Both PMMA and acrylic are common options for manufacturing, design, and construction. These versatile and aesthetically pleasing materials are crucial across a range of industries, from automotive to interior design, and many in between. But do these materials stand for the same thing? If not, how do they differ? Professionals seeking clear distinctions or hobbyists eager to learn more will find the answer in this article, which explains the differences between PMMA and acrylic. In one place, we will summarize the properties, applications, and advantages of each material to help you make the right decisions for your projects. Follow along as we explain the science, functionality, and applications of the two extraordinary materials.

What are the Key Differences Between PMMA and Acrylic?

PMMA (Polymethyl Methacrylate) and acrylic are associated with one another in that PMMA is the name of the chemical that is referred to as “acrylic” in common language. Yet, the difference is only in wording and form. PMMA” is typically used in conjunction with raw material or polymer in its purest chemical form, whereas “acrylic” is used in commercial transactions more.” Furthermore, acrylic is often used to describe a family of plastic materials which added some modified to make them perform better, whereas PMMA denotes the pure base polymer.

Understanding the Basics of PMMA vs Acrylic

Polymethyl methacrylate (PMMA) is an acrylic glass with high optical clarity. When compared to glass, PMMA is transparent, lightweight, offers almost 92% in light transmittance, and has better impact resistance. PMMA has a density of 1.19 g/cm³, which is less than half that of traditional glass, offering significant advantages in weight-sensitive applications. PMMA is very useful for making lenses, fixtures, and displays. PMMA also displays great resistance to weathering; it can maintain transparency and structural integrity after prolonged exposure to UV light and outdoor conditions.

Applications of Acrylic and PMMA

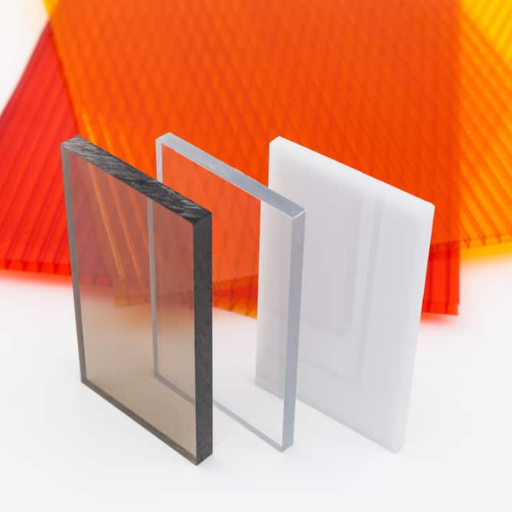

Acrylic is a general term that covers products made of PMMA, which finds applications in a variety of industries. For example, acrylic sheets or panels are frequently used in construction for windows, barriers, and skylights. PMMA is also widely used in the automotive industry for the production of tail lights and panel meters due to its impact resistance and clarity. In addition to industrial applications, acrylic materials are popular in crafting and making decorative items because of their ease of forming, shaping, and machining into complex designs.

Comparison of Strength and Durability

Although PMMA and acrylic share common characteristics, the properties of some acrylic products can be modified by the addition of other substances, impacting their strength and performance. A pure form of PMMA is more brittle, although it has better scratch resistance. Contrarily, modified acrylic formulations, such as those used for airplane windows or safety barriers, can be less brittle, allowing them to withstand impacts. The tensile strength of PMMA, at 60 to 80 MPa, is adequate for most standard applications; however, the correct formulation should be chosen depending on the specific application.

Knowing these properties enables consumers and industries to optimize their projects with ease by choosing the most suited material.

Comparing Optical Clarity in PMMA and Acrylic Materials

Polymethyl Methacrylate or PMMA, together with acrylic materials, are known to have great optical clarity, which is very useful in areas where clear visibility is required. PMMA is one of the clearest pourable plastics known, boasting a light transmittance of approximately 92%. This surpasses glass transmittance, which is usually around 90%. Acrylic materials, unless labeled as PMMA, tend to be less transparent due to their formulation and manufacturing processes.

