In the arena of injection molding, Polyphenylene Oxide (PPO) is arguably one of the most preferred thermoplastic materials, considering its high thermal stability and mechanical strength. The melting point is one of the most essential characteristics that determine its performance and processing behavior. Understanding the melting point of PPO material is crucial for manufacturers, engineers, and industry professionals who aim to leverage its potential in applications ranging from automotive parts to electronic devices. This article examines the technical aspects of the melting point of PPO, including its influence on the material’s performance and its suitability for molding processes and end-use applications. By the end of this discussion, readers will understand why the melting point of PPO is more than just a thermophysical property, but rather, an unparalleled requirement for the durability, efficiency, and precision expected in molded components.

What is PPO and its Melting Point?

A high-performance thermoplastic, Polyphenylene Oxide (PPO) boasts superior mechanical and thermal stability. In contrast to common thermoplastics, however, PPO does not have a distinct melting point, but rather a glass transition temperature of approximately 210°C (410°F). This attribute has industrial relevance, as it allows PPO to maintain its rigidity and performance even in high temperatures, making it an ideal material for harsh environments.

Definition of Polyphenylene Oxide (PPO)

Polyphenylene oxide, often referred to as PPO, is a thermoplastic polymer with low moisture absorption, high resiliency toward dimensional alterations, and resistance to a wide variety of chemicals. Its dielectric characteristics are essential for its use in electrical and electronic devices that demand reliable operation under varied and changing external conditions and environmental factors. Furthermore, hydroxylated hydrocarbons such as paradichlorobenzene, phenol, methylene chloride, and hydrochloric acid, PPO also has excellent resistance to other acids, making it useful in various industries. It is used in parts like pump housings for the automotive industry, in consumer goods like kitchen appliances, and many other applications.

Two Noryl compounds, which are PPO, are polymer blends with another type of polymer, such as polystyrene, to improve their impact strength while maintaining other properties. The blends also optimize it from an economic perspective and make other materials meet particular engineering needs. The contemporary developments in the formulated polyphenylene claim to focus on improvements of flame retarding as well as renewal of used materials to aid comply with the industrial and environmental direction in standards. This flexibility illustrates how polymers are used in a wide range of fields and with many differing demands.

Melting Point of PPO: Key Temperature

Because of its amorphous structure, Polyphenylene Oxide (PPO) does not have a singular melting temperature but rather a glass transition temperature (Tg) around 210°C (410°F). At this temperature, PPO transitions from a rigid, glassy state to a more flexible, rubbery state. For mechanical thermal stability, PPO’s Tg defines an upper operating temperature, but is liable to lose its mechanical properties. PPO blends, which undergo thermal processing, often contain modifiers or reinforcements designed to improve or change the material’s thermal behavior, raising the effective functional temperature for advanced engineering applications.

How PPO Differs from Other Polymers

One of the distinguishing factors of PPOs is their unmatched synergistic thermal, mechanical, and chemical properties compared to other polymers. Ranging from industrial to engineering polymers, most undergo severe dimensional changes at high temperatures. PPO is an exception, as it maintains remarkable resistance even to mechanical forces, alongside its high glass transition temperature (Tg), making it advantageous for thermally stressed structures. Hydrolysis and oxidation resistance are two traits of PPO that differentiate it from other polyesters and polymers, which, by nature, are prone to damage by moisture and oxygen-laden surroundings.

Another notable difference is its density, which is significantly lower than that of other engineering-grade polymers, such as polycarbonate (PC) or polyamide (PA). Its low density, along with its inherent stiffness and tensile strength, allows for the manufacture of lighter components without compromising structural integrity. Additionally, PPO has a low water absorption rate, which ensures that its dimensions remain almost unchanged when humidity levels change, unlike nylon, which tends to swell under such conditions.

PPO is often blended with other materials, such as polystyrene (PS), to improve processability without losing the desired properties. Such blends tend to have a favorable cost-to-performance ratio that is often not achievable with other high-performance polymers. These properties, combined, make PPO a versatile and high-value material for automotive manufacturing, electrical components, and industrial equipment.

What are the Properties of PPO?

