The process of manufacturing thermoplastic vulcanizates (TPVs) encapsulates an interplay of advanced engineering, innovative technologies, and sophisticated material science. Given their widespread adoption in the automotive industry and consumer goods, TPVs are particularly valued for their ability to blend rubber-like elasticity with the processability of thermoplastics. In this article, we aim to explain the complete TPV manufacturing workflow, walking through each stage from material formulation to final product transformation. Thorough discussions of dynamic vulcanization, specific additives, and innovations focused on efficiency will showcase several mastered techniques.

What is the TPV Manufacturing Process?

The TPV (Thermoplastic Vulcanizate) manufacturing process involves blending thermoplastic and elastomeric materials to create a highly durable and flexible end product. The key steps include:

- Material Preparation: Base materials, typically polypropylene and rubber, are prepared and measured for accurate mixing.

- Dynamic Vulcanization: The rubber component undergoes vulcanization during the mixing process. This process heats the materials while shearing and crosslinking the rubber particles, ensuring elasticity and strength in the final product.

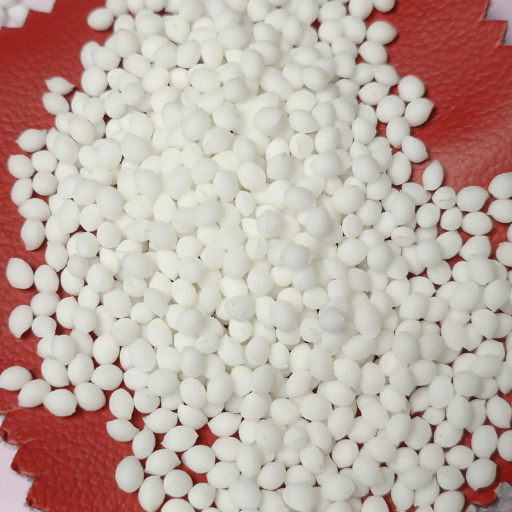

- Cooling and Granulation: The blended material is cooled and then granulated into pellets, making it easy to handle and use in subsequent manufacturing applications.

This process ensures that TPVs combine the resilience of rubber with the processability of thermoplastics, making them suitable for a wide range of industrial uses.

How is TPV produced using extrusion?

In the case of TPV produced via extrusion, my first step would be loading the extruder with a carefully designed mixture of thermoplastic and pulverized vulcanized rubber. The extruder performs preheating, melting, mixing, and even heating, in stages using counter rotatiing screws combined with high shear forces. It is at this point that the thermoplastic matrix begins to melt, and the rubber particles are uniformly dispersed, enhancing the mixture, which starts to adhere to the two-phase system. Metabolically activated rubber particles dispersed in the rubbery thermoplastic matrix are rigourously stirred and heated as the extruder barrel moves along the screw. Unlike other methods, this process facilitates modification with other components to expand the thermoplastic elastomer’s scope of application. Then the extruded TPV cools and is cut into pellets or any desired form, ready for use.

What role does dynamic vulcanization play in the production of TPV?

Dynamic vulcanization is one of the key steps in the manufacture of thermoplastic vulcanizates (TPVs), as it provides the distinct material properties that TPVs possess compared to other polymer blends. In dynamic vulcanization, the rubber component of the TPV is partially cross-linked and simultaneously dispersed in the thermoplastic matrix during melt spinning in a heat and ultra-high shear environment. This leads to the formation of rubber particles with dimensions in the micrometer range, which are dispersed within the continuous phase of the thermoplastic. This yields a morphology that endows TPVs with the distinguishing attributes of elasticity, resilience, thermal stability, and thermal elastoplastisity. Cured rubber particles offer greater resistance to deformation, while the thermoplastic matrix provides resistance to deformation and allows for easy processing through heating and recycling. A greater degree of these mechanical properties makes TPVs suitable for extensive use in applications that require strong performance, withstanding various environmental conditions.

What are the key steps in the production process of TPV?

