Manufacturing procedures for various sectors are revolutionized by the HDPE (High-Density Polyethylene) pellets, yet very few people discuss their pros and cons. Known for their strength and flexibility, these materials have great applications. Still, do we know what HDPE pellets truly are? What holds significance in everything, like vital infrastructure and eco-friendly packages? In this post, we unfold every bit of information regarding HDPE pellets, including their characteristics, uses, the value they provide to the companies, and the environment. From an eco-lover to a manufacturer, everyone is going to be fascinated by the possibilities of these materials and learn how they influence our lives.

What are HDPE Pellets and their Characteristics?

High Density Polyethylene (HDPE) pellets are small uniform granules manufactured from a thermoplastic known to be strong and durable. Commonly known as being lightweight, impact resistant, and extremely versatile, HDPE is noted for its excellent chemical resistance, high strength to density ratio, and moisture resistance. Because of these useful characteristics, HDPE is used in pipes, packaged goods, and various industrial products.

Understanding High-Density Polyethylene

High-Density Polyethylene (HDPE) is an industrially important thermoplastic polymer based on petroleum, fully lightweight, chemically resistant and has high strength.

How are HDPE Pellets Made?

Manufacturing HDPE pellets starts with polymerization of ethylene gas which is done with Ziegler-Natta or chromium catalysts. Ethylene monomers undergo heat and pressure in a reactor where it gets converted to long-chain polyethylene. The process guarantees the resulting material will have high-density with little branching of the molecular structure which adds to the material’s strength and durability.

The next step after synthesizing polyethylene is to cool, solidify, and cut it into uniform granules or pellets. Modern industry has increased HDPE pellet precision and functionality, making them easier to control between the melt flow rate and density. Quality control testing is done with the polystyrene pellets so that it can meet performance standards for various applications.

Estimates suggest that over 100 million tons of HDPE are produced every year, making it one of the most widely produced plastics. Its potential is further enhanced as recycled HDPE can be used to manufacture products such as outdoor furniture, pipes,a nd plastic bottles. These facts showcase the remarkable science and sustainable development involved in the production of HDPE pellets.

Key Properties of HDPE

| Key Property | Description |

|---|---|

|

Pressure Rating (PSI) |

Indicates maximum pressure pipe can handle. |

|

Material Composition |

High-density polyethylene ensures durability and strength. |

|

Wall Thickness |

Thicker walls increase pressure resistance. |

|

Pipe Diameter |

Larger diameters generally lower pressure ratings. |

|

Temperature Resistance |

Performance varies with operating temperature. |

|

Surge Pressure Capacity |

Can handle 1.5x recurring and 2x occasional pressure surges. |

|

Impact Strength |

Exceptional resistance to physical impacts. |

|

Tensile Strength |

High resistance to pulling forces. |

|

Hydrostatic Strength |

Long-term resistance to internal pressure. |

|

Flexibility |

Allows bending without breaking under stress. |

|

Corrosion Resistance |

Immune to rust and chemical degradation. |

|

Fatigue Resistance |

Withstands repeated pressure cycles effectively. |

|

Burst Pressure |

Maximum pressure before failure during testing. |

|

Environmental Adaptability |

Performs well in various soil and weather conditions. |

|

Joining Methods |

Heat fusion ensures leak-proof connections. |

Common Applications of HDPE in Industry

- Packaging – High-Density Polyethylene (HDPE) is utilized in creating containers, bottles, and caps for food and other products because of its strength and moisture resistance.

- Construction – It is used in the manufacture geomembranes, pipes, and plastic wood, which aids in construction and environmental projects.

- Automotive – HDPE is used in fuel tanks, bumpers, and many internal parts of a vehicle because they are light and impact resistant.

- Healthcare – MDPE is utilized in medical devices and packaging, providing adequate safety and cleanliness.

- Agriculture – HDPE is employed in irrigation systems and with plastic films for managed water supply and crop shielding.

These applications illustrate the importance and usefulness of HDPE across various sectors.

