Plastics aid in the efficiency of modern manufacturing; however, balancing performance with environmental care is a growing concern for today’s industries. One of the innovations paving the way toward a greener future is HDPE (High-Density Polyethylene) plastic pellets. This article details how these adaptable pellets aid in fostering sustainable manufacturing practices because of their durability, recyclability, and versatility across countless industries. If you are a manufacturer wanting to lessen your environmental impact or if you’re simply a curious reader wanting to learn about the effects of HDPE plastics, this blog post will explain the reasons why these pellets are changing the landscape of sustainable production.

What are HDPE Pellets?

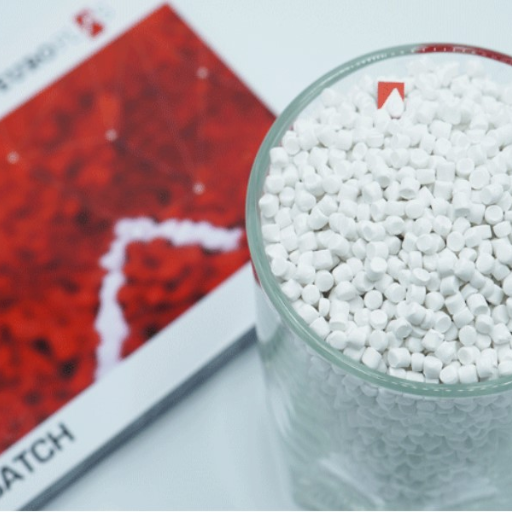

The solid, small pieces of high-density polyethylene, a thermoplastic polymer, are referred to as HDPE pellets. These pellets are widely utilized in the manufacturing industry which requires these materials due to its strength, durability, and the ease with which it can be melted and molded into new shapes. The non-toxic and lightweight nature of these pellets makes them easily recyclable, and an essential component used for the creation of lasting products across various industries, like construction, packaging, and automotive.

Definition and Composition of HDPE Pellets

A preferred option for various industries, HDPE pellets are beneficial due to numerous reasons. Their impact resistance and high tensile strength ensure durability, even under extreme conditions. Moreover, their melting point rests squarely at 120-130°C (248-266°F), which allows them to be reshaped or repurposed with little degradation. Also of note, these pellets have superb chemical resistance, which makes them appropriate for packaging hazardous items such as cleaning or industrial chemicals.

On the sustainability front, HDPE is completely recyclable, and the energy needed to recycle is miles ahead compared to producing virgin plastic. Statistics demonstrate that recycling a ton of HDPE saves nearly fifty-one percent of the energy needed for new production. In addition, these pellets are lightweight, enabling a significant reduction in transportation costs and emissions. These attributes contribute to fostering innovation and sustainability in modern manufacturing, making HDPE pellets an essential material.

How are HDPE Pellets Made?

The production of HDPE pellets begins with the polymerization of ethylene gas, typically derived from natural gas or petroleum. This process occurs under controlled conditions of heat and pressure, using catalysts such as Ziegler-Natta or metallocene. The polymerization results in the formation of long chains of high-density polyethylene, characterized by a low degree of branching, which gives HDPE its unique properties like high strength-to-density ratio and chemical resistance.

Once the HDPE polymer is synthesized, it undergoes further processes to form pellets. The material is melted and extruded through specialized machinery to produce thin, continuous strands. These strands are then cooled, typically using water baths or air-cooled systems, to solidify them before being cut into uniform pellet sizes. The resulting pellets are thoroughly dried to remove any moisture and are then packaged for industrial use.

Research indicates that modern advancements in extrusion technology have significantly improved the energy efficiency of this process. Additionally, newer methods such as the use of renewable ethylene sources made from bioethanol are contributing to a more sustainable production cycle. HDPE pellets are versatile and find applications in industries ranging from packaging to construction, reflecting the importance of precision and innovation in their manufacturing process.

Common Applications of HDPE Pellets

- Packaging Industry

-

-

- Bottles and Containers: HDPE is useful in making milk jugs, juice jugs, and detergent bottles because it is tough and does not break down easily.

- Plastic Bags: HDPE plastic bags are usually found in grocery stores and are strong but lightweight.

- Caps and Closures: Product quality is maintained through caps and closures manufactured from HDPE pellets, which add value to the product.