PPO is characterized by several key properties that make it a valuable engineering thermoplastic:

- High Heat Resistance: PPO remains stable at elevated temperatures, making it suitable for applications that require thermal durability.

- Mechanical Strength: It exhibits excellent stiffness and impact resistance, even in demanding conditions.

- Low Moisture Absorption: PPO resists water uptake, ensuring dimensional stability and consistent performance in humid environments.

- Electrical Insulation: With superior dielectric properties, it is ideal for electrical and electronic components.

- Chemical Resistance: PPO shows strong resistance to acids, bases, and various organic chemicals.

These properties collectively contribute to PPO’s versatility across a range of industrial applications.

Thermal Properties of PPO Material

The thermal stability of Polyphenylene Oxide (PPO) is impressive and is therefore helpful in high-heat applications. PPO exhibits structural integrity over a broad range of temperatures due to its glass transition temperature (Tg), which is generally around 210°C, and a melting point greater than 260°C. Dimensional stability is provided through its low coefficient of thermal expansion (CTE), even under thermal cycling conditions. Moreover, PPO maintains strong mechanical properties and resists thermal degradation due to prolonged exposure to high temperatures, showcasing excellent thermal resistance. As a result of these features, PPO is useful in extreme thermal environments for critical components such as automotive parts, electrical housings, and industrial equipment.

Mechanical Properties and Strength of PPO

PPO has standout engineering properties, including mechanical strength, impact resistance, and stiffness, making it suitable for use in various engineering fields. Its tensile strength is usually between 60 and 80 MPa, depending on the specific grade of the material and other factors, such as the presence of glass fiber reinforcements. Moreover, its flexural modulus value is also high, typically ranging from 2400 to 3800 MPa, which allows for smooth deformation under stress. PPO also exhibits superior dimensional stability due to its low moisture absorption and creep resistance, which preserve its shape and strength under long-term loads. These properties make it worthwhile for structural components in industrial applications that need high durability and reliable mechanical performance.

Electrical Properties: Dielectric Loss and Conductivity

The exceptional electrical properties of Polyphenylene Oxide (PPO) make it suitable for use in electrical insulation and electronic components. Its dielectric constant, which ranges from 2.5 to 3.5 depending on temperature and frequency, is also low, which reduces energy loss in PPO’s high-frequency environments. In addition, PPO’s dielectric strength is renowned, surpassing 15 kV/mm, and its exceptional strength ensures reliable insulation in high-voltage conditions. The material also has a low dissipation factor of less than 0.01 at standard testing frequencies, which results in minimal energy loss and heat buildup in electrical systems. These factors, along with low conductivity and high resistivity, help PPO prevent leakage currents, making it ideal for demanding electronic and industrial applications that require long-term performance and operational safety.

What are the Advantages and Disadvantages of PPO?

Advantages of PPO

- High Thermal Stability: PPO exhibits excellent resistance to high temperatures, making it suitable for applications that require consistent performance in high-temperature environments.

- Electrical Insulation: Its low electrical conductivity and high resistivity ensure superior insulation, reducing the risk of leakage currents.

- Chemical Resistance: PPO resists water absorption and is impervious to many chemicals, ensuring durability in harsh environments.

- Dimensional Stability: It maintains its shape and properties over a wide temperature range, even under mechanical stress.

- Low Dissipation Factor: Minimizes energy loss, improving the efficiency of electrical systems.

Disadvantages of PPO

- Processing Difficulty: PPO can be challenging to mold and process due to its high melting temperature and viscosity.

- Brittleness: While strong, it tends to be brittle under high stress, limiting its use in dynamic load-bearing applications.

- Cost: PPO is more expensive than some alternative materials, which impacts its cost-effectiveness in specific industries.

- Limited UV Resistance: PPO is susceptible to degradation when exposed to prolonged UV light, unless additives are used.

These factors make PPO a material with significant advantages for specific high-performance applications, though its limitations must be considered during material selection.

