PFA and FEP are among the peak-performing fluoro polymers considering their utility in diverse regions. Striking features and unmatched flexibility explain their prominence. However, PFA and FEP, especially in regard to film or resin applications, can be rather intricate and detailed. This article aims to assist users in understanding these materials better with their traits, salient features, and how they can be used for maximum output. No matter if the goal is to find suitable materials for an advanced industrial procedure or if there is a need for explanation of properties, here you will find all the answers. Therefore, let’s look at the primary difference, figure out the perks, and find out which works best for what users look for. LP in selecting the right material based on the specific requirements of an application.

What is PFA, and How Does it compare to Other Fluoropolymers?

PFA, or Perfluoroalkoxy Alkane, is a fluoropolymer that stands out for its chemical resistance, non-stick properties, and high temperature endurance. It has PTFE (Teflon) like traits but is more flexible and stronger, making it ideal for applications where mechanical stress are present. While other fluoropolymers like FEP may prove useful, PFA has far greater stress-crack resistance and resiliency to high temperatures; this makes it especially useful in demanding industrial, medical, and chemical applications.

Characteristics of PFA and Its Chemical Resistance

PFA (Perfluoroalkoxy alkane) is known for its excellent chemical resistance, which makes it very useful for aggressive chemical environments. It has exceptional resistance to high-strength acids, bases, and, even at higher temperatures, most organic solvents. The reason why it is non-reactive is that the carbon-fluorine bonds in its molecular structure are very inert due to the immense carbon-fluorine bonds that exist within it.

Perhaps the most extreme characteristic of PFA is that it does not lose any structural integrity when exposed to a temperature above 500°F (260°C). For example, PFA-coated parts in chemical processing systems can withstand hydrochloric acid (HCl) and sulfuric acid (H₂SO₄) without system performance losses. Moreover, PFA is known to have lower gas or liquid permeability compared to other fluoropolymers, which makes it more useful in containing volatile or hazardous substances.

New industrial reports claim that PFA retains its mechanical and chemical resilience for extended periods even when exposed to extreme levels of pH, which makes it preferable in industries such as semiconductor manufacturing, which have ultrapure and highly corrosive chemical processes. Its claimof resistance to stress-cracking further enhances its rim charm, ensuring reliability and performance in applications that involve mechanical strain.

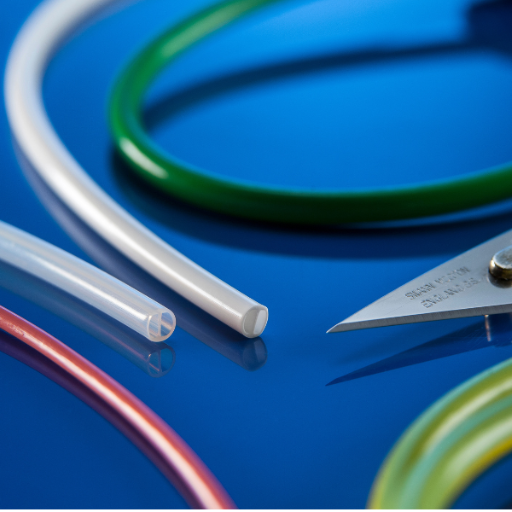

Applications of PFA in Tubing and Heat Shrinkable Products

Due to its tremendous performance characteristics, PFA is valued exceptionally across numerous industries. Below are applications where PFA tubing and heat-shrinkable products are of great functional value.

- Semiconductor Manufacturing

-

-

- Use: PFA tubing is extensively used for the transfer of ultrapure and highly corrosive chemicals in semiconductor fabrication processes.

- Reason: PFA’s unrivaled purity and chemically indestructible nature guarantee that no contamination occurs.

- Data: Exceeds industry standards with temperature resistance of 260°C and extreme pH conditions while maintaining structural integrity.

-

- Pharmaceutical and Biotechnology Sectors

-

-

- Use: In drug manufacturing and bioprocessing, PFA tubing is used for fluid transfer.

- Reason: Permissible leaching materials in the environment guarantee stringent sterilization safeguards.

