From the manufacturing of new devices to the conception of articles of daily use, plastics have shaped every realm of the modern world. But not every type of plastic serves the same purpose. Due to their unique properties, polycarbonate (PC) and polypropylene (PP) are two widely used types of plastics that serve different purposes. If you are a product designer, an engineer, or simply interested in the materials that serve as the building blocks for a lot of things, knowing the differences between these two can aid in using the correct type of plastic for the correct application. This guide will provide you with the vital information on the distinctions, uses, and benefits of PC and PP plastics, enabling you to appreciate the impact these materials have on various fields and your life.

What is PP Plastic and How is it Commonly Used?

Polypropylene (PP) is a low-density and stiff thermoplastic polymer widely used across various industries. Its use in containers, bottles, and food storage products is particularly popular due to its resistance to moisture and chemicals. PP’s resilience and durability also make it widely sought after in the automobile industry for parts such as bumpers and dashboards, additionally, PP is also used in textiles such as carpets and upholstery. PP’s popularity in different industries can be attributed to its balanced strength, flexibility, and low cost.

Characteristics of Polypropylene

Polypropylene (PP) possesses a wide range of characteristics that make it valuable across multiple applications. It is known for its high resistance to chemicals, including acids and bases, which ensures durability when exposed to aggressive substances. The material has a melting point ranging between 130°C to 171°C (266°F to 340°F), making it suitable for manufacturing products exposed to moderate heat. Additionally, PP is lightweight, with a density of approximately 0.9 grams per cubic centimeter, making it one of the lightest commercially available plastics.

It also demonstrates excellent fatigue resistance, allowing it to retain its shape even after repeated bending or flexing, which is ideal for hinges and wearables. Furthermore, PP is environmentally friendly compared to many other plastics as it is 100% recyclable and used in applications involving food-grade materials, due to compliance with safety regulations. Its insulating properties make it an effective choice for electrical components, while the ability to mold and customize adds to its adaptability for modern innovations.

Applications That Require PP Plastic

- Automotive Industry

The automotive business makes extensive use of polypropylene in the manufacture of bumpers, dashboards, and coolant reservoirs. The lightweight nature, along with the durability and resistance to chemicals of polypropylene, makes it an excellent choice for these applications. For example, consider these uses:

-

-

- Bumper parts (amounting to 32% of a vehicle’s plastic materials usage).

-

Dashboard panels (customized for impact resistance and economical manufacturing).

-

- Packaging Industry

PP is a preferred material for both flexible and rigid packaging, like containers for food and beverages. Plastic polypropylene is also known for its scaling protective features, such as meeting safety regulations for direct food contact and shielding food against moisture. Examples are:

-

-

- Containers for storing food

- Caps and Cap Closures

- Flexible film packaging

-

- Household Goods

Due to the durability along with the low cost of PP, it’s quite moldable, which makes it highly appealing to consumers, thus offering numerous consumer products and household goods. Applications are:

-

-

- Boxes for storage

- Consumable goods such as Toasters or Irons

-

Utensils such as Forks and Spoons that are dishwasher safe

-

- Medical Industry

As a result of its applications in medicine and pharmaceuticals, polypropylene (PP) is one of the most widely used thermoplastics, given its non-toxic and resistant to heat properties:

-

-

- Syringes and Medical Vials

- Sterilizable Trays and Containers

- Surgical Sutures

-

- Electrical Components

Polypropylene’s beneficial electrical insulating properties make it useful for:

-

-

- Cable Insulations

- Capacitor Films

-

Battery Housings

-

- Textile Industry

Because of its lightweight and moisture-resistant Properties, PP is used in the production of fibers for textiles. Most notably, it is used in the creation of:

-

-

- Carpets and Rugs

- Upholstery

- Industrial Fabrics and Geotextiles.

-

- Construction Sector

In the construction sector, Polypropylene is employed for the manufacture of piping systems, insulation materials, and protective sheets. The most common are:

-

-

- Plumbing Pipes and Fittings.

- Concrete Additives (enhanced durability and strength)

-

Protective Wrap Film

-

The wide appeal of industries needing polypropylene demonstrates why it still prevails as one of the most valuable and versatile forms of plastic in use in today’s civilization.

Why is PP widely used in Packaging?

Thanks to its unique versitality, functionality, and cost-effectiveness, Polypropylene (PP) is highly utilized in the packaging industry. This material is widely used in the packaging industry because of its great strength, and resistance to moisture, chemicals, and fatigue. Recent studies suggest that the market for PP packaging is growing due to increasing demand in food, beverages, healthcare, and e-commerce industries.