Comparison with Other Engineering Plastics

Polyphenylene oxide (PPO) has distinguishing characteristics, particularly when compared to other engineering plastics, which make it beneficial for specific applications. For example, it has much better dimensional stability and lower water absorption than polyamide (PA), making it adequate for high-humidity and moisture-rich environments. Furthermore, it has greater hydrolysis resistance than some other materials, such as polyester (PET), which adds to its usefulness in harsh aqueous conditions.

In the case of polycarbonate (PC), PPO offers distinct advantages in value compared to performance for medium-duty applications, even though PC outperforms PPO in terms of optical clarity and impact resistance. Moreover, while thermoplastics such as acrylonitrile butadiene styrene (ABS) are known for their advanced toughness and ease of processing, PPO blends like PPO-PS (polystyrene) have superior thermal performance, mechanical retention at elevated temperatures, and overall strength.

This analysis shows that the engineering prowess of Polyphenylene oxide as an engineering plastic stems from the defined applications requiring strong thermal performance, chemical resistance, and outstanding dimensional stability – features that PPO provides, but other plastics fail at. Selecting the right materials for an application should always be tailored to the specific needs of that application to enhance performance and reduce lifecycle costs.

What are the Applications of PPO?

Polyphenylene Oxide (PPO) is widely used in applications that require high thermal stability, mechanical strength, and resistance to environmental factors. Common uses include:

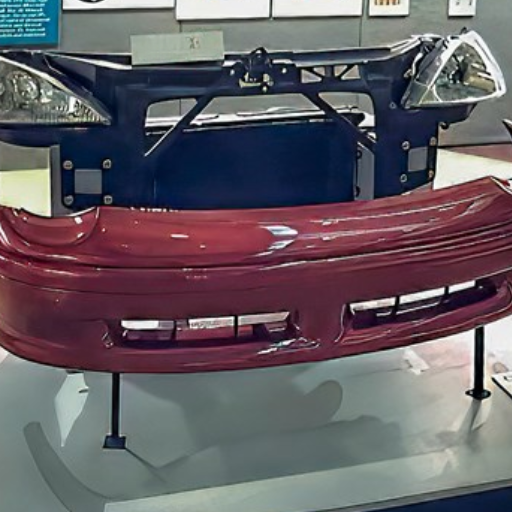

- Automotive Components: PPO is used in parts such as instrument panels, structural components, and fluid handling systems due to its heat resistance and dimensional stability.

- Electrical and Electronics: It is employed in connectors, insulators, and circuit boards, benefiting from its excellent dielectric properties and durability.

- Industrial Equipment: PPO finds use in pump housings, valves, and other equipment exposed to chemicals or high temperatures.

- Consumer Goods: It is also used in kitchenware and household appliances where heat and impact resistance are critical.

These applications leverage PPO’s unique material properties to ensure reliable performance in demanding environments.

Common Industrial Applications of PPO

Advances in materials science and engineering have led to the increased application of polyphenylene oxide (PPO) in various industries. For example, its integration into electric vehicle (EV) components is on the rise in the automotive industry due to low moisture absorption and high thermal stability. These attributes further augment the functionality of battery casings, connectors, and charging systems. Moreover, in the electronics industry, the emergence of 5G technology is one of the new trends that requires great insulating material and mechanical heat resistance, an area in which PPO outshines.

In addition to these industries, PPO is also gaining traction in the healthcare market for the production of surgical instruments and diagnostic devices, given its biocompatibility, resistance to chemicals, and compatibility with sterilization processes. These factors positively guarantee performance and sterility over many cycles. Waterway industrial systems also take advantage of PPO’s hydrolysis resistance, making it suitable for membranes and other parts used in desalination and water purification. The diversity of modern industrial challenges is being continuously responded to through innovation in materials technology, highlighting PPO as one of the most in-demand engineering materials.

PPO in Electrical and Electronic Components

In the electrical and electronics industry, polyphenylene oxide (PPO) is widely used because of its excellent thermal stability, dielectric properties, and flame retardancy. Its PPO Retardant grade ability to perform at high temperatures makes it helpful in insulating parts of transformers, circuit boards, and other high-frequency connectors. Moreover, PPO has low moisture absorption, which reduces the chances of electrical failure due to humidity or other environmental factors.