The production of thermoplastic vulcanizates (TPVs) involves a carefully controlled process to achieve the desired properties of elasticity, durability, and thermal stability. The main steps in the production process include:

- Material Selection: The primary components of TPVs are a thermoplastic resin—such as polypropylene—and an elastomer like ethylene propylene diene monomer (EPDM) rubber. These materials are chosen for their compatibility, performance characteristics, and ability to form a stable combination.

- Blending: The thermoplastic and elastomer are combined under high shear forces in an extruder or an internal mixer. During this step, the two materials are mixed to form a macro-phase separation where the rubber forms dispersed particles within the thermoplastic matrix.

- Dynamic Vulcanization: This is the most critical step in the process. Crosslinking agents, typically sulfur or peroxide-based systems, are introduced during the blending process. Under controlled heat and shear conditions, the elastomer undergoes partial crosslinking while simultaneously being mixed with the molten thermoplastic. This results in the creation of fine, crosslinked rubber particles distributed within the matrix.

- Cooling and Pelletizing: After achieving the desired level of crosslinking and homogeneity, the molten TPV is cooled, solidified, and cut into pellets for easier handling and further processing.

- Quality Testing and Control: The final TPV material undergoes rigorous mechanical and thermal testing to ensure it meets industry standards. Key parameters such as tensile strength, elongation at break, hardness, and thermal stability are assessed to verify consistency across batches.

By refining these steps, manufacturers can ensure high-performance TPVs suitable for demanding applications such as automotive components, medical devices, and industrial seals.

What Are the Different Methods of TPV Production?

Thermoplastic vulcanizates (TPVs) are primarily produced through two key methods:

- Dynamic Vulcanization: This is the most common method of TPV production. It involves blending a thermoplastic resin with a rubber component under heat and shear, during which the rubber phase is selectively cured. The result is a material that exhibits both thermoplastic and elastomeric properties, making it ideal for durable and flexible applications.

- Static Vulcanization: While less common, this method cures the rubber component without applying shear. The process typically relies on chemical crosslinking agents to develop the desired elasticity within the TPV matrix.

Both methods are designed to combine the resilience of elastomers with the easy processability of thermoplastics, ensuring performance suitable for a wide range of industrial applications.

How does the screw extruder work in tpv manufacturing?

In TPV production, the screw extruder is essential to facilitate the dynamic vulcanization step. It works by feeding and melting the thermoplastic and elastomeric matrices while stirring each under appropriate temperature and pressure conditions. Within the casing of the extruder, the design of the screw guarantees adequate separation as well as good blending of the crosslinking agents which allows the control of the property of the material to a reasonable degree. A homogeneous TPV blend is achieved, which contains the requisite elasticity and strength needed for downstream shaping and finishing operations.

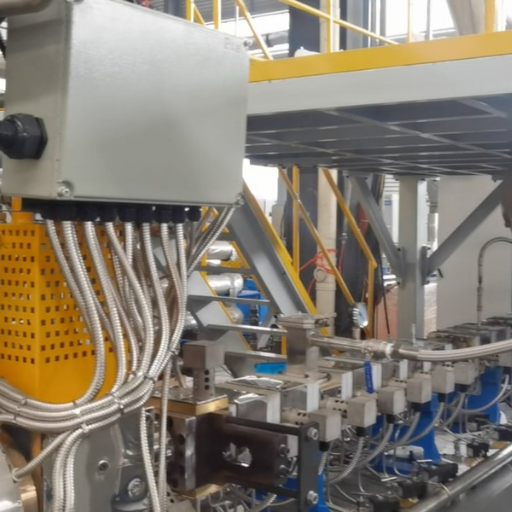

What is the significance of the twin screw extruder in producing tpv?

Due to mixing, process control and ability to accommodate complicated formulations, twin screw extruders are very important in thermoplastic vulcanizates (TPVs) production. Unlike single screw extruders, the twin screw system has a co-rotating or counter-rotating configuration which provides adequate mixing and dispersion of materials. This is especially important when processing TPVs, because a precise combination of thermoplastic polyolefins and cross-linked elastomers is needed to provide the final product with elasticity, high durability, and resistance to chemical attack.

