Thermoplastic vulcanizates (TPVs) are a fantastic class of materials that offer the elasticity of rubbers and the processing versatility of thermoplastics. Their advanced polymers, TPVs, have transformed entire industries, such as the automotive and consumer goods sectors, by providing unparalleled capabilities in extreme applications. But how do you define what TPV plastic is and what makes it so versatile? It doesn’t matter if you’re a materials engineer, a product designer, or just interested in new-age materials; this guide aims to provide all readers with helpful information on TPV plastics.

What are TPV and Its Characteristics?

Thermoplastic vulcanizates, or TPVs, are a type of polymeric material that possesses both the elasticity of rubber and the processability of thermoplastics. This unique composition of TPVs is achieved through a dynamic vulcanization process of finely dispersed rubber thermoplastic blends. This dynamic vulcanization results in the flexibility and durability of TPVs, as well as their resistance to heat, chemicals, and mechanical wear. TPVs can be easily molded, extruded, or even recycled, making them suitable for use in the automotive, construction, and consumer goods industries. Their unique versatility, while maintaining high-performance TPVs, applies to parts and products that require multifunctional utilities.

What is the composition of TPV material?

In TPVs, a thermoplastic and an elastomeric component are mixed to create a PP matrix, where elastomeric EPDM rubber domains are cross-linked. The dispersed polystyrene domain copolymer develops a thermoplastic vulcanizate elastomer that undergoes a complex dynamic vulcanization process during mixing, which simultaneously cross-links and melts the rubber particles. This TPV microstructure is formed by blending grafted styrene with saturated rubbers at temperatures above the glass transition temperature of polystyrene.

Additives such as stabilizers, fillers, plasticizers, and processing aids are added to the composition to enhance the material’s performance characteristics. TPV’s processability in the specific application, as well as its heat resistance and UV stability, is improved due to these additives. It is easier to manufacture and recycle thermoplastics, which makes TPV more appealing due to its elastomer-like elasticity, without relying on raw materials.

What are the key properties of TPV?

Thermoplastic vulcanizates (TPVs) have an exceptional set of characteristics. TPV’s properties provide ample room for diverse applications. The sharpest feature of TPV would have to be its outstanding elasticity and flexibility, which is almost identical to that of ancient vulcanized rubber. This makes TPV favorable for dynamic and static sealing applications. TPVs provide remarkable fatigue endurance and facilitate effective performance during repeated flexing or stressing.

TPVs withstand the extremes of heat and cold due to their unrivaled Thermal stability, making them function effectively from around -60 °C to 135 °C (or -76 °F to 275 °F), an extreme range of temperatures. In addition, TPVs are very useful in automotive and industrial settings due to their chemical resistance against oils, fuels, and greases.

Additionally, TPVs exhibit low density, providing the benefit of weight reduction compared to conventional rubber materials. They can also be processed easily using standard thermoplastic processes, such as injection molding and extrusion. Not only does the ease of fabrication, coupled with recyclability, lower production expenses, but it also enhances sustainability by reducing waste. All of these factors make TPV best suited for situations where high performance, long-life durability, and economical manufacturing processes are required.

How does TPV differ from traditional rubber?

Vulcanized rubber, also known as thermoset rubber, is a traditional form of rubber that involves a curing or vulcanization step, which yields a permanently cross-linked molecular framework. This chemical bond, while endowing thermoset rubber with considerable strength and elasticity, renders it incapable of being recycled and severely restricts its reshaping potential.

In contrast, TPVs blend the elastic properties of vulcanized rubber with the processability of thermoplastics. The structure of TPVs consists of a finely dispersed rubber phase within a thermoplastic phase and permits melting and reforming several times without detriment to material properties. Such mechanical reusability helps reduce waste and aligns with contemporary sustainability targets. In addition, TPVs can be processed using efficient thermoplastic processes, such as injection molding and extrusion, unlike traditional rubber, which is slower and more cumbersome due to intensive molding and vulcanization. This shift is beneficial not only for the environment but also for the mass production cost in TPVs.

How Does TPV Compare to TPE?

Both Thermoplastic Vulcanizates (TPVs) and Thermoplastic Elastomers (TPEs) possess a flexible and rubbery nature in addition to being easily processed. The main differentiating factor is that TPEs are more flexible in terms of softness and elasticity, making them suitable for products such as crosses, consumer goods, and soft-touch components. However, TPVs excel in heat resistance, durability, and long-term performance, making them suitable for demanding applications such as automotive seals and components installed under hoods. While both are recyclable and processed through thermoplastic methods, TPVs are more cost-effective in long-term high-demand situations.

