For advanced engineering plastics, the glass-like properties and uses of Polyphenylene Sulfide (PPS) and Polyphthalamide (PPA) must be considered when selecting the appropriate material. These multipurpose plastics are equally used by automotive, aerospace, and electronics companies, which demand high thermal, chemical, and mechanical resistance. However, what differences exist between PPS and PPA, and how do those properties cater to application requirements? This article addresses some fundamental differences between these plastics, giving high-level comparisons to aid engineers, designers, and manufacturers in selecting the right material for their projects.

Introduction to PPS and PPA Plastics

Overview of Polyphenylene Sulfide (PPS)

Polyphenylene Sulfide (PPS) is a high-performance thermoplastic polymer notable for its exceptional resistance to temperature changes, chemical attacks, and mechanical stresses. Being semicrystalline, PPS ensures resistance to degradation at very high temperatures, and due to its melting temperature of around 280°C (536°F), it finds use in some of the harshest conditions. This property implies that the material offers resistance against many chemicals that can damage other materials, which increases the aging and performance of this polymer in various industrial applications.

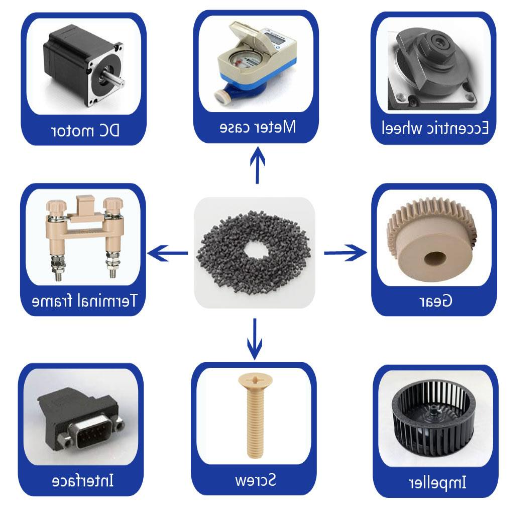

Light in weight and balancing strength with stiffness, PPS finds the most significant application areas in the automotive, aerospace, and electronic fields. For example, in automotive applications, fuel system components, electrical connectors, and many under-hood applications demanding stringent performance requirements are commonly made using PPS. To improve its mechanical properties and dimensional stability, PPS is often compounded with glass fibers or carbon fibers, allowing precision components with tight tolerances to be fabricated.

Another advantage of PPS is its self-extinguishing nature and retention of its properties when subjected to continuous high temperatures. Because of these traits, PPS is replacing metallic parts in high-temperature settings, thereby contributing to weight reduction of great design consequence. Owing to this unique property profile, PPS has brought about further innovations in almost every industry, assisting manufacturers in attaining higher levels of performance and durability.

Overview of Polyphthalamide (PPA)

Polyphthalamide expresses resistance to high temperatures, structural loads, and chemical environments of application. The PPA molecular structure enhanced crystallinity, thus making the polymer crystalline, stiff, and strong even in high-temperature conditions. Applications in automotive, electronics, and industrial machinery make ideal places for PPA to be used in demanding applications where wear and precision clash.

Another feature of PPA is moisture absorption resistance. This way, mechanical and electrical properties remain stable in humid or wet environments- a trademark property of conventional polyamides that tend to swell and lose strength with exposure to moisture. PPA, many reinforcement, and filler types, such as glass fibers or mineral fillers, can be used as synergists by bringing to bear their special properties towards attaining the desired set of properties that may involve, for instance, dimensional stability or impact resistance.

Recent changes in PPA formulations aim to improve processability with minimal cycle time during injection molding and enhance the surface finishing of consumer-related products. Light in weight, PPA fills an essential niche for high-performance materials that aim to reduce weight to improve energy efficiency in automotive or aerospace areas. With further advancement, PPA supports high-end applications whilst addressing the rising demand for sustainable and efficient materials in contemporary manufacturing.