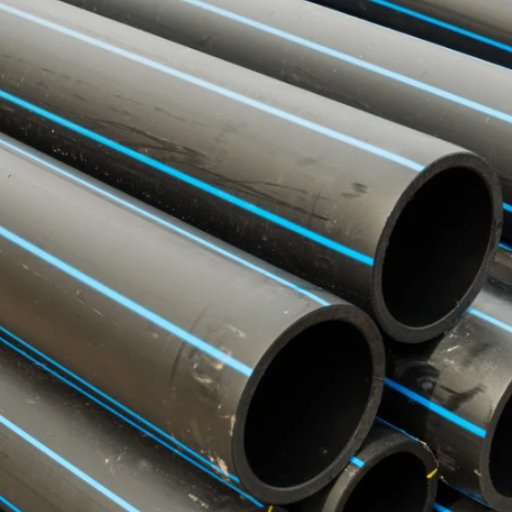

Uses of HDPE Pipes in Construction

The outstanding characteristics of high-density polyethylene, or HDPE, make these pipes corrosion-resistant and highly flexible. I use them for water distribution, gas pipelines, and high-pressure-ready drainage systems because of their superior temperature and condition tolerance. Their lightweight nature directly translates to faster work efficiency and installation, an essential need for construction sites.

Role of HDPE Sheets in Packaging

The importance of HDPE sheets in the packaging business stems from their remarkable resilience and adaptability. Sheets are routinely used to design and manufacture packaging containers, bottles, and protective pads. They are ideal for maintaining the integrity of perishable goods, industrial products, and even some hazardous items because of their resistance to moisture, chemicals, and impact. Other advantages include the lightweight nature of HDPE sheet, its recyclability, which supports reduced carbon footprint initiatives, and its alignment with sustainable, eco-friendly packaging policies. Industry research suggests that the food, beverage, and pharmaceutical industries will steadily increase their consumption of HDPE in other forms of packaging plastic, thereby increasing the general demand in the packaging industry. This shift confirms the material’s efficiency, environmental benefits, and strengthens its industry-leading position in advanced modern packaging systems.

Why are HDPE containers widely used?

The unmatched strength, flexibility, and affordability of HDPE makes high-density polyethylene containers a preferred choice. From household cleaners to complex industrial chemicals, HDPE’s impact, moisture, and chemical resistance makes it suitable for a variety of applications. Moreover, the USDA hdpe approved containers for food-safe applications because of their low permeable toxic nature, guaranteeing safety for food and beverages.

As noted by experts, HDPE container adoption is rapidly growing in the agricultural, consumer goods, and pharmaceutical industries. For example, the HDPE container market size was valued at about $52 billion dollars in 2022 alone, with forecasts estimating a compound annual growth rate (CAGR) of 4.5% between 2023 and 2030. This increase can be attributed to a greater emphasis on sustainability, as HDPE containers are fully recyclable, helping industries meet stringent, environmentally driven policies.

Furthermore, these containers are lightweight, which lowers shipping expenses, carbon emissions, and fuel consumption during transportation. Additionally, their high degree of moldability enables manufacturers to create uniquely shaped and sized containers designed to meet industrial specifications. This collection of practical, ecological, and economical advantages portrays HDPE as an optimal industry solution.

The Recycling Process of HDPE Pellets

The recycling process of HDPE pellets begins with the collection and sorting of HDPE materials, such as bottles and containers. These materials are thoroughly cleaned to remove any contaminants. Next, they are shredded into small pieces and melted down. The molten plastic is then extruded and formed into new HDPE pellets, which can be used to manufacture a wide range of products. This process reduces waste and supports sustainable manufacturing practices.

Steps in Recycling HDPE

- Collection and Sorting: The initial step includes a collection of HDPE materials such as plastic bottles, shampoo containers, and milk jugs. Infrared sensors and other sorting technologies are now more frequently utilized to separate HDPE from other plastics and impurities, guaranteeing better quality products.

