Thermoplastic vulcanizates (TPVs) have wide applications in the construction and automotive industries due to their incredible flexibility, durability, and toughness. One of the most essential features of TPVs is their temperature resistance, which affects their performance in harsher environments. Suppose you’re an engineer, a product designer, or someone fascinated with advanced materials. In that case, this detailed breakdown will help you understand why TPVs perform well at extremely high and exceedingly low temperatures.

What is TPV and Its Temperature Resistance?

Thermoplastic vulcanizates (TPVs) are a subclass of modern elastomers produced via the dynamic vulcanization of rubber within a thermoplastic matrix. This means that, unlike thermoplastics, TPVs have the elasticity and flexibility of rubber, along with the ease of processing associated with plastics. Furthermore, they can be relied upon to survive severe temperature changes, as even in extreme conditions, their characteristics do not deteriorate. More specifically, the materials can withstand continuous high temperature degradation of up to 275°F (135°C) and still retain flexibility when subjected to -60°F (-51°C). These performance characteristics in extreme temperatures make TPVs a definite choice for high-performance automotive seals, industrial gaskets, and electrical insulation.

How does TPV compare to other thermoplastics?

I believe that the combination of rubber elasticity and thermoplastic processability makes TPV unique compared to other thermoplastics and the most versatile. When compared to other standard thermoplastics, the material can withstand harsh exposure to heat, chemicals, and cold temperatures without being damaged. This, coupled with the fact that the material is easy to recycle, makes it highly sought after where sustainability is a focus. Other thermoplastics may be cheaper or easier to mold, but can’t match TPV’s durability and adaptability in demanding environments.

What is the typical temperature range for TPV materials?

Thermoplastic Vulcanizates (TPVs) stand out among other materials due to their versatility, particularly because of their broad operational temperature range. For example, TPVs don’t break down under stress from -40°F to 275°F (-40°C to 135°C). These figures highlight the suitability of such materials for demanding environments, ranging from automotive parts exposed to extreme cold or high temperatures under the hood. Furthermore, some formulations of TPV incorporate enhanced thermal stability, which allows short-term exposure to elevated temperatures without significant degradation.

What are the mechanical properties of TPV at high temperatures?

When the temperature rises, the mechanical characteristics of thermoplastic vulcanizates TPVs maintain an essential balance of flexibility and strength, which enables the application under severe thermal conditions. The elasticity of TPVs is generally preserved up to their maximum continuous use temperature, which is typically between 110°C and 135 °C. The industrial seal or gasket TPVs used in the automotive and aerospace industries still maintain tensile strength, tear resistance, and elasticity, albeit at a slightly lower level than when tested at lower temperatures. Moreover, the compression set resistance at elevated temperatures is enhanced by advancing the formulation of the TPVs, which aids in long-term sealing under thermal stress. With a combination of properties such as sustained elasticity, specific tensile properties, and resistance to degradation, these materials are reliable at sustained high temperatures, helping to maintain the integrity of critical systems.

How Does TPV’s Heat and Chemical Resistance Work?

The combination of structure and formulation gives Thermoplastic vulcanizates (TPVs) their unique heat and chemical resistance. TPVs consist of a cross-linked rubber component dispersed within a thermoplastic matrix. The rubber cross-linked structure helps TPVs maintain flexibility and elasticity when heated, while the thermoplastic matrix adds rigidity and strength. TPVs are also often modified by incorporating specialized additives to improve resistance to chemicals such as oils, acids, and solvents. Their performance in harsh environments ensures TPVs maintain their reliability for demanding applications that use this combination of materials.

What makes TPV suitable for automotive applications?

Due to the rigorous demands of automotive applications, Thermoplastic vulcanizates (TPVs) possess particular value for the automotive industry. Their combination of extreme flexibility, durability, and resistance to environmental stress is ideal for various auto parts. Rubber TPVs are exposed to extreme temperatures, UV radiation, and chemicals like gasoline, oil, and brake fluids. These exposures give TPVs long-term performance for under-the-hood and exterior parts.