Importance of Understanding Material Differences

Understanding the variances among materials is pivotal toward fabricating products capable of performance, cost-efficiency, and sustainability. Each of the materials possesses distinct properties, for instance, strength, thermal resistance, weight, and corrosion tolerance, that can affect the performance of a product in any way, including the duration of its operational life. For instance, polymers like PPA are highly sought after because they can tolerate extremes of temperature and harsh chemicals, enabling advanced engineering applications. In contrast, metals offer structural rigidity and conductivity required in industries where stability and efficiency matter.

The automotive, aerospace, and consumer electronics industries rely on carefully chosen materials to satisfy performance goals while ensuring adherence to environmental regulations and market trends. As lightweight composites and bio-based materials gain more currency, correctly identifying and using materials will give businesses a boost. Material optimization is often one of the main ingredients in cutting down waste and production costs, illustrating how well-informed material selection strategies interplay with modern manufacturing.

Material Properties of PPS and PPA

Physical and Chemical Properties of PPS

Polyphenylene Sulfide (PPS) is an engineering thermoplastic known for its special physical and chemical features. PPS is thermally very stable, with a typical melting point close to 280°C (536°F); hence, it can work under extreme temperatures. It is inherently flame-retardant, usually obtaining a UL94 V-0 rating without additional flame-retardant additives.

Its outstanding physical property is that PPS can remain mechanically strong and rigid even at high temperatures. It exhibits a high degree of dimensional stability, resisting warping, shrinkage, and deformation, enabling applications with very close tolerances. Chemical resistance is also essential to PPS; it resists almost no chemicals, including acids, bases, fuels, and most organic solvents. Additionally, PPS is resistant to hydrolysis; it maintains its strength even in hot water and steam applications, which means the polymer is functional under harsh environments.

Due to its physical and chemical properties, PPS serves an array of industrial applications, including automotive parts, connectors in electronics, and industrial machinery. The lightweight plastic’s ability to survive harsh operating environments allows manufacturers to replace metal parts, thereby streamlining overall system performance.

Physical and Chemical Properties of PPA

Polyphthalamide (PPA) is a famous high-performance thermoplastic due to its resistance to welding, forging, Extreme temperature, chemicals, or mechanical stress. PPA boasts superior thermal stability and generally has a melting point ranging between 500°F and 570°F (260°C to 300°C), thereby finding applications in ultra-demanding scenarios like automotive and electronics. It absorbs less moisture than regular polyamides, ensuring dimensional stiffness in humid environments.

Chemically, it can withstand harsh action from several such substances as automotive fluids, fuels, cleaning agents, etc. PPA has evolved as a dependable candidate for the replacement of metals in lightweighting scenarios due to a favorable high strength-to-weight ratio and creep resistance to loading. Moreover, fortification with glass fiber or other fillers could significantly improve the mechanical properties of PPA, including tensile strength and stiffness, which then qualifies it for structural and functional components.

High strength and physical and chemical attributes make PPA suitable for durable and cost-effective solutions offered in several industries. This allows, among other factors, for design flexibility or system performance optimization.

Comparison of Toughness and Structural Integrity

Every analysis should consider toughness and structural integrity, taking into account any particular application, composition of the material, or environmental considerations. Toughness is a material property referring to a material’s capacity to absorb energy and plastic deformation without fracture; this is important in applications exposed to impact or sudden loads. In contrast, structural integrity speaks about the ability of a material or design to retain its shape and serve its function while withstanding applied forces over time.

PPA has an excellent balance of toughness and structural integrity due to its inherent flexibility and high thermal and chemical stress resistance. For example, Glass fiber-reinforced PPA offers tensile strength values beyond 200 MPa and is helpful for automotive under-the-hood components wherein mechanical stresses and elevated temperatures are present. Furthermore, PPA is proven to keep stable dimensionally even in wet atmospheres, a significant factor when integrity is required for long-term use.

Such a property balance renders PPA super versatile, especially in fields requiring mechanical resilience and precision. By adjusting the filler content or using advanced formulations, manufacturers can increase toughness and structural performance to meet the requirements of demanding applications, thus minimizing the chances of failure and securing longevity.

