The invention of thermoplastic elastomer (TPE) pellets represents a new milestone in the world of flexible and durable plastics. When it comes to versatility, TPEs are resilient rubbers that can be used across numerous sectors, including automotive, medical, and consumer goods, among others. In this particular blog post, we will discuss the composition, benefits, and core attributes of TPEs. Furthermore, we will explain the eco-friendly potential of TPE and its implications for next-generation product design.

What are TPE Pellets?

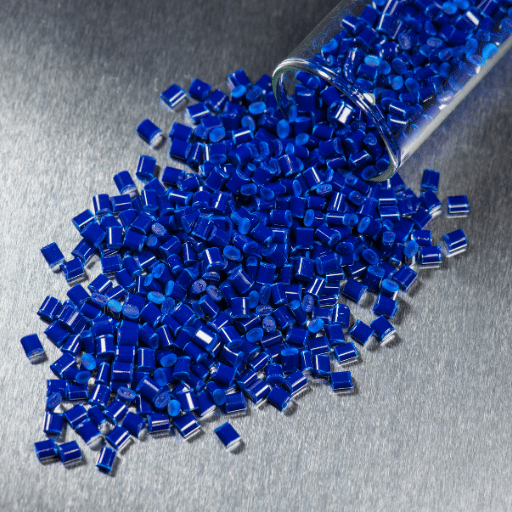

TPEs are elastomers that are made by blending rubber and plastic, resulting in thermoplastic elastomer (TPE) pellets. These materials are unique in that they can maintain flexibility and durability while withstanding processes similar to those of recycling. What’s more is that TPE can be used in various production steps, such as injection molding and extrusion, making the material a favorite among industrialists. TPEs provide phenomenal elasticity, abrasion resistance, and reusability. All of which enhances the material’s sustainability. TPE’s adaptability allows it to be used in products ranging from automotive parts to medical devices and consumable products.

Definition of TPE and Its Properties

An example of a material that combines the desired versatility of a thermoplastic and rubber is thermoplastic elastomer (TPE). Their molecular structure yields unique characteristics because they are composed of soft and hard crystalline segments. The soft segment provides the needed flexibility, whilst the hard crystalline segments contribute strength and durability.

TPEs possess numerous industrial advantages, including superior elasticity, resistance to abrasion, endurance against chemicals and harsh radiation, and flexibility over a wide temperature range. They are also recyclable, meaning they can be processed without losing their vital properties, while still aligning with sustainable practices. This makes TPEs incredibly resilient, as seen in various industries, including automotive, construction, consumer goods, and healthcare. Ultimately, TPEs stand out owing to their combination of durability and lightweight.

Differences Between TPE and Other Plastics

I see some distinct aspects when comparing TPE to other plastics. Unlike conventional thermosetting plastics, which are not reusable once cured, TPEs, as their name suggests, are reprocessable and recyclable because they maintain thermoplastic characteristics. In addition, while many conventional plastics lack the elasticity required for specific applications, TPE offers the flexibility of rubber and can be processed like plastics. This remarkable combination of properties enables TPE to surpass more rigid polymers in applications that require durability, adaptability, and compliance.

Common Uses of TPE Pellets

Due to their distinctive characteristics, TPE pellets are multifunctional and are used in many industries. For example, I use them in medical device manufacturing, such as tubing and seals, where biocompatibility and flexibility are crucial. They are also essential in consumer electronics for soft-touch components such as grips and protective cases. Moreover, I buy TPE pellets for gaskets, trims, and weather sealing automotive parts because of their superior softness, strength, and durability. Their reliable strength, resilience, and adaptability make them a key raw material in high-performance products.

How are TPE Pellets Processed?

The properties of TPE pellets undergo several sequential processes to achieve them. To achieve results, polymers with their additives undergo blending first. The compound is then fed to an extrusion device where it is both melted and heated. However, TPE granules are used for molding, extrusion, and other processes. To enable their safe usage, the molten blend is deposited into strands, which are cooled by water or air. After they are transformed into pellets of uniform size, they can be used further. Reliable results and high quality are achieved through this process for many industrial works.

Methods of TPE Processing

Thermoplastic elastomers (TPEs) are mainly processed using three techniques depending on the desired application and material characteristics:

- Injection Molding – This method involves heating TPEs to a molten state and injecting them into molds to create precise shapes and complex designs. It is widely used for manufacturing automotive parts, seals, and components for consumer products.

- Extrusion – TPEs are melted and shaped into continuous profiles, such as tubing, cables, or sheets. This method is suitable for producing materials that require flexibility and durability.