Furthermore, the lightweight design of TPVs helps reduce vehicle weight, significantly improving fuel efficiency and easing TPV emissions standards requirements. The ability to TPV process through molding, extruding, or thermoforming into intricate designs, such as seals, gaskets, and air ducts, adds to their precision and complexity. Their recyclability also supports the growth of the automotive industry, as it focuses on sustainable, green manufacturing. All the factors combined showcase the importance of TPVs as a significant factor in the modern vehicle world.

How do chemical resistance and temperature resistance interact in TPV?

Tough combinations of chemical and temperature resistances are necessary for TPV performance in demanding environments, making thermoplastic vulcanizates (TPVs) exhibit precisely those qualities. Chemical-resistant TPVs are essential due to oils, fuels, and other aggressive substances to which TPVs are susceptible. For industrial and automotive use, chemical resistance is critical. When combined with the ability to withstand extreme heat near engine components and cold sub-zero temperatures, the need for temperature resistance is clear.

The properties of TPVs interact at the molecular level, combining the elasticity of rubber with the processability of thermoplastics. This creates a resistant, cross-linked network that does not undergo chemical degradation, and a thermoplastic phase that remains stable with changing temperatures. For instance, TPVs in under-hood applications can remain flexible but are still resistant to chemical attacks from oil and coolant exposure at high temperatures. This combination of properties allows TPVs to maintain reliable performance during simultaneous chemical and thermal stress, prolonging material fatigue and enhancing lifecycle value for the manufacturers.

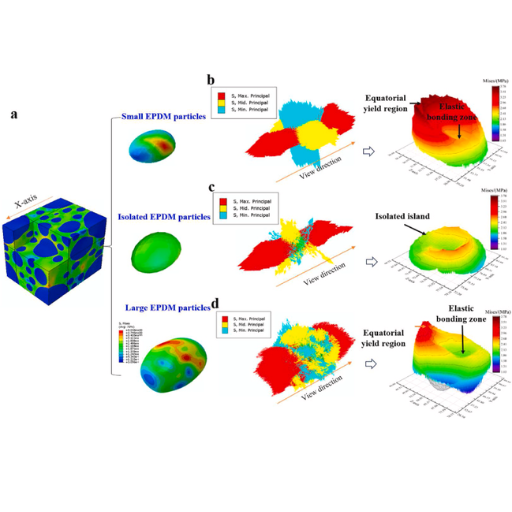

What are the implications of EPDM in TPV compounds?

The use of EPDM (ethylene-propylene-diene monomer) dramatically improves the performance of TPV compounds in applications with extreme environmental challenges. With EPDM, the molecular properties translate into superior thermal stability, ozone resistance, weathering durability, and greater endurance for components subjected to harsh outdoor elements or extreme temperatures. Furthermore, the flexibility and elasticity of EPDM enhance the performance of the interphase with the TPVs’ thermoplastic matrix, yielding materials with greater impact resistance and excellent compression set properties. The addition of EPDM to TPV compounds increases their resistance to harsh chemicals, UV radiation, and mechanical fatigue. This is attributed to the modifying effect of EPDM. This is why EPDM-modified TPVs are widely adopted in the automotive, construction, and industrial equipment sectors, which thrive on reliability and material durability.

What Are the Advantages of Using TPV in Manufacturing?

The benefits of Thermoplastic Vulcanizates (TPVs) in manufacturing are pretty significant. Their properties give them broad usefulness by merging rubber’s flexibility with the plastic’s ease of processing. TPVs possess lightweight, tough, chemical-resistant, UV-resistant, and temperature-resistant properties, ensuring long-term reliability for harsh applications. In addition, they support sustainable TPVs that are recyclable, which aid in environmental efforts. These attributes, which are moldable and easily extruded, ensure minimal production time and costs, speeding up manufacturing timelines, making them suitable for various industries.