- Cleaning: After sorting, the collected materials are cleaned thoroughly by industrial Washing Systems. This step addresses the removal of labels, adhesives, and any residues from the plastic.

- Shredding: Clean HDPE is fed onto shredders, which transform the plastic into smaller flakes or shreds. These uniform bits increase the simplicity of further processing, along with optimizing the separation of any remaining contaminants.

- Melting and Extrusion: The molten HDPE is then extruded into strands after heating the molten plastic above its melting point under controlled temperatures, which vary between 356 and 518°F (180 to 270°C) modulo the type of HDPE being recycled.

- Pelletizing: The chopped plastic is then shaped into small pellets, which are ground into new products. The chopped HDPE pellets can then be transformed into pipes, containers, automobile parts, and even furniture.

- Quality Control: Prior to packaging, the pellets go through strict quality inspection processes which check for adherence to industry standards and contamination of any kind. This step ensures maximum flexibility in manufacturing processes which can utilize the pellets.

Benefits of HDPE Recycling

Recycling HDPE plastic cuts the negative impact on the environment by eliminating plastic waste dumped in landfills. Recycling one pound of HDPE saves approximately 1.8 pounds of CO2 emissions, verifying its ability to reduce greenhouse gas emissions. Furthermore, the energy used to produce recycled HDPE is 88% less than that of virgin plastic, which makes it more affordable and effective.

Challenges in Recycling HDPE

Recycling HDPE plastic has many advantages but also faces many difficulties which hinder productivity and broader acceptance. Some additional obstacles include the lack of proper classification and sorting systems, wide spread inefficiency in recycling systems, as well as low estimation for global plastic recovery. Recycling economics also plays an important part as well.

Like most cases, economics will play a crucial part. In certain cases, the price for recycling HDPE will be more than the price needed for creating new, raw plastic. And this is even more true when oil prices are low. This discrepancy in cost makes adopting newer recycling technologies much more difficult. Investing into more cost efficient advanced recycling techniques is important in overcoming these obstacles.

Out of all the 10 to 15 percent of products that do undergo proper recycling, most people will classify them as HDPE, which is also done incorrectly, placing even more unprocessed plastic products into landfills. Everything considered, depositing unregulated HDPE remains more financially favorable compared to extensive recycling systems.

The last and easiest challenge which needs solving involves contamination. For food grade, HDPE and associated materials like adhesives and food containers need to be cleaned thoroughly. Contaminated obsolete stages trade off the quality of reproducible grade HDPE.

Advantages of Using HDPE in Manufacturing

- Durability: Products needing strength and longevity can use HDPE since it’s highly resistant to impact.

- Lightweight: Because of its lightweight nature, refraining from transport costs and energy expenditure during manufacturing is yet another benefit of using HDPE.

- Chemical Resistance: Its use for store containers, piping and industrial applications is seen useful because it resists geodetic corrosion and most chemicals.

- Recyclability: Conforming to more sustainable practices, HDPE’s wide reusability makes it easier to manufacture products responsibly.

- Versatility: Its use spreads from construction to packaging since HDPE can easily be molded into various shapes and sizes.

Why Choose HDPE Plastic?

I selected HDPE plastic because it is long-lasting, lightweight, and resistant to chemicals and corrosion, which makes it ideal for many applications. Furthermore, it can be recycled, thus supporting eco-friendly practices. Most importantly, it can be easily reshaped to suit diverse requirements.

Environmental Impact and Recyclability

Both biomass and plastic waste can be converted into pellets, which provide an opportunity to benefit the environment even further. Transforming plastic waste into pellets can assist in reducing landfill pollution. Research indicates that producing plastics from recycled pellets compared to virgin materials grants a 30-50% reduction in greenhouse gas emissions. This, in turn, greatly helps mitigate the adverse impacts of climate change.