Many developments in PPO formulations have improved their compatibility with other materials, including glass and carbon fibers, which have enhanced high-performance and ultra-lightweight tailoring in terms of mechanical strength and dimensional stability. These characteristics are particularly beneficial in manufacturing enclosures and housings for electronic appliances, as both safety and durability are equally important. Its compliance with strict regulatory requirements, such as UL 94 rating certifications for flammability, adds to PPO’s dependability for use in industrial and consumer electronics. In addition, the continuous modification of PPO blends enhances design freedom for new technologies, such as IoT-enabled devices with miniature components.

How is PPO Prepared and Characterized?

Copper catalyst systems, along with 2,6-dimethylphenol, can generate polyphenylene oxide (PPO) through oxidative polymerization using oxygen. This results in a thermoplastic polymer exhibiting unique mechanical and thermal attributes. To characterize the polymer, its chemical structure can be verified by Fourier Transform Infrared Spectroscopy (FTIR), and its thermal behavior can be assessed using Differential Scanning Calorimetry (DSC). Further characterization methods, including Gel Permeation Chromatography (GPC), are employed for molecular weight quantification. The yield strength and flexibility are then obtained through mechanical testing to ensure the polymer is suitable for industrial purposes.

Synthesis Methods for Polyphenylene Oxide

PPO is mainly produced from the oxidative polymerization of 2,6-dimethylphenol using copper-based catalysts. This process, referred to as the oxidative coupling reaction, involves oxygen as the oxidant and facilitates the polymerization of phenolic monomers. A crucial part of this reaction consists of the catalyst, which is typically a copper (I)-amine complex. These dictate the molecular weight and structure of the polymer to be formed.

Recent developments in synthesis methods have looked into other catalyst systems, such as organometallic catalysts, for their potential to make the reactions more efficient, eco-friendly, or both. In addition, scholars have studied how optimizing the temperature, the solvent used, and the reaction duration affects the yield to meet specific material requirements. These factors are essential when designing processes to make PPO for use in industry, where specific thermal, mechanical, and electrical insulating properties are required.

Characterization Techniques for PPO

For polyphenylene oxide (PPO), it is necessary to employ a diverse set of modern analytical tools to properly assess its structure and properties, as well as its suitability for specific tasks. For a polymer of this type, its molecular structure and the functional groups associated with it are verified using various Spectroscopic techniques such as NMR and Fourier Transform Infrared (FTIR) spectroscopy. The characterization of polymers using NMR has the advantage of detecting the aromatic backbone without adding complexity, as seen in the case of PPO. In contrast, FTIR can determine the presence of ether linkages, which are essential to the polymer’s chemical makeup.

Using thermal analysis methods such as Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA) helps one to understand the polymer’s thermal stability and its glass transition temperature (Tg). These factors are crucial in evaluating the material’s performance at higher temperatures and its effectiveness in high-temperature applications. Aside from these, the polymer’s mechanical strength and viscoelastic characteristics are assessed through tensile testing and dynamic mechanical analysis (DMA) at different temperatures and environmental conditions.

To study the surface morphology of the material with Scanning Electron Microscopy (SEM), advanced imaging methods are applied. This understanding is fundamental when it comes to material and coating interactions. For electrical purposes, the insulation properties of PPO, as well as its dielectric constant, can be examined using other techniques, such as dielectric spectroscopy. Comprehensive assessment and optimization of PPO for industrial and commercial applications is possible by using these techniques, ensuring performance that meets specific requirements.

Chemical Modification of PPO for Enhanced Properties

Incorporating new uses for polyphenylene oxide (PPO) and improving its features requires chemical modification of PPO. The polymer’s thermal, mechanical, and chemical properties can be modified through techniques such as grafting, copolymerization, and chain extension. For instance, the chemical grafting of aliphatic and aromatic groups increases the solubility and processability of PPO, making it suitable for specific fabrication processes. Furthermore, PPO can be blended with other polymers or functional groups to increase thermal strength and enhance its overall compatibility with composite materials. There is development in the field of reactive extrusion and controlled polymerization, which precisely tailors the molecular structure of PPO to create materials with high mechanical strength, passive insulation, and increased solubility or chemical resistance. These modifications help meet the requirements of the automotive, electronics, and aerospace industries, where advanced materials are needed for greater efficiency and durability during operational use.