- Data: Satisfies requirements of USP Class VI and FDA standards in safety and compliance.

-

- Aerospace and Automotive Engineering

-

-

- Use: For harsh environments, PFA heat-shrinkable products are used as electrical insulators and for protective coverings.

- Reason: Exhibits excellent stability during exposure to high temperatures and harsh chemicals.

- Data: Can withstand extreme temperatures of -200 degrees Celsius to 260 degrees Celsius consistently.

-

- Chemical Processing Industry

-

-

- Use: PFA tubing is used in production plants that handle aggressive chemicals.

- Reason: Low maintenance and permanently resistant to chemical cracking, long-term corrosion, and safe operations.

- Data: Contains a tensile strength of up to 2300 psi coupled with exceptional stress-crack resistance.

-

- Medical Devices

-

-

- Use: In the case of PFA heat shrinkable products, they are used for the assembly and insulation of delicate components into subassemblies for medical devices.

- Reason: Their flexibility guarantees reliability in complex, intricate applications, and biocompatibility makes them suitable for use within the human body.

- Data: Provides a characteristic dielectric strength of about 2000 V/mil, which is safe and works efficiently.

-

- Electrical and Electronics Industry

-

-

- Use: Used as protection insulation for wires, cables, and sensors.

- Reason: PFA’s superior dielectric and flame-resisting properties ensure greater dependability of electronic systems.

- Data: Exhibits a dielectric constant as low as 2.1 along with a flammability rating of UL 94 V-0.

-

These applications demonstrate the exceptional capabilities as well as versatility of PFA products and are, therefore, essential for the applications requiring functionality, accuracy, and stringent operational limits.

Exploring the Unique Properties of FEP Fluoroplastics

Known as FEP fluoroplastics, are one of the most important types of fluoroplastics because of their high functionality. These types of materials can easily survive high temperatures of around 204 degrees Celsius, or 400 degrees Fahrenheit, and still perform excellently. Their unique blend of extreme toughness and flexibility guarantees chronic reliability in highly advanced industrial systems.

Fluorinated Ethylene Propylene (FEP) provides supreme electrical insulation due to its low dielectric constant and high weather resistance, making it appropriate for wire and cable insulation, chemical processing equipment, non-stick coatings, and more. Its unparalleled weather resistance expands the number of its industrial applications. Like all other types of fluoroplastics, FEP exhibits superb chemical resistance, non-stick features, and thermal stability.

What Makes FEP Film Unique?

FEP film, of course, has incredible properties of chemical resistance, thermal stability, and electrical insulation. These properties are what make it essential throughout a wide range of industries. Its incredible resistance to harsh chemicals underscores one of its key advantages. This places it at the forefront of chemical processing, whether it be lining or barrier films. Besides that, FEP film has a high working temperature range, between -328°F (-200°C) and 400°F (204°C), performing well under extreme heat or cryogenic conditions.

The film’s nonstick features and low-friction surface are additional notable advantages. This, as well, is crucial for sectors such as optics or food processing where sleek, pristine surfaces are a must. FEP film also shines in light transmission, exceeding 95%, leading to its widespread use in solar panel covers and scientific imaging technologies.

Additionally, the enhanced weather aspects make FEP film durable and resilient, allowing its use in harsh outdoor environments for a longer duration. Its low dielectric constant (approximately 2.1) guarantees exceptional electrical insulation, clinically assisting dependable performance in flexible printed circuit components and high-frequency cables.

With the nonstick capabilities, chemical resistance, thermal endurance, and more all put together, FEP film becomes a highly reliable and versatile material for many commercial applications. It’s astonishing that FEP film can adapt to the innovations of modern technology.

How Does FEP Perform in High Temperature Environments?

FEP (Fluorinated Ethylene Propylene) is an excellent polymer for high-temperature applications due to its exceptional thermal stability. In particular, he has mastered maintaining the mechanical and electrical characteristics of the polymer itself while at rest at an extreme temperature. FEP exhibits a continuous use temperature of around 200 degrees Celsius (392 degrees Fahrenheit) without material deterioration. This makes it highly reliable in extreme conditions.