PP has a wide area of applications in packaging, especially due to its lightweight, which further lowers the cost of transportation, and molding capabilities into inflexible films and stiff containers. Furthermore, it protects perishable products such as food items from external forces due to its durability and maintains their freshness. PP is one of the most used materials in the global plastic packaging industry, which proves that its use is more than millions of tons every year. Its numerous sustainable characteristics, such as reusability and recyclability, further assert why PP is ideal for the plastic packaging industry. These reasons make Polypropylene the most sought-after plastic in modern businesses due to changing demand and the need for eco-friendly packaging solutions.

Exploring PC Plastic and Its Applications

Polycarbonate plastic is a tough, flexible material that has many applications in different industries. It is widely used in automobile parts, eyewear, construction materials, and electronic components due to its high impact resistance, transparency, and ability to withstand heat. Furthermore, polycarbonate’s ability to be shaped into many different forms, as well as its lightweight, makes it a preferred choice in constructions that need durable and clear materials. Its strength, combined with high adaptability, makes it extremely useful in modern polecarbonate manufacturing.

What Makes Polycarbonate Unique?

Due to its beams outstanding features suitable for various industries and consumer use, Polycarbonate (PC) stands out. This goes hand in hand with its lightweight structure which is very crucial in the automotive and aerospace industries. It’s high impact resistance is one of the most astounding properties, being 250 times stronger than glass which vertically enhances safety and security measures.

Compared to conventional glass, polycarbonate is much lower risk in terms of shattering while still providing fantastic optical clarity and transmitting 89% of light. These properties allow for it to be a core component for light fixtures, barriers, lenses and many more. Polycabonate is also able to withstand extreme temperatures due to its working range of -40 Fahrenheit to 248 °F leading to reliable performance at both hot and cold temperatures.

The circular economy PC plastics provide when recycled advances due to technology, rendering less environmental impact and waste. Ultimately, highlighting why polycarbonate remains an essential and adaptable material for other modern industries is due to its distinct attributes.

Common Uses of PC Plastic

The usefulness of Polycarbonate (PC) plastic is widespread due to its astonishing strength, clarity, and ability to withstand heat. Given below are some applications of Polycarbonate (PC) materials:

- Electronics and Electrical Components

Polycarbonate (PC) plastics are heavily used in consumer electronics such as protective cases, boards, and connectors due to provided insulation against heat and electricity. As a case in point, PC materials are used in multitude of LED light diffusers and housings because of their mechanical strength and optical transparency.

- Automotive Industry

PC is used in the headlights lenses, dashboards, and glazing components of vehicles. Polycarbonate’s strength to weight ratio helps lower the vehicle’s weight which in turn improves the fuel economy of the vehicle. For instance, recent advancements have shown that PC glazing can reduce vehicle weight by up to fifty percent compared to glass.

- Construction and Architecture

Polycarbonate sheets are commonly used in roofing, skylights, and sound barriers. Their impact strength and UV protection make them a long-lasting polycarbonate option outdoors. Research shows that polycarbonate panels maintain transparency while blocking up to 99.9% of harmful UV radiation.

- Medical Devices

Since it is biocompatible and easy to sterilize, PC is used in surgical instruments, incubators, and drug delivery systems. Studies suggest that polycarbonate’s enduring repeated cycles of sterilization without degradation make it an invaluable material in the healthcare field.

- Consumer Goods and Packaging

Polycarbonate is widely used in everyday items such as reusable water bottles and eyewear lenses. Its shatter resistance improves safety, while its clarity enhances appearance. PC is well known for its use in sports goggles and safety glasses because of its ability to withstand high impacts.

Usage of polycarbonate in different fields as mentioned above shows its unmatched adaptability and highlights its importance in contemporary production and polycarbonate innovations.

Why PC is Preferred for Certain Applications

Like any other material in the industry, polycarbonate (PC) has its own unique properties that play in its favor. It also has an impact resistance over 250 times stronger than glass. This ensures durability in critical applications like bullet-resistant windows alongside protective equipment. PC also has superior optical clarity, providing 89 percent light transmission, making it suitable for eyewear lenses, automotive headlamps, and transparent enclosures.

Other major advantages of PC include heat resistance, making it suitable for higher temperature applications. It can withstand temperatures of 125°C and above. PC offers flexibility, lowering the weight of a final product, which improves fuel efficiency for automobiles and aerospace. Due to it being easier to mold and recycle, PC also promotes sustainable production along with environmental goals. Because of this PC is extremely valuable across various industries like construction, healthcare, and consumer goods.