- Blow Molding – Used for hollow objects, TPEs are melted and inflated into a mold to form items like squeeze bottles or containers. This method ensures lightweight and resilient products.

These methods emphasize efficiency, versatility, and high product quality, making TPEs a preferred material for diverse industries.

Role of Injection Molding in TPE Production

Due to accuracy, scalability, and fast performance, injection moulding is often used during the molding of thermoplastic elastomers (TPEs). For this technique, a blend of TPE is injected into a custom-designed mold, which is sealed. The mixture is injected under high pressure. Such processes enable the manufacture of complex pieces while maintaining remarkable accuracy.

One of the most notable benefits of injection molding is optimizing production cycles. Modern injection molding machines have advanced features, including high-speed operations, improved temperature control, and shorter cycle times. Additionally, this method ensures the accuracy of material dosage, which minimizes waste and meets sustainable manufacturing goals.

TPEs, such as those used for automotive parts, medical devices, and consumer products, have a wide range of applications. For instance, injection molding maintains the structural integrity and long-term functionality of TPE automobile seals, regardless of extreme environmental shifts. Furthermore, the use of multi-material injection TPEs with other polymers into a single product has expanded due to recent advancements, therefore increasing functionality and aesthetic appeal.

The continued advancement of material engineering and industrial innovation is achieved through injection molding due to its unmatched versatility, ability to uphold strict quality standards, and its impact on TPE production.

Recycling and Reprocessing of TPE Material

The value of thermoplastic elastomers (TPEs) lies greatly in their recyclability and sustainability. This makes them a critical material concerning environmental issues within the manufacturing industry. TPE’s properties allow for mechanical recycling, where scrap or post-industrial waste is shredded, melted, or re-extruded into new products without significant loss of material properties. Moreover, advanced chemical recycling techniques are being developed to break down TPEs into their base monomers or other usable chemical components, enabling further refinement and reuse.

Novel innovations in material separation, such as density separation and spectroscopy-based sorting systems, have improved the overall efficacy of TPE recycling, especially when dealing with multi-material products. According to industry statistics, the energy expenditure related to TPE recycling is noticeably lower than that of producing pristine materials in terms of latent energy consumption, thereby reducing the overall carbon footprint. In addition, closed-loop recycling systems have been adopted in various industries, where production waste is reintegrated into the manufacturing cycle and bypasses the supply chain.

What are the Applications of TPE?

Thermoplastic elastomers (TPEs) have a broad range of applications due to their flexibility, strength, and ease of processing. Specific components in the automotive industry, such as seals and gaskets, as well as interior surfaces, are made using particular types due to their tough mechanical properties and wear resistance. Medical-grade TPE is also produced for various applications, such as tubing, grips, and seals, that need to be both sterile and comfortable for the patient. Their soft feel and high-performance attributes make TPEs suitable for consumer goods, such as footwear, sporting goods, and even tool handles. The unparalleled multifunctional capabilities of such materials allow a variety of industries to employ TPEs, positioning them as an ideal and modern manufacturing material.

Industries Utilizing TPE Products

Due to the special blend of elasticity, toughness, and ease of processing, Thermoplastic elastomers (TPEs) are critical for different sectors. The automobile industry is one of the main customers, using TPEs for sealing systems, interior parts, airbags, and vibration dampeners. Thermoplastic elastomers are subjected to very high and low temperatures, as well as mechanical stress, which is vital for automobiles. Construction also benefits from TPEs, as they are used for sealing and weather-resistant materials, such as window gaskets, expansion joints, and roofing membranes.

Moreover, the healthcare sector extensively uses TPEs in medical tubing, syringe plungers, and wearable devices due to their sterilizability, biocompatibility, and flexibility. For example, TPEs are used in the design of consumer goods, such as electronics, in plug housings, cable connectors, and protective casings, to enhance ergonomics and durability. Finally, the packaging sector uses TPEs in closures that can be opened and resealed, as well as soft-touch grips and functional protective layers, meeting the requirements of both advanced and eco-friendly materials. Their extensive application range highlights the role of TPEs in modern engineering and product design.

Comparison of TPE with Silicone and Rubber

With TPE, silicone, and rubber, I observe that each material has its benefits depending on the application. In my opinion, the most striking feature of TPE is its ease of processing and low cost—the ability to melt, reshape, and recycle it repeatedly sets it apart from traditional rubber. Silicone is superior in terms of withstanding extreme temperatures, biocompatibility, and chemical stability, especially in medical and food-grade applications. When it comes to heavy-duty applications, rubber, particularly vulcanized types, is unmatched due to its excellent durability, abrasion resistance, and elasticity. TPE excels in versatility and sustainability, whereas silicone and rubber dominate in areas where extreme performance or durability is required.

