While we may encounter different forms of plastics in our everyday life, one feature that stands out is HDPE (High-Density Polyethylene) plastic and its use in round containers for consumables such as food and shampoo. In this segment, we will look at why these two types of plastics- HDPE and Polypropylene are widely used across the globe; what their properties are, where they are used, and if they are suitable for your new project. Moreover, if you are working on designing new products or product marketing strategy revolving around modularity and easy-to-grasp comprehension, distinguishing these two plastics is a must in order to simplify handling. Hence, this paper will aid you in determining and understanding the distinct advantages and specific uses of Polypropylene and HDPE plastics.

What are the differences between PP and HDPE?

There are four distinct differences between HDPE and PP.

- Density and Strength: Compared to PP, HDPE is stronger, more denser, as well as more rigid and durable. This makes HDPE ideal for applications requiring greater strength. Its composition allows it to withstand external forces.

- Heat Resistance: Due to the fact that PP has a higher melting point than HDPE, it is more ideal for high temperature environments.

- Durability: HDPE is more weather-resistant and impact-resistant when compared to PP. However, PP offers better resistance to repeated bending despite not being very ductile.

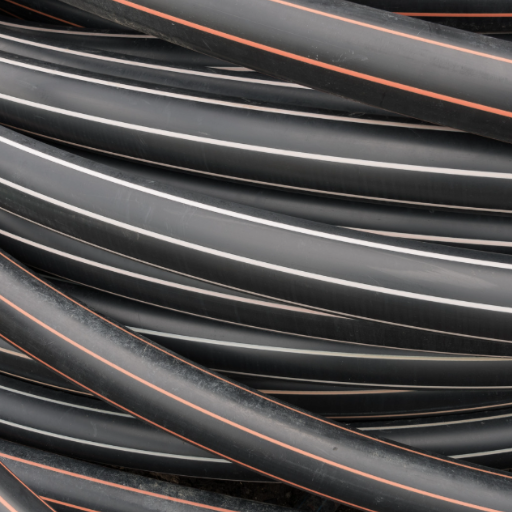

- Common Uses: Containers, outdoor furniture, and piping are common applications for HDPE, while food packaging, automotive parts, and textiles make use of PP.

With knowledge of the defined differences, one can choose the correct material according to its strength, flexibility, heat resistance, and the application it will be used for.

Understanding the density of these plastics

The application of high-density polyethylene (HDPE) and polypropylene (PP) is strongly related to their density. The figure for HDPE is 0.93 to 0.97 g/cm³, while for PP it is lower at 0.89 to 0.92 g/cm³. The higher density of HDPE, unlike other thermoplastics, gives it strength and sensitivity, which further improves its usefulness and endurance for rigid applications like piping and industrial containers.

The lower number for PP means that it is lightweight which is helpful for materials used in packaging and parts for cars, where less weight is important. The differing densities of these materials influence their mechanical properties with preference on HDPE for the polymers that stress toughness and structural stability, while PP features low weight and high flexibility.

By knowing these ranges associated with density, best choices are reachable altogether with understanding the requirements from industrial or commercial sides. One side knows which materials to go for, while the other gets value for their money.

Exploring chemical resistance and durability

Both HDPE (High-Density Polyethylene) and PP (Polypropylene) are well known for their superb chemical resistance, which makes them suitable for various industries. Commonly used in chemical storage tanks, piping, and other sensitive equipment, HDPE is particularly resistant to acids, alcohols, and bases. PP is also widely used in the manufacturing of laboratory equipment and automotive parts due to its high resistance to organic solvents, bases, and acids.

These materials also exhibita great degree of strength under extreme conditions. Particularly, HDPE is exceptional at resisting environmental stress cracking and impact even at low temperatures. Data shows that depending on specific grades, HDPE offers a tensile strength of approximately 31 to 38 MPa. This ensures reliable performance in heavy-duty applications. PP balances durability and flexibility with tensile strength ranging from 22 to 30 MPa, making it suitable for objects that require repeated bending, like living hinges in caps or containers.