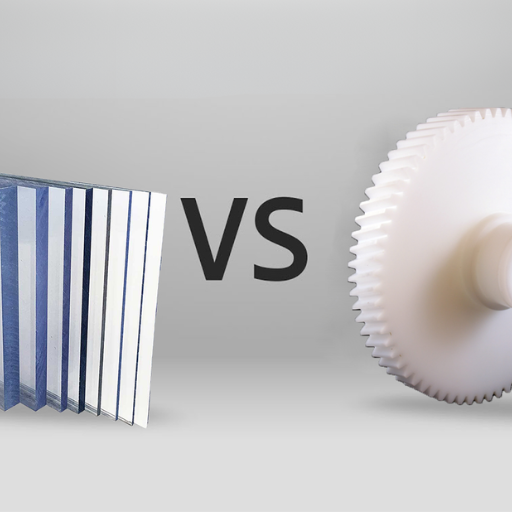

Differences Between PC and PP Plastic

These are some of the polycarbonate (PC) and polypropylene (PP) plastics.

- Strength and Durability: PC is more expensive and required for applications needing high strength and impact resistance. It is a brittle material. PP is lightweight and flexible but not strong under strain.

- Heat Resistance: PP pliability is reduced when exposed to elevated temperatures, heat and high stress environments, making it less suitable than PC. PC is more heat resistant and can withstand higher temperatures.

- Transparency: Polycarbonate is naturally transparent and is more suitable for applications that require clarity, such as lenses and windows, while PP is opaque.

- Chemical Resistance: PP is better than PC in chemical resistance, especially with Acids and Bases. PC may be exposed to certain chemicals.

- Recyclability: Both of these plastics are recyclable. PP is more friendly for for the environment and consider recyclable more often than PC.

Such differences dictate their appropriateness for different uses across industries.

Comparing PP vs PC: Properties and Characteristics

1. Strength and Durability

Polycarbonate (PC) is around 60% tougher and more impact-resistant than Polypropylene (PP) as its tensile strength is approximately 9,000 psi in comparison to PP’s 4,800 psi. This makes PC preferable for applications that demand impact resistance, such as bulletproof glass, safety goggles, and even some auto parts. On the contrary, PP is easier to bend and more suited for applications that require flexibility, such as storage containers or packaging materials.

2. Heat Resistance

When it comes to heat resistance, PC certainly outdoes PP with a higher heat deflection temperature that is typically around 284°F (140°C) compared to PP which is at 212°F (100°C). PC also holds its form and remaining structure at high temperatures which makes it favorable for complex devices such as medical equipment and electronics. Although not heat resistant, PP is well known for creating microwave safe containers.

3. Environmental Resistance

Both plastics have good resistance to water and environmental factors, but differ in their particular features. PP possesses better resistance to moisture, making it popular in food packaging and certain piping systems. PC, however, is treated with special coats that help it excel in UV resistance, which is useful in outdoor applications like greenhouses or skylights.

4. Transparency and Aesthetics

PC’s transparency makes it useful for lenses and eyewear PC. Its glass-like characteristics optically require clarity. PP being semi-transparent or opaque works better where transparency isn’t vital such as car interiors or textiles.

5. Cost-Efficiency

PP is easier on the pocket compared to PC, which is why it is the preferred option in bulk production where cost is a major concern. Lower-cost fuel is increasing its popularity in disposables and packaging. On the other hand, the higher price of PC is due to its highly functional performance attributes and strengths, which make it useful in high-end industries.

6. Weight Comparison

PP is one of the lowest-density plastics with a weight of 0.9 g/cm³. This low weight makes it ideal for parts where lightweight is an advantage. PC is heavier due to its more dense structure, which is about 1.2 g/cm³, but is still light enough for many structural applications.

These differentiations underscore the advantages of both PP and PC, assisting manufacturers and engineers in choosing the best-suited material to address particular needs. Their distinct characteristics expand industrial and commercial uses, rendering both essential in contemporary materials science.

Impact Resistance and Durability

The impact resistance characteristics of polycarbonate (PC) make this thermoplastic one of the most durable, as it can sustain blows that would destroy other materials. The impact resistance of polycarbonate is said to be almost 250 times greater than that of standard glass. PC is used in applications like bulletproof glass, automotive parts, and safety wear.