Modern twin screw extruders have segmented barrel configurations and variable screw elements, allowing manufacturers to optimize processing conditions for specific TPV formulations. The vulcanization of TPV is a highly exothermic reaction that requires precise temperature control and effective shear management. Besides improving the physical and mechanical properties of the TPV, vulcanization optimally enhances the material’s attributes. Moreover, twin screw extruders allow for uninterrupted processing, which improves system scalability, lowers production expenses, and reduces variability from one production batch to another. The impact of these factors makes a twin screw extruder extremely important in achieving careful standards for TPV construction in the automotive, consumer goods, and healthcare industries, as this equipment provides such versatility.

What are the advantages of using injection molding for TPV parts?

Producing TPV parts via injection molding comes with a plethora of advantages. In my opinion, injection molding guarantees ease of execution, coupled with exceptionally high precision, making it a favorable option for complex geometric parts that require tight tolerances. Furthermore, this method allows for mass production and drastically minimizes material waste, helping to control costs. Lastly, the adaptability of injection molding encompasses the ability to incorporate smooth surface finishes and customization for numerous required demands, making it suitable for demanding standards in all industries.

What Materials Are Used in the TPV Manufacturing Process?

Thermoplastic vulcanizates (TPVs) are created through the coupling of thermoplastic and rubber constituents. The main parts are usually a polyolefin, such as polypropylene (PP), and a cross-linked elastomer, often ethylene propylene diene monomer (EPDM) rubber. The process also includes compatibilizers to ensure good blending of the materials, as well as stabilizers and processing aids to enhance the overall strength and effectiveness of the end product. These materials are selected to ensure elasticity, strength, and heat resistance, thus making TPVs appropriate for critical applications.

What types of polymer blends are used in TPV?

Thermoplastic vulcanizates (TPVs) are produced by carefully blending specific polymers to achieve distinct characteristics for different applications. Polypropylene (PP) is used as the thermoplastic matrix, while ethylene-propylene-diene monomer (EPDM) rubber serves as the dispersed elastomeric phase. The blending stage usually adds polyolefin elastomers (POEs) as compatibilizers to enhance surface adhesion between the thermoplastic and elastomeric phases. These compatibilizing agents improve the dispersion of elastomers, thereby increasing the material’s mechanical properties. Moreover, to strengthen, increase stiffness, or add specific thermal qualities, reinforcing agents and fillers such as talc or carbon black may be added, depending on the end use. Other highly effective materials, such as advanced stabilizers and antioxidants, are also added to TPV materials to resist mechanical wear, UV, oxidizing radiation, or heat, ensuring long-term performance and durability. This widens the scope of application for TPVs to automotive parts, industrial seals, and other industrial components.

How do additives and masterbatches contribute to TPV properties?

In customizing Thermoplastic Vulcanizates (TPVs) for particular uses, additives and masterbatch formulations are particularly important. Modifier additives such as plasticizers and fillers increase the TPV’s workability, toughness, and appearance. For instance, plasticizers enhance flexibility, allowing TPVs to operate in applications that demand greater elongation and reduced rigidity. Meanwhile, fillers such as carbon black or silica also improve wear resistance and dimensional stability.

Masterbatches guarantee appropriate distribution of functional parts within the polymer matrix, such as UV stabilizers, flame retardants, or colorants. This uniform distribution mitigates concerns with consistent quality, performance, degradation, or variation in information used in environments and end products. As a result, the range of applications for TPVs, including automotive, construction, and consumer goods, is endless. All these components work together to provide TPVs with the balance of strength, flexibility, and environmental resistance needed for a diverse range of industrial applications.

What are the common rubber materials utilized in TPV?

Ethylene propylene diene monomer rubber (EPDM) and natural rubber (NR) are the two most common rubber materials in thermoplastic vulcanizates (TPVs). The grade of EPDM rubber is highly favored due to its exceptional resistance to heat, oxidation, and weathering, making this material suitable for use in extremely harsh environments. Moreover, the fact that it is compatible with thermoplastic materials guarantees optimum blending during the dynamic vulcanization process. Less common natural rubber (NR) is, however, used for specific purposes that require extremely high elasticity and outstanding mechanical attributes. Other rubber elastomers elastically blended into the matrix of TPV compounds include nitrile rubber (NBR) because of its better oil resistance and butyl rubber (IIR) due to its air impermeability. The selection of rubber materials is mainly determined by the end product’s application to ensure a proper combination of mechanical and physical properties, such as strength, flexibility, and resistance to environmental factors.