-

- Construction Industry

-

-

- Pipes and Fittings: Water supply to boreholes, gas distribution and drainage systems make use of HDPE pipes as they have a high tensile strength and resist corrosion.

- Geothermal Applications: These pellets are formed into pipes used for geothermal heat energy transfer.

- Composite Materials: To manufacture construction panels and decking, strong HDPE composites must be reinforced.

-

- Agriculture

-

-

- Irrigation Systems: HDPE pellets are further processed to make durable irrigation pipes that can withstand weathering.

- Greenhouse Films: HDPE can be formed into thin films, which create vital protective barriers to crops from adverse weather conditions.

-

- Automotive Sector

-

-

- Fuel Tanks: The HDPE automotive sector uses fuel tanks made of impact-resistant and corrosive resistant flexible materials. Pellets of HDPE are molded into strong fuel tanks.

- Automotive Components: Bumpers, interiors, and trims are all assist at employing adaptable design parts such as HDPE.

-

- Consumer Goods

-

-

- Toys: The non-toxic alias of HDPE allows its use for children’s toys, which makes it safer.

- Household Items: HDPE is also used for making storage bins, laundry baskets, and cutting boards which are everyday items.

-

- Other Applications

-

-

- Cables and Conduit: HDPE is used to insulate wires as well as to guard the wires from water, extreme temperatures, and other extreme conditions.

- Industrial Packaging: Bulk containers for Industrial chemicals are most commonly used in the creation of drums. The HDPE industrial category suits this purpose.

- Medical Applications: Medical grade containers and equipment can be made of HDPE. This provides them with a sterile and long lasting structure.

-

Because of its adaptability and eco-friendliness, HDPE remains an important plastic across many industries.

Benefits of Using HDPE Granules

Because of the many advantages HDPE granules offer, they are a favored material across a myriad of uses:

- Durability: HDPE granules are highly resistant to impact, abrasion, and wear, ensuring long-lasting performance.

- Lightweight: Transporting and handling costs are significantly lowered as the HDPE granules are sturdy, yet lightweight.

- Chemical Resistance: Polyethylene products can withstand a plethora of chemicals, thus making them ideal for industrial or packaging purposes.

- Recyclability: Environmental conservation is achieved through the reduction of waste, making them more sustainable due to their recyclability.

- Moisture Resistance: Their storage and piping applications make them ideal, as they provide exceptional protection against moisture.

Strength and Durability of HDPE Granules

HDPE granules are well-known for having one of the highest strength-to-density ratios, making HDPE one of the most durable industrial and consumer materials. These granules display tensile strength between 0.20 and 0.40 N/mm², which enables them to be placed under considerable stress without failing. In addition, HDPE’s melting point of 120°C to 180°C increases performance in applications above this temperature.

The durability of HDPE granules also derives from their astounding impact resistance, which, in combination with other factors, ensures long life even under demanding circumstances. This is the reason why HDPE is ideal for pipeline systems, which are constantly under pressure, and for storage containers which need to endure abrasion and impact on a daily basis. Also, the resistance of the material to UV radiation greatly improves its outdoor lifespan. All of these attributes demonstrate why HDPE is a preferred material in industries where strength and durability are required.

Environmental Impact of HDPE

High-Density Polyethylene, or HDPE, affects the environment in two distinct ways. First, it is easily recyclable which lowers its ecological impact if managed properly. Studies showed that in some places, HDPE recycling rates have surpassed thirty percent. Recycled HDPE is used to create goods such as containers, piping, and even plastic lumber, further enhancing the economy.

Second, exposed plastic HDPE products can also lead to pollution. Being non-biodegradable, HDPE can persist in landfills and even in the ocean for decades, worsening the plastic pollution crisis. The initial step of creating HDPE also emits greenhouse gases as it’s processed using petrochemical resources. Fortunately, developments like bio-based HDPE and renewable production methods change the situation by reducing the reliance on fossil fuels. As a result, although HDPE is useful and durable, it is essential to maintain sustainable methods of manufacturing, utilizing, and recycling the plastic to reduce the impact on nature.

Cost-Effectiveness of HDPE in Manufacturing

Recognized for its versatility, high-density polyethylene or HDPE is lower in cost than other metals, specialty plastics and even engineering materials. The cost of manufacturing is highly competitive which makes it better suited for large scale operations. Its price is set between $0.80 to $1.30 per pound based on the source and grade which is still cheaper than a lot of engineering materials.