The impact resistance of polypropylene (PP) is moderate, lower than that of polycarbonate, but acceptable for numerous applications. Ranging from food packaging to automotive interiors and even textiles, PP is favored in lightweight, durable applications. It is known that PP’s resistance can be further improved with the use of certain blends or additives, making it more competitive. Both PC and PP are representative of modern polymers, as the different levels of impact resistance allow meeting needs in various fields of industry.”

Chemical Resistance and Transparency

Polycarbonate (PC) displays remarkable resistance to many chemicals, particularly oils, greases, and diluted acids, which increases its value in harsh industrial and medical settings. However, it may be vulnerable to some strong alkalis or solvents like acetone. Polypropylene (PP), in comparison, is known to withstand a wide range of chemicals, most acids, bases, and organic solvents, which makes it dependable in harsh environments like chemical containers or laboratory equipment.

The most notable difference between PC and PP is their level of transparency. PC is almost as clear as glass because it can transmit up to 89% of visible light and serves as a good substitute in constructing optical lenses, protective screens, or greenhouse panels. This clarity is offered alongside impact resistance, which ensures durability without compromising visibility. In contrast, PP is naturally translucent and limited in its optical applications because, while it can be processed to different levels of opacity or clarity, it is not extrinsically translucent. The combination of these factors makes PC the material of choice where optical clarity is essential, while PP excels in chemical durability, lower costs, and situations where transparency is less critical.

How PP and PC Plastics Are Used in Food Packaging and Containers

Because of its lightweight, moisture and chemical resistant properties, PP (Polypropylene) is used widely in food storage containers. This includes yogurt cups, takeout boxes, and even microwavable food storage containers as they require products to withstand heat.

PC (Polycarbonate) transmits little light, is less used in food packing, though important in cases such as reusable water bottles and food storage containers. Also very durable, the material is tempered with rust-resistant alloys. Its use has decreased in some areas because of the worry of leaching BPA and other toxic chemicals.

Benefits of Using Polypropylene in Food Containers

Polypropylene PP’s advantages. PP’s chemical resistance ensures that its intrinsic flavor and odor retention will not be altered by food products’ flavoring. Odor retention material degradation is also PP protected due to safety, preventing harmful substances from ore leaching into food, and chemicals overpowering food.

PP lightweight while maintaining chemical PP containers have a melting point around 266°F 130 °C), proving that it retains material integrity under high temperature, making it safe for microwaving, reheating dishwasher use, so highly efficient that shipping and storing are reduced, and overall material expenses are lowered.

Being highly recyclable reduces the industrial PP waste mark, making it support anti-plastic policies, further improving its eco-friendly waste profile when compared to other gels. Its proved that newly invented plastic recyclices have heightened the recovery rates for PP materials making it more useful over other plastics, and PP possess junk in so much on being ecomonically stacked, widley used in households, and in the packaging industry globally So retaining all these perks reinforced with its safety and durability easily using makes it an excellent choice in packaging food.

Why Polycarbonate is Used in Food Packaging

Polycarbonate is a popular choice for food packaging because it provides safety, durability, and functionality. It is a type of plastic that is lightweight, highly transparent, and provides outstanding strength and impact resistance to food during storage and transportation. Consumers are able to see the contents of the packets while the food is protected at the same time. Moreover, polycarbonate can withstand heat and is resistant to sterilization methods such as boiling and steaming, making it ideal for reusable containers and baby bottles.

Polycarbonate’s structural integrity has found its use in a variety of dishes, vessels, and containers for food items. Research suggests that polycarbonate-containing materials are less prone to developing cracks or other means of deterioration that could render them unfit for use or contaminated. Guidelines from regulators like the FDA for food-grade polycarbonate set very stringent safety requirements, including barring or restricting the presence of certain substances like Bisphenol-A (BPA). With modernization, BPA-free polycarbonate materials makes them more appealing without compromising safety which meets public expectations surrounding food-packaging materials.

In addition to its increased market value, industry reports have documented polycarbonate’s cost efficiency and life span, which significantly contribute to environmental pollution linked with food-grade packaging materials. Its high reusability renders it advantageous in eliminating single-use packing materials and aids in the Sustainable Development Goals. All these characteristics make it preferable in consumer and industrial food-grade polycarbonate materials globally.

Safety Concerns with Plastic Materials

Concerns about safety issues related to polycarbonate plastics, especially with regard to their usage in food packaging, continue to rise. Some of its uses, including heat, exposure over time to food items, as well as beverages, can result in harmful chemicals seeping from the plastics containing polycarbonate. There have been major concerns with BPA or Bisphenol A, which is widely used in plastics due to its flexible nature. It is often associated with major health concerns like endocrine disruption, along with other severe damage.

