Polymethyl Methacrylate, aka PMMA, is a material that has encapsulated almost all facets of human life. Because of its versatility in design, construction, automotive, and healthcare industries, trust PMMA for its clarity, abrasive resistance, and aesthetic appeal. But what exactly makes this material so special? This article examines PMMA’s remarkable properties, its wide range of applications, and the unique innovations it offers, highlighting the solutions it provides to problems and its significance in our daily lives. Whether a professional or a curious enthusiast, let us show you why PMMA is a material scientist’s go-to material.

What is PMMA, and how is it made?

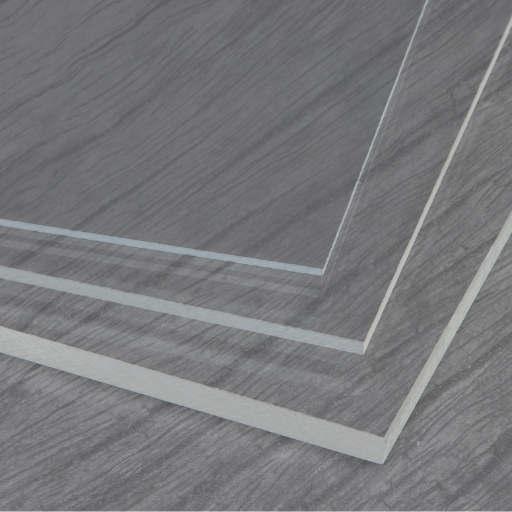

PMMA or Polymethyl methacrylate is widely known as acrylic glass. As a shorthand, PMMA is a transparent thermoplastic used as a lightweight and shatter-resistant alternative to glass. PMMA is manufactured by transforming a monomer called ethyl methacrylate into units through a chemical reaction with a catalyst. Depending on the desired quality attributes and use, bulk or solution, or suspension heterogenic polymerization can be employed. The final product from this process is a composite-like material, animal in its toughness, acrylic glass, which can be easily shaped and is highly resistant to weather conditions and transparent.

Understanding Methyl Methacrylate and Its Role

Due to the distinctive qualities of Methyl Methacrylate (MMA), it is a highly adaptable compound with applications across different industries. Its acrylic sheets, which are often sold as Plexiglas and Lucite, are some of the most recognized products. These sheets are prized for their superior optical clarity as well as their lightweight nature, providing striking resistance to impacts; thus, making them a perfect glass substitute in construction, automotive, and signage applications.

MMA is widely used in the automotive industry for manufactures of in bone cement for orthopedic surgery because of its biocompatibility along with its impact strength. Specifically, MMA is used for fuel-efficient vehicles because of lightweight components which enhances skeletal fuel economy and is also heavily relied on for durable coatings. Additionally, MMA plays a vital role in the adhesives and sealants industry due to its capacity to bond a variety of surfaces.

Renewed research suggests the global MMA market will see sharp increase in growth rate, exponentially from emerging economies with new manufacturing processes that turn obsolete ones obsolete. Take the global MMA market estimation of $15 initially, it is believed the value could go up from four to five percent every year, reaching new heights with the introduction of greener energy source in 2021.

Innovations are being achieved in the production of MMA that allow for new modifications, incorporating environmental concerns simultaneously. For example, bio-based MMA synthesis production processes and recycling technologies are being developed to reduce reliance on fossil fuels. In fossil fuels, as well as carbon emissions. These developments demonstrate the significant role the compound will play in emerging industries in the future, while also aligning with modern sustainability requirements.

The Polymerization Process of PMMA

The primary method for obtaining polymethyl methacrylate (PMMA) is still its free radical polymerization. This procedure is regarded as the most effective due to the ease of obtaining superior quality PMMA. The free-radical method of polymerization involves initiation of the methyl methacrylate (MMA) monomers through an initiator (commonly a peroxide or an azo compound), which starts the growth of the polymer chain. The reaction can be done in bulk or solution, suspension, or emulsion, based on the characteristics and application requirements of PMMA.

Critical industrial innovations have optimized this process for greater output and economic advantage. For instance, bulk polymerization is employed in applications that require optical clarity of high quality and have low contaminant levels. Newer innovations are also aimed at reducing energy expenditures during the polymerization stage by modifying the reaction conditions and other advanced methods like microwave-assisted polymerization. As per the industry, PMMA production is expected to touch nearly 4 million metric tons by 203,0, which shifts the focus towards enhanced production techniques.