How does TPV’s recyclability affect its usage in products?

The sustainability and eco-friendly goals of the modern world TPVs help many industries TPVs meet increasing environmental regulations TPVs help many industries align with. Their closed-loop recycling capabilities enable manufacturers to use TPVs, assisting many industries to reuse waste materials during production, which minimizes material loss and lowers costs. Also, reused TPVs retain a lot of their original flexibility, chemical resistance, and thermal stability, making them suitable for many industries to produce high-performance grade products without compromising quality. TPVs provide these capabilities, which aid in consumer goods, automotive, and construction, where eco-friendly materials are highly prioritized.

What role does TPV play in molding and extrusion processes?

Thermoplastic vulcanizates (TPVs) are regarded as crucial in both molding and extrusion processes due to their unique elasticity and processability. Unlike conventional elastomers, TPVs can be molded and extruded using standard thermoplastic processing equipment, which simplifies production and reduces costs. Their excellent flow characteristics also ensure reliable and accurate molding, even in intricate shapes, such as automotive seals, gaskets, and components for consumer products. As far as extrusion is concerned, TPVs offer good dimensional stability and smooth surface finishes, which are essential for weather stripping and tubing. In addition, TPVs’ ability to consistently retain specific physical attributes such as elasticity, chemical resistance, and structural integrity further strengthens their dependability in numerous industrial applications. These characteristics, in addition to TPVs’ recyclability, make them frontrunners for sustainable manufacturing in high-performance sectors. TPVs are marketed as a sustainable, high-performance material.

Why is TPV considered a durable choice for seals and gaskets?

Thermoplastic Vulcanizates (TPVs) are known for their unique attributes, combining rubber-like elasticity with thermoplastic properties, which makes them highly durable for seals and gaskets. They demonstrate superb endurance against extremely high and low temperatures, remaining flexible in cold places while retaining structural integrity in high heat. Furthermore, TPVs are body-sealing, shielding, and coating materials for assembled parts, and are resistant to many chemicals, including oils, greases, and even harsh industrial fluids, which enhances their long-term performance.

One more thing that adds to the durability is why TPVs have excellent resistance to fatigue and compression set. This means that seals and gaskets made from TPVs can be repeatedly deformed without suffering any permanent damage. Their low permeability to gases and liquids also improves their performance in harsh conditions, like automotive engines, industrial machinery, and HVAC systems.

What Are the Applications of TPV in Various Industries?

TPVs are widely used across multiple industries due to their unique combination of flexibility, durability, and resistance to extreme conditions.

- The automotive industry: TPVs are commonly used in weather seals, gaskets, and interior components, offering robust performance and long-term reliability.

- Construction: They are used in window seals, roofing membranes, and other weather-resistant applications, ensuring durability in harsh environmental conditions.

- Consumer Goods: TPVs are found in soft-touch grips, toys, and various household items, providing comfort and practicality.

- Industrial Applications: They serve in hoses, belts, and seals for machinery exposed to high temperatures and repeated movement.

- Electrical and Electronics: TPVs are used in cable insulation and connectors, enabling resilience and safety in high-performance environments.

These applications highlight TPV’s versatility and effectiveness in addressing diverse manufacturing requirements.

What specific automotive applications benefit from TPV’s properties?

Thermoplastic vulcanizates (TPVs) have become indispensable in the automotive sector due to their unique balance of rubber-like elasticity and thermoplastic processability. Several key applications across modern vehicles benefit significantly from TPV’s properties:

- Weather Seals and Gaskets: TPVs are extensively used in door, window, and trunk seals due to their exceptional elasticity, UV resistance, and long-term durability, ensuring a watertight and airproof fit.

- Air Intake Ducts: Their heat resistance and flexibility under varying temperature conditions make TPVs an ideal choice for air handling systems within engine compartments.