Studies suggest that these chemicals, albeit in minute quantities, may cause significant danger. For those reasons, many governments have ensured strict regulations or in some regions, even complete bans on certain materials. A good example would be the shift that many manufacturers are making lately on the use of BPA–free designs. There are already many studies showing that the new designs without BPA pose less contamination risks and hence, provide the same level of durability and functionality the previous versions.

Microplastics can now be considered a secondary concern. The removal of these materials results in tiny particles that can contaminate both food and water, creating long-term impacts on health and the environment. There is already significant concern on this in addition to ongoing research, as such efforts forced manufacturers to rethink their options on the design of plastic food containers, turning towards new technologies to generate nonharmful materials, safety-wise wise along with goods that are non-leaching when it comes to food.

Choosing the Right Type of Plastic for Your Needs

These are the main factors to consider when selecting a type of plastic:

- Safety: Since your application involves food storage/packaging, use materials that have labels such as food grade or free from BPA.

- Durability: Construction work and various forms of permanent storage require long-term solutions. If this is the case, go for sturdy plastics that will endure over time.

- Environmental Impact: Strive to use plastics that can be recycled or are biodegradable to decrease pollution.

- Purpose: For containers where heat resistance is necessary, Polypropylene (PP) is preferable, while polyethylene (PE) is ideal for flexible and lighter bags.

Evaluating these criteria makes certain that the selected plastic meets your function requirements while prioritizing safety and the environment.

Factors to Consider When Selecting Plastic Materials

Durability and Longevity

In drafting the design requirements, every plastic material under consideration needs to be assessed for its durability and lifespan. Polycarbonate (PC), for instance, is one of the strongest industrial plastics available today and is extensively used for engineering impact-resistant safety glasses, automotive parts, and other similar products. Likewise, acrylonitrile butadiene styrene (ABS) is also well known for its good mechanical strength and is often applied in consumer electronics like keyboards and tool housings. Use of plastics with an appropriate lifespan can improve replacement interval, thus saving money and reducing waste.

Environmental Impact

Study the environmental impact of the plastic material by assessing the recycling and biodegrading facilities available for it. A case in point is polylactic acid (PLA), which is a biodegradable plastic embraced for use in packaging materials because it can decompose into natural constituents under industrial composting conditions. On the other hand, polyethylene terephthalate (PET) is known to be one of the most widely recycled plastics in the world, and it is frequently used for beverage and food containers. Based on the latest figures, approximately 30 percent of PET plastic materials are recycled each year, thereby lessening the negative environmental effects associated with their disposal.

Chemical Resistance

A variety of plastics have distinct attributes when it comes to chemical resistance and it should match with their application. An example of this is High-density Polyethylene (HDPE) as it’s resistant to bases, alcohols, and acids which makes it perfect for containers carrying industrial chemicals or cleaning agents. Moreover, polyvinyl chloride (PVC) is also popular for its chemical resistance especially in plumbing and medical tubing.

Cost Efficiency

The cost of plastic materials depends greatly on their properties and how they’re manufactured, which greatly impacts the price. For instance, Low-Density Polyethylene (LDPE) has a straightforward manufacturing process that makes it more economically friendly in terms of packaging and insulation. On the other hand, engineering plastics such as Polyetheretherketone (PEEK) are much more expensive because of the high-performance strength and heat resistance they possess. This makes specialized applications in the medical and aerospace industries ideal. There needs to be a balance between cost and performance while selecting materials.

Evaluating the relevant attributes, such as strength, environmental impact, resistance to chemicals, and cost, allows you to meet your needs while providing proper functionality and preserving sustainability.

Understanding Thermoplastic Options

While assessing a thermoplastic, I pay closet attention to balance the following considerations: strength, heat resistance, chemical resistance, and cost. After determining the specifics of my application, I can select either a polypropylene for its low cost and functionality, or a PEEK material for its performance, ensuring I meet the sustainability goals of my project.

PC and PP in Consumer Goods

Polycarbonate (PC) and Polypropylene (PP) are both thermoplastics used frequently in the consumer products sector. Each come with advantages that serve a multitude of applications. PC is commonly used in the manufacture of eyewear, water bottles, and other electronic components due to its high degree of impact resistance, remarkable clarity, superb temperature tolerance, and the ability to endure temperatures of approximately 250°F (120°C) which is well acomplished in harsher conditions.