Reinforcement and Modifications

Reinforced with Glass Fiber: PPS vs. PPA

Glass fiber reinforcement greatly improves mechanical performance in PPS and PPA, rendering them suitable for a few industrial applications that demand high performance. PPS presents a greater tensile strength, thermal stability, and dimensional stability when glass fibers are incorporated. The best property of PPS is its chemical resistance and almost negligible water uptake, which yields steady performances in applications characterized by highly corrosive states or temperature fluctuations. These properties make glass fiber-reinforced PPS one of the few materials used in aerospace, automotive, and chemical processing sectors, where the product has to resist severe conditions.

By contrast, glass fiber-reinforced PPA has superior toughness and impact resistance compared to PPS. Although PPA may absorb some moisture, when reinforced, PPA offers excellent high-temperature strength and stiffness. The versatility and resistance of PPA to repeated thermal cycling make it an attractive option for automotive and electrical parts where mechanical endurance and precision are necessary. Moreover, further modifications of PPA with lubricants and stabilizers make this material even more adaptable, providing an added advantage in fulfilling specific performance requirements.

The choice between these two materials is often governed by the application’s requirements. PPS is mainly preferred in chemically exposed and low-moisture environments, whereas PPA is used in scenarios where a compromise between temperature resistance and toughness has to be met. When glass fiber-reinforced, both materials greatly extend the service life and reliability of parts and thus provide outstanding value in cutting-edge engineering applications.

Modifications of PPA for Enhanced Performance

In furtherance of Polyphthalamide (PPA) properties to keep pace with ever-so-demanding application requirements, manufacturers often consider tailored modifications. A primary enhancement involves the incorporation of glass or carbon fibers to impart mechanical strength, dimensional stability, and durability to PPA for structural components that work in high-stress environments. Frequently, thermal stabilizers are added to PPA to extend the resistance of these polymers when subjected to a prolonged period at elevated temperatures, thus assuring reliability in automotive and industrial applications.

Flame retardants are added to PPA formulations if electrical insulating properties are required, thereby maintaining fire safety while conforming to critical industry standards such as UL94 V-0. Further enhancements to filler modifications with mineral or ceramic fillers have opened the way to applications where dimensional precision and lower thermal expansion are of primary importance, making PPA the material of choice for such exact fit and function areas.

Surface treatments and coupling agents have improved PPA’s compatibility with other materials, primarily in overmolding procedures. With such additives, multiple materials can be joined and used in applications, providing better adhesion and performance properties in assembly-type installations, including electronics and connector systems. In such a manner, these modifications enable PPA to be flexible for further development and competition in various industries, from automotive to consumer electronics.

Impact of Reinforcement on Mechanical Properties

The reinforcement makes PPA stronger in mechanical properties and indispensable in high-performance applications. When fillers are incorporated, also called reinforcement, glass fibers, carbon fibers, or minerals, all impose great tensile strength, incredible stiffness, and great scuffing on the Polyphthalamide. For example, tensile strengths well over 200 MPa may be recorded for glass fiber-reinforced PPA in harsh environments such as automotive engine components and structural housings.

Carbon fiber reinforcement assuredly improves thermal and dimensional stability and also reduces density, thereby providing a light and strong solution for aerospace and industrial applications. Meanwhile, mineral fillers, including mica and talc, promote dimensional accuracy and surface finish of PPA, both critical for complex parts requiring very tight tolerances.

Such reinforcements enhance the strength-to-weight ratio of PPA while keeping its corrosion and thermal resistance intact. Because of these properties, industries use reinforced PPA in operations demanding durability, lightweighting, and cost-effectiveness under extreme operating conditions.

Manufacturing Considerations

Processing Techniques for PPS and PPA

Polyphenylene Sulfide (PPS) and Polyphthalamide (PPA) processing involves sophisticated methods aimed at maximizing material properties and ensuring functioning under strenuous application scenarios. Injection molding, extrusion, or compression molding methods may be used for both polymers to meet specific design and functional purposes.