What Are the Key Properties of TPV?

Thermoplastic vulcanizates (TPVs) possess a unique combination of properties that make them suitable for a diverse range of applications. The key properties include:

- Elasticity: TPV exhibits excellent flexibility and rubber-like elasticity, enabling it to recover its shape after deformation.

- Temperature Resistance: It maintains stability under a wide temperature range, offering reliable performance in extreme hot and cold conditions.

- Durability: TPV exhibits strong fatigue resistance, making it ideal for products that are subjected to repeated stress.

- Chemical Resistance: It is resistant to oils, greases, and certain chemicals, making it more applicable in industrial and automotive settings.

- Processability: Unlike traditional rubber, TPV is easily processed with standard thermoplastic methods such as injection molding and extrusion.

These attributes ensure that TPV delivers a versatile and efficient solution for demanding environments.

What are the mechanical properties and hardness of TPV materials?

Adjustable for different applications, Thermoplastic vulcanizates (TPVs) have remarkable mechanical properties along with varying degrees of hardness. Generally, the tensile strength of TPVs ranges between 5 MPa and 15 MPa, depending on the formulation and grade. Thus, the material TPVs can carry considerable weight without failure. Along with this, the stretch before breaking can go as high as 300% to over 500%, indicating repeatable elastic strain, high elasticity, and good durability. The flexibility of TPVs is enhanced by a tear strength that typically ranges from 20 kN/m to 90 kN/m, reaffirming their resistance to mechanical wear and tear.

The TPV hardness is commonly reviewed using the Shore A and Shore D measures. Most grades fall between 25A and 85A, while some specialized ones reach 40D, meaning a specialized variant can achieve a Shore D of 40. This broad TPV hardness enables meeting various design needs, from soft touch materials to rigid structural components. Moreover, TPVs exhibit exceptional compression set performance over a wide range of temperatures, providing reliable long-term dimensional stability at both hot and cold temperatures. These, alongside consistent TPVs, remain the primary hardness profile, making them the preferred material for industries needing endurance and adaptability.

How does elasticity affect the performance of TPV?

Elasticity impacts the performance of Thermoplastic Vulcanizates (TPVs) by affecting a material’s ability to absorb and recover from mechanical stress. The ability of TPVs to restore to their original shape after deformation is significant for applications such as automotive parts, gaskets, seals, and other components that require repetitive flexing. Such property extends its lifecycle whilst reducing abrasion and enhancing its durability, increasing dynamic loading. Besides, the noise and vibration damping of TPVs, which is essential in the automotive and industrial fields, is also aided by their elasticity. The demanding nature of modern engineering applications requires a wide range of features that can be addressed by TPVs, with their structural integrity and performance after prolonged use.

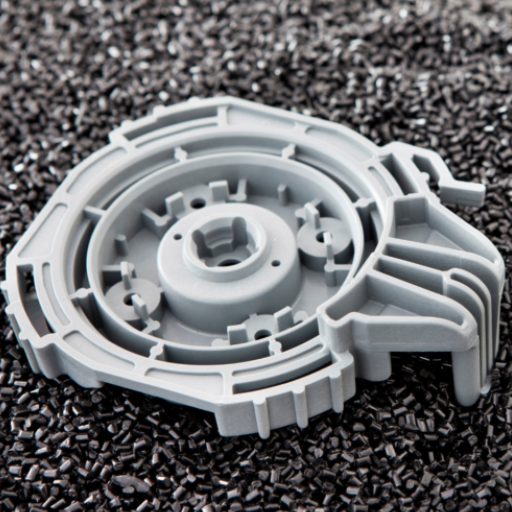

What makes TPV suitable for various applications, such as the automotive industry?