What is the difference between TPE vs TPV?

Both thermoplastic elastomers (TPEs) and thermoplastic vulcanizates (TPVs) are flexible and versatile materials with numerous applications and uses. TPEs are a class of copolymers or a physical mix of polymers, meaning they combine parts of different polymers. It offers ease of processing because it is thermoplastic, thus providing increased flexibility and softness. Sufficiently durable mechanically but versatile in design, TPEs are applicable for soft-touch grips, medical devices, and consumer products.

On the other hand, TPVs are a subclass of TPEs that incorporate a vulcanized rubber component, offering greater elasticity in addition to improved resistance to heat, chemicals, and other harsh conditions. This cross-linking process enhances the durability and lifespan of these materials during manufacturing. These attributes make TPVs well-suited for rugged industrial and automotive applications, including weather seals, under-the-hood components, and thermally stable, mechanically robust molded parts that require a high degree of thermal and mechanical stability and strength in a harsh environment.

Another very important differentiating factor is their behavior at elevated temperatures. Thermoplastic vulcanizates have a lower compression set and better retention of mechanical properties during sustained heat exposure compared to conventional TPEs, which can weaken or lose their structural integrity over time. In addition, while both are easily recycled and adapted to thermoplastic processes, TPVs are more cost-effective over time in harsh, high-demand environments.

Which applications benefit more from TPV plastic compared to TPE?

Thermoplastic vulcanizates (TPVs) are especially advantageous for use in industries with extreme service conditions due to their durability, thermal stability, and resistance to harsh environments. TPVs are critical in automotive and industrial equipment for seals, gaskets, and under-hood parts that are exposed to heat, oils, and fluids for extended periods. Weatherstripping and exterior vehicle trim are other applications that require precise fitments and continuous compression, where TPVs excel due to their ability to maintain mechanical integrity. At the same time, thermoplastic elastomers (TPEs) would deteriorate over time due to elevated temperatures and compression.

In construction, TPVs are also preferred for weather-resistant profiles, roofing membranes, and flexible tubing. Their superior resistance to ultraviolet (UV) radiation and exceptional fatigue endurance also aid in prolonged performance outdoors and other high-stress conditions. Consumer goods products, such as medical syringes, also utilize TPVs for plunger seals due to the need for sterility and withstanding repetitive motion. These characteristics make TPVs ideal in high-demand environments where long-lasting performance, precision, and dependable reliability are crucial.

How do thermoplastic elastomers work?

Thermoplastic elastomers (TPEs) are unique because they combine the elasticity of rubber and the processability of thermoplastics. TPEs have a molecular structure comprising hybrid materials with both hard and soft segments. The soft segments provide flexibility and resilience, while the hard segments, typically crystalline or glassy domains, provide mechanical strength. The hard segments of the material allow the methyl group to be physically cross-linked as it softens when heated. The material can be molded or extruded, and upon cooling, the segments re-solidify, allowing the material to retain its properties without undergoing permanent deformation. This thermal reversal sets TPEs apart from traditional thermoset rubbers, which undergo chemical vulcanization, reshaping them into solid set shapes that cannot be altered. The balance of properties enables TPEs to excel where durability, adaptability, and repeatability are essential.

What Are the Common Applications of TPV?

In modern industries that require both flexible and robust materials, Thermoplastic vulcanizates (TPVs) find extensive applications. They are widely used in the automotive sector for parts such as seals, gaskets, and ducts owing to their durability against wear and harsh environmental conditions. In the consumer industry, TPVs are used in grips and soft-touch handles for improved ease of use and durability. In the healthcare sector, TPVs are used in medical devices and tubing because they are easy to sterilize, biocompatible, and flexible. These diverse applications of TPVs enable them to be highly adaptable in industries that need dependable materials.

How is TPV plastic used in automotive applications?

The unique combination of elasticity, durability, and chemical resistance makes Thermoplastic Vulcanizates (TPVs) integral for various automotive applications. TPVs are extensively utilized in weather seals for doors and windows due to their remarkable flexibility and ability to withstand extreme temperature fluctuations over time. Moreover, TPVs are used in air ducts and bellows underneath the hood, where they are exposed to high heat and oil, making it vital for the materials to be resistant. The lightweight properties of TPVs help reduce the vehicle’s overall weight, improving fuel efficiency and reducing harmful emissions. Their excellent processability makes them parathermoplastic elastomers of choice for interior components such as soft-touch dashboards and knobs, improving comfort without compromising structural integrity.