The adoption of techniques such as water-based suspension polymerization which reduces the use of dangerous solvents has been spurred by environmental worries. These activities, along with the continuing research on bio-based MMA, comply with international sustainability efforts and seek to make PMMA production more environmentally sustainable.

Characteristics of Acrylic and Its Material Properties

Acrylic (PMMA), also referred to as polymethyl methacrylate, is one of the most commonly used thermoplastic materials due to its optical clarity and durability. One of its most impressive properties is the material’s ability to transmit light (light transmission), which can be as high as 92%. This surpasses the light transmission of ordinary glass. Therefore, acrylic is widely used for windows, lenses, and aquariums where clarity and transparency is crucial.

In addition, acrylic is known for having one of the highest strength-to-weight ratios among other materials. It is a lot more lightweight than glass, and at the same time, easier to handle because of its 17 times greater impact resistance than glass. Furthermore, acrylic is very durable when it comes to weathering, maintaining coloration and clarity when exposed to UV light and various temperatures for long periods of time.

Acrylic is compatible and can be used indoors and outdoors, as it is weather resistant to many acids, bases, and other chemicals. Due to the ease of fabrication such as cutting, molding, and thermoforming, acrylic can be utilized in different fields, increasing its versatility. Recent advancements on scratch resistance and surface hardness was noted, making the material more widely accepted in the automotive industry, construction, and interior design.

In addition, certain types of acrylics have been modified to have flame-resistant capabilities, enabling compliance with safety requirements for more specialized uses. These traits further strengthen acrylic’s standing as a material which dominates in flexibility, functionality, and beauty.

The Properties of PMMA: What Makes it Stand Out?

Polymethyl methacrylate (PMMA) is unique in its exceptional clarity, lightweight nature, and unrivaled durability. It has a higher optical transparency than glass and transmits light even more effectively. It is also suitable for indoor and outdoor applications because it is resistant to impact and weather. PMMA is easy to fabricate and shape which gives it application versatility. Because of these qualities, PMMA is an outstanding material for numerous industries.

Key Properties of PMMA

- Optical Clarity

PMMA is well-known for its excellent optical clarity as it can transmit up to 92% of visible light which makes it one of the clearest materials known. The amount of light PMMA transmits is greater than that of many other plastics and even glass. This is the reason why it is used widely in lenses, displays, and glazing.

- Durability and Impact Resistance

Sometimes referred to as acrylic glass, PMMA is lighter than glass and can withstand enormous impact. Although, when compared to polycarbonate PMMA is less durable. It is mostly used in areas needing strength and transparency, such as in protective barriers and safety glazing.

- Weather Resistance

PMMA offers excellent UV resistance and protects well against weathering which makes it ideal for outdoor material such as signboards and window adverts. Its ability to endure prolonged exposure to variable weather conditions ensures minimum loss of quality.

- Thermal Properties

With a low thermal conductivity alongside a melting point of around 160°C, PMMA is suitable for moderate heat but unfavorable in high-temperature environments.

- Versatility in Fabrication

The methods PMMA can be manipulated are countless. It can be shaped and cut using extrusion, casting, or even injection molding. Its machining capabilities allow for its use in more unique designs, such as an automobile’s inner workings or even just as decorations.

- Chemical Resistance

PMMA is resistant to a lot of chemicals including common acids and bases. Orgainic solvents may be more harmful towards PMMA, so it is best to limit contact with these solvents.

- Eco-Friendliness and Recyclability

PMMA is eco-friendly and can be recycled. Disposed PMMA parts and pieces can be used again in some way, which aides in PMMA recycling.

Automotive, construction, healthcare, and consumer goods industries all benefit from PMMA due to these properties and others.

Optical Properties and Transparency

PMMA is a transparent thermoplastic that is often known as acrylic glass. It is regarded for its unrivaled transparency and optical clarity. PMMA is one of the surpassed materials that surpasses glass, which permits visible light to pass through, with a light transmittance rate of 92%. Because of such high clarity, PMMA is preferred for making lenses, light covers, and signage.

PMMA has a low refractive index of about 1.49, which minimizes the level of distortion while ensuring optimal sharpness, hence high optical performance. PMMA is also well-known for being highly resistant to ultraviolet (UV) light, keeping its clarity and color over time without any faint yellowing or deterioration. Its long-proven UV resistance makes PMMA best for outdoor usage, like skylights and protective barriers.