Alternatively, fuel pellets produced from biomass are renewable and biodegradable fuel sources, which aid in lowering carbon emissions further. These pellets are capable of achieving up to 75% energy conversion efficiency, proven to be a better option than fossil fuel combustion. Furthermore, the application of agricultural waste and other organic materials into pellet production aids in preventing these feedstocks from decomposing and emitting methane, one of the most potent greenhouse gases.

Enhancing recyclability furthers the cause of sustainability. Plastic pellets can undergo reprocessing multiple times without irrefutable degradation of material quality, thus promoting a circular economy. Biomass fuels when combusted, leave negligible ash residues which can be used a nutrient-rich soil conditioner. Such actions help demonstrate how effective waste management, increased energy efficiency, and environmental conservation can be achieved through pelletization.

Exploring Different Types of HDPE and Their Uses

HDPE (High-Density Polyethylene) is available in different varieties for diverse applications:

- HDPE Sheets

Applied in construction, packaging, and signage due to their strength and rigidity.

- HDPE Pipes

Used for water and gas supply as well as sewage systems due to their long service life and resistance to corrosion.

- HDPE Bottles

Lightweight and non-reactive, these are used extensively in packaging industrial and household staples like detergents and beverages.

- HDPE Geomembranes

Widely used in environmental engineering as liners for landfills and ponds because of their impermeability and resistance to chemicals.

Every kind of HDPE has distinct advantages that make it appropriate for different practical uses in various sectors.

Comparing Virgin HDPE and Recycled Pellets

Picking between virgin HDPE and recycled pellets requires knowledge about their attributes and performance so that the correct choice is made for your use case.

Virgin HDPE comes from petroleum, thus, it has a uniform molecular structure, which guarantees high mechanical strength and durability. It has an outstanding tensile strength, resistance to a wide range of chemicals, and even extreme hot and cold temperatures. Consequently, virgin HDPE is reliable for sensitive applications like food-grade containers, medical products, and plastic pipes. Its composition does not undergo any changes, thus, enduring performance is guaranteed. For instance, after undergoing construction processes, infrastructure-led projects can utilize HDPE pipes for more than 50 years due to enduring stability and environmental stress resilience.

Recycled HDPE pellets, as the name suggests, are based on post-consumer or post-industrial HDPE waste materials. Recycled pellets have slightly lower mechanical performance than virgin HDPE, but are much better for the environment. They help reduce plastic waste and carbon emissions, which is important for sustainable manufacturing. Technology improvements in recycling have further softened its non-food grade uses in packaging, outdoor furniture, and construction materials. Industry analysts highlight the ability to reduce emissions by up to 50% of greenhouse gases with the use of HDPE recycled pellets compared to the production of virgin HDPE.

The distinction within the projects’ expectations terms dictates the selection of virgin or recycled HDPE. Applications subjected to stringent quality control or harsh operating environments require the use of virgin HDPE. On the other hand, non-critical applications that focus on the environmental footprint and cost benefit from using recycled HDPE.

Specific Applications of HDPE in Various Industries

Businesses and industries around the globe depend heavily on HDPE, or High-Density Polyethylene, because it is low-cost, highly durable, chemically resistant, and cost-efficient. Down below are some key applications:

- Packaging Industry

HDPE Israel is a plastic that can be found in almost every household since it is used to make containers, caps, and bottles. This thermoplastic happens to be one of the most highly produced.

- Construction Sector

Building parts like water tanks, geomembranes and pipes are commonly fabricated using HDPE. Piping with HDPE is also done because these pipes have a long life. Research has proven that these pipes can surpass 50 years of useful life if appropriately maintained.

- Agriculture

Dr R, a reputable author on agricultural issues, estimates that the addition of HDPE can make irrigation more efficient by as much as 30%. HDPE is also used for storage containers, drip irrigation systems, and even greenhouse covers.

- Automotive Industry

The automotive industry uses HDPE to make fuel tanks, seat backs, and under-hood parts. The dense and lightweight nature of HDPE helps with lifting the overall weight of the vehicle, hence increasing fuel economy and reducing carbon footprints. For instance, employing HDPE in fuel systems offers around a 25% reduction in weight compared to fueling strategies with conventional materials.