What are the benefits of using TPV rubber in wire and cable?

Due to their wide usage in wire and cable production, TPVs come with a variety of advantages, the most important of which is excellent chemical resistance. The ability of wires and cables to withstand harsh conditions and exposure to oils, fuels, and other industrial fluids is essential, and TPV’s unmatched chemical resistance helps safeguard wires and cables. This attribute also enhances their reliability in demanding applications.

Moreover, the flexibility and elasticity offered by TPVs are unmatched because they are needed to preserve the cable’s materials during repeated mechanical bending and stress. Also, their high temperature resistance ensures that wires and cables function effectively in harsh environments, including automotive, industrial, or outdoor settings. TPV’s inherent UV stability ensures that the wires damaged by sunlight will not be weakened to the point of material destruction.

In a manufacturing sense, Extrusion TPVs are easily processed, which increases production speed and decreases costs. Also, because they are thermoplastic, these materials are eco-friendly and can be recycled. Thus, thermoplastic rubber is the best material to use in wires and cables because it combines durability, functionality, and environmental responsibility.

Where else can TPV products be applied?

In addition to wires and cables, thermoplastic vulcanizates (TPV) are widely used throughout the automotive industry because they require materials with extreme elasticity and resistance to chemicals for weather seals, interior trim, and air ducts. Also, manufacturers of consumer goods, such as soft-touch grips and handles, use TPV to make their items more comfortable and durable.

Furthermore, TPVs are becoming increasingly critical in gaskets, roofing membranes, and window seals in the construction industry due to their ability to withstand severe weather conditions. In addition, they are also crucial in healthcare for medical tubing, seals, and various device parts that require biocompatibility and high sterility. The renewable energy industry is starting to appreciate TPVs for their use in solar panel junction boxes and seals, where long life, UV resistance, and overall system effectiveness are crucial. This growing adaptability of TPVs is a clear indicator of their relevance in contemporary manufacturing for integrated multi-functional and multi-performance objectives.

What Are the Processing Techniques for TPV?

Thermoplastic vulcanizates (TPVs) can be processed using a variety of standard thermoplastic manufacturing techniques, making them highly versatile. The most commonly used methods include:

- Injection Molding: TPVs are melted and injected into molds to create precise, complex shapes efficiently, making this method ideal for mass production.

- Extrusion: TPVs are heated and pushed through a die to produce continuous products, such as tubing, seals, and profiles.

- Blow Molding: Used for hollow parts, such as hoses or containers, this process involves inflating a softened TPV parison inside a mold.

- Compression Molding: This method involves compressing TPVs in a heated mold to form specific parts, typically for low-volume production.

These processing techniques capitalize on the material’s thermoplastic properties while maintaining its elastomeric performance, ensuring widespread applicability across industries.

How is TPV plastic processed using injection molding?

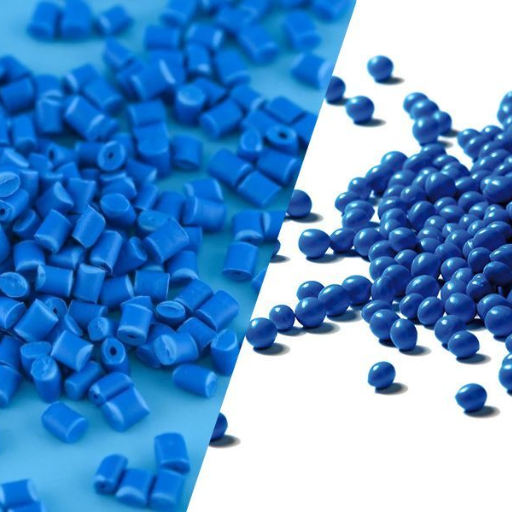

Specialized injection molding allows for precise and effective components of TPV (thermoplastic vulcanizates) due to its thermoplastic and elastomer characteristics. The first stage involves heating the TPV pellets to the required temperature and becoming molten. At this stage, the material is injected into a specially made mold under high pressure. The mold is then cooled to solidify the material, after which the part can be ejected.