The refractive index is also an important factor for optical clarity, and PMMA boasts a refractive index of about 1.4,9, which is lower than many other transparent materials. This is vital for prisms, lenses, screens, and display panels since low distortion is critical when light passes through the material. PMMA also outlasts many materials when exposed to the weather, sunlight, and transparent non-yellowing substances, maintaining clarity for outer space sustained viewing.

PMMA has higher resistance to scratching compared to other standard acrylic materials, making it suitable for applications requiring sustained visual excellence. However, project requirements need to be well analyzed as differences in the manufacturing process tend to make acrylic products less demanding optically.

The Mechanical Properties of PMMA and Acrylic

Both PMMA and Acrylic Thermoplastics have flexible applications due to their perceptible differences in mechanical properties. For instance, Polymethyl Methacrylate’s(PMMA) rigid nature allows it to easily withstand 65-75 MPa, whilst having excellent resistance to moderate impact. Moreover has a higher elasticity modulus (in the range of 2400 to 3200 MPa) as compared to standard acrylic, thus ensuring PMMA offers greater structural integrity.

Generally, Acrylic can provide good resistance to durability, flexibility, but may not stand up to PMMA in terms of tensile strength and hardness. Due to its brittle nature, Acrylic can withstand up to 5% of stress, which poses a comparative advantage due to some subcategories of acrylic having a slightly higher elongation range and thus proving to be more resistant to sudden impact.

Both PMMA and acrylic excel when challenged with extreme temperatures. While PMMA can undergo operating temperatures upto 100 degrees centigrade withouf deforming, It’s lower density standing at roughly 1.18 g/cm cubed, makes PMMA intriguingly light for applications where added bulk is a restriction. The reasoning behind these mechanical differences is critical when it comes to determining materials suitable for diverse engineering and architectural tasks.

How Does PMMA Compare to Polycarbonate?

PMMA and polycarbonate are distinct in terms of impact resistance, temperature tolerance, and cost. Polycarbonate is far more impact resistant than PMMA, making it more desirable for applications that will experience stress. PMMA, on the other hand, is scratch resistant and has superior optical clarity, which is best for use in lenses or display panels. Polycarbonate performs well in demanding environments because it has a higher tolerance to heat, but this comes with a greater cost compared to PMMA. The material selection is dependent on the requirements of the application.

Exploring the Impact Resistance of Polycarbonate vs PMMA

Polycarbonate is often heralded as the crowned king of biomaterials due to its remarkable impact resistance, reported to be up to 250 times stronger than normal glass. From the above reasoning, stunned toughness makes it favorable in the construction of applications demanding high stress, such as bulletproof windows, protective shields, and even industrial safety equipment. On the contrary, PMMA (acrylic) tends to be less durable with impacts, having an approximate 10 to 20 times stronger resistance than glass, adding again less stress endurance when stacked high against glass. Regardless of being far more brittle to withstand the force, weaker PMMA assumptions are still solid in the context of optics, aiding in the construction of signage, display panels, and even many decorative resources.

Utilizing materials in construction under heavy stress will present further evidence and test data. Polycarbonate notched Izod impact determined strength would reach, given the range of 600 to 900 J/m (joules per meter), showing that large amounts of kinetic energy is able to be absorbed without shattering. In contrast to logic, PMMA stands closer to 10 to 20 J/m of notched Izod impact strength,h, giving a lens that shatters under any prominent heavy force is highly likely. The prevailing factors highlight the primary needs serving polycarbonate, high extremes. Supported with a PMMA AI, decide on lighter aerial use, focusing on aesthetic appeal.

As mentioned before, cost or optics are just some factors that can be favored here, along with a vastly contrasting perspective. Defining as the conclusion is understanding the goal determines every project’s thoughts to altering demands, for example, ina discussion set on construction.

Thermal Properties of PMMA Versus Polycarbonate

The glass transition temperature of polymethyl methacrylate (PMMA) is around 85°C (185°F), while that of polycarbonate is about 147°C (297°F). This places PMMA at a structural disadvantage, as polycarbonate can maintain its structural integrity and does not begin to soften until definite higher temperatures. Because polycarbonate has a significantly higher Tg than PMMA, it can do much better in harsh conditions. Also note that PMMA, polymethylmethacrylate, is simpler to work with than polycarbonate, which is very hard to work with.