Moreover, FEP is still resistant to thermal stress and oxidation, which in turn prevents cracking or deterioration of the material over time. Additionally, its very low frictional coefficient and non-stick surface characteristics do not change under high temperatures. Because of these properties, it is critical in the aerospace and automotive industries, including electronic devices that undergo prolonged exposure to high heat for long durations.

To its advantages, FEP maintains exceptional dielectric strength for perforated temperatures which is instrumental for high-quality insulation materials and protective coatings. It also does relatively well when compared to other fluoropolymers in terms of heat resistance and elasticity making it ideal for flexible heat resistant applications.

Common Uses of FEP in Medical Tubing

FEP is often seen in medical tubing because of its good flexibility, chemical resistance, and biocompatibility. For catheters, drug delivery systems, and surgical instruments, I use FEP where fluid transfer accuracy is critical, thermal stability is essential, and friction must be kept to a minimum. Its transparency, along with its ability to endure sterilization, makes it even more beneficial for important medical settings.

Understanding the Difference Between FEP and PFA

Both FEP (Fluorinated Ethylene Propylene) and PFA (Perfluoroalkoxy Alkane) are well-known fluoropolymers because of their superior chemical resistance, high temperature tolerance, and non-stick characteristics. Nevertheless, there are significant differences between the two:

- Temperature Tolerance: PFA has a higher temperature tolerance than FEP, which makes it useful in extreme thermal environments.

- Flexibility: FEP is more flexible and easier to process, which makes it ideal for complex tubing and detailed molding.

- Clarity: FEP is more optically clear than PF, A, which is useful in medical applications where fluid visibility is necessary.

- Durability: PFA has enhanced tensile strength which makes it more mechanically durable and more resistant to stress-cracks as compared to other materials.

The selection between FEP and PFA is mostly driven by the application’s needs like, operating temperature, mechanical endurance, and optical clarity.

Comparing Chemical Resistance and Mechanical Properties

Both FEP and PFA, or more technically known as fluorinated ethylene propylene and perfluoroalkoxy alkane, respectively, exhibit extremely inert properties capable of enduring harsh exposures of various aggressive chemicals such as solvents, acids, and bases. Though PFA is said to offer greater chemical resistance, albeit slightly, at higher temperatures, which is ideal for more extreme conditions like semiconductor manufacturing and chemical processing.

PFA has been shown to outperform FEP in some areas, including mechanical flexibility as well as stress-crack resistance. Due to this, PFA is able to withstand greater amounts of bending, vibrations and other forms of mechanical stress prevalent in industrial settings. Applications where low levels of mechanical demand are present, FEP performs adequately especially where optical clarity and a smooth surfaced finish is of utmost priority.

Optimum performance and longevity in demanding environments are highly correlated to the selection process, which makes thermal performance an equally important factor. The operational temperature FEP can withstand is approximately 200 degrees Celsius, while PFA shows no signs of degradation up to 260 degrees Celsius. If the two materials need to be chosen from, these and application-specific requirements will play a key role in making the final decision.

Cost and Availability: FEP vs PFA

While estimating the cost factors of FEP and PFA, considering cost and availability, both are premium fluoropolymers, however, Complexities in their production and overall demand have a dire impact on their cost. FEP’s simpler production process makes it cheaper than PFA, which is more costly because of its superior temperature and chemical resistance. FEP is cheaper than PFA, which is more job-specific and expensive.

In the form of films and tubes, FEP is used in coating electronics and chemicals, while PFA is used for thermally and chemically demanding jobs. The expense also only reaches PFA users. The global market price range for FEP is $10 to $17 per pound, whereas PFA costs more. Depending on scale, purity, and other factors, Price Per FEP branded PFA usually starts from $15 and goes beyond $25 per pound.

The specific market signals enable advanced industries, like semiconductor and medical equipment manufacturing, to widen their scope for both material procurement. This increasing interest causes a rise in PFA lead times and availability since production levels are often dicey. To address the operational factors, cost factors defining manufacturing processes, and market factors determining conditions under which a company will sell a good or service, all in regard to system requirements to operate on a specific industrial level, are central to making sound planning decisions.