It can be manufactured with a variety of surface finishes such as frosted, colored, or mirrored, making it very versatile. PMMA’s unrivaled optical qualities together with these characteristic features strongly consolidate it’s dominance in application industries, automotive, architecture and consumer electronics.

Mechanical Properties and Toughness

Polymethyl methacrylate, or PMMA, is distinguished by good impact strength when compared to glass. It has around 70 MPa of tensile strength, ensuring it withstands forces of strain and stress well. Also, as a favorable property, PMMA’s Izod impact strength is between 0.1 to 20 kJ/m², which adds greater durability to the material, depending on the grade and processing. Furthermore, as such a versatile material, PMMA’s strength exceeds by tenfold that of other regular polymers. This allows PMMA to be used even in severe conditions.

Includes excellent optical grade alongside lightweight, PMMA’s addition into the performed molded parts from the emulsion processes is constantly on the rise due to the heightened convenience it offers and serves its application across several industries. Aside from emulsion processes, the advanced flexure stamina and toughness strengthens isomer gradings alloys provide PMMA is unparalleled. The structural integrity is maintained due to partially supporting superior reliability against deformation induced under diverse operating circumstances.

In fact, with an exceptional flexural modulus of 3,000 MPa, PMMA maintains temperature stability up to 105 °C. Furthermore, it does not crack under stress since making it more efficient compared to other polymers. Under various temperatures, PMMA offers characteristics such as rigidity, combined with supporting security to the polymer, which invites its use in rigid situations.

Lastly, to enhance performance and ensure sturdiness, manufacturers tend to use even tougher environment PC across repeated struck bordersel. The added materials strengthens further targets for harshen tackling providing new marketing heights for integration into powered applications stemming from ionizing radiation.

What Are the Applications of PMMA in Various Industries?

PMMA, also known as acrylic, has found its application in various sectors owing to its remarkable properties.

- Automotive: Car PMMA windows, light covers, and windshields are durable and clear, so PMMA is the best fit.

- Construction: Glass can be substituted in skylights, windows, and signage, giving these structures a lighter weight, thus,s PMMA serves as a better alternative.

- Medical: Dentures, bone cement, and intraocular lenses are some of the medical devices PMMA is used.

- Electronics: Displays and LED panels use it because of its excellent PMMA light transmission.

- Consumer Goods: PMMA furniture, decorative items, and even aquariums are becoming popular as acrylic is more beautiful than glass and more resilient than most plastics.

Such applications showcase how PMMA’s versatility enhances product performance in various fields.

Use of PMMA in Acrylic Plastic and Acrylic Glass

Polymethyl methacrylate (PMMA) is also known as acrylic glass or acrylic plastic. It is an alkene-containing plastic substitute. This is largely because it can be produced and used in numerous different industries while remaining clear, durable, and lightweight. Glass PMMA is an extraordinary alternative for conventional glass, having ten times the impact resistance and being half the weight. In protective barriers, aircraft windows, and skylights, where shatter resistance and optical clarity are equally as critical, PMMA is the main choice.

Best showcased by its use as acrylic plastic, PMMA is adaptable to a range of situations. Due to its ability to be molded, a wide variety of shapes and designs can be produced. PMMA also does not weather, yellow, or degrade from prolonged sun exposure, which extends its lifespan when used outdoors. This enables use in outdoor signage, lighting fixtures, and architectural elements. Recent industry data indicates a steady increase in PMMA usage, over 8 billion dollar market projection by 2030, reflecting increasing demand in automotive, construction, and medical fields.

Moreover, the newest developments in PMMA production are making the material more sustainable. An example is the recycled PMMA; this innovation minimizes waste as well as the carbon footprint of the production process. This amalgamation of efficiency, versatility, and sustainability reinforces the position of PMMA as a crucial material for acrylic plastic and acrylic glass domains.

Dental Applications and Contact Lenses

The biocompatible nature and versatility of PMMA, or polymethyl methacrylate, make it one of the most important materials in modern-day dentistry. Some important facts and statistics regarding the use of PMMA in dental applications are:

- Dentures and Prosthetics: PMMA is one of the most preferred materials for manufacturing prosthetic limbs due to its lightweight, strength, and ease of tailoring to each patient. Roughly 60-70% of the world’s denture bases are manufactured from PMMA.