Advantages of TPE in Automotive Applications

The characteristics and the processing capabilities of Thermoplastic elastomers (TPEs) make them advantageous for use in the automotive industry. Unlike plastics, TPEs possess the elasticity of rubber, making them an ideal option for a diverse range of components because they are easy to shape. TPEs are lightweight, which plays a significant role in improving fuel efficiency. This is important in modern automotive engineering, as it focuses on reducing environmental impact.

Moreover, TPEs have outstanding and reliable resistance to very low and high temperatures, UV light, and chemicals. Their durability makes them ideal in harsh conditions. Their recycling capabilities fit the rising focus on sustainability within the industry because TPE scraps can be reprocessed into new parts or products, in contrast to traditional vulcanized rubber. Additionally, TPEs can be specially tailored to fit particular applications such as seals, gaskets, and trims due to flexibility in texture, color, and hardness, making them perfect for mat and interior trims, as a result of modern manufacturing methods like overmolding and multi-component injection molding, advanced manufacturing techniques operand with TPEs, which increases production efficiency while decreasing waste and ultimately costs.

What types of TPE are available?

Thermoplastic elastomers (TPEs) are categorized into several main types based on their composition and performance characteristics:

- Styrenic Block Copolymers (TPE-S): These are versatile, offering excellent elasticity and processability. Commonly used in sealing, grips, and consumer products.

- Thermoplastic Polyolefins (TPE-O): Are known for their durability and resistance to chemicals, and are widely used in automotive parts and industrial applications.

- Thermoplastic Polyurethanes (TPE-U or TPU): These provide superior abrasion resistance, flexibility, and strength, making them ideal for footwear, cables, and medical applications.

- Thermoplastic Vulcanizates (TPE-V): These materials combine the properties of rubber and plastic, offering excellent heat resistance and stability, and are often used in automotive seals and hoses.

- Copolyester Elastomers (TPE-E): Distinguished by their resilience and high-performance characteristics, they are suited for demanding environments such as industrial and automotive uses.

- Thermoplastic Elastomer Blends and Alloys: These are customized blends designed for specific applications, combining properties of different TPE families for specialized performance.

Each type offers unique properties, enabling manufacturers to select the most suitable material for specific industrial and commercial applications.

Exploring Different Types of TPE

Thermoplastic Elastomers (TPEs) have become indispensable in various industries due to their versatility, durability, and cost-effectiveness. Below are some detailed insights into their prominent applications:

- The automotive industry: TPEs are widely used in automotive components, including weather seals, interior and exterior trim, and under-hood applications. Their resistance to extreme temperatures and ability to reduce noise, vibration, and harshness (NVH) make them essential materials in producing efficient and durable vehicles.

- Consumer Goods: The unique combination of flexibility and rigidity in TPEs allows them to be used in items such as household appliances, personal care products, and even packaging solutions. For example, TPEs are commonly used in non-slip components of toothbrushes and ergonomic grips for household tools.

- Medical Devices: The biocompatibility and sterilization resilience of specific grades of TPEs make them an optimal choice for medical applications. They are used in the production of surgical instruments, IV components, flexible tubing, and various other types of healthcare equipment.

- Electrical and Electronics: TPEs are used in creating cable insulations, connectors, and components that require precise functionality in various conditions. Their electrical insulating properties and excellent temperature resistance ensure safe and reliable performance.

- Construction Materials: Due to their weather resistance and flexibility, TPEs are commonly used in sealing and vibration-damping applications in the construction industry. They help ensure structural integrity and long-term performance in dynamic environmental conditions.

Through ongoing advancements in material science, TPE formulations continue to evolve, allowing for enhanced environmental sustainability, improved performance, and expanded application possibilities in industries worldwide.

Understanding Thermoplastic Polyurethane vs. TPE

TPU (thermoplastic polyurethane) and TPE (thermoplastic elastomer) are two versatile polymers with broad applications across multiple sectors. However, the differences in their applicational ranges stem from their economic and physical traits. TPU materials are highly flexible and elastic; they also have superior wear resistance, high tensile strength, and excellent abrasion resistance. The strong molecular structure of TPU allows it to provide exceptional durability against materials like automotive parts and industrial seals, as well as against chemicals, oils, and greases, making it ideal for high-performance footwear.