Additionally, HDPE’s lightweight attributes allow the transportation costs to be reduced during the supply chain process. Along with these benefits, the hoses themselves can also be rigid, which makes them easy to send without being covered in paper. HDPE has great strength-to-weight ratios as well, so the materials must be durable while keeping to a minimal quantity to ensure that the shipping expenses stay low. Moreover, because it can be recycled, the suppliers’ long-term production costs can drop significantly as these recycled pellets can be integrated into new manufacturing processes, which reduces the need for virgin material.

Water service systems using HDPE pipes can be incorporated in buildings for more than 50 years without having to suffer from living with shoddy infrastructure or dealing with repairs. This durability offers unparalleled savings over time as it does not incur frequent replacements or repairs, which burns a lot of money. Industries like automotive, construction, and packaging reap the most advantages of HDPE due to these qualities.

The increasing access to alternatives such as renewable and recycled HDPE options boosts their cost-effectiveness as these methods cut down on material costs and aid in sustainability. Therefore, HDPE is still one of the most affordable options for businesses in multiple industries.

Differences Between Virgin and Recycled HDPE Pellets

Differences Between Virgin and Recycled HDPE Pellets

The raw materials used to produce Virgin HDPE pellets are newly sourced, which contributes to their consistent quality, superior mechanical properties, and higher purity. This makes them ideal for food-grade or medical-grade applications, which are highly regulated and monitored.

Recycled HDPE pellets are made from post-consumer or post-industrial HDPE waste, but they do not undergo virgin processing. Although the structural integrity of these pellets is lower, they offer more sustainable and economic value. This makes them sufficient for sensitive applications like outdoor furniture or construction materials.

The decision to use either virgin or recycled HDPE is made based on performance requirements, project goals, sustainability aims, and budget.

Characteristics of Virgin HDPE

Virgin HDPE is notably disposable and has inherent versatility. Its physical and chemical characteristics are remarkable, which allow its impressive tensile strength, 20-37MPa, to be put to practical use. Virgin HDPE’s impact resistance capabilities are even more impressive, as it is able to withstand mechanical stress in extreme temperatures (-40°F to 176°F, -40°C to 80°C) without losing structural integrity. In addition to this, Virgin HDPE is able to withstand extreme environments as it is chemically resistant to acids, bases, and solvents.

Being resistant to acids, bases, and solvents makes virgin HDPE invaluable in harsh environments. Other noteworthy capabilities of virgin HDPE include low density (0.93-0.97 g/cm³), which makes it easier to transport and mold. Its effectiveness as a moisture barrier broadens its application scope to include packaging, shipping, and even piping. Due to its unblemished properties and composition, virgin HDPE easily complies with FDA and USDA regulations, permitting food contact applications like milk jugs, food storage bags, and beverage containers. Such programs make HDPE heavily sought after when high industrial and commercial quality standards and consistent performance.

Advantages of Recycled HDPE Pellets

The sustainable alternative to virgin HDPE is issuing recycled HDPE pellets because of their incomparable economical and environmental advantages. These were highlighted in previous examples. Using recycled HDPE in manufacturing plastic decreases the fossil fuel output emitted, like greenhouse gas emissions. For example, emissions of CO2 equivalent loses 1.5 tons for every one ton of HDPE plastic that is recycled.

Moreover, the resistance to chemicals and moisture, the durability, and the required flexibility of the plastic will not be affected by substituted recycled HDPE. The performance of these plastics will be comparable to virgin HDPE across all verticals. Manufacturing automotive parts, an essential part of a growing economy, also falls under the umbrella of packaging and building construction materials. Meeting the industrial standards while decreasing waste and cost encourages companies to take pride in their social responsibility.

Choosing the Right HDPE Pellets for Your Needs

Choosing the right HDPE pellets suitable for your needs requires a careful evaluation of several critical factors HDPE Pellet supplier, to facilitate improving the performance and lowering the cost at the same time. First of all, the melt flow index (MFI) of the pellets should be assessed as it dictates the flowability of the material in processes such as injection molding and extrusion. Thinner applications do better with higher MFIs, while thicker and more robust products require lower MFIs.