Due to it being quartz based, glass PMMA thermal conductivity falls around 0.19 W/mK. Polymethlymethacrylate also has less value in thermal conductivity which places it lower than metals. This definitely fits my needs, such as having non-operational heat applied to it. In a sense, Polycarbonate has better C-rating, but in reality, both fail on heavy thermal work applications.

Further noting the practicality of PMMA, harsher conditions in applications that involve temperature change, PMMA’s coefficient of linear thermal expansion increases, making it more dimensionally unstable. PMMA is much more sensitive to harsh mounting conditions and can easily break when large amounts of force from a plane or spear is applied. PMMA remains more passive than polymethlymethacrylate in cooling environments, which can be need for other usages.

Why Polycarbonate is an Alternative to PMMA

Polycarbonate’s PMMA alternative stands out due to superior thermal stability, impact resistance, and durability. While PMMA offers excellent clarity alongside resistance to UV light, polycarbonate surpasses glass and PMMA by 250 and 30 times impact strength respectively, making it ideal for demanding applications such as safety glazing, protective barriers, and automotive components.

Additionally, polycarbonate has a greater continuous-use temperature, typically up to 120 °C (248 °F), compared to PMMA, which generally sustains prolonged use at 90 °C (194 °F). Hence, polycarbonate is better suited for hotter environments with significant temperature variations. Polycarbonate’s greater flexibility allows for versatile forming and bending, reducing the risk of cracks during fabrication.

From a sustainability perspective, polycarbonate also offers recyclability, which, while not a prime consideration for most industries, becomes critical for eco-conscious industries looking to reduce waste. Long-term projects always require resilience, and while polycarbonate is slightly more expensive than PMMA, its performance benefits and overall durability justify the expense. These factors strengthen polycarbonate’s role as a preferred material in both industrial and consumer-facing applications.

What Are the Advantages of Acrylic?

Acrylic has a number of applications because of its unique qualities:

- Clarity and Transparency: Acrylic is highly transparent, giving it optical clarity, which makes it suitable for applications requiring a lightweight substitute for glass.

- Lightweight: Acrylic is considerably lighter than glass, making it more manageable for use and installation.

- Durability: Impact and weather-resistant, acrylic is suitable for both indoor and outdoor use.

- Cost-Effectiveness: Among other acrylic’s features, it is known to be affordable as compared to other clear materials and still maintains reliable rates of performance.

- Ease of Fabrication: It can be fabricated easily by cutting, stamping, sawing, and carving, unlike other materials, which may require extensive machining.

Acrylic as a Versatile Material for Different Applications

Acrylic’s primary uses have demonstrated its power and adaptability. It has been leveraged across numerous industries. These uses highlight its unique properties and its importance in numerous sectors. Following is a list, along with some key details, for various sectors:

- Construction and Architecture: Crylic is widely used in skylights, windows, dividers, and decorative panels. They last a long time, do not get damaged by UV rays, and are lightweight, making them a great substitute for conventional glass. Research suggests that acrylic can have an impact resistance of up to 17 times more than glass, which reduces risks in high-traffic or dangerous areas.

- Automotive Industry: Acrylic is perfect for use in vehicle lights, dashboards, and mirrors because of their strength, low weight, and long lasting transparency. The automotive industry profits from its weatherproof features which guarantee that components will remain clear and operational when exposed to the sun or harsh weather.

- Retail and Advertising: Acrylic is the preferred material for signs, displays, and point-of-sale displays. Its optical property ensures that products are visible while being strong enough to withstand constant handling. Research has shown that acrylic displays can last up to 10 years with little damage, which makes them a great marketing investment.

- Medical and Healthcare: Acrylic is often used to manufacture pieces of medical equipment and protective barriers like sneeze guards and incubator covers. It must be polished to high standards of cleanliness, which makes it preferable for medical environments. It must also be easy to maintain, light for easier transport, and set up in other healthcare settings.

- Aerospace and Transportation: Acrylic provides superb clearness as well as impact resistance which is the reason why it is used in aircraft windows and cockpit enclosures. This attribute of acrylic also enhances reliability during critical situations in very high altitudes and extreme pressure changes.