The Role of Resin in Fluoropolymer Applications

In the case of fluoropolymer uses, resin serves as the starting point for high-value products, and fluoropolymer itself is a first-grade material like carbon, which determines the entire setup builds versatility and transforms many features. It controls critical characteristics like resistance to various chemicals or solvents, thermal stability as determined by temperature, and mechanical strength. A classic example of such durable and harsh environment resins is PTFE and PFA. Choosing the right one can greatly impact productivity, and in almost every case, productivity determines profit in industries like aerospace, electronics, chemical engineering, as well as chemical processing.

Exploring Resin 3D-Printing with PFA and FEP

PFA and FEP, or Perfluoroalkoxy alkane and Fluorinated ethylene propylene, respectively, are advanced materials with specialized resin 3D-printing applications. PFA has unmatched chemical resistance; its thermal stability is roughly up to 500°F (260°C), and its non-stick properties are superb. Its precision and reliability in high-stress environments, whether heat or chemical, is unparalleled, which makes it ideal for industrial prototyping, electronics manufacturing, or other related fields.

On the other hand, FEP maintains all those benefits but has greater flexibility and transparency. Its melting point is roughly 482°F (250°C) while it maintains resistance to almost all chemicals, making it great for 3D printing when smooth, opaque surfaces are needed. FEP further aids in producing visually appealing prints with its low friction coefficient, which minimizes equipment component wear during the production cycle.

In resin 3D-printing, these materials improve performance by providing strong barrier layers with low contamination and better curing strategies. Such characteristics support the requirements of precise and safe operations in medical device fabrication, semiconductor fabrication, and aerospace industries. The application of PFA and FEP in resin 3D-printing systems enhances equipment longevity, boosts productivity, and enables the resolution of intricate as-designed scenarios with outstanding fidelity.

Why PFA Resin Might Be Preferred in Certain Industries

Perfluoroalkoxy (PFA) resin possesses distinguishing features that make it highly valuable in various industrial applications. PFA’s chemical inertness guarantees stability and non-reactivity in harsh environments, including strong acids, bases, and solvents. PFA is particularly critical in the chemical and semiconductor industries where it is routinely exposed to high-temperatures of 500°F (260°C) within the range of its operational temperatures.

In addition, PFA resin is unrivaled when it comes to non-stick and clean surface energy. In semiconductor manufacturing, PFA is predominantly utilized to fabricate tubing and linings as it ensures consistent results without contamination. PFA’s strong insulation also makes it ideal for the manufacturing of advanced electronic components beyond semiconductors, as reliability and insulation are critical within these devices.

Cross-sectional examination shows that PFA resin is often greater than substitute materials such as polytetrafluoroethylene (PTFE) because of its greater flexibility and ease in processing. These characteristics come in handy for the fabrication of more detailed parts, such as and not limited to, medical appliances and aerospace components, where a certain level of intricacy in design and material structure is critical. The adoption of PFA resin is further boosted by the fact that it consistently fulfills rigid safety and quality benchmarks fostered by grace in innovation and efficiency across numerous industries.

How to Choose Between PFA and FEP for Your Needs

When selecting between PFA and FEP, keep in mind the details of your application:

- Temperature Resistance: For environments with extreme heat, PFA outperforms FEP in high-temperature endurance.

- Flexibility: FEP stands out for its exceptional flexibility, making it ideal for use in intricate designs.

- Chemical Resistance: While FEP and PFA both have great chemical resistance, PFA is better for aggressive or high-purity applications.

- Cost: Projects that are limited by budget can benefit from PFA’s general affordability.

Consider evaluating these elements according to your goals to select the best material.

Factors to Consider: Temperature Resistance and Coefficient of Friction

Temperature Resistance

Not analyzing the temperature resistance of PFA and FEP without considering their operating limits is a crucial mistake. These materials have exceptional thermal cycling resistance, meaning they can withstand extreme shifts in temperature, and are also highly durable. PFA is able to withstand continuous use up to 260 degrees Celsius or 500 degrees Fahrenheit, ideal for high-temperature applications like semiconductor manufacturing. FEP’s maximum operating temperature is slightly lower, averaging around 200 degrees Celsius or 392 degrees Fahrenheit. While robust, these claims make FEP less extreme in thermal stability compared to PFA, meaning the latter has a clear edge when thermal stability is a concern.