From a mechanical standpoint, the tensile strength, impact resistance, and elongation of the pellets need to be evaluated. These pellets determine not only the flexibility but also the reliability of the end products. Reinforced, blended, or even both may help various industries that need extra durability.

How levels of UV and chemical resistance align with the environment your final product will be exposed to also plays an important role. For applications exposed to outdoor environments or chemicals, pellets with added stabilizers can greatly improve the life span of the product. Furthermore, recycled HDPE pellets are gaining traction with their environmentally friendly features. New reports claim that the use of recycled HDPE pellets lowers the energy cost during production by as much as 88% compared to using virgin materials. This strengthens the case for using recycled pellets while still maintaining the quality standards.

Finally, make sure to adhere to industry certifications relevant to your application. For instance, food-grade HDPE pellets must comply with FDA regulations, while those intended for medical use may need ISO 10993 certification. Meeting these parameters allows you to find the right HDPE pellets which balance tailored performance with sustainable practices.

Challenges of Using HDPE Plastic

- Environmental Concerns: Mismanagement of HDPE’s disposal methods can contribute to plastic pollution, as the material HDPE is derived from non-renewable fossil fuels.

- Recycling Limitations: The controllable factors during the recycling process can affect the quality and functionality of recycled material; therefore, even if HDPE is easily classed as a recyclable good, its quality is often compromised by rest product contaminations.

- Temperature Sensitivity: Its use in devices subjected to high temperatures is restricted due to inadequate exposure to heat, as in the case of HDPE, which has a low heat tolerance.

- Potential Degradation: Exposing HDPE to harsh surrounding conditions or UV light over an extended period of time may weaken the material, making it less durable.

- Cost Variability: The cost of HDPE is subject to market manipulation because of its connection with the petroleum market, which in turn influences the production costs.

Overcoming Plastic Waste Issues

Like any contemporary issue, the problem of plastic waste requires a unique solution, and this is exactly what is being targeted through the efforts of developed countries. To combat long-term environmental pollution, new forms of biodegradable plastics that break down faster in natural habitats are being developed. New studies estimate that global investments in sustainable materials are on the rise, and are expected to boost the GDP of the biodegradable plastics market by 9.7% CAGR from 2022 to 2030.

The implementation of chemical processes in recycling has also improved the field further, allowing for the recovery of raw goods for reuse. For instance like any other polycondensation reactions, plastic products of the recycling process can be used as fuel in advanced pyro synthesis methodologies. Due to these methods, there will be a direct decline of reliance on virgin resources, since plastic waste can now be converted into fuel stock for new plastic synthesis.

Central government policies and international organizations are also doing their part. Targets set by the European Union include the reduction of single use plastics and alternatives like reusable or compostable packing being used instead. An example of these policies includes providing funds towards aid programs aimed at achieving 55% of all plastic packaging being recyclable by 2030.

Public awareness campaigns are also impacting consumers to reduce waste at the source. For example, companies now offer take-back programs and refillable containers to reduce plastic waste. These joint efforts from industry, government, and consumers are important in overcoming issues with plastic waste and creating a sustainable future.

Handling and Storage of HDPE

High-Density Polyethylene (HDPE) is well known for its strength and usefulness across multiple fields. However, its performance is highly dependent on proper handling and storage. HDPE is best stored in a cool, dry, and well ventilated places in order to prevent undue heat or moisture exposure which could compromise its structural integrity. Studies have shown that UV exposure for long periods of time can weaken HDPE, so materials should be stored out of direct sunlight.

To avoid contamination, HDPE should be sealed and kept away from volatile structures that can compromise its integrity. The ideal temperature for storage is around 40°F and 120°F to make sure changes in stability and function do not occur. Good handling practices regarding the stacking of HDPE is also crucial to avoid warping and other forms of physical damage. For the reduction of hazards associated with improper handling and more streamlined inventory control, the use of dedicated storage systems is recommended.

Regulations and Standards for HDPE Usage

The safety, environmental concerns, and the quality of the material in the production of HDPE are guided by international and regional standards. One of the main standards is ISO 4427, which sets the requirements for HDPE piping systems for water supply and drainage. It provides guidelines of performance, durability, and pressure rating ensuring long-term suitability of HDPE products.