With PPS, injection molding is more common than any other method to develop complicated designs and shapes while maintaining excellent dimensional stability. Since PPS is processed at high temperatures, generally in the range of 550°F to 700°F, enough heat has to be given for the polymer to flow entirely without breaking the crystalline structure. Due to the slight sensitivity of PPS to moisture, drying the polymer powders before molding is very important; otherwise, moisture remaining in the polymer could impair its mechanical properties during molding.

Similarly, injection molding of PPA occurs at high temperatures because the material resists thermal degradation and maintains its structural integrity in high-temperature conditions. PPA is usually dried at typical conditions (commonly 230°F-250°F for 2-4 hours) to reduce moisture that would otherwise cause hydrolysis during molding. Melt processing proceeds from 550°F to 650°F and depends on reinforcement and grade. Care should also be given upon cooling to avoid immense warpage or shrinkage.

Each processing method is complemented by high tooling technology. High-tech molds with complex geometries and internal uniform temperature control enhance the surface finish and dimensional accuracy of the products. Furthermore, parameters like screw geometry, injection pressure, and cooling time are controlled so tightly to minimize cycle time and maximize material use.

Manufacturers also use specific additives during processing to enhance thermal stability, lubricity, and flame retardancy. The additives are compounded into PPS and PPA, making these materials composites usable in automotive, electronics, aerospace, and other sectors. Thus, careful coordination of the processing parameters with the material properties is indicative of high-quality products that can satisfy very stringent and defined operational requirements.

Challenges in the Manufacturing of Engineering Plastics

Manufacturing engineering plastics involves several complications, demanding special techniques and high precision. One major challenge is producing uniform material properties: in polymer chains, filler dispersion, and additive integration, even the smallest change may affect performance. Such a scenario occurs primarily in areas with stringent requirements, e.g., aerospace or electronics.

Another technically challenging issue refers strictly to the control of processing parameters. Engineering plastics, such as PPS and PPA composites, often require a very tight temperature and pressure window for molding. Any deviation occurring during injection molding, extrusion processing, etc., degrades the materials’ mechanical properties or dimensional stability. Consequently, advanced machinery and real-time monitoring systems are adopted by manufacturers to avoid such incidents.

Second, the challenge of environmental sustainability persists. Basically, matters of reducing carbon emissions during production and recycling high-performance thermoplastics are on one side of this dilemma, and on the other are ecological fulfillment and performance requirements that demand innovative approaches. For instance, research on engineering plastics based on biomaterials or recyclable materials is gaining more attention.

Costing is another constant problem when scaling up production aspects. The use of high-grade additives, high-tech fillers, and rigorous quality control ramps up the cost of manufacturing. Therefore, companies balance their priorities to focus on cost-saving measures such as process optimization, material substitutions, or economies of scale, making their products less expensive.

The fourth item that complicates the make-up is compliance with regulations and requirements from different markets. The other industries specify indispensable guidelines regarding safety, flame retardance, environmental impact, etc., thereby requiring ongoing adjustments to formulations and processes. How all these factors come together shows the necessity of technical know-how paired with ingenuity and good strategy during the manufacturing of plastics.

Cost Implications of Using PPS vs. PPA

When comparing PPS and PPA from cost implications, the typical factors for comparison shall be raw material cost, processing requirement, and benefits accruable from good performance over a long period. PPS has value-added properties such as thermal stability and chemical resistance, thus making it suitable for high-temperature and harsh chemical environments. However, such advantages come at relatively higher prices as, in forms of processing such as polymerization in solvent-based systems, PPS generally requires a more complicated route and energy during processing.

In contrast, PPA offers a cheaper alternative for use where an application does not tolerate extreme temperatures or chemical reactions. Thus, with low production and processing costs, PPA is primarily employed in industries working towards light-weighting, such as automotive and electronics, where price and performance must be balanced. PPA also generally allows for faster injection molding cycle times, thus further lowering manufacturing costs.

If seen in isolation, PPS may look more expensive, but its durability and long service life in tough applications make it a better buy over time. Conversely, the low initial cost of PPA and adequate performance in comparatively mild environments give it an advantage to producers willing to invest less upfront. The final decision between PPS and PPA is, therefore, an economic tradeoff against the requirements that the end-use has for certain expected performance.