- Orthodontic Appliances: PMMA is used in the manufacture of custom-made transparent orthodontic appliances because it can be easily modified and is transparent.

- Dental Fillings and Crowns: This material is especially useful as a cost-effective option in temporary fillings and crowns because of its flexibility.

- Aesthetics: Because PMMA can be fabricated to resemble teeth, it best suits aesthetic surgical interventions.

- Resistance to Wear: PMMA exhibits excellent wear resistance, which helps dental prosthetics last longer.

Contact Lenses

In the development of contact lenses, PMMA contributed greatly and enabled the creation of the contemporary technology used in lenses. Its application and features are further explained as follows:

- Historical Significance: PMMA was one of the first substances employed in the construction of rigid contact lenses during the middle of the 20th century.

- Rigid Gas-Permeable Lenses: Though PMMA lenses are becoming increasingly rare, there has been advancement into rigid gas permeable (RGP) lenses that use PMMA in their composition.

- Optical Clarity: The optical clarity of PMMA lenses is outstanding and enables users to enjoy sharp vision correction.

- Durability: Lenses manufactured from PMMA are highly resistant to scratches when proper care is taken, ensuring a long lifespan.

- Challenges: The lack of oxygen permeability of PMMA lenses contributed to the rapid decline in use in favor of silicone-based alternatives which allow for better eye health.

These applications underline the importance of PMMA in both dental and optical industries. Its impact is growing and serves motivation for new developments which are functional and enjoyable to use.

PMMA as Bone Cement in Medical Fields

Bone cement is primarily used in orthopedic surgeries where PMMA casts are utilized. Polymethyl methacrylate (PMMA) acts as a bone anchor for joint limbs, enabling firm attachment. Repeated stress on mechanical implants, such as artificial legs or shoulders, results in a certain degree of weakening of the implant. The cement helps alleviate this issue, where PMMA bone cement provides an interface where uneven strains are encountered, thus lowering the risk of implants loosening.

Studies show that the compressive strength of PMMA bone cement ranges between 70MPa and 100 MPa. These traits enable it to support considerable weight in high stress areas such as hip or knee joints. Moreover, new formulations incorporating antibiotics in PMMA enhance the cement form, reducing the chances of infection post surgery. These antibiotics help control bacterial growth in suture sites during the window of healing.

Nonetheless, problems arise with a lack of proper training since the impact on the long-term performance of the cement relies solely on the proper incorporation technique. The polymerization chemical reaction during the setting can lead to elevated temperatures, which can cause burns to tissues surrounding the wound. All things considered, it is safe to say that modern medicine has greatly benefited from the use of PMMA, ranging from surgical incapacity to enabling a better quality of life for medically challenged patients.

Exploring the Modifications of PMMA for Enhanced Performance

To further increase the efficiency of PMMA, its mechanical strength, biocompatibility, and thermal stability are undergoing further enhancements. Glass fibers, Carbon Nanotubes, and bioactive ceramics are added to PMMA in a bid to improve the strength and durability of the compound. Infection control is integrated, especially for inclusion applications where there is a high risk of infection due to implanted objects. Additionally, Improvements in the methods of polymerization have significantly reduced the rate of heat produced during curing, which lessens the possible harm to the surrounding tissues. These adjustments make certain that PMMA is still a reliable and adaptable material in medicine.

How is Modified PMMA Created?

The process of modifying pseudonormative methyl methacrylate (PMMA) begins with the synthesis of PMMA and involves various chemical engineering procedures to enhance mechanical, thermal, and biological attributes. The methyl methacrylate (MMA) free-radical polymerization is one of the simplest methods to produce polymers. During PMMA synthesis, several properties of the material can be modified by adding different nanoparticles such as silica, carbon nanotubes, or titanium dioxide that increase strength, thermal resistance, and optical clarity.

Furthermore, dental and orthopedic implants must have certain features such as flexibility, impact resistance, and surface roughness which can be attained from plasticizers and elastomers. Polymers and composites require enhanced biocompatiblity so blending constituents like hyroxyapatite improves the physical and biological compatibility with tissues. Also, advanced polymerization techniques such as atom transfer radical polymerization (ATRP) or reversible addition-fragmentation chain transfer polymerization (RAFT) enable control over molecular design to fulfill specific application needs.