- Interior Trim Components: TPVs are applied in soft-touch instrument panels, cup holders, and other trims, combining robustness with tactile comfort to enhance the passenger experience.

- Hose and Tubing Systems: TPVs are integral to under-the-hood systems, withstanding high temperatures and chemical exposure while maintaining flexibility and performance.

- Battery Components in EVs: Emerging electric vehicles employ TPVs in battery seals and cable insulation, leveraging their lightweight, durable, and electrically insulating properties to ensure safety and efficiency.

These applications highlight TPV’s ability to address the needs of the automotive industry, from enhancing energy efficiency with lightweight materials to maintaining performance in harsh environments. Their adaptability continues to drive innovation across both conventional and electric vehicle designs.

How is TPV used in wire and cable insulation?

The combination of flexibility, durability, and environmental resistance makes Thermoplastic Vulcanizates (TPVs) the most commonly used material in wire and cable insulation. This type of material provides excellent thermal stability, allowing wire and cable systems to function over a wide temperature range, typically from -60°C to 135°C, depending on the specific formulation. Withstanding extreme thermal conditions, TPVs are ideal for use in the automotive, industrial, and outdoor machinery industries.

The inability of TPVs to allow the passage of electric current makes them good insulators, ensuring safety and preventing current leakage in electrical systems. Also, their resistance to abrasion, chemicals, and UV light enhances the protective coating around wires and cables. TPVs can be easily extruded into complex shapes, making the manufacturing process of sophisticated wires and cables easy and efficient.

What are some everyday TPV products in the market?

Vast industries have adopted thermoplastic vulcanizates (TPVs) due to their unique combination of strength, elasticity, and chemical resistance. Durable and Flexible TPVs are extensively used in the automotive sector for manufacturing air ducts and cable covers, and are employed widely in construction for making window and door seals. Roofing membranes and expansion joints are durable against harsh climates. Along with soft-touch grips and TPV kitchenware, branded medical equipment also utilizes TPVs due to their unrivaled ergonomic usability.

How Does TPV’s Performance Change Under Different Conditions?

TPV’s performance can vary based on weather factors such as UV light, temperature, and humidity. The thermal stability of the application impacts operating temperatures. At elevated temperatures, TPVs maintain their strength and elasticity, while under extreme cold, flexibility also decreases, affecting resilience against impacts. Without UV stabilizers, TPVs are susceptible to degradation due to constant exposure to sunlight. The effects of water and moisture are negligible because TPVs are robust against dampness, making them reliable in both dry and wet climates.

What factors influence the temperature performance of TPV?

Several key parameters affect the temperature performance of a TPV. The first one is the specific formulation of the TPV and its associated rubber-to-plastic ratio, since this dictates its thermal properties. The second factor is the stabilizers or plasticizers, which significantly affect the ability to endure high or low temperatures. The third one includes the environmental factors such as UV exposure and varying humidity, which can influence the long-term stability of thermal performance. It is possible to optimize the design and material selection factors in such a way that ensures reliable performance across a wide temperature range on a TPV.

How does resilience to high heat affect TPV’s usability?

The ability to withstand high heat is crucial for thermoplastic vulcanizates (TPVs) in splice TPV applications, due to the extreme conditions to which TPVs are subjected. High-heat resistance TPVs can withstand elevated temperatures, flexing, and structural strain, which makes them relevant in industries like automotive that depend on parts like seals, gaskets, and hoses that are constantly exposed to high temperatures. For example, TPVs that can withstand around 150°C without degrading are most suitable for under-the-hood components. This attribute helps prevent material fatigue, which minimizes the chance of deformation or cracking and maximizes the product’s lifespan. Also, heat resistance is crucial in maintaining product stability in uncontrolled thermal environments, which is vital for maintaining shape and consistent mechanical characteristics over time.

What are the impacts of weather resistance on TPV materials?