Meanwhile, PP is used more for its light weight, affordability, and affordability and is capable of being used in various manufacturing processes, allowing it to be used in the production of food containers as well as other packagingand household items. PP also melts at 320°F (160°C) which grants it heat resistance for everyday tasks.

Improperly managed, these plastics can be harmful to the environment, however, they are both recyclable, which promotes sustainable product design. For example, the replacement of pc or PP in manufacturing their goods aids in the lowering of carbon footprint as well as in raw material costs. These thermoplastics, along with the growing advancements in material science, are able to satisfy the harsh requirements of consumers for durability, sustainability, and environmental friendliness.

Reference Sources

- A Comparative Bibliometric Analysis on Plastic Waste Recycling1:

- Key Findings: This study explores the trends in plastic waste recycling, emphasizing the circular economy’s role in reducing resource consumption. It highlights the environmental impact of current plastic production and disposal methods, advocating for sustainable practices.

- Methodology: A bibliometric analysis using Scopus and Web of Science databases, covering publications from 2014 to 2023. Tools like VOSviewer and OriginPro were used for mapping and analysis.

- Comparative Study of Concrete with Polypropylene and Polyethylene Terephthalate Waste Plastic3:

- Key Findings: This research investigates the use of PP and PET plastics as partial replacements for coarse aggregates in concrete. PP showed better compressive strength and lower density compared to PET. However, PET provided higher workability.

- Methodology: Experimental analysis with varying water-cement ratios and plastic replacement percentages, focusing on mechanical properties like compressive and tensile strengths.

- Top PC Plastic Pellets Suppliers in China

Frequently Asked Questions (FAQs)

Q: What is the main difference between polycarbonate (PC) and polypropylene (PP) plastics?

A: The main difference between PC and PP plastics lies in their properties and applications. Polycarbonate plastic is known for its high impact strength and good transparency, making it ideal for applications where durability and clarity are important, such as in medical equipment and optical lenses. On the other hand, polypropylene plastic is a widely used material due to its resistance of pp to chemicals and moisture, making it suitable for packaging and containers.

Q: How does polycarbonate compare to PMMA (polymethyl methacrylate) in terms of impact strength?

A: Polycarbonate typically has higher impact strength compared to PMMA (polymethyl methacrylate). While PMMA, often referred to as acrylic, offers good transparency and is commonly used for applications like display screens and signage, PC is used for products that require more durability, such as helmets and protective barriers.

Q: What are the advantages of using polypropylene (PP) in injection molding?

A: Polypropylene (PP) is often used in injection molding due to its excellent flow properties, low density, and resistance of pp to chemicals and moisture. These characteristics make PP an ideal material for a wide range of applications, including automotive parts, household goods, and packaging materials.

Q: Why is polycarbonate considered a better choice for products exposed to high temperatures?

A: Polycarbonate is considered a better choice for products exposed to high temperatures due to its high heat resistance and ability to maintain structural integrity under stress. This makes PC a suitable material for applications like lighting fixtures and electronics components, compared to pc materials that might not withstand such conditions.

Q: In what applications is polypropylene commonly used?

A: Polypropylene is a plastic that is commonly used in a variety of applications due to its versatility and durability. PP is used in the manufacture of products like plastic cups, food containers, automotive parts, and textiles. Its resistance of pp to chemicals and moisture makes it particularly suitable for packaging purposes.

Q: How does the resistance of PP and PC to chemicals differ?

A: Polypropylene has excellent chemical resistance, making it suitable for applications where exposure to harsh chemicals is a concern, such as in packaging and piping. Polycarbonate, while also resistant, does not perform as well as PP in environments with strong chemical exposure, but it offers better impact strength and heat resistance.

Q: What are some common products made of PC and PP materials?

A: Common products made of PC include optical lenses, safety helmets, and electronic housings. Products made of PP include plastic cups, food containers, and automotive parts. Both materials serve different purposes based on their unique properties, with PC often used for its strength and PP for its chemical resistance and versatility.

Q: Is PC or PP more environmentally friendly?

A: Polypropylene is generally considered more environmentally friendly compared to polycarbonate because it is easier to recycle and produces less waste during its lifecycle. However, both materials can be recycled and repurposed, contributing to sustainability efforts in various industries.

Q: What is the difference in transparency between acrylic (PMMA) and polycarbonate?

A: Acrylic (PMMA) offers better transparency and is often used for applications where clarity is essential, such as display screens and acrylic aquariums. Polycarbonate also provides good transparency but is chosen for applications that require higher impact strength and durability, despite slightly less clarity compared to PMMA.