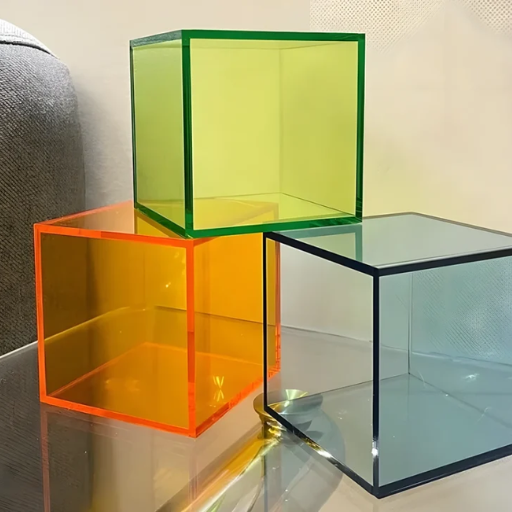

- Art and Design:

Acrylic is especially popular among artists and designers for sculptures, frames, and other artistic creations because of its vibrant colors and its ability to take on unique shapes. Its elasticity makes fabrication simple which encourages artistic expression and widen their creativity.

Due to the fact that its use is versatile, acrylic remains a preferred alternative wherever the need arises for strength, low weight, appearance and cost efficiency.

The Unique Properties That Acrylic Offers

Acrylic stands out due to its unique combination of qualities that make it useful in numerous industries. It boasts excellent optical clarity, with a light transmission percentage of up to 92%, comparable to that of glass. This makes it excellent for uses where clear vision is required, such as in aquariums, cars, and even eyeglasses. In addition, acrylic is lightweight; it weighs half as much as a glass of the same thickness, meaning that handling it is easier and it reduces the load on the structures.

It has superb weather durability, being able to withstand long durations of UV exposure, and harsh elements without yellowing or losing strength. This makes it a preferred option for outdoor signs and for architectural elements. In addition, it is highly resistant to impacts as it is up to 17 times stronger than glass which reduces the chances of breakage and increases the longevity of the material.

In terms of thermal properties, acrylic may be warped into different forms when heated beyond 320°F (160°C). Softening it allows the molding process to be executed with ease. This characteristic supports its versatility in creative industrial projects. Coupled with its sustainability, the ability to recycle acrylic, alongside reclaimed sheets often possessing minimal loss in quality when repurposed, adds to its value. These outstanding features contribute to acrylic being an essential material for modern manufacturing, design, and engineering.

Where Acrylic is Widely Used and Why

The use of acrylic is widespread in architecture, signage, and furniture due to its lightweight nature and high durability. It’s also favored in the automotive and medical sectors because of its strength and molds easily, as well as its recyclability which makes is friendly to the environment.

What Are the Disadvantages of Acrylic?

Though versatile, acrylic has some limitations. It tends to get scratched, which affects its visual clarity over time. Compared to glass, acrylic is less heat resistant, which makes it prone to warping and melting at high temperatures. In addition, the acrylic can also be described as brittle and may crack or break under hard impact. Even though it can be recycled, improper disposal adds more concerns to the environment.

Understanding UV Light Degradation in Acrylic

Acrylic materials are highly vulnerable to the more prolonged ultraviolet light features that may cause irreversible alterations to their physical as well as optical properties. With time, acrylic suffers from photo-wasting, which causes disfigurement, yellowing, and less transparency than before. With the right Acrylic UV stabilizers, studies suggest that UV destruction can start within a few hundred hours of brazenly exposed to sunlight.

With time, the molecular breakdown can also lead to a reduction in tensile strength. The more advanced UV radiation testing deals with the unsupported acrylic. The lack of additives with time can lead to a loss of 20-30% of the strength claimed to be protected under intense UV. Hence why most manufacturers resort to using UV protective additives, which tend to greatly increase the lifespan of their products. In regard to the acrylics ‘ UV-resistant features, even the treated tend to fail the higher the UV concentration is. Understanding the risks of treated acrylic materials is important for anyone needing lasting outdoor capabilities.