Melt surface, injection pressure, and cooling time need to be monitored and measured accurately so that the flow and surface quality of the final product meet standards. The typical melt temperature for TPV granules depends on the grade or formulation, but generally ranges between 360°F and 450°F (182°C and 232°C). Thermoset rubbers require longer cycle times when being TPV injected compared to the latter due to their thermosetting characteristics, which makes them ideal for extensive production without excessive costs.

Injection molding is best suited for producing TPV-based products, which often have complex configurations and close tolerances, such as automotive parts, gaskets, and seals. It also has a positive effect on reducing fuel consumption by lowering the material scrap rate. Thus, aiding in the production of bulk quality parts continually.

What is the role of compression in shaping TPV?

The application of heat and pressure in TPV (thermoplastic vulcanizate) compression molding transforms raw material into complex designs. In this process, carefully measured TPV material is inserted into the heated cavity of the mold. Following this, the mold is closed and subjected to a predetermined compressive force. When heat and pressure are applied simultaneously, NHF flows evenly throughout the cavity, and the component shape is precise. This approach is most efficient for large and ruggedly durable parts, where complex detailing is not particularly sought after. Other benefits of compression molding include reduced material waste, uniform curing, enhanced mechanical properties, improved yield for strength and stiffness components, and many more, which are especially vital for high-performance industry applications.

What are the advantages of using TPV pellets?

Thermoplastic vulcanizates (TPV) pellets are very easy to process and offer numerous advantages, making them a preferred material in various industries. For starters, TPV offers remarkable flexibility and outstanding elastomeric properties on par with thermoset rubber, and combined with ease of handling due to being a thermoplastic. Thermal, chemical, and UV extremes do not affect TPV pellets, proving reliability for construction, automotive, and appliance industries. TPV pellets also provide exceptional sealing, making them highly popular in various industry sectors as well.

Additional benefits include lower production costs, as TPV pellets can be processed using standard methods like injection molding and extrusion, which significantly reduces the time required. Furthermore, they are easy to handle and have a low density. Beyond performance, TPV materials are easily processed and maintain high strength. This increases efficiency during energy consumption for applications that use these materials. In addition to this modern standard in materials science, these TPV materials are benign, with zero toxicity, and can be recycled, forming sustainable polymers.

What Are the Advantages of Using TPV Over Other Materials?

- Flexibility and Durability: TPV combines the elasticity of rubber with the processability of plastics, offering superior flexibility while maintaining long-term durability under extreme conditions.

- Lightweight: Its low density reduces the overall material weight, making it ideal for applications where weight reduction is crucial, such as in the automotive and consumer goods industries.

- Cost Efficiency: TPV materials streamline manufacturing processes, such as injection molding, which reduces production time and costs compared to traditional thermoset rubbers.

- Environmental Sustainability: TPV is recyclable, aligning with sustainability goals by reducing waste in production and disposal.

- Resistance to Harsh Environments: It exhibits excellent resistance to heat, UV radiation, and various chemicals, outperforming many alternative materials in demanding environments.

What makes TPV a durable choice for gaskets?

TPV, also known as Thermoplastic Vulcanizates, demonstrates cost-effective flexibility, along with both cost-effectiveness and efficiency, for gaskets. This is TPV’s durable feature. Its extreme flexibility and elasticity provide gaskets the ability to seal tightly in all ranges of pressure and heat without cracking or deforming. This trait is essential in applications where sealing air or water passages is crucial, even in extreme situations.

The resistance TPV offers to chemicals, oils, and solvents is a result of TPV’s enhanced durability, which prevents material degradation. Also, the ability to endure extremely lengthy durations of UV radiation and other high temperatures makes TPV’s gaskets even more suitable for outdoor or hot environments. Unlike conventional rubber products, TPV is lightweight yet rugged, further reducing stress on surrounding components, improving installation, and enhancing TPV’s robustness.

Supporting ecological sustainability is another key advantage because TPV has less energy consumption during manufacturing and is more easily recyclable. This enhances overall production costs. Compared to others, TPV stands out for its mechanical reliability, thermal and chemical strength, making it ideal for use in gaskets for construction, automotive, and industrial machinery.

How does TPV plastic offer better chemical resistance?