Compared to TPE, TPE is a class of materials that combines the advantages of thermoplastics and rubber. The elasticity combined with the durability of conventional rubber allows TPE to overcome the limitations posed by raw elastomers, while enabling the polymer to be processed as a thermoplastic. While some materials from the TPE group pose unique elastomeric characteristics, such as styrenic block copolymers (TPS), olefinic thermoplastic elastomers (TPO), TPE TPU, and polyurethanes (which can be considered a type of TPE), TPEs are easier to process than TPU. General-purpose TPE is used in softer-touch applications, such as flexible connectors and medical devices.

In application-centric settings, TPU usually performs better than TPE in high-strain scenarios with extreme mechanical and thermal requirements. On the other hand, TPE is often applied in low-strain scenarios that favor cost-effectiveness and greater design flexibility. Each material’s unique properties are pivotal for manufacturers to tailor solutions to address distinct engineering problems.

Characteristics of Thermoplastic Vulcanizates

Thermoplastic Vulcanizates (TPVs) are among elastomers classified as thermoplastic vulcanizates, or thermoplastic vulcanized rubber (TPR), which merge the benefits of thermoplastic processing with the toughness and elasticity of vulcanized rubber. They are produced via dynamic vulcanization, which TPV defines as chemically cross-linking a dispersed rubber phase within a continuous thermoplastic envelope. These polymers are still considered traditional thermoplastics, such as extrusion and injection molding, wherein complexity is integrated into the structure, providing features of mechanical strength and flexibility, enhanced processes, such as lebility, temperament.

Key properties of thermoplastic vulcanizates (TPVs) are high tensile characteristics, resistance to heat and chemical exposure, and the ability to withstand extensive dynamic fatigue. These materials perform well in harsh conditions and are commonly used in industrial applications such as automotive gaskets, seals, and flexible tubing. Furthermore, thermoplastic vulcanizates (TPVs) are lighter than vulcanized rubber due to their lower density, making them beneficial for product design. Changes in compounding have advanced the performance profiles of TPVs, broadening high-performance applications for TPVs to include under-the-hood automotive components and industrial machinery.

What is the Hardness of TPE Material?

The hardness of Thermoplastic Elastomers (TPE) materials varies based on their formulation and intended use. TPE is usually measured using the Shore scales, predominantly Shore A and Shore D. TPEs tend to have an extensive range of softness, going from 20 Shore A to approximately 85 Shore D. The range of softness in TPE allows for its utilization in a variety of applications ranging from soft grips to long lasting structural parts.

Measuring Hardness in TPE Pellets

To test the hardness of TPE pellets, standardized instruments like durometers are used. The choice of the Shore scale, either A or D, is selected based on the estimated hardness of the material. A Type A durometer is ideal for soft grade TPEs, while Type D durometers are used for harder grades ranging from 30 to 85 Shore D.

A specimen of the TPE pellet sample needs to be placed under the foot of the durometer, with the sample in a position that allows it to contact the surfaces, so that all readings are taken consistently. Other elements, such as sample thickness, uniformity, and environmental conditions, must be taken into account to make the data credible. Even in such fields, the methods provided in the SOP guides (D2240) provided in the ASTM ensure the reliability and consistency of results during hardness tests. All methods, however, provide significant assistance during the workout stages for tests conducted on TPE pellets to evaluate mechanical properties and determine if standards are met.

Impact of Hardness on Performance

Thermoplastic elastomers (TPEs) possess a unique physical characteristic that sets them apart from rubbers and plastics: their hardness. This primary trait makes TPEs more suitable for a variety of tasks. While having a rubber-like structure, TPE’s softness enables it to perform various functions, such as bounding devices and impact cushioning products. TPE elastomers also come with the added feature of a sealant, which brings more advantages because it allows us to make customized seal types. Having strong, rubber-like components that can withstand a lot of wear makes TPEs the ideal choice for seals, gaskets, and shoe soles. All these peripherals allow TPEs to possess remarkable resilience while enabling soft movements.

Soft Elastomer Variants of TPE

An elastomer class under Thermoplastic Elastomers (TPE) features soft elastomer variants that are well-suited for multifunctional applications due to their flexibility, low hardness, and excellent tactile properties. These materials have Shore A hardness values ranging from 5 to 50, making them suitable for use in soft and comfort-centric products, such as ergonomic grips, seals, and overmolded parts. Modification of processing techniques has enabled the development of these variants with increased elasticity, chemical resistance, and better thermal stability.