Recent studies have shown that silver nanoparticles, osteoporosis, and quaternary ammonium compounds can be incorporated into PMMA matrices, and significant biofouling mitigation on medical apparatus is achievable. For example, research indicated that PMMA reinforced with silver nanoparticles is able to retain up to 99% antibacterial activity and still remain structurally sound. With these tailored alterations, PMMA is further advancing as an engineered polymer of choice for contemporary medical and industrial uses.

Benefits of Modified PMMA

The use of PMMA across several industries is worth noting; this is because modified PMMA offers advanced functionality and accuracy. Its unique antimicrobial characteristics make it all the more paramount, and this is especially true when it’s infused with bioactive materials like silver nanoparticles. Research has also shown that modified PMMA can reduce bacterial adhesion by more than 90%, thus greatly mitigating infection risks in medical apparatus such as bone cements and catheters. Other than the medicine, modified PMMA also displays astonishing thermal stability, which broadens its scope of application to other harsher conditions. As an example, it can be used safely in electrical and electronic parts when combined with flame-retardant additives to improve heat resistance. Apart from electronics and healthcare, the high optical clarity and UV resistance of modified PMMA make it ideal for automobile lighting and protective coatings. These innovations emphasize the adaptability and importance of modified PMMA towards challenges facing modern engineering and medicine.

Common PMMA Grades and Their Uses

Different grades of polymethyl methacrylate (PMMA) exist to meet the needs of different industries. Every grade of PMMA has distinct properties for meeting specific applications.

- Optical Grade PMMA

Primarily Used for Lenses, optical fibres, LED lights and similar uses. Optical grade PMMA permits 92% light transmission and high UV protection which is suitable for outdoor applications and where clarity is needed.

- Medical Grade PMMA

This one is tailored specifically for Intraocular lenses, Dental Implants, and Bone Cement Therefore, it meets strict standards regarding biocompatibility. Medical grade PMMA also has outstanding resistance to bio sterilization and structural deterioration from repeated autoclaving or gamma irradiation, also known as sterilization.

- Impact-Modified PMMA

Modification is for toughened PMMA applications. This grade contains impact modifiers with good clarity. Widely used for automotive headlight lenses, barriers, signage, and other rigid materials exposed to high operational stress.

- UV-Resistant PMMA

Used in solar panels, outdoor glazing, and greenhouses. UV-resistant PMMA is designed for prolonged sun exposure. Less material degradation and discoloration caused by ultraviolet light improves product lifespan.

- Heat-Resistant PMMA

These grades are suitable for high temperature conditions, within the automotive passenger compartment or industrial equipment panels. Its thermal stability in extreme environments places the upper limit of its heat deflection temperature at approximately 100°C.

This paragraph explains that by dividing PMMA into these grades, producers and designers can opt for the most appropriate variant for their specifications, thus achieving maximum functionality across various applications.

Addressing the Disadvantages of PMMA and Biocompatibility

Disadvantages of PMMA

Despite its numerous applications, PMMA has significant drawbacks. PMMA has lower impact resistance than most plastics, making it more likely to crack or shatter under stress. Another disadvantage is PMMA’s lack of flexibility, which impedes its usefulness in applications where deformation is required. Moreover, it can be scratched and degraded by UV light unless specially coated.

Biocompatibility of PMMA

It is widely used in medicine for intraocular lenses and bone cement because PMMA is generally accepted as biocompatible, with a few exceptions. The specific formulation and additives might change. Compliance with relevant standards effectively mitigates risks pertaining the safety and efficacy in such applications.

Is PMMA Recyclable?

Polymethacrylate methyl ester, or PMMA, is a type of plastic which can be recycled though not as easily as other types. It is classified as a thermoplastic which means it can be softened and reshaped when heat is applied. The most prevalent type of recycling is mechanical. In this method, PMMA waste is shredded and turned into new materials. This method is not perfect because it might lower the quality of the material over time.

Depolymerization is an advanced method of chemical recycling which some researchers are looking into. This method converts the PMMA back into its monomers, methyl methacrylate (MMA), which can then be purified for use in producing high-quality PMMA. Research shows that PMMA can efficiently be chemically recycled with material recovery rates reaching 98%.

Although there is room for improvement, if people had better knowledge of PMMA and other plastics and accessible recycling facilities, this would improve the efficiency of PMMA usage.