The distinct blend of thermoplastic and elastomeric attributes TPV (Thermoplastic Vulcanizates) plastic possesses offers remarkable chemical resistance. The chemical resilience of this material is contributed to by cross-linked rubber particles dispersed within a thermoplastic matrix, providing resistance against oils, greases, and industrial fluids. This structure ensures that minimal deterioration occurs when the TPV material is exposed to aggressive chemicals or harsh environmental elements, making it suitable for demanding applications. Moreover, TPV demonstrates stable performance over a wide temperature range, further enhancing its suitability for chemically intensive processes. In addition, its resistance to permeation and swelling enhances dependability in applications, such as seals, hoses, and gaskets, where prolonged exposure to chemicals is a critical requirement.

What are the elastomeric properties of TPV?

Thermoplastic vulcanizates (TPV) are designed to provide outstanding elastomeric characteristics, such as the flexibility of rubber while retaining the processability of thermoplastics. Key elastomeric features of TPV include high resilience and remarkable elasticity, which enable TPV to recover after deformation quickly. This material exhibits low compression set values, ensuring sealing and flexibility performance even when subjected to sustained loads or elevated temperatures over long periods. In addition, TPV has high tensile strength and elongation at break. Thus, it is ideal for dynamic applications with repetitive mechanical stress.

Another essential characteristic is the material’s performance at very low and high temperatures, where it should remain flexible in extreme cold and not soften or deteriorate in high temperatures. Because of these attributes, along with TPV’s resistance to fatigue, it is widely used in vibration dampers, bellows, and weather seals. TPV is ideal for use in industrial and automotive applications because it is weather-resistant and retains its elasticity after exposure to UV and ozone, ensuring long-term durability.

What Are the Challenges Associated with TPV?

While TPV comes with a myriad of advantages, it also has its downsides. One major drawback is the cost, as TPV is more expensive than traditional rubber products, which can limit its use in price-sensitive applications. Moreover, TPV’s processing is more complicated and needs to be executed under specific temperature and tooling conditions to maintain proper functionality. Although TPV is tough, specific, specialized elastomers can withstand extreme temperatures far better than TPV, limiting its use in high-heat environments.

What is compression set in TPV plastic?

Compression set in TPV plastic is defined as the material’s resistance to permanent deformation due to a compressive force over time and temperature. This value helps assess how well TPV will perform over time in sealing applications, or where gaskets and O-rings are used, which require elasticity and shape retention over time. Compression set is defined as the difference between the original thickness and the thickness of the material after the force is removed, expressed as a percentage of the original thickness. The lower the compression set value, the better the material’s recovery, resilience, and sealing performance. The compression set of TPV is greatly influenced by material formulation, temperature, and duration of the applied load. These values are essential to ensure the material will perform optimally in reliable, long-lasting service conditions.

How does high temperature affect TPV performance?

The performance attributes of thermoplastic vulcanizates (TPVs) are greatly affected by high temperatures. Thermocompression molding (TCM) and injection molding are the most common methods used to fabricate TPVs. Exposure to high temperatures can accelerate the thermal degradation of the TPV material, potentially compromising both its mechanical and physical properties. Significant changes include deterioration in tensile strength, elongation at break, and strain. In addition, elevated temperatures may alter the swimming thiol and crosslinking TPVs, causing an increase or decrease in the density and elasticity of the TPV.

Another vital aspect is thermal aging, which is the property of a material being subjected to heat for an extended period, leading to oxidative reactions within and on the outer surface of the material. This phenomenon may lead to surface discoloration, cracking, and loss of sealing ability over time. The thermal stability of TPV is highly dependent on the formulation, especially on the stabilizers, plasticizers, and curing agents employed. Usually, high-grade TPVs are designed to withstand high temperatures for an extended period while still maintaining their key performance features. Achieving these goals requires selecting the right materials and performing the appropriate tests to ensure the expected operating conditions.

What are the limitations of TPV thermoplastic?

Even though TPV (Thermoplastic Vulcanizate) thermoplastics have the remarkable ability to combine rubber-like elasticity with thermoplastic workability, they do come with some drawbacks. Certain fully vulcanized rubbers are TPVs’ most troublesome counterparts, as they are better in terms of temperature stability. TPVs are less suitable for extremely high-temperature environments, especially for continuous use, as they will eventually soften the thermoplastic or impair its mechanical properties under such conditions. Moreover, TPVs are known to be less resistant to certain chemicals, oils, and solvents; therefore, they cannot be used in highly aggressive chemical environments. Their high cyclic load or deformation sustained over time is troublesome because they may be subject to creep or permanent deformation. While TPVs process efficiently into final shapes, their cost relative to traditional elastomers can be a problem in cost-sensitive applications because customary elastomers are usually cheaper. Engineers and designers need to know these limitations because they are essential for selecting the right material for a given application and its surrounding environment.