Both materials boast excellent longevity when exposed to harsh outdoor conditions. With the addition of UV-stabilized grades, HDPE and PP demonstrate extended life spans under prolonged sunlight exposure. Understanding these features enables engineers and designers to select the appropriate material according to the harsh environmental challenges and compatible chemicals.

Comparing impact resistance in different applications

| Application | Key Point | HDPE | Polypropylene |

|---|---|---|---|

|

Pipes and Tubing |

Strength and rigidity |

High impact resistance |

Moderate impact resistance |

|

Automotive Parts |

Flexibility under stress |

Good for heavy-duty components |

Suitable for lightweight components |

|

Packaging |

Resistance during handling |

Durable, handles impacts well |

Flexible and less durable |

|

Sports Equipment |

Resilience against repeated impacts |

Strong, retains form in use |

Flexible for low-impact needs |

|

Chemical Storage |

Resistance to damage from spills |

Excellent chemical durability |

Less chemical durability |

|

Outdoor Applications |

UV and environmental exposure |

Superior UV resistance |

Requires additives for UV resistance |

|

Food Containers |

Impact during transportation |

Maintains integrity in drops |

Less robust when dropped |

|

Netting Applications |

Force resistance in use |

Highly durable, stiff for tension |

Flexible but less impact-proof |

|

Toys |

Durability during handling |

High resistance to rough handling |

Suitable for lighter wear |

|

Medical Equipment |

Resistance to sterilization impacts |

Moderate, limited to low heat |

Higher handling heat sterilization |

How does polypropylene compare to HDPE in terms of recycling?

Both Polypropylene (PP) and High-Density Polyethylene (HDPE) can be recycled, albeit their recycling processes differ from one another.

- Recycling Availability: Compared to PP, HDPE has more widespread availability in recycling programs. Numerous curbside collection systems as well as recycling facilities possess the ability to process HDPE proficiently.

- Recycling Efficiency: Due to the high prevalence of packaging, including easily sortable and identifiable bottles and containers, HDPE is more commonly used. Consequently, HDPE tends to have higher recycling efficiency.

- Challenges with PP: PP, as a material, has varied applications, making it more difficult to recycle. Due to this, PP encounters more challenges within recycling systems, resulting in significantly lower recycling rates.

Nonetheless, other materials seem to lack the organized recycling system HDPE seems to have.

Recycling processes for HDPE and PP

The recycling of HDPE (High Density Polyethylene) starts with collection. During this step, cuddles like bottles and jugs are separated from the mixed waste streams containing HDPE. Following this, HDPE products come to the washing stage, where food residues, labels, and other forms of contaminants are removed. Subsequently, they are ground into small pieces called pellets or flakes. These flakes are then heated to an extent where they can be reshaped and further transformed into new materials. These materials can then be used to manufacture other products such as new piping, plastic lumber, constituents for building other containers, and so on. Currently available information suggests that HDPE has a considerably high recycling rate, with the global figures hovering close to 30% – a testament to its use in industrial applications as well as packaging.

Recycling polypropylene (PP) works almost identically. PP is more versatile in terms of what it can be used for. Items like food containers, automotive parts, and even shipping textiles make the sorting and recovering stage much more difficult. Once sorted under the collection step, PP items get cleaned, shredded into flakes, sorted, and melted. The gained materials from these processes can now fulfill a new purpose: the manufacture of automotive parts, construction materials, or even recyclable containers. Despite the numerous uses, these materials still face restrictions in terms of recycling, bound by global standards. It is believed that less than 10% of PP is recycled, as PP’s barriers to identification and recovery infrastructure greatly limit its recyclable potential.

Developments in technology, including new sorting technologies and chemical recycling techniques, are proving to enhance efficiency how HDPE and PP are recycled. These innovations seek to maximize the amount of plastic that is recycled, thus minimizing damage to the environment and fostering sustainability.

Environmental impact of recycling these plastics

Recycling high-density polyethylene (HDPE) and polypropylene (PP) plastics significantly reduces environmental harm compared to producing virgin plastics. According to recent data, recycling HDPE can save up to 90% of the energy used in creating new resin from raw materials. Similarly, the recycling of PP requires approximately 88% less energy than producing virgin PP. This reduction in energy consumption directly correlates to a decrease in greenhouse gas emissions, helping mitigate climate change.