TPVs distinguish themselves as multi-purpose materials because of their blending capabilities with elastomers and thermoplastics. The ability of these materials to withstand heat as well as their thermal stability over time is exceptional, making them suitable for use in automotive engines and engine parts. Lastly, the fact that these materials are lightweight contributes to the reduction of weight in vehicle,s which is essential for fuel savings and reducing emissions about modern regulations.

Moreover, TPVs are more resistant to damaging conditions, such as oils, greases, and harsh environmental conditions, which extends their durability in extreme applications. Their recyclability further aligns with sustainability efforts by cutting down waste in manufacturing processes. Lastly, TPVs enable detailed designs and easy manufacturability through ordinary methods, such as injection molding, which reduces production costs for a wide range of sectors, including automotive, consumer, and medical industries.

How Does the TPV Molding Process Work?

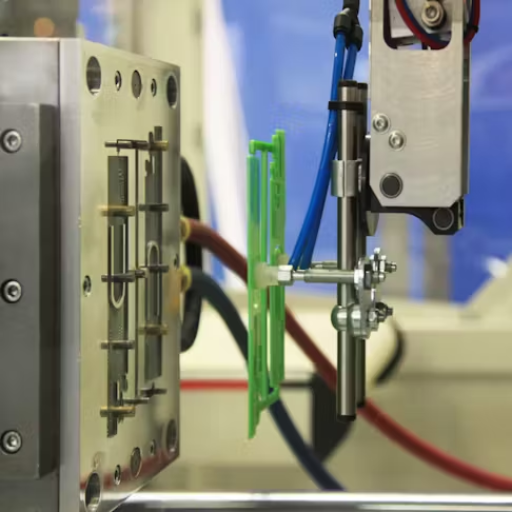

The TPV molding process primarily consists of injection molding due to its flexibility and effectiveness. To begin, TPV pellets must first be heated within the molding apparatus to a molten state. This molten material is then injected into a pre-designed mold cavity at a defined pressure. After filling the mold, the material undergoes a cooling phase to solidify into the mold’s shape. Upon cooling and solidifying, the final component is removed from the mold, thus completing the cycle.

What are the steps involved in the molding process for TPV?

The molding process for thermoplastic vulcanizates (TPVs) involves several critical and methodical steps to ensure optimal product integrity and performance. Below is a detailed breakdown of these steps:

- Material Preparation: TPV granules or pellets are dried to remove moisture content, which can negatively impact the molding process. Accurate dosing and blending of the material ensure consistent properties.

- Material Melting: The TPV is fed into the molding machine’s hopper, where it is progressively heated inside the barrel by rotating screws and external heaters. This softens the material into a fully molten and homogenous state.

- Injection into the Mold: Once the material is adequately melted, it is injected at a controlled, high pressure into the mold cavity. The pressure and speed of injection are precisely adjusted based on the mold design and the properties of the TPV.

- Cooling and Solidification: The injected material is left in the mold to cool and solidify. The cooling process is typically facilitated by a thermal control system within the mold, ensuring uniform temperature distribution to prevent warping.

- Ejection: After the TPV material has fully solidified into the shape of the mold cavity, the mold opens, and the finished product is ejected using ejector pins or other mechanisms. Careful ejection is critical to avoid damaging the part.

- Post-Processing: Depending on the application, the molded TPV part may undergo additional steps such as trimming, quality inspections, or secondary operations (e.g., bonding or assembly).

This well-defined process leverages the unique properties of TPVs, including their elastic resiliency and durability, to produce precise components used in various sectors, such as automotive seals, consumer goods, and industrial applications.

What is the difference between injection molded TPV and other methods?

The primary distinct feature of TPV injection molding compared to other methods is efficiency and precision. In my view, injection molding is best suited for shaping intricate geometries, especially when tight tolerances are required, due to its consistent material flow and detail replication. Other processes like extrusion or compression molding tend to work better with simple, continuously repeating profiles, but lack the detail and accuracy devotion of injection molding. Furthermore, injection molding offers advantages in terms of faster cycle times and better scalability. Once again, for high-volume production, it is the most suitable option. As for me, it’s mostly the application that dictates the choice, such as design intricacy, volume of production, and the performance requirements of the materials.

