially important i.e. the polyamide finds it harder to hold its water molecules than the virgin polyester does, so more moisture remains in the skin when wearing the former. The softness and elasticity of a fiber are also crucial factors which limit the mobility of the user of the sportswear and outdoor gear. In these kinds of clothing, elongation and elasticity are the main reasons for keeping the size and shape as they should. Both the fabrics of polyester and polyamide are as a rule synthetical and are very used in the textile industry and can be processed so as to make them stops to getting dirty and not lose the color of the dye.

Do the yarn tensile strength and outdoor gear durability somehow come into the comparison?

Polyamide has several forms like nylon which are stronger in terms of tensile strength and have higher tensile strength per filament and because of this nylon can be converted to fishing nets, windbreaker fabrics, and technical outerwear for resistance to wear. When it comes to resisting heat and sunlight and keeping the dimensional stability along with the wrinkle-resistant performance, polyester has a superior level of performance, making itself the first choice for upholstery and portable outerwear where shape retention is a big issue. The chemical processing of both these synthetic polymers is possible for additional abrasion resistance, but then again, the recycled nylon and virgin polyester have different end-of-life profiles and their recycling infrastructure varies. For the cases of heavy-duty products like ropes or sportswear where elongation and unrestricted movement are the main concerns, polyamide’s elongation and toughness contribute to its advantage. In the end, the adjustment of the tensile strength, elongation, and wear resistance according to the user’s particular needs is the critical selection factor.

Which yarn is more suitable for moisture management and wicking in sportswear?

Polyester is usually the best option when it comes to the moisture-wicking sportswear because polyethylene terephthalate fibers can be tailored with capillary structures which can take the sweat away from the skin more effectively. Polyamide on the other hand has a much better hydrophilicity compared with polyester, so it can absorb more moisture (higher moisture regain) but may feel clammy unless appropriately finished or blended. For next-to-skin athletic garments, wick, softness, and anti-static finishes are the factors filled the market by manufacturers for to optimize comfort and performance. Polyester in activewear, when you need quick dry and colorfastness; is a common choice as well as polyamide that provides elasticity and freedom of movement for tight-fitting sports garments. Both are the n most commonly used synthetic fibers and can be blended to have different characteristics like wick and softness caferequired by the consumer.

What yarn care, ease of care, and wrinkle resistance differences should I expect for garments?

Polyester is widely recognized for its being high-maintenance-resistant and non-wrinkle properties, of ften, it needs less care by ironing and even shows excellent resistance to shrinkage when compared with natural or cellulose fiber clothes. On the other hand, Polyamide may be affected by high temper atures and might ne ed a gentler wash cycle to keep its elastic and amide bond strengths; shrinking and loss of shape are quite possible if garments are wet or dried with hot air. onHide and visible siblings of both textiles are partially non-static in their normal state depending on surface treatment and some colorfasting agents besides the anti-static, may slow down color fading of the fabrics in the wards and households. We might come up with different disposal recommendations for recycled nylon and virgin polyester, and we might need the closed-loop cycling technologies which are starting to develop now, to make the environment green. Polyest er, although more resistant to wear and tear, is rated higher in the category of personal habit of maintenance w hen we are looking at ordinary dress from used yarn, while Polyamide stands as the choice when comfort and fit are most important.

What are the comparisons like between the different yarn types with regard to the environmental impacts, recycling, and end-of-life options?

Polyester, which is mainly polyethylene terephthalate, is supported by a well-developed recycling infrastructure and the existence of multiple recycling schemes that can convert bottles into either virgin polyester or recycled polyester, but polyester indeed often sheds microfibers and might lead to the problem of not-so-clean coordinated resistance. Nylon can also be recycled—recycled nylon is being made and nylon can also come from bio-based feedstocks or reclaimed fishing nets—still, polyamide recycling facilities are less advanced when compared to polyester, and closed-loop systems are not that common. Both are synthetic polymers that incorporate ester linkages (polyester) or amide bonds (polyamide), and none belongs to the category of natural fibers as cellulose; thus, the choice of their end-of-life pathways is a mere function of localized recycling and collection systems. Bio-based types and the newest closed-loop methods are targeted at reducing the existing environmental burdens and handling the problem of microplastic release in due course. In case the recycling system is in place recycled nylon or recycled polyester could be among the sustainable products.

Which yarn should I choose for upholstery, home textiles, and heavy-use applications?

Polyester is the favorite material for wrinkleless, color fast, and dimensionally stable home textile and upholstery products. And thus it is the number one synthetic option for fabrics that are intended to last long. Polyamide is the second one because of its high strength and wear resistance in the most hazardous areas. It can be used for blending or technical yarns in the case of objective applications like bridges. These nylon fibers are about 25% the weight but 200% the strength of steel and so on. Softness, anti-static, and the care guide are three main factors influencing the purchase of textiles. Generally, polyester will be the first choice due to the reason of cleaning time, while polyamide can make the user experience even more pleasant by providing a softer touch and better fitting option. In heavily used contexts such as outdoor gear, polyamide’s superior tensile strength and elasticity are quite advantageous, while polyester is more widely used in packable and wrinkle-resistant outdoor outerwear. The choice between the two fabrics will always be decided by the amount of softness, tensile strength, static behavior, moisture, and so on.