Additionally, recycling these plastics reduces landfill waste and environmental pollution. For instance, it is estimated that recycling 1 ton of plastic prevents around 2 tons of carbon dioxide emissions and saves up to 3 cubic yards of landfill space. These environmental savings demonstrate the critical role of recycling in conserving natural resources, reducing fossil fuel dependency, and curbing plastic pollution, which otherwise poses significant threats to ecosystems and wildlife. Through continued advancements in recycling infrastructure and technology, these benefits can be further amplified for a more sustainable future.

Which type of plastic is more suitable for food packaging?

The best kind of plastic for packaging food is polyethylene terephthalate (PET). It is lightweight and strong as well. PET helps keep food fresh and safe as it provides an excellent barrier to oxygen and moisture. Moreover, it is food safe under regulatory standards and is recyclable.

The role of food containers and safety standards

Food containers are vital in maintaining the quality, freshness, and safety of food products within the supply chain and storage. Modern containers now are not solely aimed at avoiding contamination, but preserving the food’s best conditions and extending shelf life. This is the case with high-barrier materials like PET and polypropylene, which are used all over because they exclude moisture and oxygen, primary contributors to food spoilage.

Food containers also ensure public safety, thus, food safety standards are crucial. Policies from the FDA and European Food Safety Authority (EFSA) stipulate detailed examinations of container materials to confirm they do not permeate harmful substances into the enclosed food and drinks. Industry reports indicate that upwards of 60% of food packaging worldwide is made from recyclable or reusable materials, highlighting the positive changes towards sustainability without compromising safety. Other known innovations that actively focus on these elements are smart packaging, capable of monitoring food freshness, and biodegradable coatings.

Advantages of polypropylene for food packaging

- Lightweight and Durable

Polypropylene both protects the contents and greatly reduces transportation costs due to its remarkably low weight.

- Cost-Effective

Polypropylene also offers lower production rates with no dip in quality, thus providing an advantage to manufacturers.

- High Resistance to Temperature Variations

Polypropylene can endure high and low temperatures with ease, making it ideal for food storage. Foods can be frozen or microwaved without issue.

- Moisture Barrier Properties

Polypropylene prevents external moisture from contaminating sensitive materials, making it useful in preserving food and extending its shelf life.

- Recyclability

Polypropylene is recyclable which improves its sustainability reputation for food packaging. It is now accepted by many recycling programs which increases social responsibility.

What factors affect the strength and durability of HDPE and PP?

Tensile strength and impact resistance of these plastics are influenced by several factors:

- Material Density

For HDPE, the impact resistance increases with the material density; the same crystalline structure requires stressed HDPE for PP to function properly.

- Temperature Resistance

Both materials have their own melting and effective boiling points. While HDPE performs well under subzero temperatures, PP performs better in significantly warmer temperatures.

- Additives and Stabilizers

Polypropylene and polyethene undergoes environmental stress and UV attack more efficiently when applied stabilizers or grade increases enabling the HDPE and PP.

- Manufacturing Process

Extrusion and Injection molding are examples of processes that influence the sets of strength and durability of the plastics.

- Exposure to Environmental Factors

Both materials are relatively poor in mechanical property retention when exposed to UV radiation, chemicals, and high moisture.

Understanding tensile strength and flexibility

Tensile strength describes how much pulling or stress a material can withstand before breaking. Bendability, or flexibility, indicates how much a material can be deformed without breaking. High Density Polyethylene (HDPE) has a lower tensile strength than polypropylene (PP). HDPE typically has tensile strength ranging from 21 to 37 MPa, whereas PP exhibits a tensile strength of approximately 25 to 33 MPa. However, PP is more flexible, with an elongation at break ranging from 200-700%, compared to HDPE’s 20-80%.