- Healthcare Applications

In healthcare, HDPE is useful in the development of medical-grade containers, prosthetics, and laboratory equipment. Its non-toxic and chemically inactive traits guarantee HDPE’s reliability and safety. Advancements in the last few years focused on sterilization of medical grade HDPE, making it more suitable for sensitive applications.

These different applications demonstrate HDPE’s adaptability, alongside accentuating the importance of sustainable, durable, and low-cost engineered solutions across multiple industries.

Reference Sources

- Pelletizing UHMWPE with HDPE Blends1:

- Key Findings: A novel tapered die with air cooling improved the tensile strength of UHMWPE/HDPE blends by 40%. The process enhanced molecular diffusion and reduced oxidation.

- Methodology: Used a twin-screw extruder and Fourier Transform Infrared Spectroscopy (FTIR) for material characterization.

- Plastic Pellets in 3D Printing2:

- Key Findings: Direct pellet printing offers advantages over filament-based methods, including reduced waste and broader material compatibility.

- Methodology: Discussed the conversion of waste into pellets and their use in fused filament fabrication (FFF).

- Fuel Pellets from Biomass3:

- Key Findings: Biomass-derived pellets are a sustainable energy source with high energy conversion efficiency (~75%).

- Methodology: Reviewed pelletization processes and economic feasibility for diverse biomass feedstocks.

- Top HDPE Plastic Pellets Suppliers in China

Frequently Asked Questions (FAQs)

Q: What are HDPE pellets?

A: HDPE pellets are small granules made from high-density polyethylene, a versatile and widely used plastic material known for its strength and durability. These pellets are essential in the manufacturing of various products due to their high impact resistance and insulating properties.

Q: What is the manufacturing process of HDPE?

A: The manufacturing process of HDPE involves polymerizing ethylene gas under controlled conditions of high pressure and temperature to create high-quality HDPE. The molten HDPE is then cooled and cut into pellets to produce plastic products for various applications.

Q: How are recycled HDPE pellets used?

A: Recycled HDPE pellets are used in many applications, including packaging applications, outdoor applications, and piping applications. They provide a sustainable option for manufacturing durable products while minimizing waste and environmental impact.

Q: What makes HDPE a preferred material for various applications?

A: HDPE is preferred due to its high chemical resistance, strength, and ability to withstand high temperatures. It is also lightweight, making it an ideal material for various applications including packaging, piping, and outdoor products.

Q: What are the benefits of using HDPE in piping applications?

A: HDPE is used in piping applications because it is resistant to corrosion, has high impact strength, and can handle high temperatures. This makes HDPE pipes durable and long-lasting, suitable for a variety of environmental conditions.

Q: How does HDPE perform in high-temperature environments?

A: HDPE performs well in high-temperature environments due to its high melting point and thermal stability. These properties make it suitable for products that require exposure to high temperatures without compromising integrity.

Q: Why is HDPE considered a versatile and widely used material?

A: HDPE is considered versatile and widely used because it can be molded into a wide range of shapes and sizes, making it suitable for different applications. Its properties, such as chemical resistance and durability, contribute to its extensive use in various industries.

Q: What are some common products made from HDPE pellets?

A: HDPE pellets are used to make a variety of applications, including bottles, containers, toys, piping systems, and construction materials. The durability and strength of HDPE make it ideal for creating long-lasting products.

Q: How does HDPE contribute to environmental sustainability?

A: HDPE contributes to environmental sustainability by being recyclable. Recycled plastic pellets from HDPE can be reused in manufacturing processes, reducing the demand for new raw materials and minimizing waste.

Q: What properties of HDPE make it suitable for outdoor applications?

A: HDPE is suitable for outdoor applications due to its high impact resistance, UV stability, and ability to withstand various weather conditions. These properties ensure that products made from HDPE maintain their integrity and performance over time.