Reference Sources

1. Thermoplastic Elastomers: Emerging Trends and Applications in Rubber Manufacturing

- Key Findings: This study examines the versatility of thermoplastic elastomers (TPEs), including TPVs, in industries such as automotive, healthcare, and construction. TPVs are noted for their weather resistance, elasticity, and high-temperature stability, making them ideal for applications such as vehicle weather seals and parts for appliances.

- Methodology: The research involved a comprehensive review of literature, industry reports, and research articles to analyze the properties, applications, and emerging trends of TPEs, with a focus on their role in the rubber manufacturing industry.

- Key Findings: This study investigates the use of microfibrillar cellulose (MFC) as a filler in thermoplastic natural rubber (TPNR), a blend of natural rubber and polypropylene prepared through dynamic vulcanization. It highlights the role of TPVs in achieving improved mechanical properties and recyclability.

- Methodology: The study prepared TPNR blends with varying MFC concentrations and evaluated their morphology, mechanical properties, and melt flow index. Dynamic vulcanization was used to create the TPVs, and results were analyzed using scanning electron microscopy and mechanical testing.

3. Achieving More Sustainable Solutions Through Process Intensification

- Key Findings: This paper discusses advancements in sustainable materials, including TPVs, emphasizing their recyclability and role in reducing environmental impact. TPVs are highlighted for their ability to combine the elasticity of rubber with the processability of thermoplastics.

- Methodology: The study reviews recent innovations in material science, focusing on the development and application of TPVs in creating sustainable and high-performance products.

4. Top TPV Plastic Pellets Suppliers in China

Frequently Asked Questions

Q: What is a thermoplastic vulcanizate?

A: A thermoplastic vulcanizate (TPV) is a type of thermoplastic elastomer that combines the properties of thermoplastic materials with vulcanized rubber. TPVs are created by blending rubber with thermoplastic resins, providing enhanced elasticity, durability, and heat resistance.

Q: How do thermoplastic vulcanizates differ from TPEs?

A: While both thermoplastic vulcanizates (TPVs) and thermoplastic elastomers (TPEs) offer a combination of plastic and rubber properties, TPVs are formulated explicitly by vulcanizing rubber particles within a thermoplastic matrix. This results in improved mechanical properties and thermal stability compared to standard TPE compounds.

Q: What are the applications of thermoplastic vulcanizates?

A: TPVs are used in a wide range of applications, including automotive parts, seals, gaskets, and various consumer products. Their versatility allows them to be utilized in plastic injection molding and extrusion processes, making them suitable for both industrial and everyday uses.

Q: What is Santoprene TPV?

A: Santoprene TPV is a specific brand of thermoplastic vulcanizate that combines polypropylene with EPDM rubber. It is well-known for its excellent resistance to heat, chemicals, and UV light, making it ideal for outdoor applications and automotive components.

Q: Can TPV parts maintain their original shape after deformation?

A: Yes, TPV parts possess good elastic recovery properties, allowing them to return to their original shape after being deformed. This makes them advantageous in applications requiring flexibility and resilience.

Q: What is the role of vulcanization in thermoplastic vulcanizates?

Vulcanization is a chemical process that involves cross-linking rubber molecules, enhancing their strength and durability. In thermoplastic vulcanizates, vulcanization occurs during the manufacturing process, resulting in improved elasticity and mechanical properties compared to non-vulcanized rubber.

Q: What types of thermoplastic materials are commonly used in TPV formulations?

A: Common thermoplastic materials used in TPV formulations include polypropylene (PP) and various grades of polyethylene. These materials are combined with rubber components, such as EPDM, to create the desired properties of the final product.

Q: How does the durability of TPVs compare to traditional rubber materials?

A: TPVs generally offer superior durability compared to traditional rubber materials due to their thermoplastic nature and the vulcanization process. They exhibit resistance to compression set, wear, and environmental factors, making them suitable for long-lasting applications.

Q: How can TPV be processed?

A: TPV can be processed using standard thermoplastic processes such as injection molding and extrusion. These methods allow manufacturers to create complex shapes and components efficiently while maintaining the material’s desired properties.