Applications of PPS and PPA Plastics

Typical Applications of PPS in Industry

From my experience, Polyphenylene sulfide (PPS) is widely accepted for its phenomenal thermal and chemical resistance, and this acceptance has made it the preferred material in engineering disciplines that demand strength under extreme conditions. In the case of automobiles, PPS is utilized for parts such as pump housings, electric connectors, and under-hood components since it can resist very high temperatures and the adverse effects of chemicals like harmful fuel and coolant. These characteristics guarantee unwavering functionality and durability, all in the most trying environment, because automotive manufacturers have to meet very stringent performance and safety standards.

Going beyond automotive applications, PPS is highly employed in electronics and electrical fields, where its ability to insulate against electricity permits its utilization in making switches, sockets, PCB components, and other precision equipment. Additionally, PPS is utilized in aerospace and heavy industrial manufacturing industries for components subject to heavy wear and tear, such as bearings and seals. Being flame-resistant and stable under mechanical stresses has benefited the manufacture of components that must withstand rigorous operational requirements and retain structural integrity. In short, this rare amalgamation of properties allows PPS to perform varied functions in a highly diverse industrial environment.

Applications of PPA in Engineering Solutions

When engineering has demanded a solution, I almost always go with PPA-polyphthalamide because of its distinguished ability to stand against extreme conditions. With high thermal resistance, it can be used where components must withstand extreme heat, such as automotive engine components that could be subjected to temperatures much higher than conventional materials. One can also say that the material has excellent chemical resistance to maintain its shape under exposure to harsh fuels, oils, and industrial chemicals, making it an indispensable option in manufacturing environments where performance and durability are critical.

On the other hand, the exceptional hardness that PPA offers can make a big difference. I find it helpful in almost all complex application areas requiring high stiffness and dimensional stability. From precision gears and bushings to electrical connectors, PPA will not let you down, at least not without severe deformation or failure. Another plus worth mentioning is that humidity and/or wet environment won’t affect it because of its low moisture absorption property, thereby ensuring functional integrity over time.

They call PPA the high-performance plastic in engineering because it is versatile and rugged. It represents the answer to a question that has yet to be asked and can be applied in any situation, from automotive to electronics to industrial machinery. It prompts engineers to expect it to deliver excellent results that meet or exceed the exacting standards of advanced engineering design.

Future Trends in PPS and PPA Usage

Looking ahead, there appears to be a growing demand for PPS and PPA materials because of technological evolutions and sustainability consciousness. For industries such as automotive, lightweighting comes into play simply to reduce fuel consumption and emissions. This would perhaps be the perfect opportunity for these polymers to step in. Their high strength, durability, and thermal resistance make ideal substitutes for heavier metal parts, particularly in electric vehicles (EVs), where materials that perform exceptionally well must handle heat dissipation and retain structural integrity. Thus, as transportation becomes gradually sustainable, the PPS and PPA polymer applications will increase in the long term.

Another emerging trend is their use with electronics. The advent of 5G coupled with increasingly small devices demands materials capable of withstanding high temperatures while maintaining dimensional stability. The electrical insulation properties of PPS and the capacity of PPA for complex geometries are solutions to this challenge. I foresee these polymers becoming increasingly widely used in circuit boards, connectors, and precision components where manufacturers must place high-performance requirements side-by-side against cost constraints.

Lastly, as industries focus more on environmental goals, I am of at least a semi-certain opinion that sustainable practices in PPS and PPA production will see continuous innovation. These materials will fit into circular economy paradigms through bio-based sourcing or recycling improvements. Whether it be reducing energy use in manufacturing or developing new recycling routes, the possibility for green advancements will usher in widespread industrial uptake of these materials.