Exploring Chemical Resistance Challenges in Acrylic

Acrylic, while valued for its clarity and versatility, can face challenges when exposed to certain chemicals. For example, prolonged contact with substances such as ammonia, acetone, and ethanol can cause surface crazing, clouding, or even structural degradation. Studies have shown that acrylic is highly resistant to weak acids and alkalis, making it suitable for a broad range of applications. However, its vulnerability to stronger solvents and organic compounds highlights the importance of understanding the operational environment. To mitigate these risks, manufacturers recommend avoiding direct exposure to aggressive cleaning agents or industrial chemicals. Furthermore, testing in controlled environments has demonstrated that adding stabilizers or protective coatings can improve chemical resistance, reducing potential damage and enhancing durability. These practices are integral when considering the use of acrylic in chemically demanding applications, such as industrial processing tanks or laboratory equipment.

Which is Better for Specific Applications: PMMA or Acrylic?

While choosing PMMA or acrylic for certain applications, it is important to note that PMMA is a subtype of acrylic. As such, the choice is predominantly influenced by the characteristics needed for the application. PMMA would be appropriate for high optical clarity applications, as well as those needing scratch resistance and rigidity, like lenses and display panels. For applications needing flexibility, ease of fabrication, or lower costs, general-purpose acrylic becomes more favorable. It is crucial to assess all of the factors–strength, transparency, and even chemical resistance–in order to make the best decision.

Choosing PMMA for Outdoor Applications

Also referred to as acrylic, PMMA is well-known for its exceptional resistance to weather conditions; therefore, it is particularly suitable for outdoor uses. The material has very good resistance to UV rays such as sunlight. PMMA keeps its translucence and strength even when exposed to direct sunlight for long periods which lowers the chances of yellowing and surface deterioration compared to other options.

Moreover, the durability of PMMA under changing temperatures and adverse conditions guarantees its performance in outdoor applications. PMMA can withstand temperatures of -40°F and 194°F (-40°C and 90°C) without significant deformation or loss of properties. It is also highly water-resistant which makes it useful for outdoor signage, skylights, and protective fences.

Industrial tests and research have shown that coated PMMA sheet surfaces resistant against scratches, dirt, and environmental pollutants can be enhanced further increasing durability. To improve weathering performance for aesthetic purposes without sacrificing strength, treatments that block UV rays can be used. As a result, PMMA is more popular when long-term reliability in critical outdoor applications is essential.

When to Use Acrylic as an Alternative to Glass

Plexiglass, or PMMA, is a well-known type of acrylic glass that is lighter in weight and offers better impact resistance than glass. Its ease of use makes it very popular during construction as it does not burden workers with excess weight. It has around 17 times greater resistance to force in comparison to normal glass, making it advantageous for schools, public spaces, and sports facilities where the well-being of children is a priority. Additionally, its other main benefit, being lightweight, is guaranteed, as it is half the weight of regular glass.

Its versatility makes it appropriate in almost every scenario. It is preferred in signage and display cases as it can transmit up to 92% of visible light,t which is extremely advantageous. Recent studies have shown that it far surpasses the clarity of traditional glass. It can be easily shaped into complex forms, cut, and thermoformed, all while retaining its strength. Recent innovations in coating technology have enabled it to achieve greater scratch resistance, as well as UV protection, making it ideal for outdoor applications such as shelters, greenhouses, and even the construction of skylights.

Due to its lower weight, higher durability, and better optical properties, acrylic performs exceptionally well in applications that demand safety, design flexibility, or cost efficiency over glass. Furthermore, the material’s weather resistance and durability make it practical for the residential and commercial sectors, especially in regions that experience extreme weather temperatures.

Evaluating PMMA and Acrylic for Acrylic Products

Advantages of PMMA in Acrylic Products

PMMA, also known as acrylic, is a versatile material due to its ultra-lightweight, clear, and weather-resistant properties. Recent studies show that PMMA provides superior light transmission at 92% compared to many other materials, making it superb for optical applications. Also, PMMA is several times stronger than glass in terms of impact resistance, which increases safety for protective barriers, signage, and automotive parts.