Across industries, standards such as ASTM D3350 set forth requirements for HDPE resin, which also encompass its density, melt index, tensile strength, and environmental stress crack resistance. Adherence to such standards guarantees uniformity and dependability in the manufacturing steps.

From the compliance side, the U.S. Food and Drug Administration (FDA) and the European Union have stringent regulations on food-grade HDPE materials. These regulations prevent HDPE products used in food packaging from containing harmful chemicals, guaranteeing consumer safety.

Waster management and recyclability are two key issue under environmental regulations. For example, many countries have laws that mandate a minimum percentage of re-cycled content for HDPE production.

All these regulations and standards requires strict QC and frequent audits to ensure global benchmarks in safety and performance are achieved for HDPE solutions.

Exploring Various Applications of High-Density Polyethylene

Common Applications of High-Density Polyethylene (HDPE)

The Light-weight, resistance toward chemicals, and durability of HDPE contribute to it being one of the most widely used materials. Some applications include:

- Packaging: Non-toxic and moisture resistant, it is used to manufacture food and beverage containers, caps, and bottles.

- Piping Systems: Its strength and corrosion resistance make HDPE ideal for water supply, irrigation, and sewage systems.

- Construction Materials: Weatherproof and insulation geomembranes and sheets incorporate HDPE.

- Household Products: Comprised of strong and easy to maintain plastics, cutting boards, crates and bins are made from HDPE.

- Automotive Components: Known for their wear and tear resistant nature, HDPE made fuel tanks and protective linings are also installed in vehicles.

These applications best describe their multifunctional importance and usefulness in numerous sectors across the globe.

Injection Molding and HDPE

One of the most popular ways of processing High-Density Polyethylene (HDPE) is by using it as a raw material for injection molding. Due to the lightweight and durable characteristics of HDPE, it is widely used in various applications. The process of injection molding consists of two main steps: melting HDPE pellets into a liquid and injecting the melted material into a mold and letting it cool and solidify.

Moving forward, the advantages of HDPE’s polymer properties include: an outstanding strength-to-density ratio, a low melting temperature of 210°F to 270°F (99°C to 132°C), and energy efficiency during molding. The mechanical properties also boost the longevity of the products made with HDPE. Common examples are bottle caps, containers, piping systems, and certain car parts. According to a market research projection, the demand for components made of HDPE and modified with other materials will steadily increase, with direct revenue surpassing $85 billion by 2030.

Moreover, HDPE’s recyclability makes it favorable from an environmental perspective. It commonly comes from injection-molded waste or post-consumable goods, which reduces the waste created and increases sustainability. The economic and versatile prospects ensure HDPE’s dominance in modern manufacturing solutions.

Blow Molding with HDPE Plastic

The blow molding process for HDPE plastic is one of the most common and efficient methods for manufacturing hollow parts and containers. It enables precision and consistency in mass production. The following highlights outline and summarize the most important information regarding blow molding using HDPE:

- Applications: Blow molding is primarily integral in creating bottles, drums, fuel tanks, plastic auto parts, and general plastic household containers. The application of blow molding is versatile, serving both high-quantity and low-quantity needs.

- Strength and Durability: Like many other thermoplastics, HDPE can also sustain impact strength and environmentally induced stress cracking quite well when used on blow molding products.

- Process Efficiency:

- Cycle Times: Blow molding is one of the fastest methods in the industry, making it highly efficient, especially in mass production.

- Wall Thickness Control: The process guarantees consistent wall thickness, important for the strength of the products.

- Material Utilization:

- Recyclability: HDPE employed in blow molding is capable of containing recycled materials, which do not considerably diminish the performance HDPE is known for.

- Raw Material Savings: The process reduces waste of materials, which saves money.

- Temperature Resistance:

- HDPE remains fairly operational in medium heat environments as it has a melting point which ranges between 120 – 160 Degrees Celsius (248 – 320 Fahrenheit). These temperatures allow for moderate use of external HDPE products.

- Production Output:

- The designs and dimensions of the items can alter how many units a machine can produce; however, machines blowing HDPE into HDPE items can output thousands each day.

- Economical Advantage:

-

Transportation, recycling, and manufacturing of blow molded items becomes more effective and cheaper due to cost efficient nature of HDPE and its lite weight.