Reference Sources

- PPS vs. PPA – MakeItFrom

- PPA Plastic | Material Series for Product Design – FirstMold

- Engineering Plastics (PPS/PPA Resin) – Nutrition Chemicals

- Applications of Polyphenylene Sulfide (PPS) – SpecialChem

- PPS Plastics – Polyphenylene Sulfide Properties & Applications – MCAM

- Top PC Plastic Pellets Suppliers in China

Frequently Asked Questions (FAQs)

What is the Difference in Resin Composition between PPS and PPA Plastic?

PPS is a thermoplastic polymer with a hydroxyl radical and sulfide linkage, capable of resisting chemical reaction, heat, and weather; thus, it finds application mainly in the automotive sector and where parts require resistance to harsh environments. On the other hand, PPA is an aromatic polyamide with high mechanical strength and dimensional stability, permitting it to be used in severe conditions. Due to their unique properties, both resins are utilized differently. For instance, PPA is typically blended with nylon to enhance its performance characteristics further. Knowing these differences assists in inserting the right material for particular applications.

How does the mechanical strength of PPA compare with that of PPS?

Generally, PPA outperforms PPS in mechanical strength, notably tensile strength and rigidity. PPA has high mechanical integrity and is resistant to moisture absorption, which is appropriate for roles demanding durability and chemical resistance. PPS is more potent when chemical resistance takes center stage, for example, in pump wear rings and air-cooling pumps. State the mechanical criteria for thermal properties and how the application environment will affect them. Where mechanical strength is predominant, PPA is often the polymer of choice.

What are the thermal properties of PPS and PPA plastics?

PPS plastic has high thermal resistance, keeping its stability even when exposed to permanent temperature elevations, with a negligible degree of degradation. Thus, it is mainly used for automotive parts subjected to ultrasound thermal loads. Conversely, PPA plastic retains high thermal properties but ranks higher in the melting point parameter; thus, it can maintain mechanical integrity when stressed thermally. Hence, these resins’ thermal and electrical properties lend themselves to being involved in various applications, crossing an intersection from personal disruptive consumer goods to industrial ones. Thermally, what specific application requires the property should weigh in the argument for either PPS or PPA.

What are the dimensional stabilities available in PPA as compared to PPS?

Dimensional stability becomes essential in an application where clear-cut precision is demanded. Due to the PPA polymer structure, PPA exhibits better dimensional stability in retaining its shape and integrity for some time as temperature and humidity change. On the other hand, while PPS offers acceptable dimension stability, it would be considered substandard in an environment that demands the same physical characteristics under stress. This makes PPA more appropriate for other dimensionally varied work, such as fuel line connectors. However, the final choice will depend on the application’s specifications for dimensional stability.

What are the advantages of PPA over PPS?

PPA materials have several advantages over PPS plastics, especially regarding mechanical performance and processing flexibility. Blending PPA with nylon further improves its properties, so it can be used in high-performance applications that require exceptional mechanical strength with low moisture absorption. It also has superior wear resistance and retention in adverse environmental conditions compared to PPS. Moreover, processing methods for fabricating articles from PPA, such as injection molding, permit the manufacture of intricate designs in large volumes without compromising quality. These advantages make PPA more favorable for demanding automotive and industrial applications.

What are the key considerations when choosing between PPS and PPA for automotive purposes?

Some key areas must be considered when selecting between PPS and PPA for automotive purposes. The mechanical strength requirements and the thermal and chemical properties significantly influence the application. PPS is functional when there is a high chemical resistance, such as when components are exposed to harsh fluids. On the other hand, PPA is acceptable when high mechanical strength and dimensional stability are considered. There is also an awareness of manufacturing procedures such as injection molding, so as not to conflict with the production processes. Often, the choice depends on the specific requirements of the application.

How does blending PPA and nylon enhance its properties?

PPA blended with nylon enhances the properties of the polymer by increasing its mechanical strength and thermal stability, as well as reducing moisture absorption. This permits the development of fiber-reinforced composites with maximum rigidity and durability. This material is targeted at high-performance applications wherein strength and light-weighting characteristics are required. Due to the blend-enhanced polymer properties, the blend is acceptable for various applications, including automotive and industrial. So the engineer-designer must understand the benefits of such blends when considering materials for an application.