The weather resistance quality in thermoplastic vulcanizates (TPVs) impacts their performance and endurance when used outdoors. TPV materials are resistant to UV radiation, ozone, and harsh weather, which helps prevent surface degradation, discoloration, and cracking over time. This is especially beneficial in automotive construction or sealing applications, as they tend to get exposed to extremely harsh environmental elements. Advanced techniques in UV stabilization are incorporated into TPV formulations, further enhancing their properties by decreasing the rate of polymer chain breakdown when exposed to sunlight. Moreover, TPVs retain their mechanical flexibility and elasticity over a wide temperature range, from freezing conditions to high heat, ensuring functionality without compromise. This combination of thermal stability and weather resistance increases service life and reduces maintenance, making TPVs the preferred TPV for critical outdoor components.

What Are the Limitations of TPV in Temperature Resistance?

Even though TPVs have superior temperature resistance when compared to a wide array of conventional materials, some considerations require attention. At exceedingly elevated temperatures, TPVs tend to soften or degrade over time, which can negatively affect their structural integrity. In the same manner, at very low temperatures that are beyond the rated performance range, TPVs risk becoming brittle, making them more prone to cracking when subjected to stress. These factors contribute to TPVs not being ideal for use in systems that operate in and endure sustained periods of extreme temperature ranges far exceeding the design limits. Making the right choice of material and conducting thorough testing will be crucial to achieving the intended results, given the specific temperature range.

Are there scenarios where TPV’s temperature resistance fails?

Alongside those considerations, designed thermoplastic vulcanizates (TPVs) must figure out the narrow band within which a set of conditions should be maintained for specific temperature ranges. For instance, in particular industrial settings, TPVs are continuously exposed to conditions where the surrounding temperature is maintained above the upper limit, leading to degradation. The degradation will most likely exhibit itself as softening, deformation, or even breakdown of the material’s balance. Another possible manifestation is rapid cycling of varying high and low temperatures, with repeated switching between thermal extremes. Such behavior has a chance of exposing the material to low-strength thermal fatigue cycles, resulting in permanently altered recovery through structural reductions that can lead to chronic endurance-based delamination and weakening, ultimately causing system collapse and reducing elasticity and overall strength.

Another scenario that may fail critically for the first time occurs in the automotive or chemical processing industries, where TPVs endure synergistic mechanical and thermal stresses combined with aggressive fluids, such as oils, acids, or solvents. The level of heat TPVs endure, in conjunction with aggressive chemical contact, can accelerate molecular breakdown, which drastically shortens the material’s lifespan. Other factors, such as manufacturing irregularities like inadequate curing or improper compounding, contribute to these weaknesses, making TPV structures more vulnerable to thermal stress. These risks can be minimized by properly evaluating application conditions, conducting rigorous testing, and ensuring the long-term reliability of TPV components.

How does compression set affect TPV in high-temperature environments?

Compression set isAnother scenario which TPV components face that influences performance most while combined with high temperature is sealing efficiency and elastic recovery, which is worsened by moderate to high thermal exposure, thus sealing mechanics of the component suffer immensely. In my opinion, the best approach would be to stress that heat is known to soften materials, and in some cases, a thermometer is used to indicate the levels of heat. This type of degradation is necessary where operating a system and containing gas or fluid to limit escape is required, as the less elastic the material, the more difficult it becomes to accomplish tight fittings.

What alternatives exist if TPV does not meet specific temperature requirements?

In the case where TPV does not meet the specified operating temperature, I would lean toward silicone rubber, fluoroelastomers (FKM), or perfluoroelastomers (FFKM) as these materials have superior thermal stability and resistance to extreme temperatures when compared to TPV. Silicone rubber is suitable for highly flexible applications at low temperatures, while FKM and FFKM excel in high temperatures and the presence of aggressive chemicals. I can select the best possible material for the harshest thermal conditions by understanding its operational environment and the material’s properties.