-

Blow molding with HDPE is an ever-growing process owing to its flexibility in use, cost structure, and application durability.

Extrusion Process and HDPE Products

My HDPE products are manufactured using the cost-efficient technique known as extrusion. During the extrusion process, raw HDPE material is melted and forced through a shaped die to produce pipes, sheets, profiles, etc. Consistent quality is achieved using this method, as well as durability and versatility, thus making HDPE products useful across industrial and commercial sectors.

Choosing the Right HDPE Pellets for Your Needs

When selecting an appropriate HDPE pellet, keep the following in mind:

- Application Requirements -Determine what the product will be used for. Will it require strength, flexibility, or resistance to temperature? This will dictate which grade of HDPE will be needed.

- Quality Standards – Check if the pellets have any relevant industry certifications that are important to your application.

- Additives and Modifiers – Choose pellets that already contain any required additives, such as UV stabilizers or colorants, if performance enhancement is required.

- Supplier Reliability – Pick a dependable supplier to ensure quality consistency and timely deliveries.

Considering these factors ensures that you make the right selection for your needs when it comes to HDPE pellets.

Factors to Consider When Selecting HDPE Pellets

- Melt Flow Index (MFI): For HDPE pellets, MFI value affects the ease of extrusion or injection molding. Lower values of MFI are better for applications which need strength and durability whereas higher MFI values are more appropriate for thinner or more detailed shapes.

- Density: HDPE pellet density varies from one type to another with a general range of 0.93 g/cm³ to 0.96 g/cm³. The higher density grades have greater stiffness, strength and even better chemical resistance, lending them to more industrial uses such as storage tanks for chemicals.

- Additives and Modifiers: UV stabilizers, impact modifiers, and flame retardants can be used to enhance the HDPE pellets. Enclosure Performance Additives make the material perform better while according to set environmental or functional considerations.

- Moisture Content: To achieve the best results during extrusion and molding, the moisture content must be kept low (usually below 0.1%), adhering to proper drying requirements. Too much moisture content can cause product defects.

- Application-Specific Requirements: Intended purpose necessitates using the specific grade of the pellet. For example, food-grade HDPE pellets are compliant with FDA guidelines, and medical-grade ones are compliant with the strict safety and sterilization standards.

- Sustainable Options: Manufacturing of recycled or bio-based HDPE pellets is on the rise due to sustainability focus. These new products meet the required performance standards but have a diminished impact on the environment.

Considering all these aspects critically helps manufacturers to guarantee that the selected HDPE pellets will fit their production processes as well as the intended applications.

Price and Availability of HDPE Pellets

Factors like crude oil prices and industry shifts in demand can determine the rate of HDPE pellets. Market updates indicate that the global HDPE pellets price is between $1,200 and $1,800 per metric ton; this value fluctuates based on regional market circumstances and the supply chain’s flow. Price volatility has occurred due to a lack of availability for raw materials and logistical issues in major manufacturing areas.

North American and Asia-Pacific suppliers secured these regions as primary suppliers which made manufacturers bound to availability. Consistent delivery further cements North America and Asia Pacific as major producers. These regions, however, faced temporary shortages due to industrial demand spikes in packaging, construction, and healthcare. Manufacturers can now attempt to adapt by diversifying their supply with long-term supplier agreements or using increasingly available sustainable recycled HDPE pellets.

Around the globe, buyers can grab opportunities provided by low prices; however, for an uninterrupted HDPE supply, lower charging HS tariffs can be crucial. Based on region, sustained efficiency can be achieved with constant promotion support. The above flexibility maintains buyers’ value and reliance on global prices while protecting against supply Halts and Highs.

Impact of HDPE Grade on Product Quality

The grade quality of HDPE (high-density polyethylene) greatly impacts the performance, durability, and usability of the finished products. Different grades of HDPE are tailored for specific applications such as packaging, construction, and piping. For example, containers and bottles are made from blow molding grade because of its better strength and moldability, while film grade is more suited for lightweight flexible applications such as bags and films.

The impact of HDPE grade selection is most visible on a product’s tensile strength, impact resistance, and chemical stability. Research shows that high-grade HDPE has better lock higher environmental stress crack resistance (ESCR), essential for automotive and chemical packaging industries. Moreover, more advanced HDPE grades tend to have better processing characteristics, a qualifier, less time and material waste during production.

