Get in touch with us

Leave a message

POM Plastic Pellets, also known as polyoxymethylene or acetal, are high-performance engineering thermoplastics prized for their exceptional mechanical strength, dimensional stability, and low friction properties. These pellets exhibit excellent wear resistance, high stiffness, and superior chemical resistance, making them ideal for precision molding applications. Commonly used in automotive, industrial, and consumer goods sectors, such as gears, fasteners, and fuel system components, POM pellets offer reliable performance in demanding environments, with a processing temperature range of 180-230°C.

POM Plastic Pellets deliver exceptional versatility and strength, revolutionizing performance across various industries. Their outstanding durability, dimensional stability, and chemical resistance ensure reliable results in challenging environments, enhancing efficiency for your manufacturing needs.

Designed to withstand demanding environments, POM Plastic Pellets offer exceptional toughness and resistance to wear, ensuring products maintain optimal performance for industrial applications.

With outstanding low-friction properties, these pellets enhance the efficiency and longevity of moving parts, perfect for bearings and sliders in engineering and consumer goods applications.

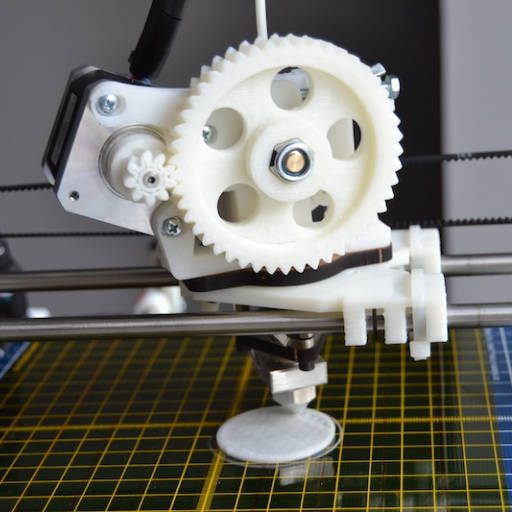

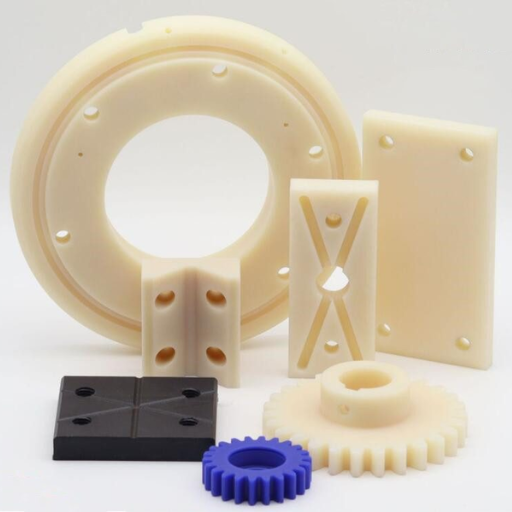

POM Plastic Pellets provide high precision and consistency in molding, making them ideal for components requiring tight tolerances, such as gears and fasteners in automotive and machinery sectors.

POM Plastic Pellets resist degradation from chemicals and solvents, ensuring durability in harsh conditions, making them a reliable choice for industrial and outdoor product manufacturing.

| Property | Value | Advantage |

|---|---|---|

| Tensile Strength | 60-70 MPa | Resists high mechanical stress effectively. |

| Impact Resistance | 80-100 kJ/m² | Offers superior toughness even at low temperatures. |

| Heat Deflection Temp | 130-150°C | Maintains structural integrity at elevated temperatures. |

| Service Temperature | -40°C to 120°C | Performs reliably in extreme environmental conditions. |

| Density | 1.40-1.42 g/cm³ | Provides a lightweight yet robust alternative to metals. |

| Friction Coefficient | 0.15-0.25 | Ensures low friction for smooth mechanical operation. |

| Chemical Resistance | High | Resists degradation from solvents and chemicals. |

POM Plastic Pellets offer unmatched versatility and strength, making them a game-changer across industries. Their durability, dimensional stability, and low friction ensure reliable performance in demanding applications, driving innovation and efficiency for your business.

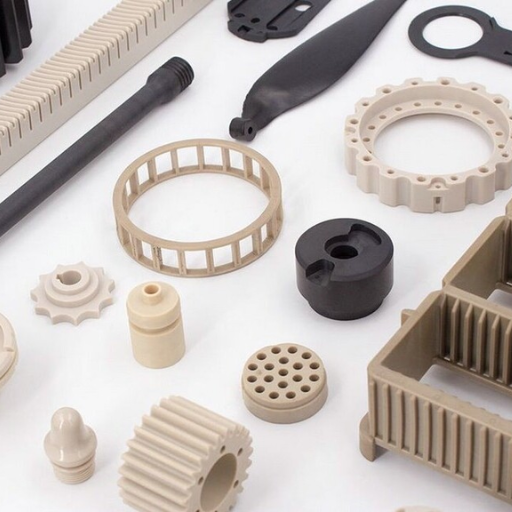

POM pellets provide components like gears and clips with excellent mechanical strength and wear resistance, enhancing vehicle performance and durability.