SBCs, or styrenic block copolymers, represent one of the most well-known subgroups due to their broad acceptance for ease of processing and versatility. SBCs are visibly transparent, which makes them appealing for consumer goods and medical products, in addition to their exceptional weatherability. Moreover, the development of molecular design allows for greater customization of TPE properties, enabling industries with rigid regulatory requirements, such as healthcare or automotive, to tailor TPEs, specifically engineered TPEs, to meet specific industrial needs.

The alternatives to soft elastomer TPEs are also advanced in terms of recyclability and sustainability, as they can be processed efficiently alongside modern manufacturing designs. Their ability to be reprocessed without losing much value makes them suitable for environmentally friendly production workflows. The improvement of soft elastomers and other thermoplastic elastomers continues to broaden their ability to meet various requirements while also enhancing performance and eco-friendliness.

Is TPE a Sustainable Option?

Because they can be reprocessed several times and are thermoplastics, elastomers (TPE) are considered more eco-friendly. TPE compounds and TPEs, as a whole, generate less shredding waste and production waste compared to conventional materials, reducing their environmental impact. However, the eco-friendliness of TPE can change depending on policies regarding manufacturing processes, the use of post-consumer goods, and other plastics, which also contribute to the eco-friendliness of TPE.

Environmental Impact of TPE Compared to Other Materials

Compared to other materials, such as thermosets and rigid plastics, thermoplastic elastomers (TPEs) offer greater environmental benefits. Unlike thermosets, which are non-removable and non-reprocessable, TPEs are 100% recyclable and can be endlessly reformed, which minimizes the waste generated throughout their lifecycle. Moreover, the processes used to manufacture TPE require relatively lower energy as compared to the processes involved in producing conventional thermosets or vulcanized rubber, thereby increasing the eco-friendliness.

In addition, the development of TPEs, such as incorporating biosourced or recycled content, is reducing reliance on fossil fuels and virgin materials. Research indicates that bio-based TPEs can reduce greenhouse gas emissions by 40% in comparison to petroleum-based TPEs. In contrast to rigid plastics, thermoplastic elastomers also have a lower density, meaning less material is used for the same function, further increasing efficiency.

While the benefits of TPEs are clear, their entire lifecycle–sourcing, production, use, and disposal–must be evaluated. Proper end-of-service strategies, such as remanufacturing into new products or chemical recycling, maximize the environmental benefits. When responsibly produced, TPEs are more environmentally friendly than many other polymers and rubber products, contributing to efforts to reduce environmental impact from industrial sources.

Recyclability of TPE Pellets

The unique properties of thermoplastic elastomers (TPEs) provide them with extraordinary potential for recycling. In comparison to traditional thermoset rubbers, TPEs do not go through an irreversible curing process. This enables them to be reused and reprocessed multiple times without significantly declining in material properties. Enhanced mechanical recycling processes enable TPE pellets to be ground down, melted, and re-extruded into new products, thereby maintaining resource efficiency in manufacturing processes.

Also, new developments in chemical recycling technologies have broadened the scope for monomer recovery from TPE waste, allowing the materials to be purified and reused in the production cycle. Current research shows that adding recycled TPE pellets to new formulations not only decreases the consumption of virgin materials but can also reduce the emission of greenhouse gases by 30 to 40 percent. Effective sorting and contamination control during the recycling process remain crucial for enhancing recyclability and for integrating TPEs into circular material economies throughout many industries.

Future of TPE in Sustainable Material Development

The newly developed technologies for the science of polymers make it possible to create thermoplastic elastomers (TPE) utilizing renewable resources, such as plant oils and natural rubber, making bio-based TPEs. These products have a lower carbon footprint since they less depend on fossil fuel materials and contribute to decreasing the carbon footprint during their life cycle.

Moreover, remarkable advancements are being achieved in the recovery of the mechanical properties of recycled TPEs, bringing their performance in demanding applications up to the level of virgin materials. Industrial studies show that the use of purpose-made compatibilizers and additives makes it possible to lessen the loss of physical properties during the recycling process, thus achieving more effective closure of the cycle in material recovery systems. Automated and AI-controlled quality systems currently being integrated into many recycling facilities are significantly lowering contamination rates, which greatly enhances the economic feasibility of industrial TPE recycling.