What is the Role of PPO in Injection Molding?

Polyphenylene Oxide (PPO) is crucial in injection molding processes due to its remarkable thermal stability, melt strength, and weight-to-strength ratio. These properties ensure that molded components PPO undergo injection molding are precisely shaped and function as intended during operation at high stress and temperatures. PPO is also a suitable and reliable material for high-performance parts in automotive and industrial components due to its bound resistance to moisture and chemicals. These features offer versatility and reliability, allowing for the quick and efficient manufacture of complex and precise components while meeting the expectations of brand consistency in quality and precision.

PPO Material in Injection Molding Processes

Due to the complex blend of mechanical, thermal, and chemical features, Polyphenylene Oxide (PPO) is unrivaled in injection molding. Precise molding and shaping through injection molding at high temperatures are possible due to its high glass transition and dimensional stability, which provide a clear, enabling space and tight tolerances. In the case of voids in circular cross-sections that are highly demanded, such as a symmetric cam-rotary shaper, pre-produced pins are considered to save costs. Lastly, low warpage and no shrink mold cavities enable manufacturers to produce a consistent and accurate product, setting the standard for precision.

In addition, the rigid, low-density, and exceptional dielectric properties of PPO make it a preferred material for lightweight yet durable electronic components. Its superior flame retardant properties make it even more applicable in safety crushing areas. The possibility of using it with various fillers and reinforcements increases the range of applications tailored to specific performance requirements. Such versatility highlights the importance of PPO elastomers in modern injection molding technologies, serving the growing demand for sophisticated, yet lower-cost, high-quality instruments.

Advantages of Using PPO in Molding Applications

In the scope of molding procedures, PPO has several key benefits. High-dimensional stability provides precision for complex geometries. Exceptional thermal resistance ensures reliability under elevated temperature conditions. Outstanding chemical resistance to aggressive substances further expands application fields. Low moisture absorption is also beneficial for prolonging useful life and minimizing warping. In conjunction with ease of processing, these attributes make PPO versatile and dependable for demanding engineering applications.

Considerations for Processing PPO

Several principles are essential when deriving performance from Polyphenylene Oxide (PPO) without jeopardizing its structure. Particularly, the molding and extrusion stages of PPO processing demand meticulous temperature management, ideally between 280°C and 320°C. Mechanical properties and surface finish may be compromised due to overheating PPO, leading to thermal degradation.

The material’s elevated melt viscosity also requires high-pressure-capable injection molding or extrusion equipment. It is vital to dry PPO completely before processing, as moisture in the material can result in deficient adhesion or voids, which deteriorate the quality of the final product.

PPO is often blended with polymers like polystyrene and nylon to ease flow behavior and address processing difficulties. These blends allow for easy processing while retaining the key properties of untreated PPO, such as chemical resistance and dimensional stability. Customizing processing aids, tooling designs, and machine settings based on the specific grade of PPO is vital for achieving uniform results across various applications.

Reference Sources

-

- Key Findings: This review highlights that PPO has a high melting point of approximately 480°C, making it suitable for high-temperature applications. However, its high melt viscosity poses challenges for processing.

- Methodology: The study reviews various modification strategies for PPO, including blending with thermosetting resins and incorporating fillers to enhance its properties for high-frequency communication applications.

-

Effect of the Flame Retardants and Glass Fiber on the Polyamide 66/Polyphenylene Oxide Composites

- Key Findings: The study examined the thermal properties of PA66/PPO composites, noting that the melting peaks of the composites were slightly lower than pure PPO due to the addition of flame retardants and glass fibers.

- Methodology: The research involved preparing composites through extrusion and injection molding, followed by thermal analysis using DSC and TGA.

-

Halogen Free Flame-Retardant Glass Fiber Reinforced PA 66 / PPO Alloys

- Key Findings: This study mentions that PPO and PA66 have similar melting points, and blending them can reduce PPO’s high melt viscosity. The study focuses on improving the flame retardancy and mechanical properties of the composites.