Ideal for manufacturing precision tools and fixtures, POM pellets offer high stiffness and chemical resistance for reliable industrial use.

POM pellets are used in surgical instruments and housings, ensuring biocompatibility and dimensional accuracy in healthcare applications.

Perfect for casings and connectors, POM pellets deliver low friction and toughness for durable electronic products.

POM pellets create robust containers and hinges, providing excellent resistance to chemicals and wear in packaging systems.

Used in lightweight, durable components like buckles and sliders, POM pellets enhance performance in sports equipment.

Suzhou YifuHui New Material Co., Ltd. provides top-quality POM plastic pellets with cutting-edge manufacturing and rigorous quality standards. Products are customized for a variety of applications, including automotive, industrial, and consumer goods, delivering outstanding strength, durability, and precision to boost competitiveness.

With an extensive global supply network, competitive pricing, and dedicated support, seamless delivery and tailored solutions are guaranteed. Focused on innovation and reliability, Suzhou YifuHui fosters dependable partnerships that surpass expectations, supporting sustained client success in evolving markets.

Understand from our clients what they say about doing business with us and the unique value addition we provide.

Yes, certain grades of POM (Polyoxymethylene or Acetal) are specifically formulated and certified to meet stringent food safety standards, such as those by the FDA or relevant EU regulations, making them suitable for use in food contact applications.

POM is considered a mid-range engineering plastic. It is more expensive than common commodity plastics like polyethylene or polypropylene but generally less expensive than high-performance polymers, offering a good balance of cost and mechanical properties.

POM plastic is highly durable, possessing excellent stiffness, hardness, and dimensional stability. It exhibits superb wear resistance and low friction properties, making it ideal for parts that experience repeated stress, movement, or contact with other surfaces over time.

No, POM (Polyoxymethylene) is not the same as polycarbonate (PC). They are distinct types of engineering polymers with different chemical structures and properties. Polycarbonate is known for its high impact strength and transparency, whereas POM is known for its strength, stiffness, and wear resistance.

POM plastic is widely used in applications requiring high stiffness, low friction, and excellent wear resistance. Common uses include mechanical gears, bearings, fasteners, conveyor belts, components for automobiles, zippers, plumbing fittings, and various parts in consumer electronics and appliances.

To clean POM plastic components or surfaces, it is generally recommended to use mild soap or detergent with lukewarm water. Avoid using harsh chemicals, strong solvents, or abrasive cleaners, as these could potentially degrade the surface or affect the material's properties.

Stay inspired and innovative by following our blog, where we share the latest best practices, techniques, breakthroughs, and insights in the field.

Elevate your products with high-quality POM plastic pellets, renowned for exceptional strength, stiffness, low friction, and wear resistance. Ideal for precision parts in demanding applications like automotive, mechanical gears, and consumer goods. Partner with us to access reliable POM supply at competitive prices, boosting your production efficiency and ensuring component durability. Contact us today for a quote or sample.

A: POM is also widely known by its alternative name, Polyacetal. You might also encounter terms like polyoxymethylene plastic, polyacetal resin, or simply acetal resin when referring to this material.

A: Polyacetal material boasts high mechanical strength and rigidity, excellent fatigue resistance, good dimensional stability, low coefficient of friction, superb wear properties, and good chemical resistance, especially against many solvents.

A: POM exists in two main forms: Homopolymer (POM-H) and Copolymer (POM-C). Homopolymer generally offers slightly higher mechanical strength and stiffness, while Copolymer provides better thermal and chemical resistance, particularly against hot water and strong alkalis.

A: POM plastic material is frequently used in precision engineering parts, such as gears, bearings, bushings, fasteners, components for automotive interiors, plumbing fittings, zippers, and parts in consumer electronics and industrial machinery.

A: Polyoxymethylene plastic is primarily processed using standard thermoplastic techniques like injection molding, extrusion, and blow molding. It typically requires precise temperature control due to its narrow melting range.

A: Polyacetal POM exhibits good resistance to a wide range of chemicals, including many solvents, fuels, and oils. However, it can be susceptible to degradation by strong acids and strong alkalis, particularly at elevated temperatures.

A: Compared to Nylon, pom plastik generally offers higher stiffness and hardness, better dimensional stability (less moisture absorption), and superior creep resistance. Nylon typically has better abrasion resistance in some applications and higher impact strength.

A: The typical continuous operating temperature range for POM material is generally between -40°C to around 85°C to 100°C, depending on the specific grade (homopolymer vs. copolymer) and the load conditions.

Discover premium plastic pellets and engineering resins, including PC, ABS, PA66, POM, PMMA, HDPE, and more at Yifuhui Plastic.