Reference Sources

-

Thermoplastic Elastomers: Emerging Trends and Applications in Rubber Manufacturing

- Key Findings: This study highlights the heat resistance of TPVs, particularly in automotive applications such as under-hood components and weather seals. It emphasizes the material’s ability to withstand high temperatures while maintaining elasticity and durability.

- Methodology: A comprehensive review of literature and industry reports was conducted to evaluate the properties and applications of thermoplastic elastomers, including TPVs.

-

Properties of Microfibrillar Cellulose Filled Thermoplastic Natural Rubber

- Key Findings: The study discusses the use of high-heat-resistant rubbers, such as EPDM, in TPV preparation, which enhances their thermal stability. It also explores the mechanical and thermal properties of TPVs reinforced with microfibrillar cellulose.

- Methodology: An experimental analysis was conducted on TPVs prepared through dynamic vulcanization, focusing on their thermal and mechanical properties under varying conditions.

-

- Key Findings: Although not directly related to TPVs, this study introduces a technique for measuring interfacial temperature and velocity in multiphase flows, which could be applied to analyze the thermal behavior of TPVs under dynamic conditions.

- Methodology: The study developed and validated a novel infrared imaging technique to measure temperature and velocity fields in heated flows.

- Top TPV Plastic Pellets Suppliers in China

Frequently Asked Questions

Q: What are thermoplastic vulcanizates (TPVs)?

A: Thermoplastic vulcanizates are a type of thermoplastic elastomer (TPE) that combines the properties of rubber and plastic. They are created through a process called dynamic vulcanization, which involves cross-linking a rubber component within a thermoplastic matrix, resulting in a material that is both more durable and flexible.

Q: How do thermoplastic vulcanizates compare to conventional thermoplastics?

A: TPVs offer a unique combination of properties that are often superior to conventional thermoplastics. They exhibit high elasticity, excellent impact resistance, and improved heat resistance, making them suitable for a variety of applications where traditional thermoplastic materials might fail.

Q: What is the use temperature for thermoplastic vulcanizates?

A: The use temperature for thermoplastic vulcanizates can vary depending on the specific formulation, but they generally have a service temperature range of -40°C to 120°C (-40°F to 248°F). This makes them suitable for applications that require resistance to both low and high temperatures.

Q: Can thermoplastic vulcanizates resist oils and chemicals?

A: Yes, TPVs are known for their oil resistance and fluid resistance, which allows them to withstand exposure to various chemicals without significant degradation. This property makes them ideal for applications in automotive and industrial environments where oil and chemical exposure is everyday.

Q: What are the physical and mechanical properties of TPVs?

A: The physical and mechanical properties of thermoplastic vulcanizates include high tensile strength, hardness, elasticity, fatigue resistance, and impact resistance. These properties can be tailored through the selection of polymers and the vulcanization process, allowing for a wide range of applications.

Q: How are thermoplastic vulcanizates manufactured?

A: TPVs are typically manufactured through a process called injection molding, where a rubber component is dynamically vulcanized in the presence of a thermoplastic polymer. This process allows for the creation of complex shapes and elements that exhibit the desired elastomeric properties.

Q: Are thermoplastic vulcanizates recyclable?

A: Yes, thermoplastic vulcanizates are recyclable due to their thermoplastic nature. Unlike thermoset rubber, which cannot be remolded once cured, TPVs can be reprocessed and reused, making them an environmentally friendly option compared to traditional rubber materials.

Q: What types of polymers are commonly used in TPVs?

A: Common polymers used in the formulation of thermoplastic vulcanizates include ethylene-propylene-diene monomer (EPDM) rubber and polypropylene (PP). The combination of these materials contributes to the overall properties of the TPV, such as heat resistance and tensile strength.

Q: What applications are thermoplastic vulcanizates used for?

A: TPVs are used in a wide range of applications, including automotive parts, seals, gaskets, and consumer products, due to their excellent durability, resistance to oils, and ability to maintain performance under varying temperatures. Their versatility makes them a popular choice in both industrial and commercial sectors.