The use of TPEs for soft plastics in automotive and aerospace segments highlights the usefulness of such engineering grades of thermoplastic elastomers in fuel consumption and overall material usage. Research shows that lightweighting strategies are conservative in nature, using thermoplastic elastomers rather than traditional materials lowers vehicle weight by 10 to 15%. This is astonishing in terms of energy efficiency numbers. These facts together with the recyclability and durability of TPEs makes them critical for the purpose of sustainable manufacturing.

In my opinion, advancing changes in closed loop systems and recycling technologies will be critical in the future of thermoplastic elastomers TPEs in sustainable material development. We can limit the impact on environment without restricting performance, by changing the material’s formulation as well as enhancing the ease of recycling. Other industries also have tremendous influence in the wide adoption of sustainable solutions and the integration of thermoplastic elastomers in circular economy systems.

Reference Sources

-

Twin Screw Compounding in the Production Chain for TPEs

- Key Findings: This study examines the production of TPEs using twin-screw extruders, focusing on the differences in processing requirements for various TPE types, such as TPO (Thermoplastic Polyolefin) and TPV (Thermoplastic Vulcanizates). It highlights the importance of optimizing extruder design and process parameters to ensure efficient production and high-quality pellets.

- Methodology: The research reviews the design and operational parameters of twin-screw extruders, comparing configurations for different TPE formulations and their impact on throughput and product quality.

-

Reprocessing of Injection-Molded Magnetorheological Elastomers Based on TPE Matrix

- Key Findings: This study demonstrates the use of TPE as a matrix for magnetorheological elastomers (MREs), emphasizing its reprocessability and recyclability. It discusses the thermo-mechanical degradation of TPE during reprocessing and its impact on material properties.

- Methodology: The research involves multiple reprocessing cycles of TPE-based MREs, analyzing changes in molecular weight, viscosity, and mechanical properties to evaluate the material’s performance and sustainability.

-

Thermoplastic Elastomeric (TPE) Materials and Their Use in Outdoor Electrical Insulation

- Key Findings: This paper discusses the application of TPE pellets in outdoor electrical insulation, highlighting their durability, flexibility, and resistance to environmental factors. It also explores the material’s adaptability for various industrial uses.

- Methodology: The study reviews the properties of TPEs and their performance in outdoor applications, supported by experimental data and case studies.

- Top TPE Plastic Pellets Suppliers in China

Frequently Asked Questions

Q: What are TPEs, and how do they differ from conventional plastics?

A: TPEs, or thermoplastic elastomers, combine the properties of rubber and plastic. Unlike conventional plastics, TPEs have elastomeric properties, allowing them to stretch and return to their original shape, making them a versatile material suitable for a wide range of applications.

Q: What are the main applications of thermoplastic elastomer materials?

A: Thermoplastic elastomer materials are widely used in products that require flexibility and durability, such as automotive parts, medical devices, consumer goods, and soft touch grips. Their recyclability also makes them a preferred choice in sustainable manufacturing.

Q: Can TPEs be recycled, and how does that compare to other materials like silicone or rubber?

A: Yes, TPEs are recyclable, which is one of their significant advantages over traditional rubber and silicone materials. While natural rubber and silicone can be more challenging to recycle, TPEs can be reprocessed and reused in various applications, contributing to environmental sustainability.

Q: What are the chemical resistance properties of TPEs?

A: Thermoplastic elastomers exhibit good resistance to various chemicals, making them suitable for applications exposed to oils, greases, and other harsh substances. This chemical resistance is a crucial factor in selecting materials for specific industrial applications.

Q: How do thermoplastic olefins compare to other TPE formulations?

A: Thermoplastic olefins (TPOs) are a specific type of TPE that combines polypropylene with elastomeric materials. They offer good impact resistance and are often more cost-effective than other TPE formulations while still providing beneficial properties like flexibility and recyclability.

Q: What makes TPEs a better choice than natural rubber in specific applications?

A: TPEs can be engineered to have specific properties, such as enhanced durability, UV resistance, and improved processing characteristics compared to natural rubber. This level of customization makes TPEs a more versatile material for many applications, especially where consistent performance is needed.

Q: Are there any specific advantages of using TPEs in blow molding processes?

A: Yes, TPEs are highly suitable for blow molding due to their excellent flow characteristics and ability to be processed at lower temperatures compared to traditional plastics. This results in energy savings and reduced production costs while maintaining high-quality output.

Q: How do the thermoplastic and elastomeric properties of TPEs enhance product performance?

A: The combination of thermoplastic and elastomeric properties in TPEs allows for products that are flexible, durable, and easy to process. This unique blend enables manufacturers to create items that require soft touch, resilience, and superior performance under varying conditions.