The difference in flexibility performance makes HDPE ideal for robust applications such as industrial containers or pipes where strength highly matters. For automotive components or textiles where frequent yet low-stress bending occurs, flexible PP is preferred. Also impacting these properties are additives, temperature, and processing methods, highlighting the need for a material that best attends to the mechanical requirements of a specific use case.

The impact of UV resistance on longevity

UV resistance is fundamental when it comes to polymers and plastics used for long periods of time outdoors, impacting their life span. Ultraviolet (UV) radiation can cause photo-degradation of materials, which results in discoloration, reduction in mechanical properties, and even surface cracking. As an example, untreated polypropylene will most likely show severe degradation within months when subjected to direct sunlight. However, UV-stabilized formulations can increase service life to 5-10 years, depending on certain environmental factors.

Additives like UV absorbers, hindered amine light stabilizers (HALS), and antioxidants are designed to improve the UV resistance of materials. For instance, HALS has been shown to prevent polymer degradation effectively because they capture free radicals produced by the UV exposure which interrupts the degradation cycle. Research has shown that incorporating such stabilizers enables maintained mechanical and aesthetic properties over extended periods of time, even in high-UV environments.

Selecting the right elements and stabilizing additives is crucial in fields such as automotive, construction, and outdoor consumer goods, as the products face prolonged sunlight exposure. In addition, certain geographic locations, material thickness, and even coloration can further impact durability. Research suggests that further use of darker pigments, such as carbon black, increases UV resistance by efficiently absorbing harmful radiation. Surely, UV resistance is of great importance when considering the reliability and performance of materials during their expected service life.

How heat resistance varies between HDPE and polypropylene

For a number of applications, requiring heat resistance is a situation affected a lot. In this case, two plastics, HDPE (High-Density Polyethylene) and Polypropylene, can be distinguished. Compared to polypropene, HDPE is confirmed to have a lower resistance to heat. Its melting point lies somewhere between 120 °C to 130 °C, while polypropene’s superior value is around 130°C to 171°C (266 °F to 340 °F). This allows polypropylene to be used in high-temperature exposure applications.

Due to higher temperatures, polypropene manages better the maintenance of its structural stock as well, leading to improved thermal stability while HDPE is confirmed to soften in as low as 100 °C (212 °F) and loses rigidity. This attribute allows polypropene to be used in auto parts, food processors and any other devices that require tough heat resistance.

Moreover, with respect to thermal resistance, the Vicat softening temperature adds another layer of understanding. HDPE has a Vicat softening point ranging from 50°C to 80°C (122°F to 176°F), while polypropylene adds approximately 140°C (284°F), confirming it as a stronger contender with respect to thermal load. A superb indicator of comparing heat resistance. From the softening point, one can observe the striking difference in commercially used polymers due to their molecular structures. Here, a distinct shift in heat resistance outlines the uniqueness in molecular structures, where the higher crystallinity of polypropylene strengthens its thermal properties.

When selecting the right material, how do HDPE and PP perform in specific applications?

- HDPE (High-Density Polyethylene): Having an exceptional impact strength and overall flexibility makes HDPE an ideal choice for piping, containers, and even for geomembranes. Its performance in harsh chemical environments is unmatched, as well as durability in moderate temperature surroundings.

- PP (Polypropylene): As automotive components, medical equipment, and even food containers, the need for lightweight materials with high heat resistance makes PP excel. The fatigue-resistant rigidity also makes it ideal for products subjected to repeated use, such as hinges and lids.

The difference between HDPE and PP purely depends on application requirements like temperature, flexibility, chemicals, or stress exposure wieghed against severity.

Why HDPE may be preferred for chemical tanks

The chemical industry utilizes High-Density Polyethylene (HDPE) tanks as its primary type of plastic tank because they are durable, resist deformation under toxic chemicals, and are low in cost. HDPE withstands extreme temperatures from -40°F to 176°F, depending on the grade utilized. Unlike metals, which have a tendency to corrode when subjected to harsh chemicals, HDPE retains its non-corrosive nature.

Because HDPE is relatively lightweight compared to other plastics, its ease of transport, structural rigidity, and cost-efficiency greatly reduces set up and transportation expenditure.