How do temperature and pressure affect the molding of TPV?

The molding of Thermoplastic Vulcanizates (TPV) is highly dependent on temperature and pressure; these parameters greatly affect flow, curing, and the final piece’s performance. A temperature-dependent viscosity characterizes pre-formed TPVs, meaning that flow and mold fillability improve more easily at high temperatures. Compounding matters further, excess temperatures can lead to over-curing or thermal decomposition, which will damage physical properties like elasticity and tensile strength. Inversely, inadequate temperatures could cause these properties to be enhanced, leading to irreversible harm.

On the contrary, Pressure assists in the uniform material distribution within the mold cavity and minimizes defects such as voids or incomplete fill. A lack of pressure may result in rough part formation, which compromises the component’s structural integrity. However, excessive pressure can cause mold stress or flashing at the parting line. Specific pump settings and temperatures depend on the TPV grade, the melt flow index of the TPV, and the part’s geometry being processed. Precision calibration and advanced modern machinery provide accuracy and repeatability, which boost output to meet the needs of high-precision industrial applications.

What Are the Applications of TPV Materials?

The excellent flexibility, durability, heat resistance, and recyclability of thermoplastic vulcanizates make them useful in many industries. Examples include automotive parts such as weather seals, hoses, and interior trims, which benefit from the high-performance characteristics TPVs offer. These materials are also used in consumer products, medical devices, and industrial equipment, especially those that require soft-touch, chemical-resistant, highly elastic, and durable components. The combination of long-lasting performance and environmental sustainability helps make TPVs an excellent choice for designed components.

Where is TPV commonly used in the wire and cable manufacturing industry?

In manufacturing wires and cables, thermoplastic vulcanizates (TPVs) are crucial due to their flexibility, durability, and thermal resistance. Together with other forms of TPV composites, these materials are commonly utilized in the production of jackets that not only provide insulation but also shield the jacketed wires and cables from environmental factors such as ultraviolet rays, moisture, and mechanical abrasion. Because TPVs can withstand extreme temperatures, they are well-suited for both indoor and outdoor applications, including electric vehicle power cables, data transmission cables, and charging cables. In addition, TPVs are often used in strain relief features and grommets where their elastic and abrasion-resistant properties support the longevity and dependability of the wire systems. The ability to recycle TPVs increases their value in contemporary manufacturing, which incorporates the ever-growing need for sustainability in the industry.

What industries benefit from the use of TPV and its properties?

The unique balance of flexibility, durability, and thermal stability makes thermoplastic vulcanizates (TPVs) valuable across numerous industries. The automotive industry is among the largest beneficiaries, utilizing them for weather seals, interior trim, and under-the-hood components where high heat resistance and long-term dependability are essential. The construction industry also uses TPVs in window seals, roofing membranes, and vibration dampeners due to their ability to withstand harsh environmental conditions and low manufacturing costs. Moreover, the medical industry uses TPVs in syringes, tubing, and fluid delivery systems where biocompatibility and simple sterilization are critical. The electrical and electronics sector utilizes TPVs in cable insulation and connectors, as their insulating properties and strength improve safety and performance. The growing emphasis on sustainability makes the ease of recycling TPVs even more appealing for companies in various industries.

How is tpv utilized in producing seals and gaskets?

Thermoplastic vulcanizates (TPVs) have gained immense popularity in the making of seals and gaskets due to their strength, elasticity, durability, and chemical resistance. TPVs are often used in extreme environments, enduring conditions such as severe temperatures, chemicals, and even prolonged exposure to UV radiation. The flexibility of TPVs and their low compression set make them easy to mold, ensuring precision during manufacturing and reliable sealing for automotive weatherstripping, industrial machinery, and fluid containment systems. In addition to exhibiting superior resilience, TPVs are also capable of maintaining their structural integrity over long periods. Their adaptability to various operational requirements makes them a versatile choice across multiple industries, and further yields increased appeal due to the sustainability that manufacturers are migrating towards.