Coefficient of Friction

The coefficient of static friction according to both surface finishing and specific formulation lies between 0.1 and 0.2. PFA, FEP, and both put forth low friction properties, making them highly sought after in anti-friction and non-stick endeavors. With skirted surfaces known to be dynamic systems, less energy emittance makes the materials effective in seals, bearings, and cable coatings. Involving movement or wear, the coefficient of friction is one primary consideration, making both PFA and FEP desirable. Simplistically stated, because of FEP’s subtle differences in surface finish, it would seem to be superior to PFA for highly smooth surfaced applications.

A user can choose a material that best performs for their needs by balancing temperature resistance and coefficient of friction appropriately.

Evaluating the Thickness and Transparency of Films

The thickness and clarity of films have a significant impact in their respective fields of application. For instance, mechanical properties, such as tensile strength, flexibility, and durability, rely on thickness. Films utilized in packaging show this balance to an extent where a thinner profile is needed for cost reduction, while still providing barrier properties at an adequate level. Research shows the range of common film materials, like polyethylene and polypropylene, is between 10 and 200 microns for diverse applications.

Psychological factors are also important in some areas, such as food packaging or display windows, where optical transparency is required. A film’s clarity depends on the properties of the polymer itself, its additives, and the film’s thickness. To illustrate, polycarbonate films are famed for their superb clarity, where transmittance for light is mostly above 89%. On the other hand, electronics industries that need to see other parts placed inside have to deal with thicker films or added coated that reduce transparency, which becomes critical.

To achieve these standards, precision is paramount, and for this purpose, advanced testing, like haze measurements, is preferred, allowing the gap between countertop strength and clarity including functionality to be bridged while still keeping rigorous demands set by the industry.

Industry-Specific Recommendations: Electrical Insulation and Coating

In the case of electrical insulation, polyimide films are exceptional due to their remarkable dielectric strength, along with high mechanical properties and thermal stability. These films can endure 269°C to 400°C, enabling them to operate in extreme conditions such as in aerospace, automotive, and the electronics industry. Recent information suggests that polyimide insulating films have dielectric strengths of more than 200 kV/mm, which guarantees dependable performance in high-voltage applications.

For coating purposes, these coats are made from advanced polymers which are intended to increase surface performance as well as defend against chemical corrosion and increase durability. One such example includes the widely used fluoropolymer-based coatings due to their low surface energy and resistance to environmental degradation. They have exceptional barrier properties and can sustain their function even when exposed to UV rays for long periods of time or in chemically aggressive environments. There have been more recent advancements in the industry that focus on incorporating nanotechnology into coatings for applications that require enhanced scratch and self-cleaning capabilities.

The developments highlighted above on electrical insulation and coatings demonstrate the modern engineering ability to customize material properties with the precision required by modern industries for safety, efficiency, and exceptional durability.

Reference Sources

1. Erosion-Corrosion Failure of a Carbon Steel Pipe Elbow – a Case Study

- Authors: S. Tandon, M. Gao, Richard McNealy

- Publication Date: 2009-03-22

- Journal: Corrosion

- Summary: This study investigates a failure case of a carbon steel elbow in a flow line. The elbow experienced a leak after three years of operation, attributed to a combination of erosion and corrosion mechanisms. The authors proposed a two-step mechanism involving the destruction of protective films by fluid flow and subsequent galvanic corrosion. The study emphasizes the importance of design considerations to prevent similar failures.

- Methodology: The authors conducted macroscopic and XRD analyses to understand the corrosion mechanisms and proposed preventive measures based on their findings(Tandon et al., 2009).