In addition to all these benefits, tanks constructed from HDPE are also designed to be UV resistant, thereby maintaining their rigidity over extended durations of sunlight exposure.

Based on the support of industry data, properly maintained and with adequate use, HDPE offers an impressive service life of over 20 years. Its tensile strength and resistance to impact make it an environmentally conscious option as well. Such attributes culminate in efficiently fulfilling the needs of chemical storage with HDPE.

How polypropylene is ideal for household items

Polypropylene (PP) is a flexible and strong plastic that has gained acceptance for various household items because of its properties. Polypropylene is commonly used in food storage containers, chairs, and even rugs, as it exhibits high resistance to chemicals, heat, and impact. One of its standout attributes is its lightweight nature which makes it easy to handle as well as transport while offering exceptional durability.

Along with this, it has superb moisture and stain resistance making it a good fit for items in used in kitchens and bathrooms. Polypropylene is known to be able to withstand high temperatures, commonly up to 120 degrees Celsius (248 degrees Fahrenheit), often times being used in microwavable and dishwasher safe products. Its recyclability additionally meets the need of modern households that support in sustainable materials. These features combined make it an appealing option for consumers and establish polypropylene as a reliable choice for everyday use.

Reference Sources

- Polypropylene vs. HDPE: Material Differences and …

- HDPE and PP Plastics: What to Know When Purchasing for …

- HDPE vs. Polypropylene: A Comprehensive Comparison

- Top HDPE Plastic Pellets Suppliers in China

Frequently Asked Questions (FAQs)

Q: What is the main difference between HDPE and Polypropylene?

A: The main difference between HDPE and Polypropylene lies in their density and chemical resistance. HDPE, or high-density polyethylene, has a higher density and excellent chemical resistance, making it suitable for applications like plastic bottles and containers. Polypropylene, on the other hand, has a lower density than HDPE and offers good chemical resistance, making it ideal for applications requiring fatigue resistance and flexibility.

Q: How does the durability and strength of HDPE compare to Polypropylene?

A: HDPE is often preferred for its durability and strength, especially in applications where resistance to impact and environmental stress is critical. Polypropylene, while offering good chemical resistance, is less durable under stress and has lower impact resistance compared to HDPE plastic.

Q: What are the common uses of HDPE plastic?

A: HDPE plastic is used in a variety of applications due to its high density and excellent chemical resistance. It is often used for manufacturing plastic bottles, containers, pipes, and even HDPE sheets which are highly resistant to impact and weather conditions.

Q: Why is HDPE often chosen over Polypropylene for certain applications?

A: HDPE is often chosen over Polypropylene when higher strength, impact resistance, and chemical resistance are required. Its high density makes it suitable for applications such as heavy-duty containers and outdoor furniture, where durability is essential.

Q: Can you explain the fatigue resistance of Polypropylene compared to HDPE?

A: Polypropylene is well-known for its fatigue resistance, meaning it can endure repetitive stress without cracking. This property makes it suitable for applications like living hinges and other components that require flexibility. HDPE, while offering high strength, is less flexible compared to Polypropylene.

Q: What factors should be considered when deciding between HDPE and PP?

A: When deciding between HDPE and PP, consider the specific requirements of your project, such as chemical resistance, strength, flexibility, and environmental conditions. HDPE is preferred in applications requiring high density and strength, while PP is chosen for its lower density and flexibility.

Q: How does the chemical resistance of HDPE compare to Polypropylene?

A: Both HDPE and Polypropylene offer good chemical resistance, but HDPE is often more resistant to a wider range of chemicals. This makes HDPE the preferred material for containers that store corrosive substances.

Q: What types of projects are best suited for Polypropylene?

A: Polypropylene is best suited for projects that require flexibility and fatigue resistance, such as automotive parts, textiles, and components with hinges. Its lower density than HDPE also makes it ideal for lightweight applications.

Q: How do HDPE and Polypropylene perform in terms of environmental impact?

A: Both HDPE and Polypropylene are recyclable and considered environmentally friendly plastics. However, choosing the right material for your project should also consider the energy required for production and the potential for biodegradation or recycling.