Applications and Performance Metrics

PMMA products perform best under harsh conditions. For example, in the case of consumer electronics, PMMA’s optical clarity when exposed to ultraviolet radiation ensures a longer product lifespan. Industry reports suggest that PMMA remains structurally sound within the harsh limits of –30°F to 350°F, arguably one of the most extreme weather conditions. This thermal stability is useful for outdoor installations and industrial settings where these temperatures are commonly experienced.

Sustainability and Customization

In addition to performance, PMMA’s recyclability is becoming more popular. Enhanced recycling methods contribute to lower emissions and waste by recovering PMMA. Plus, the versatility of PMMA in manufacturing allows for different tailored shapes, colors, and finishes, meeting a wide array of design options. These factors combined make PMMA increasingly sought after in construction, aviation, and medical fields, which need reliable materials while being ecologically responsible.

Fusing its distinct characteristics with the established dependability, PMMA continues to produce innovative and modern acrylic products spanning various applications.

Reference Sources

- Acrylic (PMMA) Guide – Xometry

- Poly(methyl methacrylate) – Wikipedia

- Polymethyl Methacrylate (PMMA/Acrylic) – Kemal Manufacturing

- Top PMMA Plastic Pellets Suppliers in China

Frequently Asked Questions (FAQs)

Q: What are the main differences between PMMA and Acrylic?

A: PMMA, or polymethyl methacrylate, is a type of acrylic plastic known for its clarity and optical properties. While PMMA is a specific type of acrylic, the term “acrylic” is often used broadly to describe similar transparent materials. The key differences lie in their chemical properties and manufacturing processes, such as cast acrylic and extruded acrylic.

Q: How do the chemical properties of PMMA compare to polycarbonate?

A: The chemical properties of PMMA and polycarbonate differ significantly. PMMA offers excellent optical clarity and UV resistance, making it an ideal choice for outdoor applications. In contrast, polycarbonate has better impact resistance and heat resistance, making it suitable for more demanding environments. Deciding which material is best depends on the specific needs of your project.

Q: What are the advantages of using PMMA over polycarbonate?

A: PMMA has several advantages compared to acrylic and polycarbonate, including superior optical clarity and UV stability. These characteristics make it an ideal choice for applications requiring a transparent material with a high-quality finish, such as displays and lighting. However, PMMA is more brittle than polycarbonate and less resistant to impact.

Q: What are the common applications of PMMA and polycarbonate?

A: PMMA is commonly used in applications that require transparency and aesthetic appeal, such as signage, displays, and acrylic surfaces. Polycarbonate, on the other hand, is favored in scenarios where impact resistance and durability are crucial, such as in safety glasses, automotive parts, and as an alternative to polycarbonate for glazing.

Q: How does PMMA perform in machining compared to polycarbonate?

A: Machining polycarbonate and PMMA both require careful handling due to their thermoplastic nature. PMMA can be machined to achieve high precision and clarity, making it suitable for detailed acrylic parts. Polycarbonate, however, offers better resistance to cracking and chipping during machining, which can be advantageous in more demanding applications.

Q: What are the physical properties of PMMA?

A: PMMA has excellent optical properties, offering high transparency and clarity. It also possesses good scratch resistance and is lightweight. However, it is less impact-resistant than polycarbonate and can be more prone to cracking under stress. Understanding these physical properties can help determine if PMMA is the right choice of material for your project.

Q: Can PMMA be used as an alternative to polycarbonate?

A: PMMA can be used as an alternative to polycarbonate in applications where impact resistance is not a critical factor. Its superior clarity and aesthetic appeal make it suitable for projects where visual appearance is a priority. However, for applications requiring higher strength and durability, polycarbonate may be a better choice of material.

Q: What are the disadvantages of each material, PMMA and polycarbonate?

A: PMMA offers excellent optical clarity but lacks the impact resistance of polycarbonate, making it more prone to breaking. Polycarbonate, while highly durable and impact-resistant, can be more expensive and less UV-stable over time. Understanding the disadvantages of each material helps in deciding which material is best for your application.

Q: How do PMMA and acrylic polymers differ?

A: PMMA is a specific type of acrylic polymer known for its high clarity and light transmission properties. Acrylic polymers encompass a wider range of materials, including both cast and extruded acrylic. The differences between these materials lie in their manufacturing processes and specific physical properties, which affect their suitability for various applications.