- Methodology: The composites were prepared using extrusion and injection molding, and their thermal and mechanical properties were evaluated.

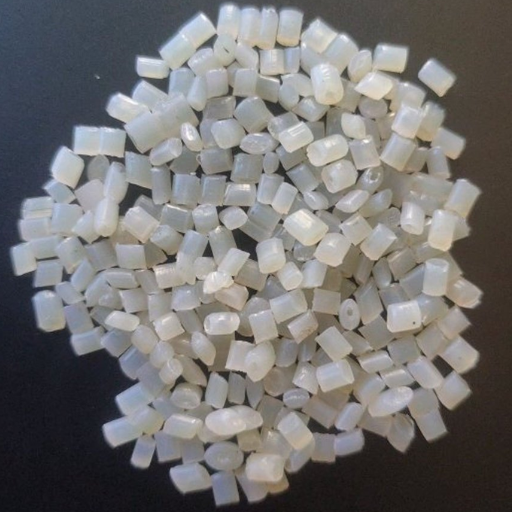

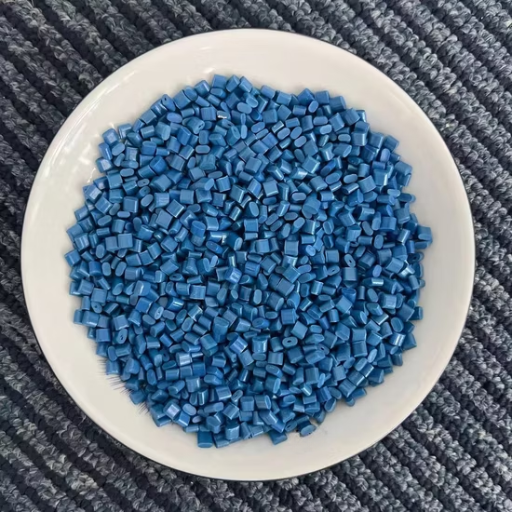

- Top PPO Plastic Pellets Suppliers in China

Frequently Asked Questions

Q: What is the melting point of PPO material?

A: The melting point of polyphenylene oxide (PPO) material is typically around 230°C, which indicates its high thermal stability and heat resistance.

Q: How does polymerization affect the properties of PPO?

A: Polymerization plays a significant role in determining the molecular structure of PPO, which in turn affects its physical properties such as heat resistance, water absorption, and overall dimensional stability.

Q: What are the applications of PPO in injection molding?

A: PPO is widely used in injection molding for applications requiring good dimensional stability, high heat resistance, and excellent dielectric properties, such as in automotive and electrical components.

Q: How does the preparation and characterization of PPO influence its performance?

A: The preparation and characterization of PPO are critical as they influence its molecular weight, polymer chains, and therefore its thermal stability, mechanical strength, and chemical resistance.

Q: What is the significance of water absorption in PPO materials?

A: PPO materials exhibit low water absorption, which contributes to their excellent dimensional stability and reduces the risk of swelling or warping in humid environments.

Q: Can PPO be modified for enhanced properties?

A: Yes, modified PPO (also known as modified polyphenylene ether) can be created to improve its properties, such as impact resistance and processing temperature, often by blending it with polystyrene or incorporating glass fibers.

Q: What is the glass transition temperature of PPO?

A: The glass transition temperature of PPO is typically around 210°C, which is a crucial factor in determining its performance in high-temperature applications.

Q: What are the chemical resistance properties of PPO?

A: PPO exhibits good chemical resistance, particularly to phenolic compounds and various solvents, making it suitable for applications where exposure to harsh chemicals is a concern.

Q: How does the molecular structure of PPO contribute to its performance?

A: The linear polymer structure of PPO allows for large free volume, which enhances its processing and high melt viscosity, contributing to its suitability in high-performance applications.

Q: What are the advantages of using PPO in high-performance applications?

A: The advantages of using PPO in high-performance applications include its excellent thermal stability, high heat resistance, low moisture absorption, and good dimensional stability, making it ideal for demanding environments.