Producers of lower grades without compromising PD HDPE, bio-based, and recycled options are shifting toward these alternatives, which indicates an increasing demand for eco-friendly materials. Supported by a market shift trend, estimating a 6% annual growth in recycled HDPE usage. Manufacturers standing behind eco-focused strategies leverage initiatives to better position themselves in the market.

Like manufacturers, buyers need to align the suitable HDPE grade to the application for maximum value, balancing compliance and costs.

Reference Sources

-

Assessing the Environmental Footprint of Recycled Plastic Pellets2:

- Key Findings: Recycling plastic waste reduces carbon emissions by 42% compared to virgin plastic production. Using renewable energy sources like solar power further minimizes environmental impacts.

- Methodology: Life-cycle assessment (LCA) was conducted using the Gabi software, comparing scenarios with varying levels of solvent recovery during recycling.

-

Plastic Recycling in Indonesia3:

- Key Findings: Mechanical recycling of HDPE, LDPE, and PP into pellets is effective for resource conservation and reducing environmental impact. The quality of recycled pellets depends on sorting, washing, and extrusion parameters.

- Methodology: Field studies and data collection from recycling facilities, focusing on mechanical recycling processes.

-

Optimization of Glass-Powder-Reinforced Recycled HDPE for Additive Manufacturing4:

- Key Findings: Adding 10% glass powder to recycled HDPE improves its mechanical properties and sound absorption capabilities, making it suitable for 3D printing applications.

- Methodology: Experimental optimization of extrusion parameters and mechanical testing of 3D-printed specimens.

- Top HDPE Plastic Pellets Suppliers in China

Frequently Asked Questions (FAQs)

Q: What are resin pellets, and how are they used in plastic manufacturing?

A: Resin pellets, also known as plastic resin pellets, are small granules made from high-density polyethylene or other polymers. They serve as the raw material in the plastic manufacturing process, where they are melted and molded into a wide range of applications, including plastic products like bottles and containers.

Q: How does using recycled plastic contribute to sustainable manufacturing?

A: Using recycled plastic in manufacturing helps reduce the amount of plastic waste in landfills, conserves natural resources, and lowers the carbon footprint of the production process. High-quality recycled HDPE pellets can replace virgin plastic resin in many applications, promoting more sustainable practices.

Q: What are the different types of HDPE available for manufacturing?

A: There are various types of HDPE, including injection grade and blow molding grade HDPE. Each type offers specific properties suitable for different applications, such as low moisture absorption and high strength, ensuring that manufacturers can choose the best grade for their specific needs.

Q: What are the environmental benefits of high-density polyethylene?

A: High-density polyethylene offers several environmental benefits, including its recyclability and durability. It can be repeatedly recycled without significant degradation, reducing the need for virgin resin and minimizing plastic waste in landfills. This makes it a preferred choice for sustainable plastic products.

Q: How does the price of HDPE affect plastic manufacturing?

A: The price of HDPE can significantly impact plastic manufacturing costs. Fluctuations in the price of virgin resin or recycled HDPE pellets can influence the overall expense of producing plastic products, affecting decisions regarding material sourcing and production methods.

Q: What role does plastic recycling play in the production of HDPE products?

A: Plastic recycling is crucial in the production of HDPE products as it facilitates the reuse of plastic resin, reducing the demand for raw materials and decreasing the amount of plastic waste. By using recycled HDPE, manufacturers can create sustainable products while conserving resources and energy.

Q: Why is low moisture absorption important in HDPE applications?

A: Low moisture absorption is important in HDPE applications because it enhances the durability and performance of the final plastic products. It ensures that the material maintains its strength and integrity even in moist environments, making it ideal for outdoor and industrial applications.

Q: What are the typical applications of HDPE resin pellets?

A: HDPE resin pellets are used in a wide range of applications, including blow molding applications for creating plastic bottles, containers, and piping systems. Their versatility, strength, and recyclability make them suitable for various industrial and consumer products.

Q: How does the use of virgin plastic resin compare to recycled HDPE in terms of environmental impact?

A: Virgin plastic resin generally has a higher environmental impact compared to recycled HDPE due to the extraction and processing of raw materials. Recycled HDPE helps reduce the amount of plastic waste and conserves natural resources, thus offering a more sustainable solution.