Understanding the Brittle Nature of PMMA

Polymethacrylate methyl ester, or PMMA, is a type of plastic which can be recycled though not as easily as other types. It is classified as a thermoplastic which means it can be softened and reshaped when heat is applied. The most prevalent type of recycling is mechanical. In this method, PMMA waste is shredded and turned into new materials. This method is not perfect because it might lower the quality of the material over time.

Depolymerization is an advanced method of chemical recycling which some researchers are looking into. This method converts the PMMA back into its monomers, methyl methacrylate (MMA), which can then be purified for use in producing high-quality PMMA. Research shows that PMMA can efficiently be chemically recycled with material recovery rates reaching 98%.

Although there is room for improvement, if people had better knowledge of PMMA and other plastics and accessible recycling facilities, this would improve the efficiency of PMMA usage.

Biocompatibility of PMMA in Medical Applications

Polymethyl methacrylate (PMMA) is widely utilized in medical applications due to its high level of biocompatibility and mechanical stability. PMMA is primarily used in applications such as bone cement, intraocular lenses, and dental implants. Its non-toxic nature, combined with its ability to bond well with human tissues, makes it a reliable choice in the medical field.

For instance, in orthopedic surgeries, PMMA bone cement acts as a filler to secure implants within the body and distribute mechanical loads effectively. Studies have shown its compressive strength ranges between 70-100 MPa, making it a suitable medium for load-bearing applications. Additionally, the material’s optical clarity is highly beneficial in ophthalmology, particularly for producing intraocular lenses used in cataract surgery. These lenses exhibit exceptional stability and high refractive index values, ensuring improved patient outcomes.

Furthermore, PMMA’s chemical inertness minimizes adverse reactions when implanted into the human body, reducing the risk of inflammation or long-term complications. Advances in material engineering have also allowed for the development of PMMA composites, incorporating antimicrobial agents to combat infection risks in joint replacement surgeries. With proper sterilization techniques and formulation enhancements, PMMA continues to meet stringent biocompatibility standards, solidifying its role in modern medicine.

Reference Sources

-

Poly(methyl methacrylate) – Wikipedia: A comprehensive overview of PMMA, including its properties, applications, and history.

-

Polymethyl Methacrylate (PMMA) – Omnexus – SpecialChem: Detailed insights into PMMA’s characteristics, production, and uses.

-

A Review of the Properties and Applications of Poly (Methyl …): A scholarly review of PMMA’s properties and its diverse applications.

- Top PMMA Plastic Pellets Suppliers in China

Frequently Asked Questions (FAQs)

Q: What is polymethyl methacrylate (PMMA), and how is it made?

A: Polymethyl methacrylate, often known as acrylic, is a synthetic polymer made by polymerizing methyl methacrylate monomers. This process forms long polymer chains, resulting in a transparent and tough material.

Q: What are the main characteristics of PMMA material?

A: PMMA material is known for its clarity, lightweight nature, and resistance to impact and UV light. It is also more brittle compared to other plastics but offers excellent optical properties.

Q: How is PMMA often used in various industries?

A: PMMA is often used as a lightweight alternative to glass in applications such as windows, aquariums, and displays. It is also widely used in medical and dental applications, including PMMA denture bases and bone cement.

Q: What are PMMA sheets and where are they commonly used?

A: PMMA sheets, also known as acrylic sheets, are flat pieces of PMMA material. They are often used in construction, signage, and as protective barriers due to their transparency and toughness.

Q: Why is PMMA considered a versatile polymer?

A: PMMA is considered versatile because it can be adapted for a broad range of applications, from consumer products to industrial uses, thanks to its optical clarity, durability, and resistance properties.

Q: How does PMMA compare to other thermoplastics?

A: Compared to other thermoplastics, PMMA offers superior optical clarity and UV resistance, although it is more brittle. It is also known for its ease of processing and ability to be welded.

Q: What are some of the available PMMA products?

A: Available PMMA products include sheets, rods, and tubes, as well as custom-molded parts used in various applications such as automotive lighting, electronic devices, and optical lenses.

Q: Can PMMA’s toughness be increased?

A: Yes, the toughness of PMMA can be increased by adding impact modifiers during the polymerization process, which enhance its fracture toughness and resistance to cracking.

Q: Is PMMA also known as acrylic, and why?

A: Yes, PMMA is also known as acrylic. This is because it is a type of acrylic plastic, made from the polymerization of the acrylic monomer methyl methacrylate, giving it its common name.