Reference Sources

1. Thermoplastic Elastomers: Emerging Trends and Applications in Rubber Manufacturing

- Key Findings: This review discusses the manufacturing processes of thermoplastic elastomers, including TPVs, emphasizing their adaptability and processability. It highlights the use of dynamic vulcanization, where cross-linked elastomers are dispersed in a thermoplastic matrix, which gives TPVs their unique properties.

- Methodology: A comprehensive review of literature and industry reports was conducted to analyze the properties, applications, and advancements in TPE manufacturing, including the role of dynamic vulcanization in producing TPVs.

- Key Findings: This study examines the cross-linking process in elastomer blends, a critical step in TPV manufacturing. It highlights the role of nano-fillers in enhancing the mechanical and thermal properties of the vulcanizates.

- Methodology: The research involved preparing elastomer blends with varying nano-zinc concentrations and analyzing their cross-linking characteristics, morphology, and mechanical properties using advanced testing methods.

3. Development and Characterization of PLA Biofilament Combined with Perifiton Biomass for 3D Printing

- Key Findings: Although not directly related to TPVs, this study offers insights into the manufacturing of composite materials using advanced techniques such as extrusion and 3D printing. It emphasizes the importance of material blending and processing conditions in achieving desired properties.

- Methodology: The study involved blending PLA with biomass and then extruding it to produce biofilaments. The mechanical and thermal properties of the filaments were evaluated to assess their suitability for 3D printing.

4.Top TPV Plastic Pellets Suppliers in China

Frequently Asked Questions

Q: What is the role of elastomer in the TPV manufacturing process?

A: Elastomers, particularly thermoplastic elastomers (TPE), play a crucial role in the production of thermoplastic vulcanizates (TPV). They provide flexibility and resilience, contributing to the overall properties of the final product.

Q: How does the preparation process for TPV differ from traditional plastic manufacturing?

A: The preparation process for TPV involves a dynamic vulcanization process where rubber particles are cross-linked within the thermoplastic phase. This differs from traditional plastic manufacturing, which typically does not include the same level of chemical interaction or blending of rubber and plastic.

Q: What is a twin-screw extruder, and how is it used in TPV production?

A: A twin-screw extruder is a key piece of processing technology used in TPV production. It allows for efficient mixing and melting of raw materials, with the ability to control shear rates and temperatures, which are essential for achieving the desired characteristics of TPV.

Q: What types of fillers are commonly used in thermoplastic vulcanizate formulations?

A: Common fillers in thermoplastic vulcanizate formulations include calcium carbonate, silica, and various other additives designed to enhance properties such as tensile strength, processing efficiency, and thermal stability.

Q: Why is the dynamic vulcanization process necessary in producing TPV?

A: The dynamic vulcanization process is crucial because it allows for the simultaneous cross-linking of rubber and the formation of a thermoplastic matrix, resulting in a material that exhibits both the elasticity of rubber and the processability of plastic.

Q: What are the typical temperature ranges used in the TPV manufacturing process?

A: The temperature range during the TPV manufacturing process can vary, but it typically falls between 180°C and 220 220°C. Maintaining the correct temperature is essential for achieving adequate mixing and the desired properties of the final product.

Q: How does the blending process impact the properties of the final TPV product?

A: The blending process is vital as it ensures uniform dispersion of the rubber phase within the thermoplastic phase, which directly influences the mechanical properties, such as tensile strength and flexibility, of the final TPV product.

Q: What are some typical applications of thermoplastic vulcanizates?

A: Thermoplastic vulcanizates are widely used in automotive parts, medical devices, consumer goods, and various industrial applications due to their excellent durability, flexibility, and resistance to weathering and chemicals.

Q: How does the choice of raw materials affect the characteristics of TPV?

A: The choice of raw materials, including the type of elastomer (e.g., EPDM or polypropylene), directly affects the characteristics of TPV, such as its elasticity, thermal stability, and resistance to chemicals and UV exposure.

Q: What is the significance of the compression and shear factors during the TPV processing technology?

A: Compression and shear factors are significant in TPV processing technology as they influence the mixing efficiency and the resultant material properties. Proper control of these factors ensures optimal dispersion of components and desired performance characteristics in the final product.