2. Corrosion and Strength Changes of Agricultural Steel Pipes Elapsed 20 Years under the Greenhouse Environment

- Authors: S. Nam, Hee-Ryu ryong, M. Choi, Hyun-Ho Shin

- Publication Date: 2020-04-01

- Journal: Environmental Science

- Summary: This research evaluates the corrosion and strength changes in galvanized steel pipes used in greenhouses over a 20-year period. The study found that untreated pipes showed significant corrosion, while those with protective coatings exhibited minimal degradation. The findings highlight the effectiveness of protective treatments in extending the lifespan of agricultural steel pipes.

- Methodology: The authors installed various treatments on pipes and conducted experiments to measure surface corrosion and strength changes over time(Nam et al., 2020, pp. 196–201).

3. On the Effect of Soil Water Saturation on Buried Steel Pipe Responses under External Load

- Authors: Yadong Zhang, R. Wong

- Publication Date: 2023-03-29

- Journal: Canadian Geotechnical Journal

- Summary: This study examines how soil water saturation affects the deformation of buried steel pipes under external loads. Full-scale tests were conducted, revealing that increased saturation leads to significant changes in pipe deformation. The research provides insights into the design and safety of buried pipelines in varying soil conditions.

- Methodology: The authors performed full-scale tests on a buried steel pipe and developed a three-dimensional finite element model to analyze the effects of various parameters on pipe responses(Zhang & Wong, 2023).

4. Top PFA Resin Suppliers in China

Frequently Asked Questions (FAQs)

Q: What are PFA and FEP films, and how do they differ from PTFE?

A: PFA (Perfluoroalkoxy) and FEP (Fluorinated Ethylene Propylene) films are types of fluoropolymer materials. PFA film is known for its high chemical resistance and crack resistance, while FEP film is valued for its transparency and lower cost. Both materials have similar properties to PTFE (Polytetrafluoroethylene), such as a low coefficient of friction and high-performance characteristics, but they are more melt processable than PTFE, making them easier to use in a variety of applications.

Q: How does PFA film compare to FEP in terms of chemical resistance?

A: PFA film offers higher chemical resistance compared to FEP film, making it more suitable for applications involving aggressive chemicals and high temperatures. While FEP also provides good chemical resistance, PFA is often chosen for more demanding environments.

Q: Is PFA better than FEP for aerospace applications?

A: PFA is often considered better than FEP for aerospace applications due to its superior crack resistance and ability to withstand higher temperatures. These properties make PFA a preferred choice in situations where durability and performance under stress are critical.

Q: What are the similarities between PFA and PTFE tubing?

A: Both PFA and PTFE tubing exhibit high chemical resistance, a low coefficient of friction, and excellent non-stick properties. However, PFA is more melt processable, allowing for easier fabrication and welding processes than PTFE.

Q: How is FEP heat shrink used compared to PFA?

A: FEP heat shrink is often used in applications requiring transparency and a release film, such as when a clear view of the underlying material is necessary. In contrast, PFA heat shrink is selected for its higher chemical resistance and durability in harsher environments.

Q: What makes PFA a copolymer of hexafluoropropylene and tetrafluoroethylene?

A: PFA is a copolymer composed of hexafluoropropylene and tetrafluoroethylene, which gives it its unique properties. This composition allows it to maintain high-performance characteristics while being more processable than PTFE.

Q: Are there specific applications where FEP tubing is preferred over PFA?

A: FEP tubing is preferred in applications where a transparent film is required, such as in laboratory settings or fluid handling systems where visual monitoring is important. Its lower cost compared to PFA also makes it an attractive option for less demanding applications.

Q: Can PFA film be used as a release film in high-temperature applications?

A: Yes, PFA film can be used as a release film in high-temperature applications due to its high chemical resistance and ability to withstand elevated temperatures without degrading.

Q: What process advantages does PFA offer compared to PTFE?

A: PFA offers several process advantages over PTFE, including being melt processable, which allows for easier fabrication and welding. This makes PFA suitable for applications that require complex shapes or precise fittings.

Q: How do PFA and specially treated FEP film differ in use?

A: PFA is typically used in environments requiring high chemical resistance and durability, whereas specially treated FEP film is used where transparency and a release film are important. The treatment enhances FEP’s properties for specific applications, but PFA remains more robust for harsh conditions.